|

Coiled Tubing

In the oil and gas industry, coiled tubing refers to a long metal pipe, normally in diameter which is supplied spooled on a large reel. It is used for Well intervention, interventions in oil well, oil and gas wells and sometimes as production tubing in depleted gas wells. Coiled tubing is often used to carry out operations similar to Wireline (cabling), wirelining. The main benefits over wireline are the ability to pump chemicals through the coil and the ability to push it into the hole rather than relying on gravity. Pumping can be fairly self-contained, almost a closed system, since the tube is continuous instead of jointed pipe. For offshore operations, the 'footprint' for a coiled tubing operation is generally larger than a wireline spread, which can limit the number of installations where coiled tubing can be performed and make the operation more costly. A coiled tubing operation is normally performed through the Drilling rig, drilling derrick on the oil platform, which is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coiled Tubing Drilling

Coiled Tubing Drilling (CTD) is a drilling method that combines coiled tubing and directional drilling. Drilling Market Focus: Coiled Tubing Use Growing Faster than Drilling Industry, The Oil and Gas Journal, 19 Sept 2005, Retrieved 30 July 2014 It uses a mud motor to create a system for reservoirs. Niobrara Wells Prove BHA for Coiled Tubing, Drilling Contractor, 15 Mar 2012, Retrieved 30 July 2014 , Introduction to Coiled T ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Equipment

Industrial technology is the use of engineering and manufacturing technology to make production faster, simpler, and more efficient. The industrial technology field employs creative and technically proficient individuals who can help a company achieve efficient and profitable productivity. Industrial technology programs typically include instruction in optimization theory, human factors, organizational behavior, industrial processes, industrial planning procedures, computer applications, and report and presentation preparation. Planning and designing manufacturing processes and equipment is the main aspect of being an industrial technologist. An industrial technologist is often responsible for implementing certain designs and processes. Accreditation and certification The USA-based Association of Technology, Management, and Applied Engineering (ATMAE), accredits selected collegiate programs in Industrial Technology in the USA. An instructor or graduate of an Industrial Te ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Petroleum Production

The petroleum industry, also known as the oil industry, includes the global processes of exploration, extraction, refining, transportation (often by oil tankers and pipelines), and marketing of petroleum products. The largest volume products of the industry are fuel oil and gasoline (petrol). Petroleum is also the raw material for many chemical products, including pharmaceuticals, solvents, fertilizers, pesticides, synthetic fragrances, and plastics. The industry is usually divided into three major components: upstream, midstream, and downstream. Upstream regards exploration and extraction of crude oil, midstream encompasses transportation and storage of crude, and downstream concerns refining crude oil into various end products. Petroleum is vital to many industries, and is necessary for the maintenance of industrial civilization in its current configuration, making it a critical concern for many nations. Oil accounts for a large percentage of the world's ener ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oil Industry

The petroleum industry, also known as the oil industry, includes the global processes of exploration, extraction, refining, transportation (often by oil tankers and pipelines), and marketing of petroleum products. The largest volume products of the industry are fuel oil and gasoline (petrol). Petroleum is also the raw material for many chemical products, including pharmaceuticals, solvents, fertilizers, pesticides, synthetic fragrances, and plastics. The industry is usually divided into three major components: upstream, midstream, and downstream. Upstream regards exploration and extraction of crude oil, midstream encompasses transportation and storage of crude, and downstream concerns refining crude oil into various end products. Petroleum is vital to many industries, and is necessary for the maintenance of industrial civilization in its current configuration, making it a critical concern for many nations. Oil accounts for a large percentage of the world's energy consum ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

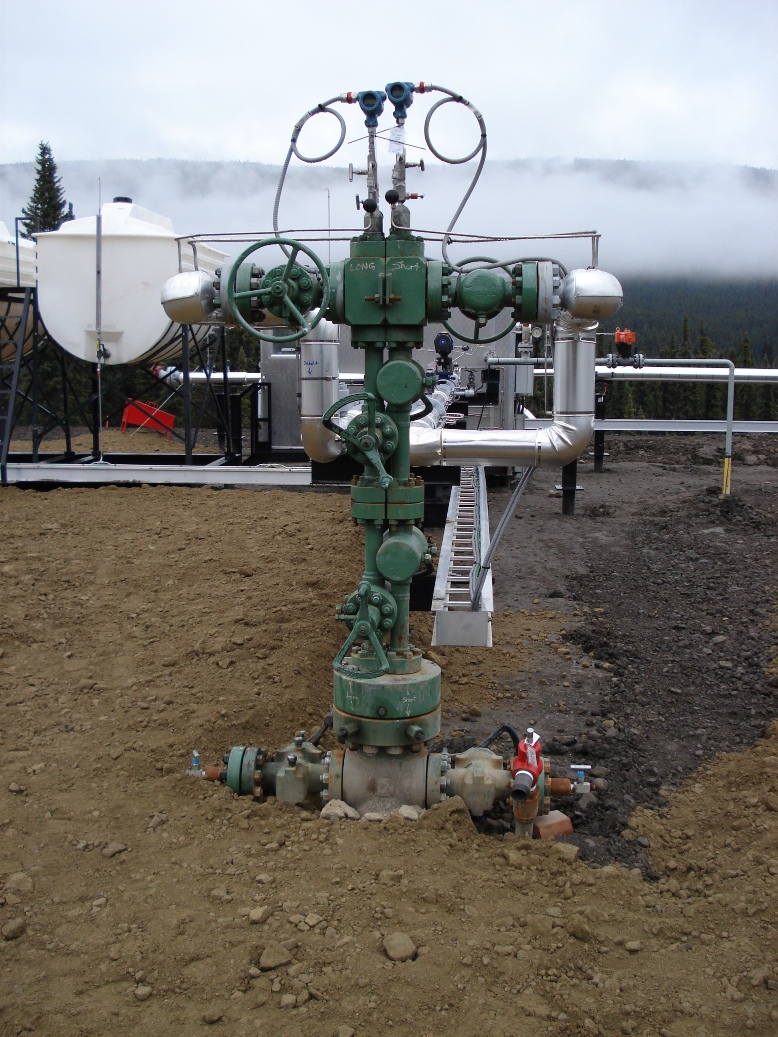

Christmas Tree (oil Well)

In petroleum and natural gas extraction, a Christmas tree, or tree, is an assembly of valves, casing spools, and fittings used to regulate the flow of pipes in an oil well, gas well, water injection well, water disposal well, gas injection well, condensate well, and other types of well. Overview The first primitive Christmas tree was used by the Hamill Brothers to bring Spindletop under control. It consisted of a T-valve, with a and valve on the vertical pipe, and a 6-inch valve on the horizontal pipe. The vertical valve was closed first, and then the valve to the horizontal pipe. Christmas trees are used on both surface and subsea wells. It is common to identify the type of tree as either "subsea tree" or "surface tree". Each of these classifications has a number of variations. Examples of subsea include conventional, dual bore, mono bore, TFL (through flow line), horizontal, mudline, mudline horizontal, side valve, and TBT (through-bore tree) trees. The deepest installe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Preventer

A gybe preventer, preventer, or jibe-guard, is a mechanical device on a sailing vessel which limits the boom's ability to swing unexpectedly across the boat due to an unplanned accidental jibe. During an unplanned accidental jibe (or ''gybe''), neither the crew nor the boat is set up properly to execute a planned jibe. As a result, the uncontrolled boom will swing across the boat potentially inflicting injury or knocking crew members overboard. The mainsheet or traveller can also inflict serious injury. Uncontrolled jibes may also damage the boat itself. Rigging a preventer on a yacht's mainsail is often performed when the wind is behind the beam (i.e. when it's coming from more than 90° off the bow). It can also be useful at other times when there is more swell than wind, a situation when the wind may not have the strength to keep the boom in place as the boat dips and rolls. On any boat that is sailing downwind without a preventer, strict 'heads-down' procedures must b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wireline (cabling)

In the petroleum industry, oil and gas industry, the term wireline usually refers to the use of cable, or "wireline," to collect subsurface geophysical and petrochemical data. The subsurface information describes and allows for analysis of subsurface geology, reservoir properties and production characteristics. Wireline can also refer to the delivery of well construction services such as pipe recovery, perforating, plug setting and well cleaning and fishing. There are four basic types of wireline: multi-conductor, single conductor, slickline and braided line. Other types of wireline include sheathed slickline and fibre-optic lines. Multi-conductor lines consist of external armor wires wound around a core of typically 4- or 7-conductors. The conductors are bound together in a central core, protected by the outer armor wires. These conductors are used to transmit power to the downhole instrumentation and transmit data (and commands) to and from the surface. Multi-conductor cables ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Well Logging

Well logging, also known as borehole logging is the practice of making a detailed record (a ''well log'') of the geologic formations penetrated by a borehole. The log may be based either on visual inspection of samples brought to the surface (''geological'' logs) or on physical measurements made by instruments lowered into the hole (''geophysical'' logs). Some types of geophysical well logs can be done during any phase of a well's history: drilling, completing, producing, or abandoning. Well logging is performed in boreholes drilled for the oil and gas, groundwater, mineral and geothermal exploration, as well as part of environmental, scientific and geotechnical studies. Wireline logging Different industries, as mining, oil and gas uses wireline logging to obtain a continuous record of a formation's rock properties, also, groundwater consultants. Wireline logging can be defined as being "The acquisition and analysis of geophysical data performed as a function of well b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bottom Hole Assembly

A bottom hole assembly (BHA) is a component of a drilling rig. It is the lowest part of the drill string, extending from the bit to the drill pipe. The assembly can consist of drill collars, subs such as stabilisers, reamers, shocks, hole-openers, and the bit sub and bit. The BHA design is based upon the requirements of having enough weight transfer to the bit (WOB) to be able to drill and achieve a sufficient Rate of Penetration (ROP), giving the Driller or Directional Driller directional control to drill as per the planned trajectory and to also include whatever Logging While Drilling (LWD) / Measurement While Drilling (MWD) tools for formation evaluation. As such BHA design can vary greatly from simple vertical wells with little or no LWD requirements to complex directional wells which must run multi-combo LWD suites. Prior to running a BHA most oilfield service providers have software to model the BHA behaviour such as the maximum WOB achievable, the directional tendencies ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drilling Fluid

In geotechnical engineering, drilling fluid, also known as drilling mud, is used to aid the drilling of boreholes into the earth. Used while drilling oil and natural gas wells and on exploration drilling rigs, drilling fluids are also used for much simpler boreholes, such as water wells. The two main categories of drilling fluids are water-based muds (WBs), which can be dispersed and non-dispersed, and non-aqueous muds, usually called oil-based muds (OBs). Along with their formatives, these are used along with appropriate polymer and clay additives for drilling various oil and gas formations. Gaseous drilling fluids, typically utilizing air or natural gas, sometimes with the addition of foaming agents, can be used when downhole conditions permit. The main functions of liquid drilling fluids are to exert hydrostatic pressure to prevent formation fluids from entering into the well bore, and carrying out drill cuttings as well as suspending the drill cuttings while drill ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |