|

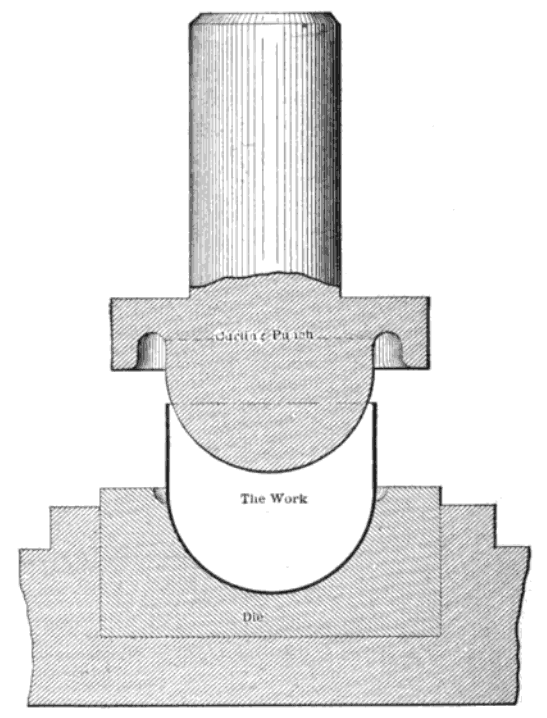

Compound Operation (dies)

A die is a specialized machine tool used in manufacturing industries to cut and/or Forming (metalworking), form material to a desired shape or profile. ''Stamping (metalworking), Stamping dies'' are used with a machine press, press, as opposed to ''Draw plate, drawing dies'' (used in the manufacture of wire) and ''Die casting, casting dies'' (used in Molding (process), molding) which are not. Like molds, dies are generally customized to the item they are used to create. Products made with dies range from simple paper clips to complex pieces used in advanced technology. Continuous production, Continuous-feed laser cutting may displace the analogous die-based process in the automotive industry, among others. Die stamping Blanking and piercing are two Shearing (manufacturing), die cutting operations, and Bending (metalworking), bending is an example of a die forming operation. Die forming Forming operations work by deforming materials like sheet metal or plastic using force (Compre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, Boring (manufacturing), boring, grinding (abrasive cutting), grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the workpiece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or "wikt:freehand#Adjective, freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. The precise definition of the term ''machine tool'' varies among users. While all machine tools are "machines that help people to make things", not a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tension (physics)

Tension is the pulling or stretching force transmitted axially along an object such as a string, rope, chain, rod, truss member, or other object, so as to stretch or pull apart the object. In terms of force, it is the opposite of ''compression''. Tension might also be described as the action-reaction pair of forces acting at each end of an object. At the atomic level, when atoms or molecules are pulled apart from each other and gain potential energy with a restoring force still existing, the restoring force might create what is also called tension. Each end of a string or rod under such tension could pull on the object it is attached to, in order to restore the string/rod to its relaxed length. Tension (as a transmitted force, as an action-reaction pair of forces, or as a restoring force) is measured in newtons in the International System of Units (or pounds-force in Imperial units). The ends of a string or other object transmitting tension will exert forces on the objects ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Curling (metalworking)

Curling is a sheet metal forming process used to form the edges into a hollow ring. Curling can be performed to eliminate sharp edges and increase the moment of inertia near the curled end. Other parts are curled to perform their primary function, such as door hinges. Operation In the curling operation, the flare, or burr, should always be turned away from the die. This will help prolong the life of the die by avoiding unnecessary damage due to scratching. The stroke of the die must be as long as the curl. Curling is often performed as part of a high production, multiple operation progressive forming. Tooling The curling die is designed to curl a material of specific thickness. Dies are generally made of hardened tool steel Tool steel is any of various carbon steels and alloy steels that are particularly well-suited to be made into tools and tooling, including cutting tools, dies, hand tools, knives, and others. Their suitability comes from their distinctive ... ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coin Die

Mint (coin), Minting, coining or coinage is the process of manufacturing coins using a kind of stamping (metalworking), stamping, the process used in both hammered coinage and milled coinage. This "stamping" process is different from the method used in cast coinage. A coin die (archaically spelt dye) is one of the two metallic Die (manufacturing), pieces that are used to strike a coin, one per each side of the coin. A die contains an inverse version of the image to be ''struck'' on the coin. ''Striking'' a coin refers to pressing an image into the blank metal disc, or planchet, and is a term descended from the days when the dies were struck with hammers to deform the metal into the image of the dies. Modern dies made out of hardened steel are capable of producing many hundreds of thousands of coins before they are retired and defaced. Scissel is the scrap produced in the punching of coin blanks from a continuous strip of metal. Ancient coin dies Prior to the modern era, coin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coining (metalworking)

Coining is a form of precision stamping in which a workpiece is subjected to a sufficiently high stress to induce plastic flow on the surface of the material. A beneficial feature is that in some metals, the plastic flow reduces surface grain size, and work hardens the surface, while the material deeper in the part retains its toughness and ductility. The term comes from the initial use of the process: manufacturing of coins. Coining is used to manufacture parts for all industries and is commonly used when high relief or very fine features are required. For example, it is used to produce coins, badges, buttons, precision-energy springs and precision parts with small or polished surface features. Coining is a cold working process similar in other respects to forging, which takes place at elevated temperature; it uses a great deal of force to elastically deform a workpiece, so that it conforms to a die. Coining can be done using a gear driven press, a mechanical press, or m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Broaching (metalworking)

Broaching is a machining process that uses a toothed tool, called a broach, to remove material. There are two main types of broaching: ''linear'' and ''rotary''. In linear broaching, which is the more common process, the broach is run linearly against a surface of the workpiece to produce the cut. Linear broaches are used in a broaching machine, which is also sometimes shortened to ''broach''. In rotary broaching, the broach is rotated and pressed into the workpiece to cut an axisymmetric shape. A rotary broach is used in a lathe or screw machine. In both processes the cut is performed in one pass of the broach, which makes it very efficient. Broaching is used when precision machining is required, especially for odd shapes. Commonly machined surfaces include circular and non-circular holes, splines, keyways, and flat surfaces. Typical workpieces include small to medium-sized castings, forgings, screw machine parts, and stampings. Even though broaches can be expensive, broac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polygon

In geometry, a polygon () is a plane figure made up of line segments connected to form a closed polygonal chain. The segments of a closed polygonal chain are called its '' edges'' or ''sides''. The points where two edges meet are the polygon's '' vertices'' or ''corners''. An ''n''-gon is a polygon with ''n'' sides; for example, a triangle is a 3-gon. A simple polygon is one which does not intersect itself. More precisely, the only allowed intersections among the line segments that make up the polygon are the shared endpoints of consecutive segments in the polygonal chain. A simple polygon is the boundary of a region of the plane that is called a ''solid polygon''. The interior of a solid polygon is its ''body'', also known as a ''polygonal region'' or ''polygonal area''. In contexts where one is concerned only with simple and solid polygons, a ''polygon'' may refer only to a simple polygon or to a solid polygon. A polygonal chain may cross over itself, creating star polyg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nomenclature

Nomenclature (, ) is a system of names or terms, or the rules for forming these terms in a particular field of arts or sciences. (The theoretical field studying nomenclature is sometimes referred to as ''onymology'' or ''taxonymy'' ). The principles of naming vary from the relatively informal conventions of everyday speech to the internationally agreed principles, rules, and recommendations that govern the formation and use of the specialist terminology used in scientific and any other disciplines. Naming "things" is a part of general human communication using words and language: it is an aspect of everyday taxonomy as people distinguish the objects of their experience, together with their similarities and differences, which observers identify, name and classify. The use of names, as the many different kinds of nouns embedded in different languages, connects nomenclature to theoretical linguistics, while the way humans mentally structure the world in relation to word meanings a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automobile

A car, or an automobile, is a motor vehicle with wheels. Most definitions of cars state that they run primarily on roads, Car seat, seat one to eight people, have four wheels, and mainly transport private transport#Personal transport, people rather than cargo. There are around one billion cars in use worldwide. The French inventor Nicolas-Joseph Cugnot built the first steam-powered road vehicle in 1769, while the Swiss inventor François Isaac de Rivaz designed and constructed the first internal combustion-powered automobile in 1808. The modern car—a practical, marketable automobile for everyday use—was invented in 1886, when the German inventor Carl Benz patented his Benz Patent-Motorwagen. Commercial cars became widely available during the 20th century. The 1901 Oldsmobile Curved Dash and the 1908 Ford Model T, both American cars, are widely considered the first mass-produced and mass-affordable cars, respectively. Cars were rapidly adopted in the US, where they replac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoforming

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product. The sheet, or "film" when referring to thinner gauges and certain material types, is heated in an oven to a high-enough temperature that permits it to be stretched into or onto a mold and cooled to a finished shape. Its simplified version is vacuum forming. In its simplest form, a small tabletop or lab size machine can be used to heat small cut sections of plastic sheet and stretch it over a mold using vacuum. This method is often used for sample and prototype parts. In complex and high-volume applications, very large production machines are utilized to heat and form the plastic sheet and trim the formed parts from the sheet in a continuous high-speed process and can produce many thousands of finished parts per hour depending on the machine and mold size and the size of the parts being formed. Therm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blow Molding

Blow molding (or moulding) is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding, and injection stretch blow molding. The blow molding process begins with softening plastic by heating a preform or parison. The parison is a tube-like piece of plastic with a hole in one end through which compressed air can enter. The plastic workpiece is then clamped into a mold and air is blown into it. The air pressure inflates the plastic which conforms to the mold. Once the plastic has cooled and hardened the mold opens and the part is ejected. Water channels within the mold assist cooling. History The process principle comes from the idea of glassblowing. Enoch Ferngren and William Kopitke produced a blow molding machine and sold it to Hartford Empire Company in 1938. This was the beginning of the commercial blow ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blister Packs

A blister pack is any of several types of pre-formed plastic packaging used for small consumer goods, foods, and for pharmaceuticals. The primary component of a blister pack is a cavity or pocket made from a formable web, usually a thermoformed plastic. This usually has a backing of paperboard or a lidding seal of aluminum foil or plastic. A blister that folds onto itself is often called a clamshell (container), clamshell. Blister packs are useful for protecting products against external factors, such as humidity and contamination for extended periods of time. Opacity (optics), Opaque blisters also protect light-sensitive products against UV rays. Uses Blister packs are used to package products such as toys, hardware, medication, etc. Many blister packaging machines use heat and pressure via a die to form the cavity or pocket from a roll or sheet of plastic. In recent years, improvements in cold forming—specifically allowing steeper depth/angles during forming, which minim ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |