|

Bedford M Series

{{Infobox automobile , image = 1948 Bedford MSD (LSU 544) dropside, 2012 HCVS Tyne-Tees Run.jpg , name = Bedford M-Series , manufacturer = Bedford , aka = {{ubl , , production = 1939-1953 , predecessor = Bedford WL , class = Medium-Duty truck , platform = , related = , body_style = 2-door truck , engine = {{convert, 214, cuin, L, 1, abbr=on OHV 6-cylinder , successor = Bedford TA , width = , layout = FR layout The Bedford M series is a line of commercial vehicle chassis, the first variants of which were made in 1939 by Bedford. It is a normal control 4-wheel chassis designed to carry loads of 2-3 tons. There were two wheelbase lengths offered – 10' 0" or 11' 11" – and each was fitted with the standard 6-cylinder 76 bhp petrol engine. A 4-speed gearbox with single dry plate clutch delivered power to a floating rear axle with spiral bevel final drive. Brakes were Lockheed hydraulic type and Clayton Dewandre vacuum assisted operating on all four ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Clutch

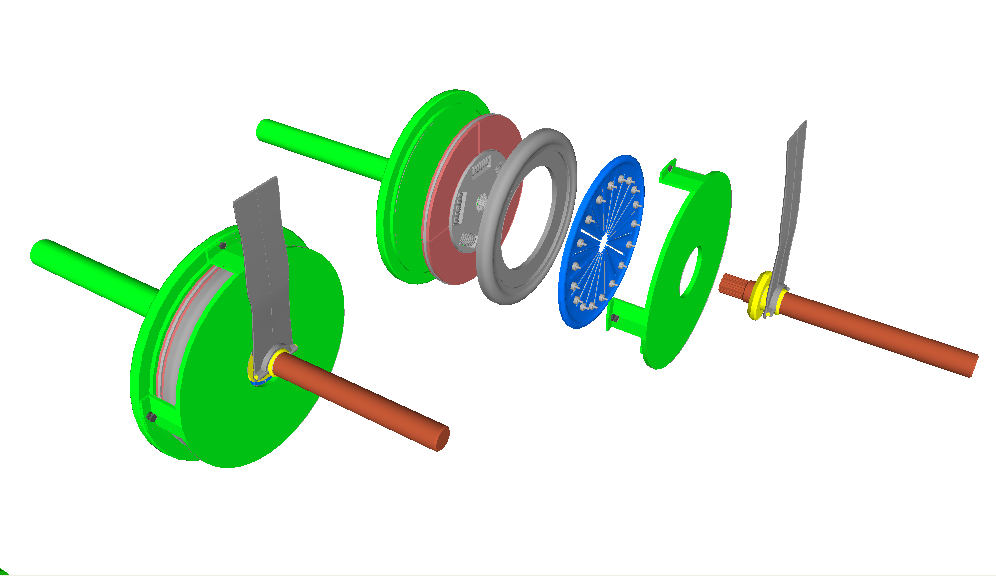

A clutch is a mechanical device that allows an output shaft to be disconnected from a rotating input shaft. The clutch's input shaft is typically attached to a motor, while the clutch's output shaft is connected to the mechanism that does the work. In a motor vehicle, the clutch acts as a mechanical linkage between the engine and transmission. By disengaging the clutch, the engine speed (RPM) is no longer determined by the speed of the driven wheels. Another example of clutch usage is in electric drills. The clutch's input shaft is driven by a motor and the output shaft is connected to the drill bit (via several intermediate components). The clutch allows the drill bit to either spin at the same speed as the motor (clutch engaged), spin at a lower speed than the motor (clutch slipping) or remain stationary while the motor is spinning (clutch disengaged). Types Dry clutch A ''dry clutch'' uses dry friction to transfer power from the input shaft to the output shaft, f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Karrier

Karrier was a British marque of motorised municipal appliances and light commercial vehicles and trolley buses manufactured at Karrier Works, Huddersfield, West Yorkshire, by Clayton and Co. (Huddersfield) Limited. They began making Karrier motor vehicles in 1908 in Queen Street South, Huddersfield. In 1920, H.F. Clayton sold Clayton and Co's Huddersfield business into public listed company Karrier Motors while keeping their Penistone operation separate. Mechanical and electrical engineers Clayton & Co Penistone, remain active in 2020 as Clayton Penistone Group. Karrier produced buses as well as their other municipal vehicles and in latter years, especially during the Second World War, Trolleybuses, notably their Karrier 'W' model. In 1934 Karrier became part of the Rootes Group where it retained its brand identity though the business was operated as part of Rootes's Commer commercial vehicle operation. The Karrier name began to disappear from products when Chrysler bought Roote ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Austin Motors

The Austin Motor Company Limited was a British manufacturer of motor vehicles, founded in 1905 by Herbert Austin in Longbridge. In 1952 it was merged with Morris Motors Limited in the new holding company British Motor Corporation (BMC) Limited, keeping its separate identity. The marque Austin was used until 1987 by BMC's successors British Leyland and Rover Group. The trademark is currently owned by the Chinese firm SAIC Motor, after being transferred from bankrupt subsidiary Nanjing Automotive which had acquired it with MG Rover Group in July 2005. History 1905–1918: Formation and development While running the original Wolseley business, which had a highly cyclical sales pattern, Herbert Austin searched for products with a steady demand. Starting in 1895, he built three cars in his free time. They were among Britain's first cars. The third car, a four-wheeler, was completed in 1899. By 1901, his fellow directors could not see future profit in motor vehicles and so ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plaxton

Plaxton is an English builder of bus and coach vehicle bodies based in Eastfield, North Yorkshire, England. Founded in 1907 by Frederick William Plaxton, it became a subsidiary of Alexander Dennis in May 2007. In 2019, the maker was acquired by Canadian bus manufacturer New Flyer which then became NFI Group. History Beginnings The business was founded as a joinery workshop, and expanded into building contracting. As a building contractor, Plaxtons built a number of notable buildings in Scarborough. Soon after World War I Plaxtons diversified and began to build charabanc bodies on Ford Model T chassis. Of more importance at the time was the construction of automobile bodywork. This included bodywork for Rolls-Royce, Sunbeam and Daimler, but principally for Crossley car chassis. This activity continued through the 1920s, but the depression of 1929–1933 created difficulties for manufacture of luxury automobiles. As a result, the manufacture of charabanc, and later coach ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bedford CA

The Bedford CA was a distinctive pug-nosed light commercial vehicle produced between 1952 and 1969 by Bedford Vehicles, Bedford in Luton, England. It was manufactured in short-wheelbase and long-wheelbase forms, each form available in either a 10–12 hundredweight, cwt or a 15 cwt version. Generally it was supplied as a light delivery van with sliding doors, but it was also available as a chassis with cowl upon which specialist bodywork could be added. The Bedford Dormobile was a Campervan, Campervan conversion based on the Bedford CA van. The CA was also exported to Canada and sold as the Envoy CA, as part of the Envoy (automobile), Envoy brand line-up. In its 17 year production run 370,000 were manufactured.Delivery van is bigger than its predecessor ''Freight & Container Transportation'' September 1970 page 35 Dimensions Body The overall profile and architecture of the CA changed little during the vehicle's seventeen-year life. There were, however, three ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vacuum Servo

A vacuum servo is a component used on motor vehicles in their brake, braking system, to provide assistance to the driver by decreasing the braking effort. In the US it is commonly called a brake booster. A vacuum servo, also known as a power booster or power brake unit, uses a vacuum, usually supplied by the engine, to multiply the driver's pedal effort and apply that effort to the master cylinder. Because the servo depends on the vacuum supplied by a running engine, a check valve is typically used in the vacuum line to maintain residual vacuum without engine support, allowing limited use even after parking. See also *List of auto parts Notes External links What is a brake booster? (a 4-page basic tutorial article, with illustrations & animation) at HowStuffWorks.com Brakes {{Automotive-part-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Brake

A hydraulic brake is an arrangement of braking mechanism which uses brake fluid, typically containing glycol ethers or diethylene glycol, to transfer pressure from the controlling mechanism to the braking mechanism. History During 1904, Frederick George Heath, Redditch, England devised and fitted a hydraulic (water/glycerine) brake system to a cycle using a handlebar lever and piston. He obtained patent GB190403651A for “Improvements in hydraulic actuated brakes for cycles and motors”, as well as subsequently for improved flexible rubber hydraulic pipes. In 1908, Ernest Walter Weight of Bristol, England devised and fitted a four-wheel hydraulic (oil) braking system to a motor car. He patented it in Great Britain (GB190800241A) in December 1908, later in Europe and the USA and then exhibited it at the 1909 London Motor Show. His brother, William Herbert Weight improved the patent (GB190921122A) and both were assigned to the Weight Patent Automobile Brake Ltd. of 23 Bridge Stre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Final Drive

A drivetrain (also frequently spelled as drive train or sometimes drive-train) or transmission system, is the group of components that deliver mechanical power from the prime mover to the driven components. In automotive engineering, the drivetrain is the components of a motor vehicle that deliver power to the drive wheels. This excludes the engine or motor that generates the power. In marine applications, the drive shaft will drive a propeller, thruster, or waterjet rather than a drive axle, while the actual engine might be similar to an automotive engine. Other machinery, equipment and vehicles may also use a drivetrain to deliver power from the engine(s) to the driven components. In contrast, the powertrain is considered to include both the engine and/or motor(s) as well as the drivetrain. Function The function of the drivetrain is to couple the engine that produces the power to the driving wheels that use this mechanical power to rotate the axle. This connection involve ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spiral Bevel Gear

A spiral bevel gear is a bevel gear with helical teeth. The main application of this is in a vehicle differential, where the direction of drive from the drive shaft must be turned 90 degrees to drive the wheels. The helical design produces less vibration and noise than conventional straight-cut or spur-cut gear with straight teeth. A spiral bevel gear set should always be replaced in pairs i.e. both the left hand and right hand gears should be replaced together since the gears are manufactured and lapped in pairs. Handedness A right hand spiral bevel gear is one in which the outer half of a tooth is inclined in the clockwise direction from the axial plane through the midpoint of the tooth as viewed by an observer looking at the face of the gear. A left hand spiral bevel gear is one in which the outer half of a tooth is inclined in the counterclockwise direction from the axial plane through the midpoint of the tooth as viewed by an observer looking at the face of the gear. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Axle

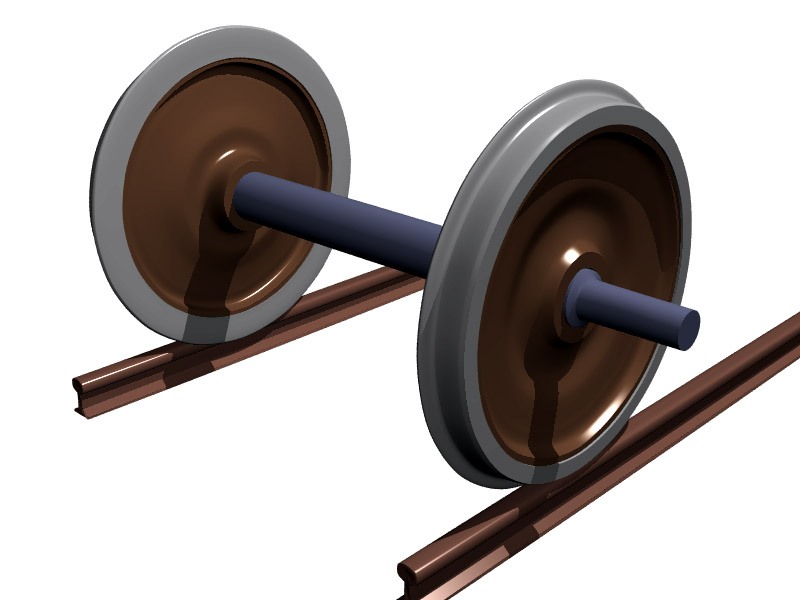

An axle or axletree is a central shaft for a rotation, rotating wheel and axle, wheel or gear. On wheeled vehicles, the axle may be fixed to the wheels, rotating with them, or fixed to the vehicle, with the wheels rotating around the axle. In the former case, bearing (mechanical), bearings or Bushing (bearing), bushings are provided at the mounting points where the axle is supported. In the latter case, a bearing or bushing sits inside a central hole in the wheel to allow the wheel or gear to rotate around the axle. Sometimes, especially on bicycles, the latter type of axle is referred to as a ''spindle (tool), spindle''. Terminology On cars and trucks, several senses of the word ''axle'' occur in casual usage, referring to the shaft itself, its housing, or simply any transverse pair of wheels. Strictly speaking, a shaft that rotates with the wheel, being either Bolt (fastener), bolted or rotating spline, splined in fixed relation to it, is called an ''axle'' or ''axle shaft ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gearbox

A transmission (also called a gearbox) is a mechanical device invented by Louis Renault (who founded Renault) which uses a gear set—two or more gears working together—to change the speed, direction of rotation, or torque multiplication/reduction in a machine. Transmissions can have a single fixed-gear ratio, multiple distinct gear ratios, or continuously variable ratios. Variable-ratio transmissions are used in all sorts of machinery, especially vehicles. Applications Early uses Early transmissions included the right-angle drives and other gearing in windmills, horse-powered devices, and steam-powered devices. Applications of these devices included pumps, mills and hoists. Bicycles Bicycles traditionally have used hub gear or Derailleur gear transmissions, but there are other more recent design innovations. Automobiles Since the torque and power output of an internal combustion engine (ICE) varies with its rpm, automobiles powered by ICEs require multiple ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |