|

Capacitive Displacement Sensor

Capacitive displacement sensors are a kind of non-contact displacement sensor, measuring the position and change of position in capacitive materials to a high resolution.Lion Precision Capacitive Sensor Overview An overview of from Lion Precision. They are also able to measure the thickness or density of non-conductive materials. Capacitive displacement sensors are used in a w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Pepperl+Fuchs Capacitive Sensor CJ8-18GM-E2-V1

Pepperl+Fuchs SE (sometimes referenced by the initialism P+F) is a German multinational company headquartered in Mannheim, Germany. The company manufactures electronic products for fabrication and process automation. It specializes in sensor manufacturing, such as sensors used in automatic doors in elevators, encoders, AS interfaces, RFID systems, barcode solutions, and explosion protection, as well as components for the automotive industry, and plant engineering. In 2022, the company's revenue exceeded €1 billion for the first time. As of April 2024, the company had approximately 6,850 employees worldwide, with more than 40 foreign subsidiaries on six continents, and manufacturing facilities in Germany, USA, Singapore, Hungary, China, Indonesia, and Vietnam. A new US headquarters is scheduled to open in late 2025. History Pepperl+Fuchs was founded in 1945 by Walter Pepperl and Ludwig Fuchs in Mannheim. The company initially operated as a workshop for repairing radio equip ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Nanometer

330px, Different lengths as in respect to the Molecule">molecular scale. The nanometre (international spelling as used by the International Bureau of Weights and Measures; SI symbol: nm), or nanometer (American spelling Despite the various list of dialects of English, English dialects spoken from country to country and within different regions of the same country, there are only slight regional variations in English orthography, the two most notable variati ...), is a units of measurement, unit of length in the International System of Units (SI), equal to one billionth (short scale) or one thousand million (long scale) of a metre, meter (0.000000001 m) and to 1000 picometres. One nanometre can be expressed in scientific notation as 1 × 10−9 m and as m. History The nanometre was formerly known as the "''millimicrometre''" – or, more commonly, the "''millimicron''" for short – since it is of a micrometre, micrometer. It was often de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Air Bearing

Air bearings (also known as aerostatic or aerodynamic bearings) are bearings that use a thin film of pressurized gas to provide a low friction load-bearing interface between surfaces. The two surfaces do not touch, thus avoiding the problems of friction, wear, particulates, and lubricant handling associated with conventional bearings, and air bearings offer distinct advantages in precision positioning, such as lacking backlash and static friction, as well as in high-speed applications. Spacecraft simulators now most often use air bearings, and 3D printing, 3-D printers are now used to make air-bearing–based attitude simulators for CubeSat satellites.Nemanja Jovanovic, et al. Design and Testing of a Low-Cost, Open Source, 3-D Printed Air-Bearing-Based Attitude Simulator for CubeSat Satellites. ''Journal of Small Satellites'' Vol. 8, No. 2, pp. 859–880 (2019). https://jossonline.com/letters/design-and-testing-of-a-low-cost-open-source-3-d-printed-air-bearing-based-attitude-simul ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Milling Machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying directions on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs). The integr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

