|

Annular Piston Valve

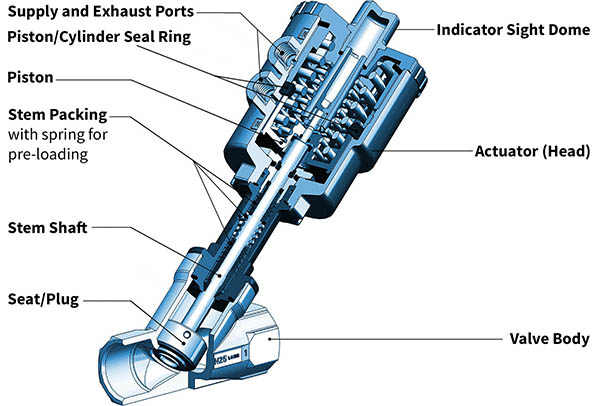

{{Unreferenced, date=June 2019, bot=noref (GreenC bot) An angle seat piston valve is a pneumatically-controlled valve with a piston actuator providing linear actuation to lift a seal off its seat. The seat is set at an angle to provide the maximum possible flow when unseated. Angle seat piston valves are particularly suited to applications where high temperatures and large flow rates are required, such as steam or water. When used in reverse some models of angle seat piston valve will eliminate water hammer when operated. Operation Pneumatic valves are operated by a pilot medium under pressure, usually compressed air but also oil or water. The valve is equipped with a pneumatic actuator supplied by a three-way solenoid valve. The pressure of the pilot medium enters the actuator cylinder and acts on the piston, which allows the seal to open or to close through the stem. The return of the seal into its rest position is usually achieved by a return spring that can be found in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Angle Valve Cross Section

In Euclidean geometry, an angle is the figure formed by two rays, called the '' sides'' of the angle, sharing a common endpoint, called the ''vertex'' of the angle. Angles formed by two rays lie in the plane that contains the rays. Angles are also formed by the intersection of two planes. These are called dihedral angles. Two intersecting curves may also define an angle, which is the angle of the rays lying tangent to the respective curves at their point of intersection. ''Angle'' is also used to designate the measure of an angle or of a rotation. This measure is the ratio of the length of a circular arc to its radius. In the case of a geometric angle, the arc is centered at the vertex and delimited by the sides. In the case of a rotation, the arc is centered at the center of the rotation and delimited by any other point and its image by the rotation. History and etymology The word ''angle'' comes from the Latin word ''angulus'', meaning "corner"; cognate words are the Gree ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pneumatics

Pneumatics (from Greek ‘wind, breath’) is a branch of engineering that makes use of gas or pressurized air. Pneumatic systems used in industry are commonly powered by compressed air or compressed inert gases. A centrally located and electrically-powered compressor powers cylinders, air motors, pneumatic actuators, and other pneumatic devices. A pneumatic system controlled through manual or automatic solenoid valves is selected when it provides a lower cost, more flexible, or safer alternative to electric motors, and hydraulic actuators. Pneumatics also has applications in dentistry, construction, mining, and other areas. Gases used in pneumatic systems Pneumatic systems in fixed installations, such as factories, use compressed air because a sustainable supply can be made by compressing atmospheric air. The air usually has moisture removed, and a small quantity of oil is added at the compressor to prevent corrosion and lubricate mechanical components. Facto ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valve

A valve is a device or natural object that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or slurries) by opening, closing, or partially obstructing various passageways. Valves are technically fittings, but are usually discussed as a separate category. In an open valve, fluid flows in a direction from higher pressure to lower pressure. The word is derived from the Latin ''valva'', the moving part of a door, in turn from ''volvere'', to turn, roll. The simplest, and very ancient, valve is simply a freely hinged flap which swings down to obstruct fluid (gas or liquid) flow in one direction, but is pushed up by the flow itself when the flow is moving in the opposite direction. This is called a check valve, as it prevents or "checks" the flow in one direction. Modern control valves may regulate pressure or flow downstream and operate on sophisticated automation systems. Valves have many uses, including controlling water for irrigation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pneumatic Actuator

A pneumatic control valve actuator converts energy (typically in the form of compressed air) into mechanical motion. The motion can be rotary or linear, depending on the type of actuator. Principle of operation A Pneumatic actuator mainly consists of a piston or a diaphragm which develops the motive power. It keeps the air in the upper portion of the cylinder, allowing air pressure to force the diaphragm or piston to move the valve stem or rotate the valve control element. Valves require little pressure to operate and usually double or ''triple'' the input force. The larger the size of the piston, the larger the output pressure can be. Having a larger piston can also be good if the air supply is low, allowing the same forces with less input. These pressures are large enough to crush objects in the pipe. On 100 kPa input, you could lift a small car (upwards of 1,000 lbs) easily, and this is only a basic, small pneumatic valve. However, the resulting forces required ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Water Hammer

Hydraulic shock (colloquial: water hammer; fluid hammer) is a pressure surge or wave caused when a fluid in motion, usually a liquid but sometimes also a gas is forced to stop or change direction suddenly; a momentum change. This phenomenon commonly occurs when a valve closes suddenly at an end of a pipeline system, and a pressure wave propagates in the pipe. This pressure wave can cause major problems, from noise and vibration to pipe rupture or collapse. It is possible to reduce the effects of the water hammer pulses with accumulators, expansion tanks, surge tanks, blowoff valves, and other features. The effects can be avoided by ensuring that no valves will close too quickly with significant flow, but there are many situations that can cause the effect. Rough calculations can be made using the Zhukovsky (Joukowsky) equation, or more accurate ones using the method of characteristics. History In the 1st century B.C., Marcus Vitruvius Pollio described the effect o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compressed Air

Compressed air is air kept under a pressure that is greater than atmospheric pressure. Compressed air is an important medium for transfer of energy in industrial processes, and is used for power tools such as air hammers, drills, wrenches, and others, as well as to atomize paint, to operate air cylinders for automation, and can also be used to propel vehicles. Brakes applied by compressed air made large railway trains safer and more efficient to operate. Compressed air brakes are also found on large highway vehicles. Compressed air is used as a breathing gas by underwater divers. It may be carried by the diver in a high pressure diving cylinder, or supplied from the surface at lower pressure through an air line or diver's umbilical. Similar arrangements are used in breathing apparatus used by firefighters, mine rescue workers and industrial workers in hazardous atmospheres. In Europe, 10 percent of all industrial electricity consumption is to produce compressed air� ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pneumatic Actuator

A pneumatic control valve actuator converts energy (typically in the form of compressed air) into mechanical motion. The motion can be rotary or linear, depending on the type of actuator. Principle of operation A Pneumatic actuator mainly consists of a piston or a diaphragm which develops the motive power. It keeps the air in the upper portion of the cylinder, allowing air pressure to force the diaphragm or piston to move the valve stem or rotate the valve control element. Valves require little pressure to operate and usually double or ''triple'' the input force. The larger the size of the piston, the larger the output pressure can be. Having a larger piston can also be good if the air supply is low, allowing the same forces with less input. These pressures are large enough to crush objects in the pipe. On 100 kPa input, you could lift a small car (upwards of 1,000 lbs) easily, and this is only a basic, small pneumatic valve. However, the resulting forces required ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solenoid Valve

A solenoid valve is an electromechanically operated valve. Solenoid valves differ in the characteristics of the electric current they use, the strength of the magnetic field they generate, the mechanism they use to regulate the fluid, and the type and characteristics of fluid they control. The mechanism varies from linear action, plunger-type actuators to pivoted-armature actuators and rocker actuators. The valve can use a two-port design to regulate a flow or use a three or more port design to switch flows between ports. Multiple solenoid valves can be placed together on a manifold. Solenoid valves are the most frequently used control elements in fluidics. Their tasks are to shut off, release, dose, distribute or mix fluids. They are found in many application areas. Solenoids offer fast and safe switching, high-reliability, long service life, good medium compatibility of the materials used, low control power and compact design. Operation There are many valve design varia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston Valve

A "piston valve" is a device used to control the motion of a fluid along a tube or pipe by means of the linear motion of a piston within a chamber or cylinder. Examples of piston valves are: * The valves used in many brass instruments * The valves used in pneumatic cannons * The valves used in many stationary steam engines and steam locomotives Brass instruments Cylindrical piston valves called Périnet valves (after their inventor François Périnet) are used to change the length of tube in the playing of most brass instruments, particularly the trumpet-like members of the family ( cornet, flugelhorn, saxhorn, etc.). Other brass instruments use rotary valves, notably the orchestral horns and many tuba The tuba (; ) is the lowest-pitched musical instrument in the brass instrument, brass family. As with all brass instruments, the sound is produced by lip vibrationa buzzinto a mouthpiece (brass), mouthpiece. It first appeared in the mid-19th&n ... models, but also ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |