|

Flory–Fox Equation

In polymer chemistry and polymer physics, the Flory–Fox equation is a simple empirical formula that relates molecular weight to the glass transition temperature of a polymer system. The equation was first proposed in 1950 by Paul J. Flory and Thomas G. Fox while at Cornell University. Their work on the subject overturned the previously held theory that the glass transition temperature was the temperature at which viscosity reached a maximum. Instead, they demonstrated that the glass transition temperature is the temperature at which the free space available for molecular motions achieved a minimum value. While its accuracy is usually limited to samples of narrow range molecular weight distributions, it serves as a good starting point for more complex structure-property relationships. Overview The Flory–Fox equation relates the number-average molecular weight, ''M''n, to the glass transition temperature, ''T''g, as shown below: :T_ = T_-\frac where ''T''g,∞ is the max ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymer Chemistry

Polymer chemistry is a sub-discipline of chemistry that focuses on the structures of chemicals, chemical synthesis, and chemical and physical properties of polymers and macromolecules. The principles and methods used within polymer chemistry are also applicable through a wide range of other chemistry sub-disciplines like organic chemistry, analytical chemistry, and physical chemistry. Many materials have polymeric structures, from fully inorganic metals and ceramics to DNA and other biological molecules. However, polymer chemistry is typically related to synthetic and organic compositions. Synthetic polymers are ubiquitous in commercial materials and products in everyday use, such as plastics, and rubbers, and are major components of composite materials. Polymer chemistry can also be included in the broader fields of polymer science or even nanotechnology, both of which can be described as encompassing polymer physics and polymer engineering.Hans-Heinrich Moretto, Manfred Sc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glass Transition

The glass–liquid transition, or glass transition, is the gradual and reversible transition in amorphous materials (or in amorphous regions within semicrystalline materials) from a hard and relatively brittle "glassy" state into a viscous or rubbery state as the temperature is increased. ISO 11357-2: Plastics – Differential scanning calorimetry – Part 2: Determination of glass transition temperature (1999). An amorphous solid that exhibits a glass transition is called a glass. The reverse transition, achieved by supercooling a viscous liquid into the glass state, is called vitrification. The glass-transition temperature ''T''g of a material characterizes the range of temperatures over which this glass transition occurs (as an experimental definition, typically marked as 100 s of relaxation time). It is always lower than the melting temperature, ''T''m, of the crystalline state of the material, if one exists. Hard plastics like polystyrene and poly(methyl methacrylate) ar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plasticizer

A plasticizer ( UK: plasticiser) is a substance that is added to a material to make it softer and more flexible, to increase its plasticity, to decrease its viscosity, and/or to decrease friction during its handling in manufacture. Plasticizers are commonly added to polymers such as plastics and rubber, either to facilitate the handling of the raw material during fabrication, or to meet the demands of the end product's application. For example, plasticizers are commonly added to polyvinyl chloride (PVC), which otherwise is hard and brittle, to make it soft and pliable; which makes it suitable for products such as shower curtains, vinyl flooring, clothing, bags, flexible plastic tubing, and electric wire insulation/coating. Plasticizers are also often added to concrete formulations to make them more workable and fluid for pouring, thus allowing the water contents to be reduced. Similarly, they are often added to clays, stucco, solid rocket fuel, and other pastes prior to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diluent

A diluent (also referred to as a filler, dilutant or thinner) is a diluting agent. Certain fluids are too viscous to be pumped easily or too dense to flow from one particular point to the other. This can be problematic, because it might not be economically feasible to transport such fluids in this state. To ease this restricted movement, diluents are added. This decreases the viscosity of the fluids, thereby also decreasing the pumping/transportation costs. One industrial application is the transport of crude oil via pipelines. Heavy crude oil/bitumen are fluids with high viscosity, especially at low temperatures. The addition of a diluent enables the diluted fluid (dilbit in the case of bitumen) to meet pipeline specifications in order for it to be efficiently transported. Typical diluent in this case is naphtha or condensate. Types of diluents more familiar to the general public include paint thinner and nail polish thinner, both of which improve the consistency and applica ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyisobutylene

Polyisobutene (polyisobutylene) is a class of organic polymers prepared by polymerization of isobutene. The polymers often have the formula Me3C H2CMe2sub>nX (Me = CH3, X = H, F). They are typically colorless gummy solids. Polymerization is typically initiated with a strong Brønsted or Lewis acid. The molecular weight (MW) of the resulting polymer determines the applications. Low MW polyisobutene, a mixture of oligomers with Mns of about 500, is used as plasticizers. Medium and high MW polyisobutenes, with Mn ≥ 20,000, are components of commercial adhesives.{{cite encyclopedia , author1=Kenneth S. Whiteley , author2=T. Geoffrey Heggs , author3=Hartmut Koch , author4=Ralph L. Mawer , author5=Wolfgang Immel , title=Polyolefins , encyclopedia=Ullmann's Encyclopedia of Industrial Chemistry , year=2005 , publisher=Wiley-VCH , place=Weinheim , doi=10.1002/14356007.a21_487 See also *Butyl rubber Butyl rubber, sometimes just called "butyl", is a synthetic rubber, a copolym ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymethylmethacrylate

Poly(methyl methacrylate) (PMMA) belongs to a group of materials called engineering plastics. It is a transparent thermoplastic. PMMA is also known as acrylic, acrylic glass, as well as by the trade names and brands Crylux, Plexiglas, Acrylite, Astariglas, Lucite, Perclax, and Perspex, among several others ( see below). This plastic is often used in sheet form as a lightweight or shatter-resistant alternative to glass. It can also be used as a casting resin, in inks and coatings, and for many other purposes. Although not a type of familiar silica-based glass, the substance, like many thermoplastics, is often technically classified as a type of glass, in that it is a non-crystalline vitreous substance—hence its occasional historic designation as ''acrylic glass''. Chemically, it is the synthetic polymer of methyl methacrylate. It was developed in 1928 in several different laboratories by many chemists, such as William Chalmers, Otto Röhm, and Walter Bauer, and first brough ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It is a poor barrier to oxygen and water vapour and has a relatively low melting point. Polystyrene is one of the most widely used plastics, the scale of its production being several million tonnes per year. Polystyrene can be naturally transparent, but can be colored with colorants. Uses include protective packaging (such as packing peanuts and in the jewel cases used for storage of optical discs such as CDs and occasionally DVDs), containers, lids, bottles, trays, tumblers, disposable cutlery, in the making of models, and as an alternative material for phonograph records. As a thermoplastic polymer, polystyrene is in a solid (glassy) state at room temperature but flows if heated above about 100 °C, its glass transition temperature ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Expansion

Thermal expansion is the tendency of matter to change its shape, area, volume, and density in response to a change in temperature, usually not including phase transitions. Temperature is a monotonic function of the average molecular kinetic energy of a substance. When a substance is heated, molecules begin to vibrate and move more, usually creating more distance between themselves. Substances which contract with increasing temperature are unusual, and only occur within limited temperature ranges (see examples below). The relative expansion (also called strain) divided by the change in temperature is called the material's coefficient of linear thermal expansion and generally varies with temperature. As energy in particles increases, they start moving faster and faster weakening the intermolecular forces between them, therefore expanding the substance. Overview Predicting expansion If an equation of state is available, it can be used to predict the values of the thermal ex ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jamming (physics)

Jamming is the physical process by which the viscosity of some mesoscopic materials, such as granular materials, glasses, foams, polymers, emulsions, and other complex fluids, increases with increasing particle density. The jamming transition has been proposed as a new type of phase transition, with similarities to a glass transition but very different from the formation of crystalline solids. While a glass transition occurs when the liquid state is cooled, the jamming transition happens when the density, or the packing fraction of the particles, is increased. This crowding of the constituent particles prevents them from flowing under an applied stress and from exploring phase space, thus making the aggregate material behave as a solid. The system may be able to unjam if volume fraction is decreased, or external stresses are applied such that they exceed the yield stress. This transition is interesting because it is nonlinear with respect to volume fraction. The jamm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

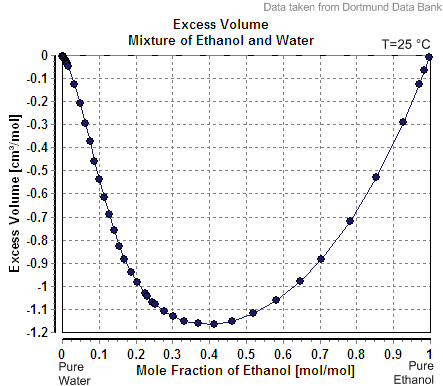

Volume Fraction

In chemistry and fluid mechanics, the volume fraction φ''i'' is defined as the volume of a constituent ''V''''i'' divided by the volume of all constituents of the mixture ''V'' prior to mixing: :\phi_i = \frac Being dimensionless, its unit is 1; it is expressed as a number, e.g., 0.18. It is the same concept as volume percent (vol%) except that the latter is expressed with a denominator of 100, e.g., 18%. The volume fraction coincides with the volume concentration in ideal solutions where the volumes of the constituents are additive (the volume of the solution is equal to the sum of the volumes of its ingredients). The sum of all volume fractions of a mixture is equal to 1: :\sum_^ V_i = V ; \qquad \sum_^ \phi_i = 1 The volume fraction (percentage by volume, vol%) is one way of expressing the composition of a mixture with a dimensionless quantity; mass fraction (percentage by weight, wt%) and mole fraction (percentage by moles, mol%) are others. Volume concentration and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shear Modulus

In materials science, shear modulus or modulus of rigidity, denoted by ''G'', or sometimes ''S'' or ''μ'', is a measure of the elastic shear stiffness of a material and is defined as the ratio of shear stress to the shear strain: :G \ \stackrel\ \frac = \frac = \frac where :\tau_ = F/A \, = shear stress :F is the force which acts :A is the area on which the force acts :\gamma_ = shear strain. In engineering :=\Delta x/l = \tan \theta , elsewhere := \theta :\Delta x is the transverse displacement :l is the initial length of the area. The derived SI unit of shear modulus is the pascal (Pa), although it is usually expressed in gigapascals (GPa) or in thousand pounds per square inch (ksi). Its dimensional form is M1L−1T−2, replacing ''force'' by ''mass'' times ''acceleration''. Explanation The shear modulus is one of several quantities for measuring the stiffness of materials. All of them arise in the generalized Hooke's law: * Young's modulus ''E'' describes t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |