|

Elastic Limit

In materials science and engineering, the yield point is the point on a stress–strain curve that indicates the limit of elastic behavior and the beginning of plastic behavior. Below the yield point, a material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible and is known as plastic deformation. The yield strength or yield stress is a material property and is the stress corresponding to the yield point at which the material begins to deform plastically. The yield strength is often used to determine the maximum allowable load in a mechanical component, since it represents the upper limit to forces that can be applied without producing permanent deformation. For most metals, such as aluminium and cold-worked steel, there is a gradual onset of non-linear behavior, and no precise yield point. In such a case, the offset yield p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

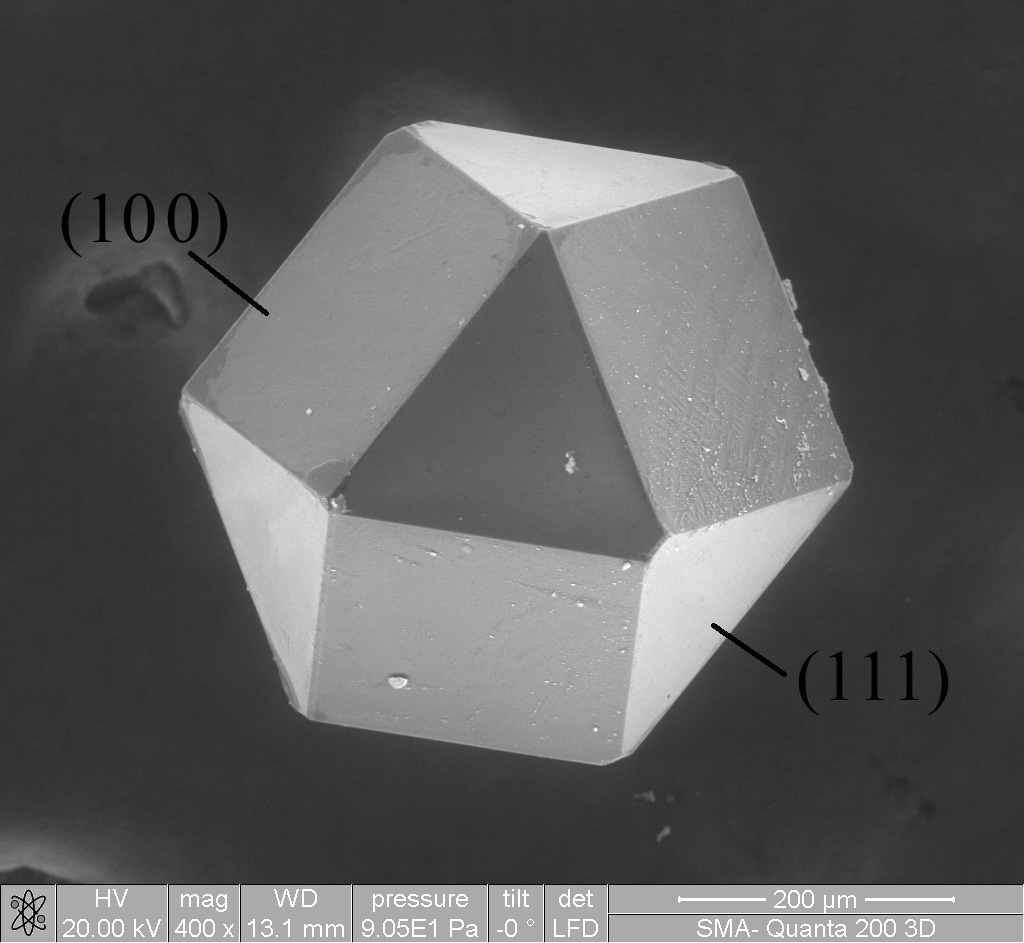

Materials Science

Materials science is an interdisciplinary field of researching and discovering materials. Materials engineering is an engineering field of finding uses for materials in other fields and industries. The intellectual origins of materials science stem from the Age of Enlightenment, when researchers began to use analytical thinking from chemistry, physics, and engineering to understand ancient, phenomenological observations in metallurgy and mineralogy. Materials science still incorporates elements of physics, chemistry, and engineering. As such, the field was long considered by academic institutions as a sub-field of these related fields. Beginning in the 1940s, materials science began to be more widely recognized as a specific and distinct field of science and engineering, and major technical universities around the world created dedicated schools for its study. Materials scientists emphasize understanding how the history of a material (''processing'') influences its struc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultimate Tensile Strength

Ultimate tensile strength (also called UTS, tensile strength, TS, ultimate strength or F_\text in notation) is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials, the ultimate tensile strength is close to the yield point, whereas in ductile materials, the ultimate tensile strength can be higher. The ultimate tensile strength is usually found by performing a tensile test and recording the engineering stress versus strain. The highest point of the stress–strain curve is the ultimate tensile strength and has units of stress. The equivalent point for the case of compression, instead of tension, is called the compressive strength. Tensile strengths are rarely of any consequence in the design of ductile members, but they are important with brittle members. They are tabulated for common materials such as alloys, composite materials, ceramics, plastics, and wood. Definition The ultimate tensile strength of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer Propene, propylene. Polypropylene belongs to the group of polyolefins and is Crystallization of polymers#Degree of crystallinity, partially crystalline and Chemical polarity#Nonpolar molecules, non-polar. Its properties are similar to polyethylene, but it is slightly harder and more heat-resistant. It is a white, mechanically rugged material and has a high chemical resistance. Polypropylene is the second-most widely produced Commodity plastics, commodity plastic (after polyethylene). History Phillips Petroleum chemists J. Paul Hogan and Robert Banks (chemist), Robert Banks first demonstrated the polymerization of propylene in 1951. The stereoselective polymerization to the isotactic was discovered by Giulio Natta and Karl Rehn in March 1954. This pioneering discovery led to large-scale commercial producti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

High-density Polyethylene

High-density polyethylene (HDPE) or polyethylene high-density (PEHD) is a thermoplastic polymer produced from the monomer ethylene. It is sometimes called "alkathene" or " polythene" when used for HDPE pipes. With a high strength-to-density ratio, HDPE is used in the production of plastic bottles, corrosion-resistant piping, geomembranes and plastic lumber. HDPE is commonly recycled, and has the number "2" as its resin identification code. In 2008, the global HDPE market reached a volume of more than 30 million tons. Properties HDPE is known for its high strength-to-density ratio. The density of HDPE ranges from 930 to 970 kg/m3. Although the density of HDPE is only marginally higher than that of low-density polyethylene, HDPE has little branching, giving it stronger intermolecular forces and tensile strength (38 MPa versus 21 MPa) than LDPE. The difference in strength exceeds the difference in density, giving HDPE a higher specific strength. It is also harder and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Fiber

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers ( Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon composite, or just carbon, are extremely strong and light fiber-reinforced plastics that contain carbon fibers. CFRPs can be expensive to produce, but are commonly used wherever high strength-to-weight ratio and stiffness (rigidity) are required, such as aerospace, superstructures of ships, automotive, civil engineering, sports equipment, and an increasing number of consumer and technical applications. The binding polymer is often a thermoset resin such as epoxy, but other thermoset or thermoplastic polymers, such as polyester, vinyl ester, or nylon, are sometimes used. The properties of the final CFRP product can be affected by the type of additives introduced to the binding matrix (resin). The most common additive is silica, but other ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

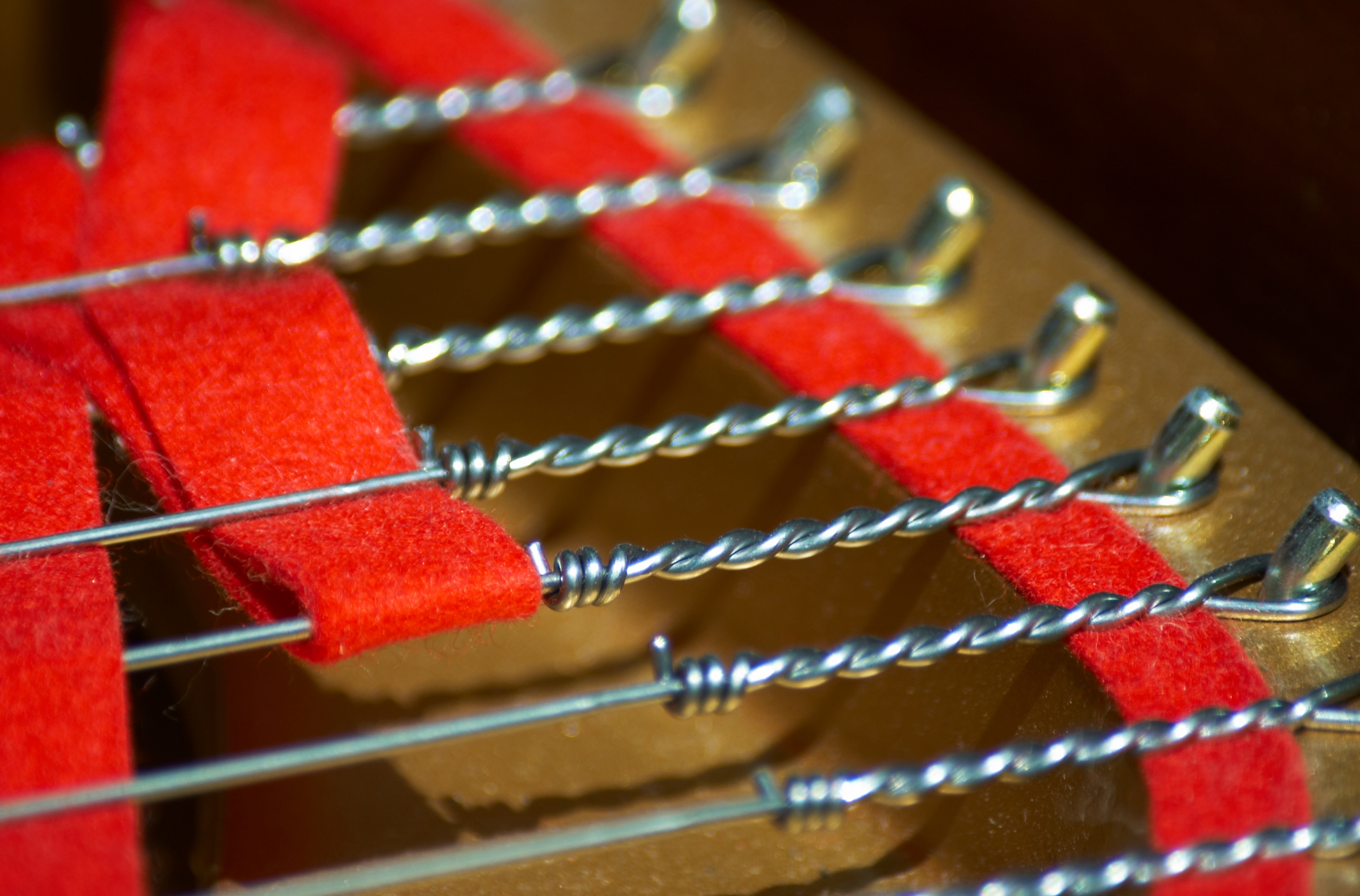

Piano Wire

Piano wire, or "music wire", is a specialized type of wire made for use in piano string (music), strings but also in other applications as Spring (device), springs. It is made from tempering (metallurgy), tempered high-carbon steel, also known as spring steel, which replaced iron as the material starting in 1834. Piano wire has a very high ultimate tensile strength, tensile strength to cope with the heavy demands placed upon piano strings; accordingly, piano wire is also used for a number of other purposes, including springs, surgical uses, and in special effects. History The oldest record of wire being made for musical instruments is from Augsburg in 1351.Dolge (1911, 124) Starting around 1800, the piano began to be built ever more ambitiously, with sturdier (eventually, iron) framing and greater string tension. This led to innovations in making tougher piano wire. In 1834, the Webster & Horsfal firm of Birmingham, United Kingdom brought out a form of piano wire made from c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

A514 Steel

A514 is a particular type of high strength steel, which is quenched and tempered alloy steel, with a yield strength of 100,000 psi (100 ksi or approximately 700 MPa). The ArcelorMittal trademarked name is T-1. A514 is primarily used as a structural steel for building construction. A517 is a closely related alloy that is used for the production of high-strength pressure vessels. This is a standard set by the standards organization ASTM International, a voluntary standards development organization that sets technical standards for materials, products, systems, and services. Specifications A514 The tensile yield strength of A514 alloys is specified as at least for thicknesses up to thick plate, and at least ultimate tensile strength, with a specified ultimate range of . Plates from thick have specified strength of (yield) and (ultimate). A517 A517 steel has equal tensile yield strength, but slightly higher specified ultimate strength of for thicknesses up to and for th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

A36 Steel

A36 steel is a common structural steel alloy used in the United States.''Steel Construction Manual'', 8th Edition, second revised edition, American Institute of Steel Construction, 1986, Ch. 1 pp. 1–5. The A36 (UNS K02600) standard was established by the ASTM International. The standard was published in 1960 and has been updated several times since. Prior to 1960, the dominant standards for structural steel in North America were A7 (until 1967) and A9 (for buildings, until 1940). Note that SAE/AISI A7 and A9 tool steels are not the same as the obsolete ASTM A7 and A9 structural steels. Chemical composition Note: For shapes with a flange thickness more than 3 in (76 mm), 0.85-1.35% manganese content and 0.15-0.40% silicon content are required. Properties As with most steels, A36 has a density of . Young's modulus for A36 steel is . A36 steel has a Poisson's ratio of 0.26 and a shear modulus of .https://www.bushwickmetals.com/a36-steel-properties/ A36 steel in plates, bars ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Elastic Limit

In materials science and engineering, the yield point is the point on a stress–strain curve that indicates the limit of elastic behavior and the beginning of plastic behavior. Below the yield point, a material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible and is known as plastic deformation. The yield strength or yield stress is a material property and is the stress corresponding to the yield point at which the material begins to deform plastically. The yield strength is often used to determine the maximum allowable load in a mechanical component, since it represents the upper limit to forces that can be applied without producing permanent deformation. For most metals, such as aluminium and cold-worked steel, there is a gradual onset of non-linear behavior, and no precise yield point. In such a case, the offset yield p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yield Surface

A yield surface is a five-dimensional surface in the six-dimensional space of Stress (mechanics), stresses. The yield surface is usually convex polytope, convex and the state of stress of ''inside'' the yield surface is elastic. When the stress state lies on the surface the material is said to have reached its Yield (engineering), yield point and the material is said to have become Plasticity (physics), plastic. Further deformation of the material causes the stress state to remain on the yield surface, even though the shape and size of the surface may change as the plastic deformation evolves. This is because stress states that lie outside the yield surface are non-permissible in plasticity (physics), rate-independent plasticity, though not in some models of viscoplasticity.Simo, J. C. and Hughes, T,. J. R., (1998), Computational Inelasticity, Springer. The yield surface is usually expressed in terms of (and visualized in) a three-dimensional Stress (physics)#Principal stresses ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |