|

Aspin Valve

An Aspin valve consists of a cone-shaped metal part fitted to the cylinder head in internal combustion. Aspin valves were first patented by Frank Metcalf Aspin in 1939, although the idea was devised before this time. The valve rotates to provide the opening and closing necessary for intake and exhaust. It is attached to the engine, vertical to the cylinder block, via a shaft at its top; this allows the valve to rotate horizontally above the cylinder and when it turns. The valve is hollow, and has a large cut-out opening in one side. This alternately allows gases into the combustion chamber A combustion chamber is part of an internal combustion engine in which the fuel/air mix is burned. For steam engines, the term has also been used for an extension of the firebox which is used to allow a more complete combustion process. Intern ..., and out to the exhaust system by lining up holes in the valve shaft with the cylinder-head ports which allows the gases to pass. References ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

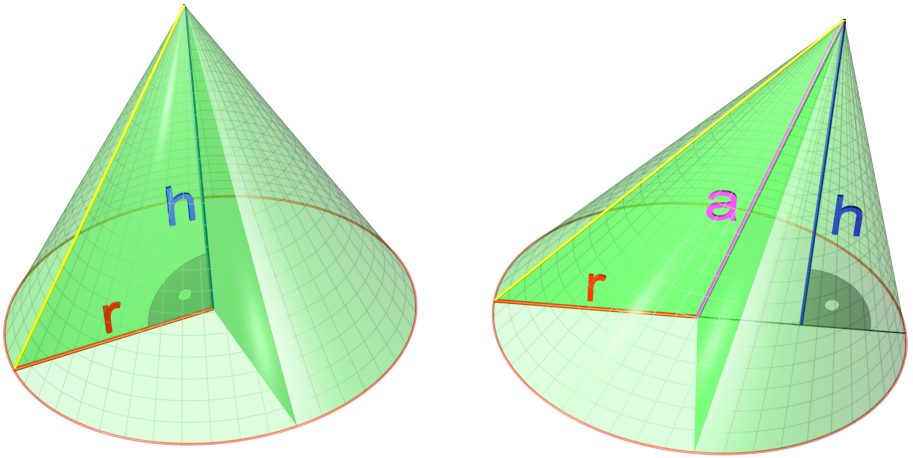

Cone (geometry)

A cone is a three-dimensional geometric shape that tapers smoothly from a flat base (frequently, though not necessarily, circular) to a point called the apex or vertex. A cone is formed by a set of line segments, half-lines, or lines connecting a common point, the apex, to all of the points on a base that is in a plane that does not contain the apex. Depending on the author, the base may be restricted to be a circle, any one-dimensional quadratic form in the plane, any closed one-dimensional figure, or any of the above plus all the enclosed points. If the enclosed points are included in the base, the cone is a solid object; otherwise it is a two-dimensional object in three-dimensional space. In the case of a solid object, the boundary formed by these lines or partial lines is called the ''lateral surface''; if the lateral surface is unbounded, it is a conical surface. In the case of line segments, the cone does not extend beyond the base, while in the case of hal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Head

In an internal combustion engine, the cylinder head (often abbreviated to simply "head") sits above the cylinder (engine), cylinders and forms the roof of the combustion chamber. In sidevalve engines, the head is a simple sheet of metal; whereas in more modern overhead valve engine, overhead valve and overhead camshaft engine, overhead camshaft engines, the cylinder head is a more complicated block often containing inlet and exhaust passages, coolant passages, Poppet_valve#Usage_in_internal_combustion_engines, valves, camshafts, spark plugs and Fuel_injection#Direct_injection, fuel injectors. Most straight engines have a single cylinder head shared by all of the cylinders and most V engines have two cylinder heads (one per bank of cylinders). Design A summary of engine designs is shown below, in chronological order for automobile usage. Sidevalve engines In a flathead engine, flathead (''sidevalve'') engine, all of the valvetrain components are cam-in-block, contained wi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Combustion

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons ( piston engine), turbine blades ( gas turbine), a rotor (Wankel engine), or a nozzle (jet engine). This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. This replaced the external combustion engine for applications where the weight or size of an engine was more important. The first commercially successful internal combustion engine was created by Étienne Lenoir around 1860, and the first modern internal combustion engine, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Intake

An intake (also inlet) is an opening, structure or system through which a fluid is admitted to a space or machine as a consequence of a pressure differential between the outside and the inside. The pressure difference may be generated on the inside by a mechanism, or on the outside by ram pressure or hydrostatic pressure. Flow rate through the intake depends on pressure difference, fluid properties, and intake geometry. Intake refers to an opening, or area, together with its defining edge profile which has an associated entry loss, that captures pipe flow from a reservoir or storage tank. Intake refers to the capture area definition and attached ducting to an aircraft gas turbine engine or ramjet engine and, as such, an intake is followed by a compressor or combustion chamber. It may instead be referred to as a diffuser. For an automobile engine the components through which the air flows to the engine cylinders, are collectively known as an intake system and may include the i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exhaust Gas

Exhaust gas or flue gas is emitted as a result of the combustion of fuels such as natural gas, gasoline (petrol), diesel fuel, fuel oil, biodiesel blends, or coal. According to the type of engine, it is discharged into the atmosphere through an exhaust pipe, flue gas stack, or propelling nozzle. It often disperses downwind in a pattern called an ''exhaust plume''. It is a major component of motor vehicle emissions (and from stationary internal combustion engines), which can also include crankcase blow-by and evaporation of unused gasoline. Motor vehicle emissions contribute to air pollution and are a major ingredient in the creation of smog in some large cities. A 2013 study by the Massachusetts Institute of Technology (MIT) indicates that 53,000 early deaths occur per year in the United States alone because of vehicle emissions. According to another study from the same university, traffic fumes alone cause the death of 5,000 people every year just in the United Kingdom. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

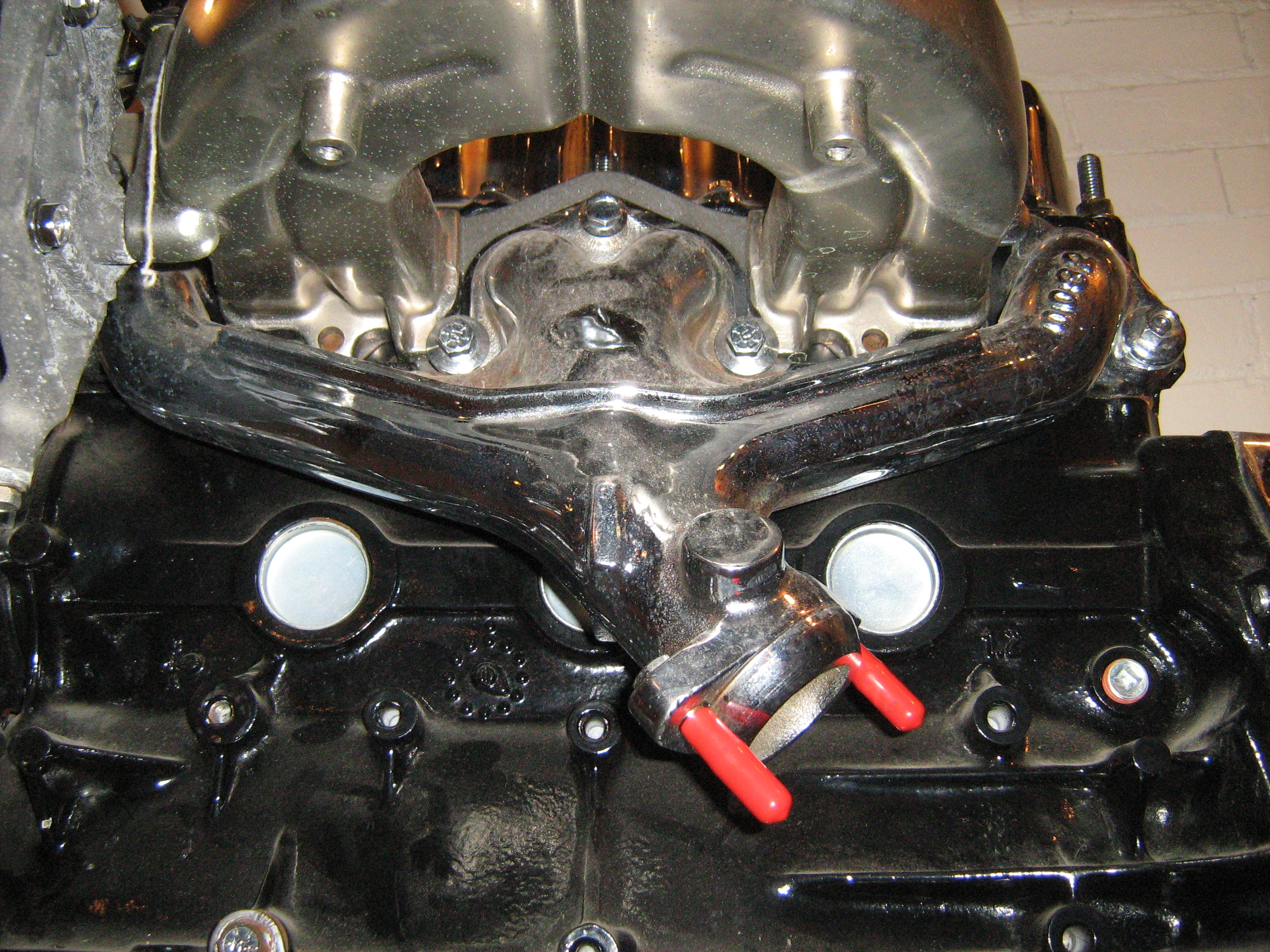

Cylinder Block

In an internal combustion engine, the engine block is the structure which contains the cylinders and other components. In an early automotive engine, the engine block consisted of just the cylinder block, to which a separate crankcase was attached. Modern engine blocks typically have the crankcase integrated with the cylinder block as a single component. Engine blocks often also include elements such as coolant passages and oil galleries. The term "cylinder block" is often used interchangeably with "engine block", although technically, the block of a modern engine (i.e. multiple cylinders integrated with another component) would be classified as a monobloc. __TOC__ Construction The main structure of an engine typically consists of the cylinders, coolant passages, oil galleries, crankcase, and cylinder head(s). The first production engines of the 1880s to 1920s usually used separate components for each of these elements, which were bolted together during engine assembly ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

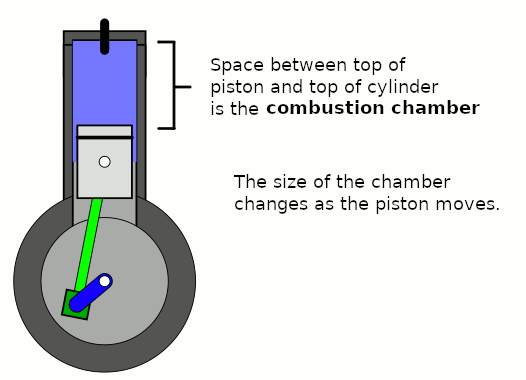

Combustion Chamber

A combustion chamber is part of an internal combustion engine in which the fuel/air mix is burned. For steam engines, the term has also been used for an extension of the firebox which is used to allow a more complete combustion process. Internal combustion engines In an internal combustion engine, the pressure caused by the burning air/fuel mixture applies direct force to part of the engine (e.g. for a piston engine, the force is applied to the top of the piston), which converts the gas pressure into mechanical energy (often in the form of a rotating output shaft). This contrasts an external combustion engine, where the combustion takes place in a separate part of the engine to where the gas pressure is converted into mechanical energy. Spark-ignition engines In spark ignition engines, such as petrol (gasoline) engines, the combustion chamber is usually located in the cylinder head. The engines are often designed such that the bottom of combustion chamber is roughly in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exhaust System

An exhaust system is used to guide reaction exhaust gases away from a controlled combustion inside an engine or stove. The entire system conveys burnt gases from the engine and includes one or more exhaust pipes. Depending on the overall system design, the exhaust gas may flow through one or more of: *Cylinder head and exhaust manifold *A turbocharger to increase engine power. *A catalytic converter to reduce air pollution. *A muffler (North America) / silencer (UK/India), to reduce noise. Design criteria An exhaust pipe must be carefully designed to carry toxic and/or noxious gases away from the users of the machine. Indoor generators and furnaces can quickly fill an enclosed space with poisonous exhaust gases such as hydrocarbons, carbon monoxide and nitrogen oxides, if they are not properly vented to the outdoors. Also, the gases from most types of machines are very hot; the pipe must be heat-resistant, and it must not pass through or near anything that can burn or can ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |