|

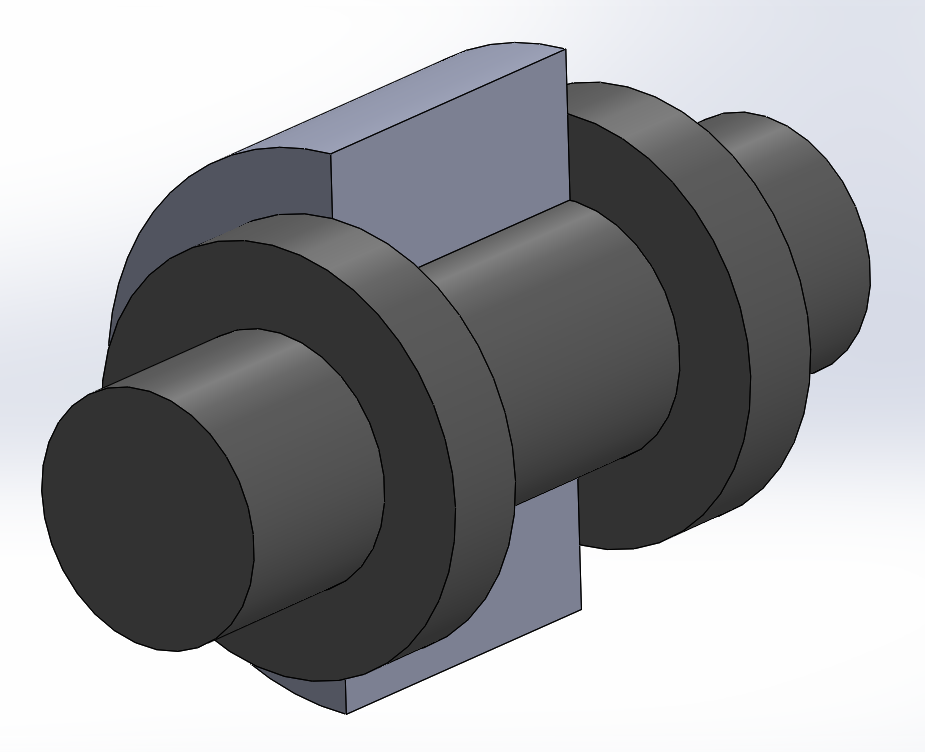

Actuator Setup

An actuator is a component of a machine that produces force, torque, or displacement, when an electrical, pneumatic or hydraulic input is supplied to it in a system (called an actuating system). The effect is usually produced in a controlled way. An actuator translates such an input signal into the required form of mechanical energy. It is a type of transducer. In simple terms, it is a "mover". An actuator requires a control device (which provides control signal) and a source of energy. The control signal is relatively low in energy and may be voltage, electric current, pneumatic, or hydraulic fluid pressure, or even human power. In the electric, hydraulic, and pneumatic sense, it is a form of automation or automatic control. The displacement achieved is commonly linear or rotational, as exemplified by linear motors and rotary motors, respectively. Rotary motion is more natural for small machines making large displacements. By means of a leadscrew, rotary motion can be adapted t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Element

Machine element or hardware refers to an elementary component of a machine. These elements consist of three basic types: # ''Structural element, structural components'' such as frame members, Bearing (mechanical), bearings, axles, Spline (mechanical), splines, fasteners, Seal (mechanical), seals, and lubricants, # ''Mechanism (engineering), mechanisms'' that Motion control, control movement in various ways such as gear trains, belt (mechanical), belt or chain drives, Linkage (mechanical), linkages, Cam (mechanism), cam and cam follower, follower systems, including brakes and clutches, and # ''Control system, control components'' such as buttons, switches, indicators, sensors, actuators and computer controllers. While generally not considered to be a machine element, the shape, texture and color of covers are an important part of a machine that provide a industrial design, styling and operational interface between the mechanical components of a machine and its users. ''Machine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automation

Automation describes a wide range of technologies that reduce human intervention in processes, mainly by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machines. Automation has been achieved by various means including Mechanical system, mechanical, hydraulic, pneumatic, electrical, electronic devices, and computers, usually in combination. Complicated systems, such as modern Factory, factories, airplanes, and ships typically use combinations of all of these techniques. The benefit of automation includes labor savings, reducing waste, savings in electricity costs, savings in material costs, and improvements to quality, accuracy, and precision. Automation includes the use of various equipment and control systems such as machinery, processes in factories, boilers, and heat-treating ovens, switching on telephone networks, steering, Stabilizer (ship), stabilization of ships, aircraft and other applic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grandfather Clock

A grandfather clock (also a longcase clock, tall-case clock, grandfather's clock, hall clock or floor clock) is a tall, freestanding, weight-driven pendulum clock, with the pendulum held inside the tower or waist of the case. Clocks of this style are commonly 1.8–2.4 metres (6–8 feet) tall with an enclosed pendulum and weights, suspended by either cables or chains, which have to be occasionally calibrated to keep the proper time. The case often features elaborately carved ornamentation on the hood (or bonnet), which surrounds and frames the dial, or clock face. The English clockmaker William Clement is credited with developing the form in 1670. Pendulum clocks were the world's most accurate timekeeping technology until the early 20th century. Further, longcase clocks, due to their superior accuracy, served as time standards for households and businesses. Today, they are kept mainly for their decorative and antique value, having been superseded by analog clock, analog and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Combustion Engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons (reciprocating engine, piston engine), turbine blades (gas turbine), a Wankel engine, rotor (Wankel engine), or a propulsive nozzle, nozzle (jet engine). This force moves the component over a distance. This process transforms chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. The first commercially successful internal combustion engines were invented in the mid-19th century. The first modern internal combustion engine, the Otto engine, was designed in 1876 by the German engineer Nicolaus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Camshaft

A camshaft is a shaft that contains a row of pointed cams in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition systems and early electric motor speed controllers. Camshafts in piston engines are usually made from steel or cast iron, and the shape of the cams greatly affects the engine's characteristics. History Trip hammers are one of the early uses of a form of cam to convert rotating motion, e.g. from a waterwheel, into the reciprocating motion of a hammer used in forging or to pound grain. Evidence for these exists back to the Han dynasty in China, and they were widespread by the medieval period. Camshafts were first described by Ismail al-Jazari in 1206. Once the rotative version of the steam engine was developed in the late 18th century, the operation of the valve gear was usually by an eccentric, which turned the rotation of the crankshaft i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanism (engineering)

In engineering, a mechanism is a Machine, device that transforms input forces and movement into a desired set of output forces and movement. Mechanisms generally consist of moving components which may include Gears and gear trains; belt drive, Belts and chain drives; Cam (mechanism), cams and cam follower, followers; Linkage (mechanical), Linkages; Friction devices, such as brakes or clutches; Structural components such as a frame, fasteners, bearings, springs, or lubricants; Various machine elements, such as splines, pins, or keys. German scientist Franz Reuleaux defines ''machine'' as "a combination of resistant bodies so arranged that by their means the mechanical forces of nature can be compelled to do work accompanied by certain determinate motion". In this context, his use of ''machine'' is generally interpreted to mean ''mechanism''. The combination of force and movement defines Power (physics), power, and a mechanism manages power to achieve a desired set of forces and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pneumatic Motor

A pneumatic motor (air motor), or compressed-air engine, is a type of motor which does mechanical work by expanding compressed air. Pneumatic motors generally convert the compressed-air energy to mechanical work through either linear or rotary motion. Linear motion can come from either a diaphragm or piston actuator, while rotary motion is supplied by either a vane type air motor, piston air motor, air turbine or gear type motor. Pneumatic motors have existed in many forms over the past two centuries, ranging in size from hand-held motors to engines of up to several hundred horsepower. Some types rely on pistons and cylinders; others on slotted rotors with vanes (vane motors) and others use turbines. Many compressed-air engines improve their performance by heating the incoming air or the engine itself. Pneumatic motors have found widespread success in the hand-held tool industry, but are also used stationary in a wide range of industrial applications. Continual attempts are b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Motor

A hydraulic motor is a mechanical actuator that converts hydraulic pressure and flow into torque and angular displacement (rotation). The hydraulic motor is the rotary counterpart of the hydraulic cylinder as a linear actuator. Most broadly, the category of devices called hydraulic motors has sometimes included those that run on hydropower (namely, water engines and water motors) but in today's terminology the name usually refers more specifically to motors that use hydraulic fluid as part of closed hydraulic circuits in modern hydraulic machinery. Conceptually, a hydraulic motor should be interchangeable with a hydraulic pump because it performs the opposite function – similar to the way a DC electric motor is theoretically interchangeable with a DC electrical generator. However, many hydraulic pumps cannot be used as hydraulic motors because they cannot be backdriven. Also, a hydraulic motor is usually designed for working pressure at both sides of the motor, whereas m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Induction Motor

An induction motor or asynchronous motor is an AC motor, AC electric motor in which the electric current in the rotor (electric), rotor that produces torque is obtained by electromagnetic induction from the magnetic field of the stator winding. An induction motor therefore needs no electrical connections to the rotor. An induction motor's rotor can be either wound rotor motor, wound type or squirrel-cage rotor, squirrel-cage type. Three-phase Squirrel-cage rotor, squirrel-cage induction motors are widely used as industrial drives because they are self-starting, reliable, and economical. Single-phase electric power, Single-phase induction motors are used extensively for smaller loads, such as garbage disposals and stationary power tools. Although traditionally used for constant-speed service, single- and three-phase induction motors are increasingly being installed in variable-speed applications using variable-frequency drives (VFD). VFD offers energy savings opportunities for i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

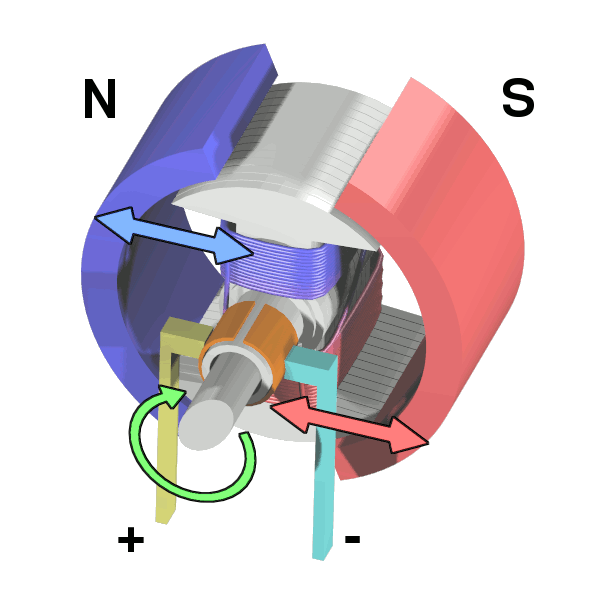

DC Motor

A DC motor is an electrical motor that uses direct current (DC) to produce mechanical force. The most common types rely on magnetic forces produced by currents in the coils. Nearly all types of DC motors have some internal mechanism, either electromechanical or electronic, to periodically change the direction of current in part of the motor. DC motors were the first form of motors to be widely used, as they could be powered from existing direct-current lighting power distribution systems. A DC motor's speed can be controlled over a wide range, using either a variable supply voltage or by changing the strength of current in its field windings. Small DC motors are used in tools, toys, and appliances. The universal motor, a lightweight brushed motor used for portable power tools and appliances can operate on direct current and alternating current. Larger DC motors are currently used in propulsion of electric vehicles, elevator and hoists, and in drives for steel rolling mills. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stepper Motor

A stepper motor, also known as step motor or stepping motor,Clarence W. de Silva. Mechatronics: An Integrated Approach (2005). CRC Press. p. 675. "The terms ''stepper motor'', ''stepping motor'', and ''step motor'' are synonymous and are often used interchangeably." is a brushless DC electric motor that rotates in a series of small and discrete angular steps. Stepper motors can be set to any given step position without needing a Rotary encoder, position sensor for feedback. The step position can be rapidly increased or decreased to create continuous rotation, or the motor can be ordered to actively hold its position at one given step. Motors vary in size, speed, step resolution, and torque. Switched reluctance motors are very large stepping motors with a reduced pole count. They generally employ closed-loop commutator (electric), commutators. Mechanism Brushed DC motors rotate continuously when DC voltage is applied to their terminals. The stepper motor is known for its proper ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Linear Actuator

A linear actuator is an actuator that creates linear motion (i.e., in a straight line), in contrast to the circular motion of a conventional electric motor. Linear actuators are used in machine tools and industrial machinery, in computer peripherals such as disk drives and printers, in valves and Damper (flow), dampers, and in many other places where linear motion is required. Hydraulics, Hydraulic or Pneumatics, pneumatic cylinders inherently produce linear motion. Many other mechanisms are used to generate linear motion from a rotating motor. Types Mechanical actuators Machine, Mechanical linear actuators typically operate by conversion of rotary motion into linear motion. Conversion is commonly made via a few simple types of mechanism: * Screw (simple machine), Screw: leadscrew, screw jack, ball screw and roller screw actuators all operate on the principle of the simple machine known as the screw. By rotating the actuator's nut, the screw shaft moves in a line. * Whe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |