|

Barré (fabric)

Barré is an unintentional repetitive horizontal pattern in fabrics that is generally undesirable and considered as a defect. It appears as a lateral stripe pattern. Barré occurs for many reasons associated with the manufacturing of textile ensembles like fiber, yarn, fabric manufacturing, weaving or knitting, or finishing faults. Reasons Barre or barrenness is a repetitious pattern in the course direction in knitted fabrics, It may involve color differences in the yarn and geometrical variations in fabric manufacturing forming the barre patterns. In knits the variation of stitch length can also cause the barre. Improper mixing of fibers can also be a reason for the barre. In blends like polyester and cotton, the reason may be dyeing also. See also * Fabric inspection Fabric inspection, also known as fabric checking, is a systematic fabric evaluation in which defects are identified. Fabric inspection helps understand quality in terms of color, density, weight, pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fabric

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the only manufacturing method, and many other methods were later developed to form textile structures based on their intended use. Knitting and non-woven are other popular types of fabric manufacturing. In the contemporary world, textiles satisfy the material needs for versatile applications, from simple daily clothing to bulletproof jackets, spacesuits, and doctor's gowns. Textiles are divided into two groups: Domestic purposes onsumer textilesand technical textiles. In consumer textiles, aesthetics and comfort are the most important factors, but in technical textiles, functional properties are the priority. Geotextiles, industrial textiles, medical textiles, and many other areas are examples of technical textiles, whereas clothing an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stripe (pattern)

A stripe is a line or band that differs in color or tone from an adjacent area. Stripes are a group of such lines. Usage and appearance As a pattern (more than one stripe together), stripes are commonly seen in nature, food, emblems, clothing, and elsewhere. Two-toned stripes inherently draw one's attention, and as such are used to signal hazards. They are used in road signs, barricade tape, and thresholds. In nature, as with the zebra, stripes may have developed through natural selection to produce motion dazzle. Stripes may give appeal to certain sweets like the candy cane. For hundreds of years, stripes have been used in clothing. Striped clothing has frequently had negative symbolism in Western cultures. Historian Michel Pastoureau explores the cultural history of these design decisions in the book, ''The Devil's Cloth.'' See also * Square tiling * Sussi cloth *The Devil's Cloth * Argyle (pattern) * Racing flags * Flannel * Gingham * Madras (cloth) * Plaid ( ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

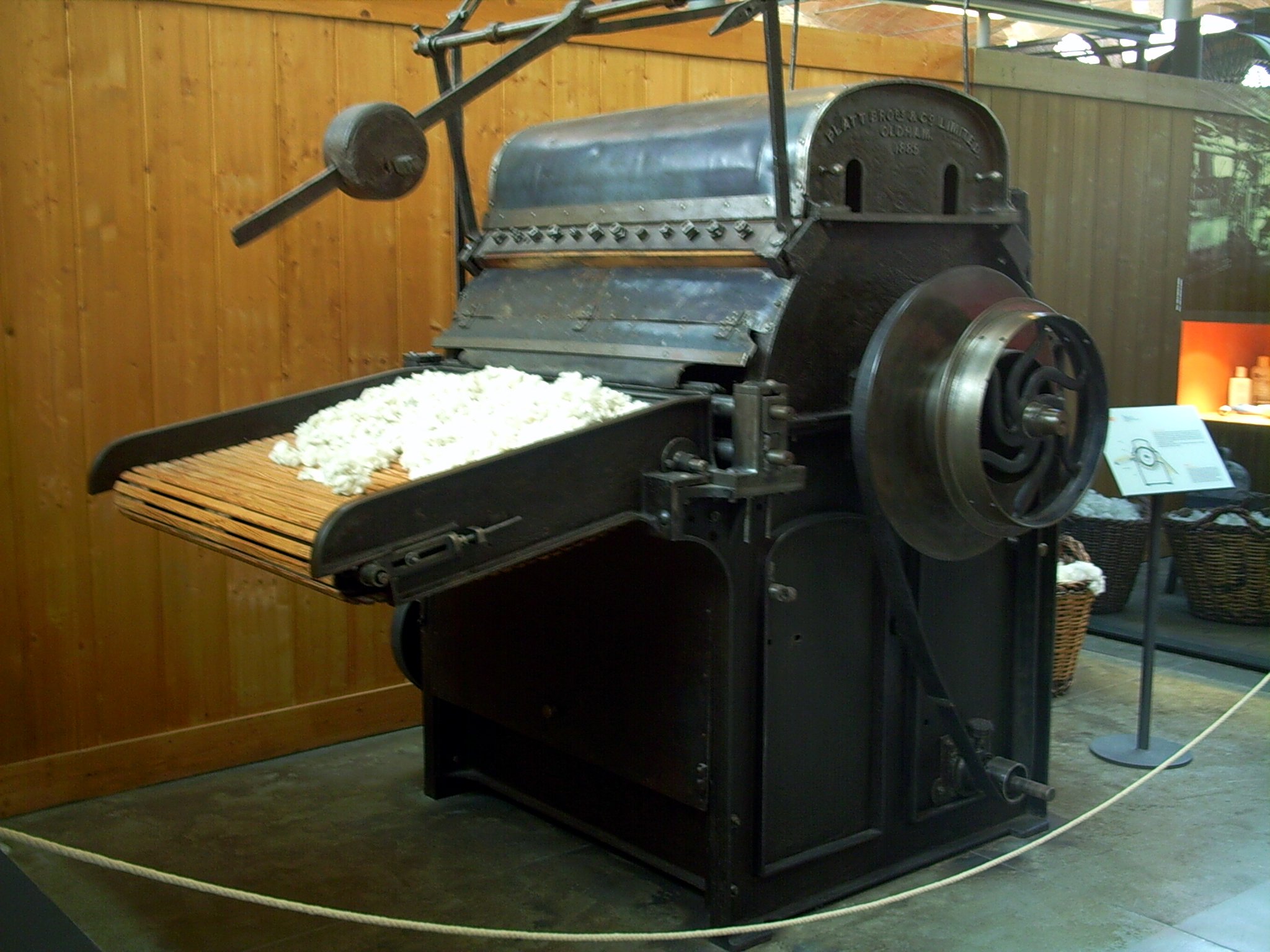

Textile Manufacturing

Textile Manufacturing or Textile Engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products. Different types of fibres are used to produce yarn. Cotton remains the most widely used and common natural fiber making up 90% of all-natural fibers used in the textile industry. People often use cotton clothing and accessories because of comfort, not limited to different weathers. There are many variable processes available at the spinning and fabric-forming stages coupled with the complexities of the finishing and colouration processes to the production of a wide range of products. History Textile manufacturing in the modern era is an evolved form of the art and craft industries. Until the 18th and 19th centuries, the textile industry was a household ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fiber

Fiber or fibre (from la, fibra, links=no) is a natural or artificial substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The strongest engineering materials often incorporate fibers, for example carbon fiber and ultra-high-molecular-weight polyethylene. Synthetic fibers can often be produced very cheaply and in large amounts compared to natural fibers, but for clothing natural fibers can give some benefits, such as comfort, over their synthetic counterparts. Natural fibers Natural fibers develop or occur in the fiber shape, and include those produced by plants, animals, and geological processes. They can be classified according to their origin: * Vegetable fibers are generally based on arrangements of cellulose, often with lignin: examples include cotton, hemp, jute, flax, abaca, piña, ramie, sisal, bagasse, and banana. Plant fibers are employed in the manufacture of paper and textile (cloth ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yarn

Yarn is a long continuous length of interlocked fibres, used in sewing, crocheting, knitting, weaving, embroidery, ropemaking, and the production of textiles. Thread is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or other lubricants to withstand the stresses involved in sewing. Embroidery threads are yarns specifically designed for needlework. Yarn can be made of a number of natural or synthetic materials, and comes in a variety of colors and thicknesses (referred to as "weights"). Although yarn may be dyed different colours, most yarns are solid coloured with a uniform hue. Etymology The word yarn comes from Middle English, from the Old English ''gearn'', akin to Old High German ''garn'', "yarn," Dutch "garen," Italian ''chordē'', "string," and Sanskrit ''hira'', "band." History The human production of yarn is known to have existed since the Stone Age and earlier prehistory, with ancient ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Weaving

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft, woof, or filling. (''Weft'' is an Old English word meaning "that which is woven"; compare ''leave'' and ''left''.) The method in which these threads are interwoven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds the warp threads in place while filling threads are woven through them. A fabric band that meets this definition of cloth (warp threads with a weft thread winding between) can also be made using other methods, including tablet weaving, back strap loom, or other techniques that can be done without looms. The way the warp and filling threads interlace with each other is called the weave. The majority of woven pro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Knitting

Knitting is a method by which yarn is manipulated to create a textile, or fabric. It is used to create many types of garments. Knitting may be done by hand or by machine. Knitting creates stitches: loops of yarn in a row, either flat or in ''the round'' (tubular). There are usually many ''active stitches'' on the knitting needle at one time. Knitted fabric consists of a number of consecutive rows of connected loops that intermesh with the next and previous rows. As each row is formed, each newly created loop is pulled through one or more loops from the prior row and placed on the ''gaining needle so'' that the loops from the prior row can be pulled off the other needle without unraveling. Differences in yarn (varying in fibre type, ''weight'', uniformity and ''twist''), needle size, and stitch type allow for a variety of knitted fabrics with different properties, including color, texture, thickness, heat retention, water resistance, and integrity. A small sample of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Finishing (textiles)

In textile manufacturing, finishing refers to the processes that convert the woven or knitted cloth into a usable material and more specifically to any process performed after dyeing the yarn or textile, fabric to improve the look, performance, or "hand" (feel) of the finish textile or clothing. The precise meaning depends on context. Textile, Fabric after leaving the loom or knitting machine is not readily useable. Called Greige goods, grey cloth at this stage, it contains natural and added impurities. Sometimes it is also Wet processing engineering, processed at fiber or yarn stages of textile manufacturing. Grey fiber or yarn or fabric goes through a series of processes such as wet processing and finishing. Finishing is a broad range of physical and chemical treatments that complete one stage of textile manufacturing and may prepare for the next step, making the product more receptive to the next stage of manufacturing. Finishing adds value to the product and makes it more a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Knitted Fabric

Knitted fabric is a textile that results from knitting, the process of inter-looping of yarns or inter-meshing of loops. Its properties are distinct from woven fabric in that it is more flexible and can be more readily constructed into smaller pieces, making it ideal for socks and hats. Weft-knit and warp-knit fabric There are two basic varieties of knit fabric: weft-knit and warp-knit fabric. Warp-knitted fabrics such as tricot and milanese are resistant to runs, and are commonly used in lingerie. Weft-knit fabrics are easier to make and more common. When cut, they will unravel (run) unless repaired. Warp-knit fabrics are resistant to runs and relatively easy to sew. Raschel lace—the most common type of machine made lace—is a warp knit fabric but using many more guide-bars (12+) than the usual machines which mostly have three or four bars. (14+) Structure of knitted fabrics Courses and wales In weaving, threads are always straight, running parallel either leng ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

List Of Knitting Stitches

This is a list of knitting stitches. Common knitting abbreviations as used in patterns are shown in parentheses. Individual stitches * Knit stitch (k) * Purl stitch (p) Variations * Elongated stitch * Plaited stitch, also known as a twisted stitch (k tbl, p tbl) * Slip stitch, may be knit or purl stitch (sl, sl st) Increases * Yarn over (yo) * Dip stitch which can be either ** A raised increase, knitting into row below (k-b, k 1 b) ** A lifted increase, knitting into the yarn between the stitches (inc, m1) * Knit front and back (kfb) * Purl front and back (, pass slipped stitch over (S1, K1, PSSO) for a left-leaning decrease. * Knit two together through the back loops (K2tog tbl) for a left-leaning decrease. Stitch patterns Knit and purl Basic * Garter stitch * Stockinette stitch, also known as stocking stitch * Reverse stockinette stitch Variations * Basket stitch * Seed stitch, also known as moss stitch * Waffle stitch Rib * English rib (or mistake rib or un ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dyeing

Dyeing is the application of dyes or pigments on textile materials such as fibers, yarns, and fabrics with the goal of achieving color with desired color fastness. Dyeing is normally done in a special solution containing dyes and particular chemical material. Dye molecules are fixed to the fiber by absorption, diffusion, or bonding with temperature and time being key controlling factors. The bond between dye molecule and fiber may be strong or weak, depending on the dye used. Dyeing and printing are different applications; in printing, color is applied to a localized area with desired patterns. In dyeing, it is applied to the entire textile. The primary source of dye, historically, has been nature, with the dyes being extracted from animals or plants. Since the mid-19th century, however, humans have produced artificial dyes to achieve a broader range of colors and to render the dyes more stable to washing and general use. Different classes of dyes are used for different t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fabric Inspection

Fabric inspection, also known as fabric checking, is a systematic fabric evaluation in which defects are identified. Fabric inspection helps understand quality in terms of color, density, weight, printing, measurement, and other quality criteria prior to garment production. Fabric inspection takes place at various stages of manufacturing, including intermediate and final. "Perching" was another term for fabric inspection. Procedure Quality control in textiles is to inspect whether a manufactured material meets the specifications set by the buyers. It is a broader aspect that includes the quality of the final product and the encompassing materials, for example, yarn and fabric. Fabric quality addresses fabric-related issues. Fabric inspection is a step of visual examination apart from the performance criteria; It finds various flaws and irregularities. Accordingly, it grades the fabrics as per quality level, fabric weight, shading color, number, and size of the defects. In additio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)