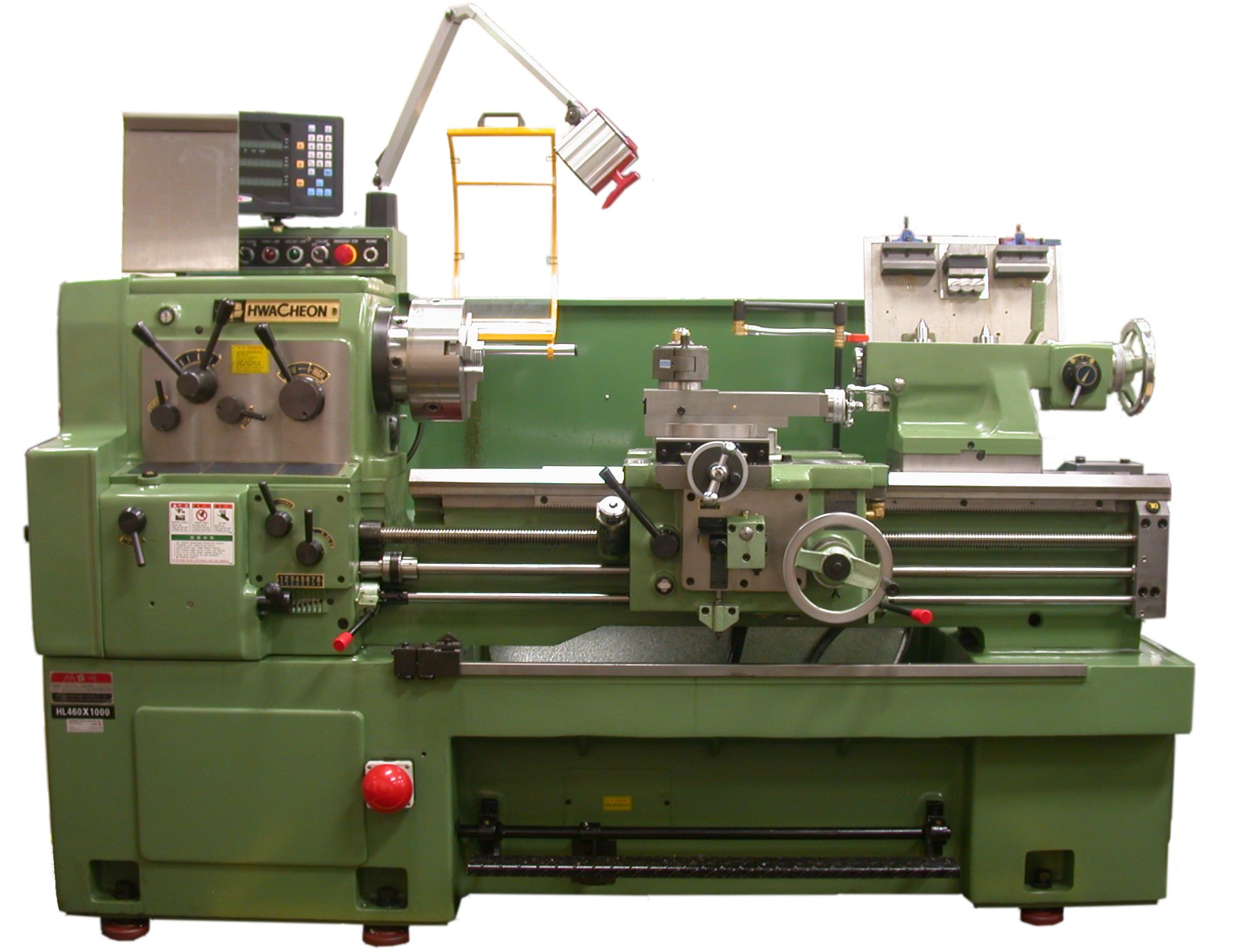

Lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Surface Grinder

Surface grinding is done on flat surfaces to produce a smooth finish. It is a widely used abrasive machining process in which a spinning wheel covered in rough particles (grinding wheel) cuts chips of metallic or nonmetallic substance from a workpiece, making a face of it flat or smooth. Sometimes a surface grinder is known as a ''flick grinder'' if great accuracy is not required, but a machine superior to a bench grinder is needed. Process Surface grinding is a finishing process that uses a rotating abrasive wheel to smooth the flat surface of metallic or nonmetallic materials to give them a more refined look by removing the oxide layer and impurities on work piece surfaces. This will also attain a desired surface for a functional purpose. The components of a surface grinding machine are an abrasive wheel, a workholding device known as a chuck, and a reciprocating or rotary table. The chuck holds the material in place by two processes: ferromagnetic pieces are held in place b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Farad

The farad (symbol: F) is the unit of electrical capacitance, the ability of a body to store an electrical charge, in the International System of Units, International System of Units (SI), equivalent to 1 coulomb per volt (C/V). It is named after the English physicist Michael Faraday (1791–1867). In SI base units 1 F = 1 kilogram, kg−1⋅meter, m−2⋅second, s4⋅ampere, A2. Definition The capacitance of a capacitor is one farad when one coulomb of charge changes the potential between the plates by one volt. Equally, one farad can be described as the capacitance which stores a one-coulomb charge across a potential difference of one volt. The relationship between capacitance, charge, and potential difference is linear. For example, if the potential difference across a capacitor is halved, the quantity of charge stored by that capacitor will also be halved. For most applications, the farad is an impractically large unit of capacitance. Most electrical and electron ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Dielectric Constant

The relative permittivity (in older texts, dielectric constant) is the permittivity of a material expressed as a ratio with the electric permittivity of a vacuum. A dielectric is an insulating material, and the dielectric constant of an insulator measures the ability of the insulator to store electric energy in an electrical field. Permittivity is a material's property that affects the Coulomb force between two point charges in the material. Relative permittivity is the factor by which the electric field between the charges is decreased relative to vacuum. Likewise, relative permittivity is the ratio of the capacitance of a capacitor using that material as a dielectric, compared with a similar capacitor that has vacuum as its dielectric. Relative permittivity is also commonly known as the dielectric constant, a term still used but deprecated by standards organizations in engineering as well as in chemistry. Definition Relative permittivity is typically denoted as (som ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Measurement

Measurement is the quantification of attributes of an object or event, which can be used to compare with other objects or events. In other words, measurement is a process of determining how large or small a physical quantity is as compared to a basic reference quantity of the same kind. The scope and application of measurement are dependent on the context and discipline. In natural sciences and engineering, measurements do not apply to nominal properties of objects or events, which is consistent with the guidelines of the International Vocabulary of Metrology (VIM) published by the International Bureau of Weights and Measures (BIPM). However, in other fields such as statistics as well as the social and behavioural sciences, measurements can have multiple levels, which would include nominal, ordinal, interval and ratio scales. Measurement is a cornerstone of trade, science, technology and quantitative research in many disciplines. Historically, many measurement syste ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Deformity

A deformity, dysmorphism, or dysmorphic feature is a major abnormality of an organism that makes a part of the body appear or function differently than how it is supposed to. Causes Deformity can be caused by a variety of factors: *Arthritis and other rheumatoid disorders *Chronic application of external forces, e.g. artificial cranial deformation *Chronic paresis, paralysis or muscle imbalance, especially in children, e.g. due to poliomyelitis or cerebral palsy *Complications at childbirth, birth *Damage to the fetus or uterus *Fractured bones left to heal without being properly Reduction (orthopedic_surgery), set (malunion) *Genetic mutation *Growth or hormone disorders *Skin condition, Skin disorders *Reconstructive surgery following a severe injury, e.g. Third degree burn, burn injury Deformity can occur in all organisms: * Frogs can be mutated due to ''Ribeiroia'' (Trematoda) infection. * Plant, Plants can undergo irreversible Cell (biology), cell deformation * Insect, In ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

Curvature

In mathematics, curvature is any of several strongly related concepts in geometry that intuitively measure the amount by which a curve deviates from being a straight line or by which a surface deviates from being a plane. If a curve or surface is contained in a larger space, curvature can be defined ''extrinsically'' relative to the ambient space. Curvature of Riemannian manifolds of dimension at least two can be defined ''intrinsically'' without reference to a larger space. For curves, the canonical example is that of a circle, which has a curvature equal to the reciprocal of its radius. Smaller circles bend more sharply, and hence have higher curvature. The curvature ''at a point'' of a differentiable curve is the curvature of its osculating circle — that is, the circle that best approximates the curve near this point. The curvature of a straight line is zero. In contrast to the tangent, which is a vector quantity, the curvature at a point is typically a scalar q ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

|

|

Orthogonal

In mathematics, orthogonality (mathematics), orthogonality is the generalization of the geometric notion of ''perpendicularity''. Although many authors use the two terms ''perpendicular'' and ''orthogonal'' interchangeably, the term ''perpendicular'' is more specifically used for lines and planes that intersect to form a right angle, whereas ''orthogonal'' is used in generalizations, such as ''orthogonal vectors'' or ''orthogonal curves''. ''Orthogonality'' is also used with various meanings that are often weakly related or not related at all with the mathematical meanings. Etymology The word comes from the Ancient Greek ('), meaning "upright", and ('), meaning "angle". The Ancient Greek (') and Classical Latin ' originally denoted a rectangle. Later, they came to mean a right triangle. In the 12th century, the post-classical Latin word ''orthogonalis'' came to mean a right angle or something related to a right angle. Mathematics Physics Optics In optics, polarization ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |