|

EspÃĐrance-Longdoz

EspÃĐrance-Longdoz was a coal mining and steel production company located in the LiÃĻge region of Belgium. The company merged with Cockerill-OugrÃĐe-Providence in 1970 to form Cockerill-OugrÃĐe-Providence-EspÃĐrance Longdoz (known as Cockerill), later being merged into Usinor, then Arcelor then ArcelorMittal. Production at Longdoz ceased in the latter part of the 20th century, the factory site was redevelopend in the 2000s into a shopping complex ''MÃĐdiacitÃĐ'', one part of the buildings at Longdoz has been preserved and is now the home of an industrial museum ''La Maison de la MÃĐtallurgie et de l'Industrie de LiÃĻge''. A later steelworks development, built at Chertal in the 1960s is still in operation (as of 2010) and is part of the ArcelorMittal group, within the LiÃĻge division. History In 1845/6 the DothÃĐe brothers established a tinplate factory in Longdoz in LiÃĻge Province, then in 1862/3 the DothÃĐe brothers merged their business with the ''SociÃĐtÃĐ anonyme des Haut ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Allegheny-Longdoz

ALZ (''Allegheny-Longdoz'') is a stainless steel producer based in Genk in Limburg province, Flanders, Belgium. In 2001 the company was merged with French stainless steel producer ''Ugine'' and in 2006 became part of the ArcelorMittal group as part of the stainless steel division. History ALZ was founded as a vertically integrated stainless steel producer in 1960 as an equal holding between EspÃĐrance-Longdoz (Belgium) (controlled by ''Evence CoppÃĐe'') and Allegheny Ludlum (USA).The Belgian economy in the twentieth century, p.171 In 1970 EspÃĐrance-Longdoz (''SociÃĐtÃĐ MÃĐtallurgique d'EspÃĐrance Longdoz'') became part of Cockerill-OugrÃĐe-Providence, and ALZ became a Cockerill subsidiary; Allegheny Ludlum disposed of its shares, and in 1971 Cockerill had a 90% stake of the shares. In 1979/80 the Cockerill group was restructure due to financial problems, and also disposed of its shares; German steel company KlÃķckner became a shareholder, in 1981 the other Flanders-based steel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

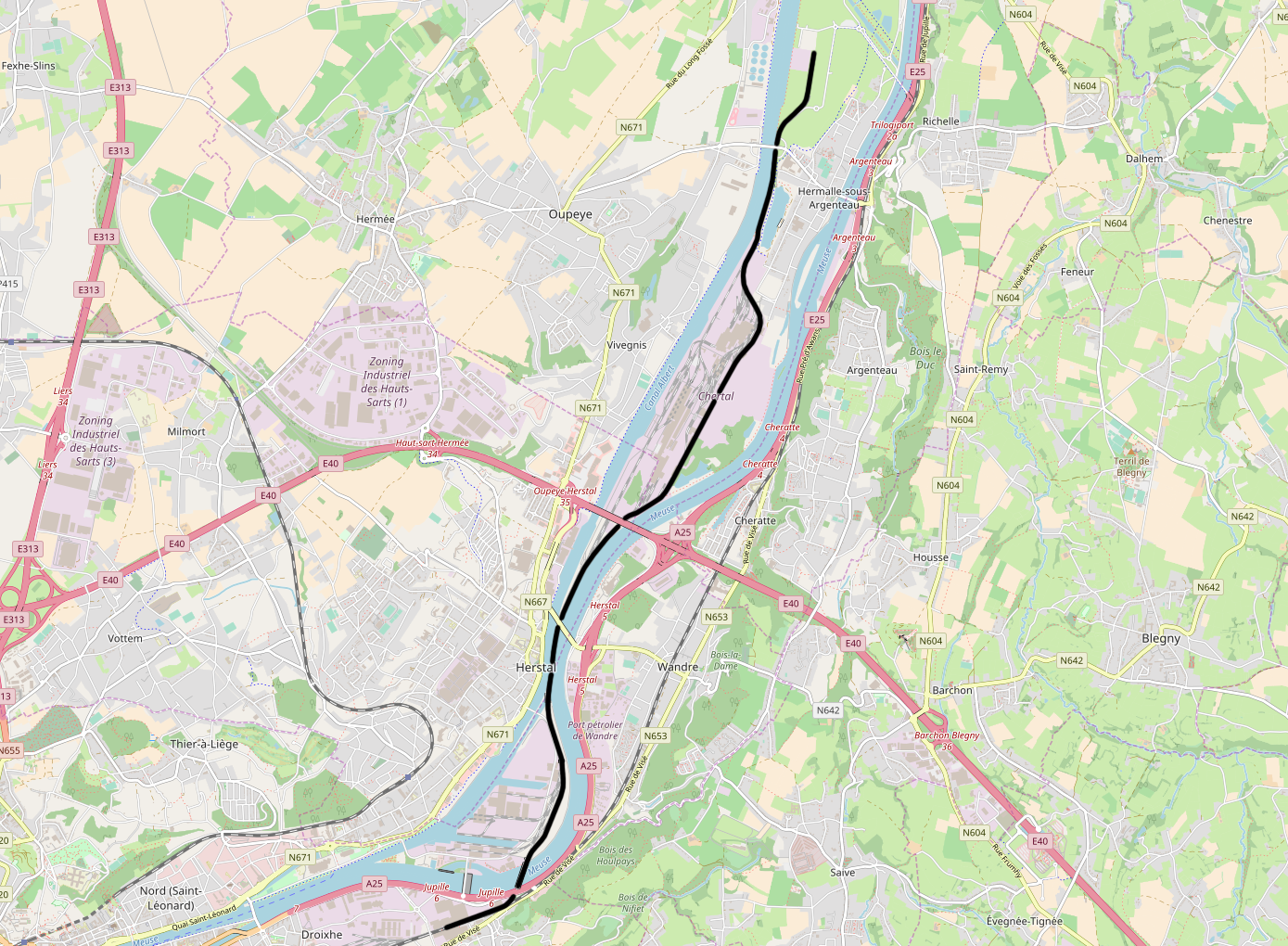

Chertal

Oupeye (; ) is a municipality of Wallonia located in the province of LiÃĻge, Belgium. On January 1, 2006, Oupeye had a total population of 23,581. The total area is 36.11 km2 which gives a population density of 653 inhabitants per km2. The municipality consists of the following districts: Haccourt, Hermalle-sous-Argenteau, HermÃĐe, Heure-le-Romain, Houtain-Saint-SimÃĐon, Oupeye, and Vivegnis. Chertal Chertal is a narrow isthmus approximately 1.5 km southeast of Oupeye bounded by the Albert Canal and Meuse. Since 1963 the land has been the site of a steel factory founded by EspÃĐrance-Longdoz EspÃĐrance-Longdoz was a coal mining and steel production company located in the LiÃĻge region of Belgium. The company merged with Cockerill-OugrÃĐe-Providence in 1970 to form Cockerill-OugrÃĐe-Providence-EspÃĐrance Longdoz (known as Cockerill), ... (as of 2010 part of ArcelorMittal LiÃĻge). See also * List of protected heritage sites in Oupeye Oupeye Chateau 01.jp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Linz-Donawitz Process

Basic oxygen steelmaking (BOS, BOP, BOF, or OSM), also known as Linz-Donawitz steelmaking or the oxygen converter process,Brock and Elzinga, p. 50. is a method of primary steelmaking in which carbon-rich molten pig iron is made into steel. Blowing oxygen through molten pig iron lowers the carbon content of the alloy and changes it into low-carbon steel. The process is known as ''basic'' because fluxes of calcium oxide or dolomite, which are chemical '' bases'', are added to promote the removal of impurities and protect the lining of the converter. The process was invented in 1948 by Swiss engineer Robert Durrer and commercialized in 1952â1953 by the Austrian steelmaking company VOEST and ÃAMG. The LD converter, named after the Austrian towns Linz and Donawitz (a district of Leoben) is a refined version of the Bessemer converter which replaces blowing air with blowing oxygen. It reduced capital cost of the plants and smelting time, and increased labor productivity. Between 1 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |