|

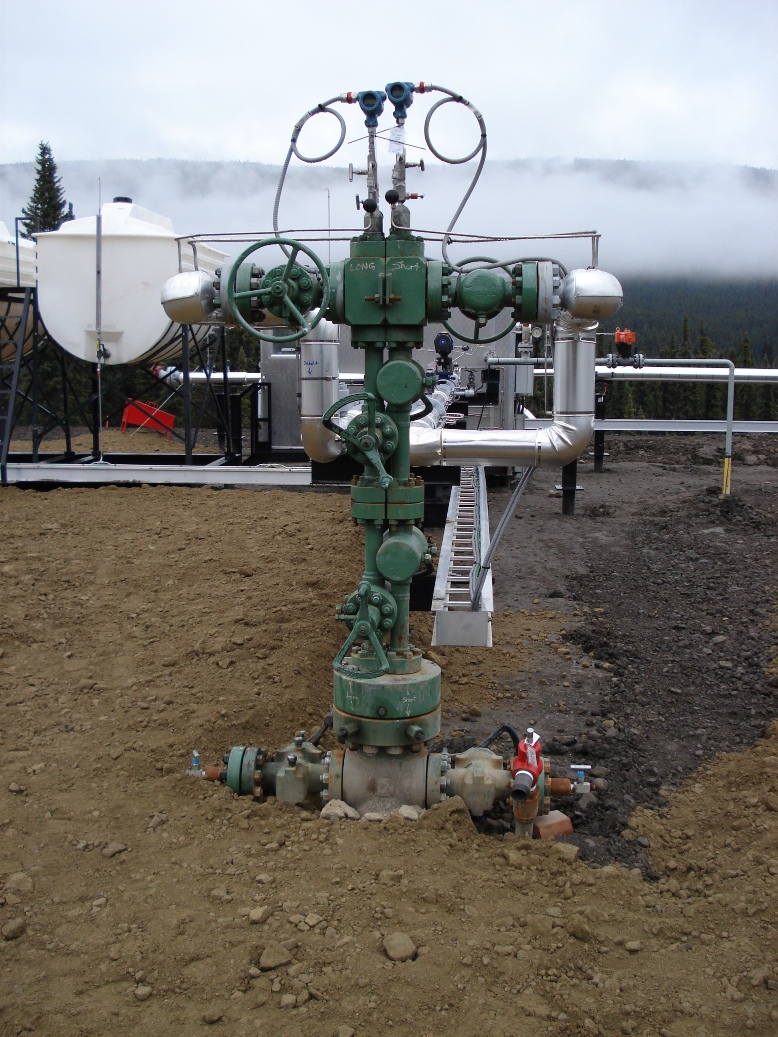

Christmas Tree (oil Well)

In petroleum and natural gas extraction, a Christmas tree, or tree, is an assembly of valves, casing spools, and fittings used to regulate the flow of pipes in an oil well, gas well, water injection well, water disposal well, gas injection well, condensate well, and other types of well. Overview The first primitive Christmas tree was used by the Hamill Brothers to bring Spindletop under control. It consisted of a T-valve, with a and valve on the vertical pipe, and a 6-inch valve on the horizontal pipe. The vertical valve was closed first, and then the valve to the horizontal pipe. Christmas trees are used on both surface and subsea wells. It is common to identify the type of tree as either "subsea tree" or "surface tree". Each of these classifications has a number of variations. Examples of subsea include conventional, dual bore, mono bore, TFL (through flow line), horizontal, mudline, mudline horizontal, side valve, and TBT (through-bore tree) trees. The deepest installe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Subsea

Subsea technology involves fully submerged ocean equipment, operations, or applications, especially when some distance offshore, in deep ocean waters, or on the seabed. The term ''subsea'' is frequently used in connection with oceanography, marine or ocean engineering, ocean exploration, remotely operated vehicle (ROVs) autonomous underwater vehicles (AUVs), submarine communications or power cables, seafloor mineral mining, oil and gas, and offshore wind power. Oil and gas Oil and gas fields reside beneath many inland waters and offshore areas around the world, and in the oil and gas industry the term ''subsea'' relates to the exploration, drilling and development of oil and gas fields in these underwater locations. Under water oil fields and facilities are generically referred to using a ''subsea'' prefix, such as ''subsea well'', ''subsea field'', ''subsea project'', and ''subsea developments.'' Subsea oil field developments are usually split into ''Shallow water'' and ''D ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Two-barrier Rule

{{Unreferenced stub, auto=yes, date=April 2012 The two barrier rule is a policy of safety for work on piping carrying high pressure and/or high temperature fluids. It is commonly used by oil companies. The rule simply states that for any work that must be done on a section of piping, which involves breaking containment, there must be at least two barriers separating the fluids from the broken area. The purpose behind specifying two barriers is to ensure redundancy. The risk of a total loss of containment is reduced if there are two independent isolations as it is highly improbable they would both fail at the same time. For example, if a section of pipe from a production line leading from a Christmas tree to the process plant, were to need replacement, this area of the piping would need isolation before the offending section was removed or oil would be able to flow freely out of the piping into the environment, causing environmental damage, a health and safety hazard and wast ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coiled Tubing

In the oil and gas industry, coiled tubing refers to a long metal pipe, normally in diameter which is supplied spooled on a large reel. It is used for Well intervention, interventions in oil well, oil and gas wells and sometimes as production tubing in depleted gas wells. Coiled tubing is often used to carry out operations similar to Wireline (cabling), wirelining. The main benefits over wireline are the ability to pump chemicals through the coil and the ability to push it into the hole rather than relying on gravity. Pumping can be fairly self-contained, almost a closed system, since the tube is continuous instead of jointed pipe. For offshore operations, the 'footprint' for a coiled tubing operation is generally larger than a wireline spread, which can limit the number of installations where coiled tubing can be performed and make the operation more costly. A coiled tubing operation is normally performed through the Drilling rig, drilling derrick on the oil platform, which is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wireline (cabling)

In the petroleum industry, oil and gas industry, the term wireline usually refers to the use of cable, or "wireline," to collect subsurface geophysical and petrochemical data. The subsurface information describes and allows for analysis of subsurface geology, reservoir properties and production characteristics. Wireline can also refer to the delivery of well construction services such as pipe recovery, perforating, plug setting and well cleaning and fishing. There are four basic types of wireline: multi-conductor, single conductor, slickline and braided line. Other types of wireline include sheathed slickline and fibre-optic lines. Multi-conductor lines consist of external armor wires wound around a core of typically 4- or 7-conductors. The conductors are bound together in a central core, protected by the outer armor wires. These conductors are used to transmit power to the downhole instrumentation and transmit data (and commands) to and from the surface. Multi-conductor cables ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Well Intervention

A well intervention, or well work, is any operation carried out on an oil or gas well during, or at the end of, its productive life that alters the state of the well or well geometry, provides well diagnostics, or manages the production of the well. Types of well intervention Pumping Pumping is the simplest form of intervention as it does not involve putting hardware into the well itself. Frequently it simply involves rigging up to the kill wing valve on the Christmas tree and pumping in a fluid determined necessary for the particular well. Wellhead and Christmas tree maintenance The complexity of wellhead and Christmas tree maintenance can vary depending on the condition of the wellheads. Scheduled annual maintenance may simply involve greasing and pressure testing the valve on the hardware. Sometimes the downhole safety valve is pressure tested as well. Slickline Slickline operations may be used for fishing, gauge cutting, setting or removing plugs, deploying o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gate Valve

A gate valve, also known as a sluice valve, is a valve that opens by lifting a barrier (gate) out of the path of the fluid. Gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully opened. The gate faces can be parallel but are most commonly wedge-shaped (in order to be able to apply pressure on the sealing surface). Typical use Gate valves are used to shut off the flow of liquids rather than for flow regulation, which is frequently done with a globe valve. When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low Drag (physics), flow resistance. The size of the open flow path generally varies in a nonlinear manner as the gate is moved. This means that the flow rate does not change evenly with stem travel. Depending on the construction, a partially open gate can vibrate from the fluid flow. Gate valves are mostly used with larger pipe diameters (from 2" to the largest pipelines) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wellhead

A wellhead is the component at the surface of an oil or gas well that provides the structural and pressure-containing interface for the drilling and production equipment. The primary purpose of a wellhead is to provide the suspension point and pressure seals for the casing strings that run from the bottom of the hole sections to the surface pressure control equipment. While drilling the oil well, surface pressure control is provided by a blowout preventer (BOP). If the pressure is not contained during drilling operations by the column of drilling fluid, casings, wellhead, and BOP, a well blowout could occur. When the well has been drilled, it is completed to provide an interface with the reservoir rock and a tubular conduit for the well fluids. The surface pressure control is provided by a Christmas tree, which is installed on top of the wellhead, with isolation valves and choke equipment to control the flow of well fluids during production. Wellheads are typically welded ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Choke Valve

In internal combustion engines with carburetors, a choke valve or choke modifies the air pressure in the intake manifold, thereby altering the air–fuel ratio entering the engine. Choke valves are generally used in naturally aspirated engines to supply a richer fuel mixture when starting the engine. Most choke valves in engines are butterfly valves mounted upstream of the carburetor jet to restrict air flow there and produce a higher partial vacuum downstream, which increases the fuel draw. In heavy industrial or fluid engineering contexts, including oil and gas production, a choke valve or choke is a particular design of valve with a solid cylinder placed inside another slotted or perforated cylinder. Carburetor A choke valve is sometimes installed in the carburetor of internal combustion engines. Its purpose is to restrict the flow of air, thereby enriching the fuel-air mixture while starting the engine. Depending on engine design and application, the valve can be activated ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Petroleum

Petroleum, also known as crude oil or simply oil, is a naturally occurring, yellowish-black liquid chemical mixture found in geological formations, consisting mainly of hydrocarbons. The term ''petroleum'' refers both to naturally occurring unprocessed crude oil, as well as to petroleum products that consist of refining, refined crude oil. Petroleum is a fossil fuel formed over millions of years from anaerobic decay of organic materials from buried prehistoric life, prehistoric organisms, particularly planktons and algae, and 70% of the world's oil deposits were formed during the Mesozoic. Conventional reserves of petroleum are primarily recovered by oil drilling, drilling, which is done after a study of the relevant structural geology, sedimentary basin analysis, analysis of the sedimentary basin, and reservoir characterization, characterization of the petroleum reservoir. There are also unconventional (oil & gas) reservoir, unconventional reserves such as oil sands and oil sh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valve

A valve is a device or natural object that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or Slurry, slurries) by opening, closing, or partially obstructing various passageways. Valves are technically Piping and plumbing fitting, fittings, but are usually discussed as a separate category. In an open valve, fluid flows in a direction from higher pressure to lower pressure. The word is derived from the Latin ''valva'', the moving part of a door, in turn from ''volvere'', to turn, roll. The simplest, and very ancient, valve is simply a freely hinged flap which swings down to obstruct fluid (gas or liquid) flow in one direction, but is pushed up by the flow itself when the flow is moving in the opposite direction. This is called a check valve, as it prevents or "checks" the flow in one direction. Modern control valves may regulate pressure or Fluid dynamics, flow downstream and operate on sophisticated Automation#Industrial automation, automat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oil Refinery

An oil refinery or petroleum refinery is an industrial processes, industrial process Factory, plant where petroleum (crude oil) is transformed and refining, refined into products such as gasoline (petrol), diesel fuel, Bitumen, asphalt base, fuel oils, heating oil, kerosene, liquefied petroleum gas and petroleum naphtha. Petrochemical feedstock like ethylene and propene, propylene can also be produced directly by Cracking (chemistry), cracking crude oil without the need of using refined products of crude oil such as naphtha. The crude oil feedstock has typically been processed by an oil production plant. There is usually an oil depot at or near an oil refinery for the storage of incoming crude oil feedstock as well as bulk liquid products. In 2020, the total capacity of global refineries for crude oil was about 101.2 million barrels per day. Oil refineries are typically large, sprawling industrial complexes with extensive piping running throughout, carrying streams of fluids b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |