|

Forming Gas

Forming gas is a mixture of hydrogen (mole fraction varies) and nitrogen. It is sometimes called a "dissociated ammonia atmosphere" due to the reaction which generates it: :2 NH3 → 3 H2 + N2 It can also be manufactured by thermal cracking of ammonia, in an ammonia cracker or forming gas generator. Forming gas is used as an atmosphere for processes that need the properties of hydrogen gas. Typical forming gas formulations (5% H2 in N2) are not explosive. It is used in chambers for gas hypersensitization, a process in which photographic film is heated in forming gas to drive out moisture and oxygen and to increase the base fog of the film. Hypersensitization is used particularly in deep-sky astrophotography, which deals with low-intensity incoming light, requires long exposure times, and is thus particularly sensitive to contaminants in the film. Forming gas is also used to regenerate catalysts in glove boxes and as an atmosphere for annealing processes. It can be p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrogen

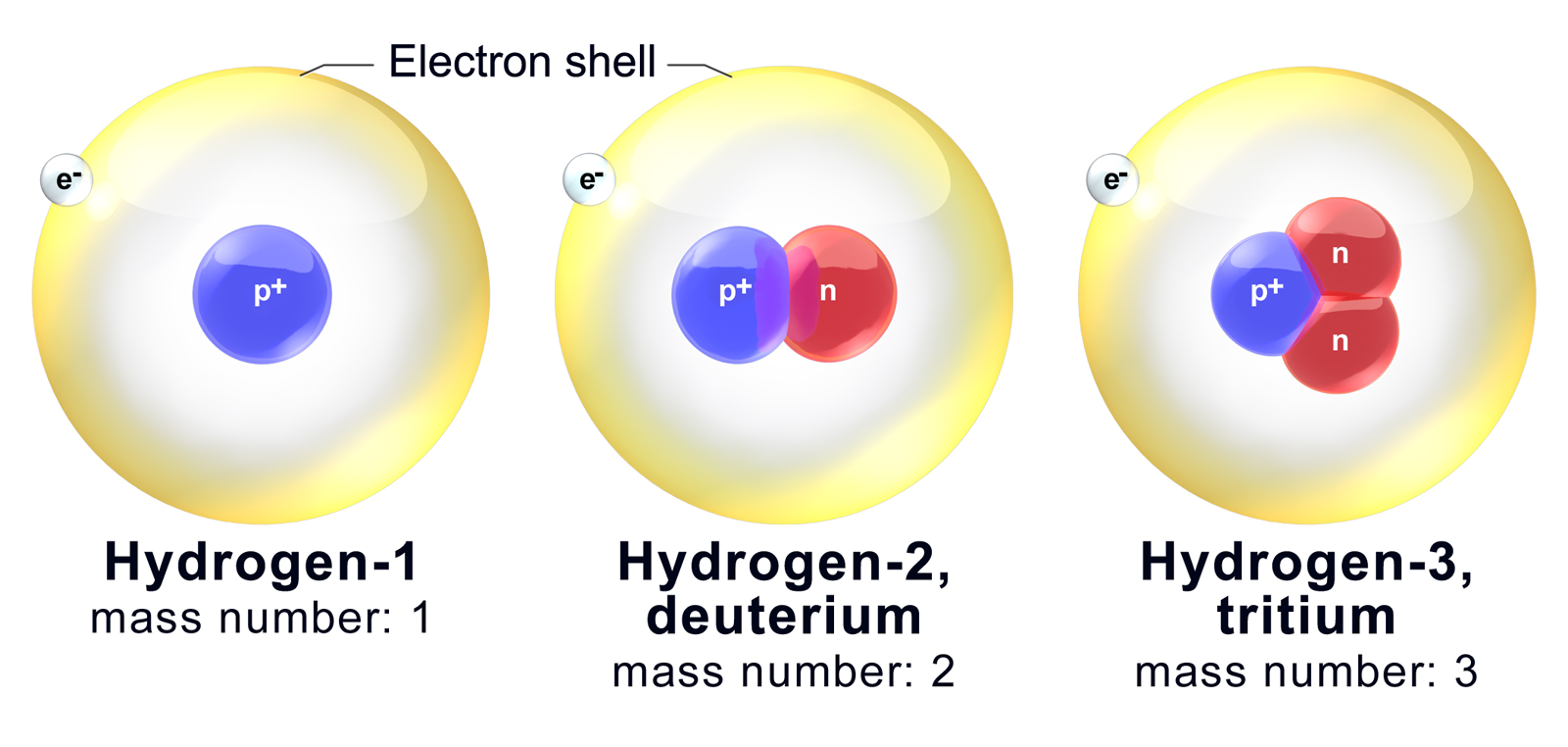

Hydrogen is a chemical element; it has chemical symbol, symbol H and atomic number 1. It is the lightest and abundance of the chemical elements, most abundant chemical element in the universe, constituting about 75% of all baryon, normal matter. Under standard conditions, hydrogen is a gas of diatomic molecules with the chemical formula, formula , called dihydrogen, or sometimes hydrogen gas, molecular hydrogen, or simply hydrogen. Dihydrogen is colorless, odorless, non-toxic, and highly combustible. Stars, including the Sun, mainly consist of hydrogen in a plasma state, while on Earth, hydrogen is found as the gas (dihydrogen) and in molecular forms, such as in water and organic compounds. The most common isotope of hydrogen (H) consists of one proton, one electron, and no neutrons. Hydrogen gas was first produced artificially in the 17th century by the reaction of acids with metals. Henry Cavendish, in 1766–1781, identified hydrogen gas as a distinct substance and discovere ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reducing Agent

In chemistry, a reducing agent (also known as a reductant, reducer, or electron donor) is a chemical species that "donates" an electron to an (called the , , , or ). Examples of substances that are common reducing agents include hydrogen, carbon monoxide, the alkali metals, formic acid, oxalic acid, and sulfite compounds. In their pre-reaction states, reducers have extra electrons (that is, they are by themselves reduced) and oxidizers lack electrons (that is, they are by themselves oxidized). This is commonly expressed in terms of their oxidation states. An agent's oxidation state describes its degree of loss of electrons, where the higher the oxidation state then the fewer electrons it has. So initially, prior to the reaction, a reducing agent is typically in one of its lower possible oxidation states; its oxidation state increases during the reaction while that of the oxidizer decreases. Thus in a redox reaction, the agent whose oxidation state increases, that "loses/Electron d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brazing And Soldering

Brazing is a metal-joining process in which two or more metal items are joined by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal. Brazing differs from welding in that it does not involve melting the work pieces. Brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. During the brazing process, the filler metal flows into the gap between close-fitting parts by capillary action. The filler metal is brought slightly above its melting ( liquidus) temperature while protected by a suitable atmosphere, usually a flux. It then flows over the base metal (in a process known as wetting) and is then cooled to join the work pieces together. Brazing joins the same or different metals with considerable strength. Process Brazing has many advantages over other metal-joining techniques, such as welding. Since brazing does not melt the base metal of the joint, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melting, melt the parts together and allow them to cool, causing Fusion welding, fusion. Common alternative methods include solvent welding (of thermoplastics) using chemicals to melt materials being bonded without heat, and #Solid-state welding, solid-state welding processes which bond without melting, such as pressure, cold welding, and diffusion bonding. Metal welding is distinct from lower temperature bonding techniques such as brazing and soldering, which do not melt the base metal (parent metal) and instead require flowing a filler metal to solidify their bonds. In addition to melting the base metal in welding, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that can be stronger than the base material. Welding also requires a form of shield to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gases

Gas is a state of matter that has neither a fixed volume nor a fixed shape and is a compressible fluid. A ''pure gas'' is made up of individual atoms (e.g. a noble gas like neon) or molecules of either a single type of atom ( elements such as oxygen) or from different atoms ( compounds such as carbon dioxide). A ''gas mixture'', such as air, contains a variety of pure gases. What distinguishes gases from liquids and solids is the vast separation of the individual gas particles. This separation can make some gases invisible to the human observer. The gaseous state of matter occurs between the liquid and plasma states, the latter of which provides the upper-temperature boundary for gases. Bounding the lower end of the temperature scale lie degenerative quantum gases which are gaining increasing attention. High-density atomic gases super-cooled to very low temperatures are classified by their statistical behavior as either Bose gases or Fermi gases. For a comprehensive l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Endothermic Gas

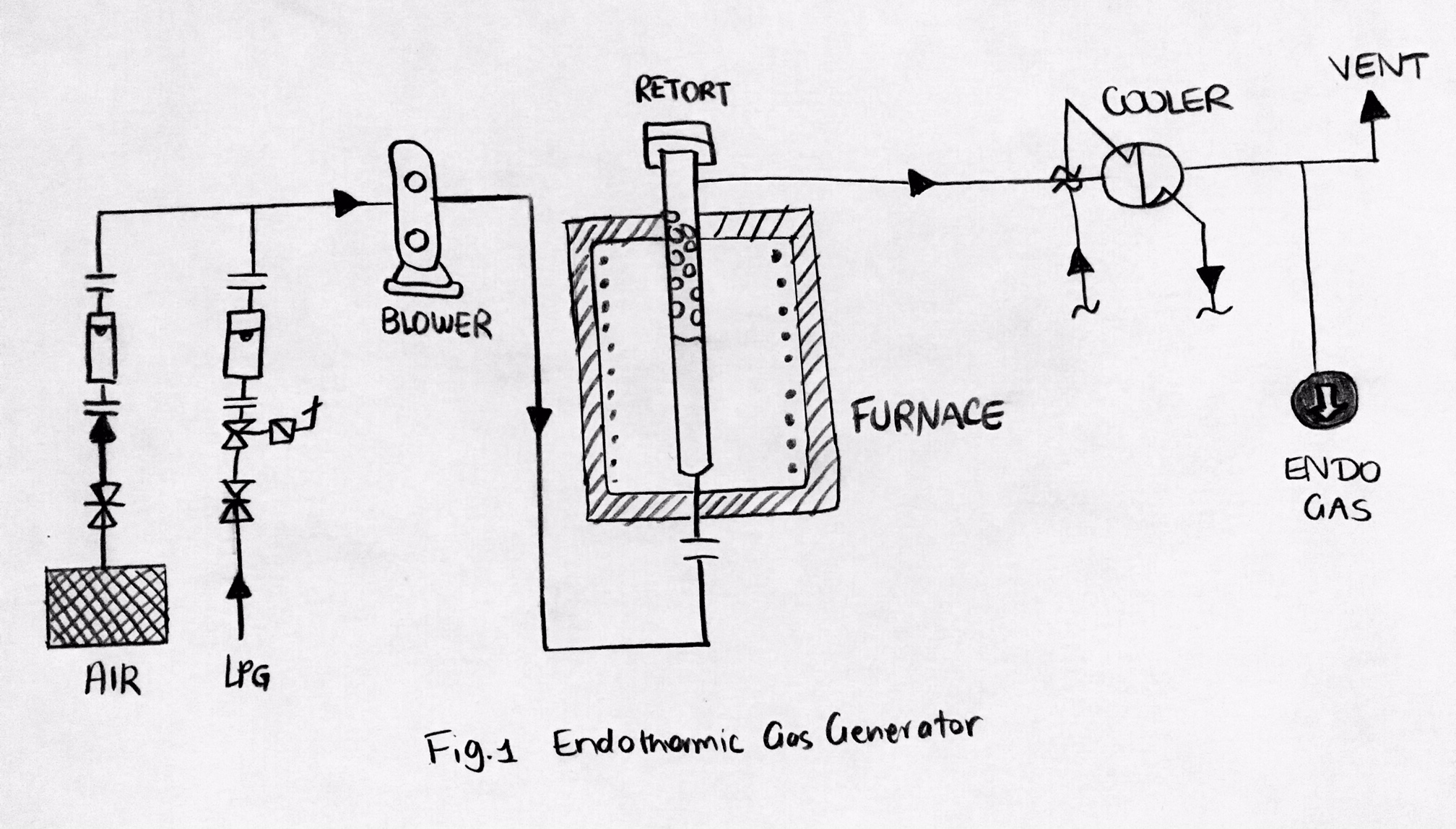

Endothermic gas is a gas that inhibits or reverses oxidation on the surfaces it is in contact with. This gas is the product of incomplete combustion in a controlled environment. An example mixture is hydrogen gas (H2), nitrogen gas (N2), and carbon monoxide (CO). The hydrogen and carbon monoxide are reducing agents, so they work together to shield surfaces from oxidation. Endothermic gas is often used as a carrier gas for gas carburizing and carbonitriding. An endothermic gas generator could be used to supply heat to form an endothermic reaction. Synthesised in the catalytic retort(s) of endothermic generators, the gas in the endothermic atmosphere is combined with an additive gas including natural gas, propane (C3H8) or air and is then used to improve the surface chemistry work positioned in the furnace. Purposes There are two common purposes of the atmospheres in the heat treating industry: # Protect the processed material from surface reactions (chemically inert) # All ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The atoms/molecules in the sintered material diffuse across the boundaries of the particles, fusing the particles together and creating a solid piece. Since the sintering temperature does not have to reach the melting point of the material, sintering is often chosen as the shaping process for materials with extremely high melting points, such as tungsten and molybdenum. The study of sintering in metallurgy, metallurgical powder-related processes is known as powder metallurgy. An example of sintering can be observed when ice cubes in a glass of water adhere to each other, which is driven by the temperature difference between the water and the ice. Examples of pressure-driven sintering are the compacting of snowfa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flux (metallurgy)

In metallurgy, a flux is a chemical reducing agent, flowing agent, or purifying agent. Fluxes may have more than one function at a time. They are used in both extractive metallurgy and metal joining. Some of the earliest known fluxes were sodium carbonate, potash, charcoal, coke, borax, lime, lead sulfide and certain minerals containing phosphorus. Iron ore was also used as a flux in the smelting of copper. These agents served various functions, the simplest being a reducing agent, which prevented oxides from forming on the surface of the molten metal, while others absorbed impurities into slag, which could be scraped off molten metal. Fluxes are also used in foundries for removing impurities from molten nonferrous metals such as aluminium, or for adding desirable trace elements such as titanium. As reducing agents, fluxes facilitate soldering, brazing, and welding by removing oxidation from the metals to be joined. In some applications molten flux also serves as ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oxidation

Redox ( , , reduction–oxidation or oxidation–reduction) is a type of chemical reaction in which the oxidation states of the reactants change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is the gain of electrons or a decrease in the oxidation state. The oxidation and reduction processes occur simultaneously in the chemical reaction. There are two classes of redox reactions: * Electron-transfer – Only one (usually) electron flows from the atom, ion, or molecule being oxidized to the atom, ion, or molecule that is reduced. This type of redox reaction is often discussed in terms of redox couples and electrode potentials. * Atom transfer – An atom transfers from one substrate to another. For example, in the rusting of iron, the oxidation state of iron atoms increases as the iron converts to an oxide, and simultaneously, the oxidation state of oxygen decreases as it accepts electrons released by the iron. Although oxidati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brazing

Brazing is a metal-joining process in which two or more metal items are joined by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal. Brazing differs from welding in that it does not involve melting the work pieces. Brazing differs from soldering through the use of a higher temperature and much more closely fitted parts. During the brazing process, the filler metal flows into the gap between close-fitting parts by capillary action. The filler metal is brought slightly above its melting ( liquidus) temperature while protected by a suitable atmosphere, usually a flux. It then flows over the base metal (in a process known as wetting) and is then cooled to join the work pieces together. Brazing joins the same or different metals with considerable strength. Process Brazing has many advantages over other metal-joining techniques, such as welding. Since brazing does not melt the base metal of the joi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Soldering

Soldering (; ) is a process of joining two metal surfaces together using a filler metal called solder. The soldering process involves heating the surfaces to be joined and melting the solder, which is then allowed to cool and solidify, creating a strong and durable joint. Soldering is commonly used in the electronics industry for the manufacture and repair of Printed circuit board, printed circuit boards (PCBs) and other electronic components. It is also used in plumbing and Metalworking, metalwork, as well as in the manufacture of jewelry and other decorative items. The solder used in the process can vary in composition, with different alloys used for different applications. Common solder alloys include tin-lead, tin-silver, and tin-copper, among others. Lead-free solder has also become more widely used in recent years due to health and environmental concerns associated with the use of lead. In addition to the type of solder used, the temperature and method of heating also p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melting, melt the parts together and allow them to cool, causing Fusion welding, fusion. Common alternative methods include solvent welding (of thermoplastics) using chemicals to melt materials being bonded without heat, and #Solid-state welding, solid-state welding processes which bond without melting, such as pressure, cold welding, and diffusion bonding. Metal welding is distinct from lower temperature bonding techniques such as brazing and soldering, which do not melt the base metal (parent metal) and instead require flowing a filler metal to solidify their bonds. In addition to melting the base metal in welding, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that can be stronger than the base material. Welding also requires a form of shield to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |