|

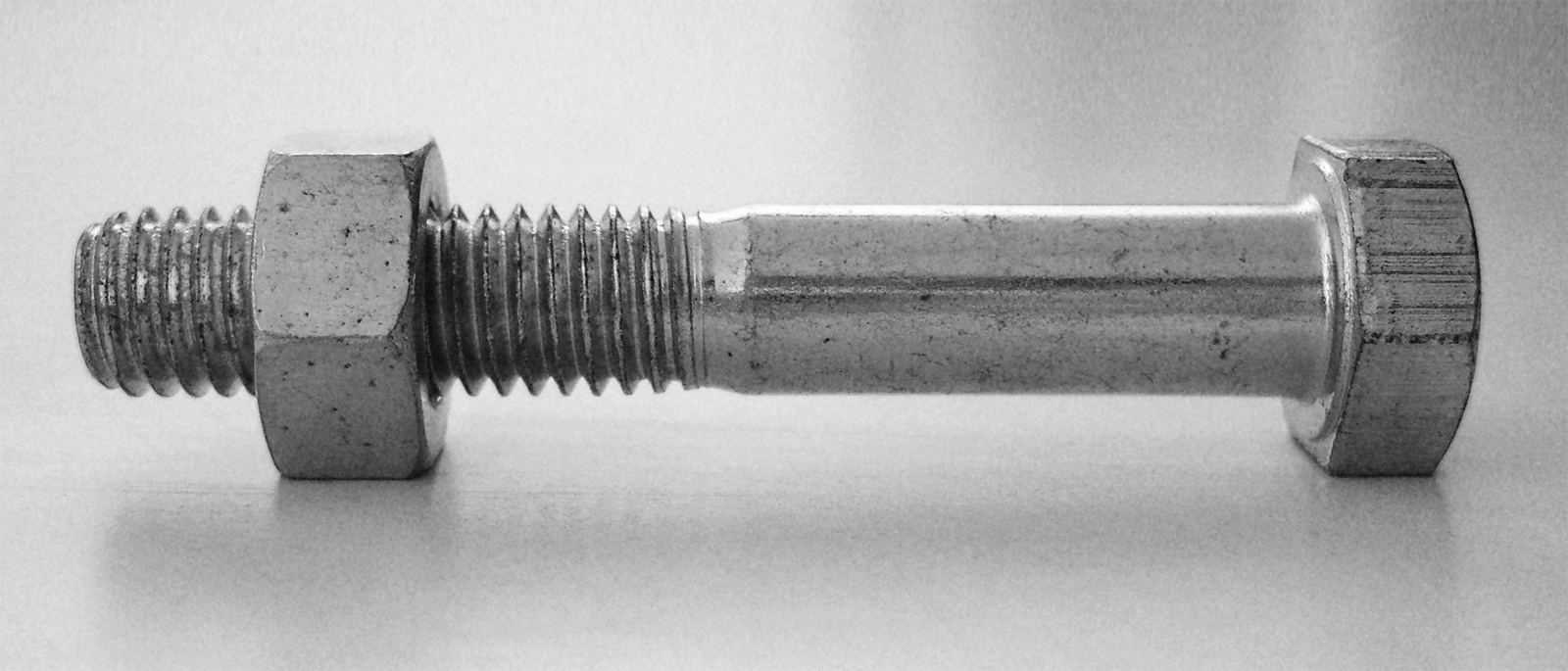

ASTM A490

ASTM A490 and ASTM A490M are ASTM International standards for heavy hex structural bolts made from alloy steel. The imperial standard is officially titled ''Standard Specification for Structural Bolts, Alloy Steel, Heat Treated, 150 ksi Minimum Tensile Strength'', while the metric standard (M) is titled ''Standard Specification for High-Strength Steel Bolts, Classes 10.9 and 10.9.3, for Structural Steel Joints''... In 2016, specifications A325 and A490 were officially withdrawn by ASTM and replaced by ASTM F3125. A325 and A490 heavy hex structural bolts are now grades under the new F3125 specification. Connection types There are also three connection types defined:. *SC: A slip critical connection. *N: A bearing type connection where the threads are on the shear plane. *X: A bearing type connection where the threads are not on the shear plane. Mechanical properties These bolts are equivalent to ASTM A325 bolts in application and geometry, but are made to a higher strength. The im ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ASTM International

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services. Some 12,575 ASTM voluntary consensus standards operate globally. The organization's headquarters is in West Conshohocken, Pennsylvania, about northwest of Philadelphia. It is founded in 1902 as the American Section of the International Association for Testing Materials (see also International Organization for Standardization). History A group of scientists and engineers, led by Charles Dudley, formed ASTM in 1898 to address the frequent rail breaks affecting the fast-growing railroad industry. The group developed a standard for the steel used to fabricate rails. Originally called the "American Society for Testing Materials" in 1902, it became the "American Society for Testing And Materials" in 1961. In 2001, ASTM of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ksi (unit)

The pound per square inch or, more accurately, pound-force per square inch (symbol: lbf/in2; abbreviation: psi) is a unit of pressure or of stress based on avoirdupois units. It is the pressure resulting from a force of one pound-force applied to an area of one square inch. In SI units, 1 psi is approximately equal to 6895 Pa. Pounds per square inch absolute (psia) is used to make it clear that the pressure is relative to a vacuum rather than the ambient atmospheric pressure. Since atmospheric pressure at sea level is around , this will be added to any pressure reading made in air at sea level. The converse is pounds per square inch gauge (psig), indicating that the pressure is relative to atmospheric pressure. For example, a bicycle tire pumped up to 65 psig in a local atmospheric pressure at sea level (14.7 psi) will have a pressure of 79.7 psia (14.7 psi + 65 psi). When gauge pressure is referenced to something other than ambient atmospheric pressure, then the u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ASTM Standards

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services. Some 12,575 ASTM voluntary consensus standards operate globally. The organization's headquarters is in West Conshohocken, Pennsylvania, about northwest of Philadelphia. It is founded in 1902 as the American Section of the International Association for Testing Materials (see also International Organization for Standardization). History A group of scientists and engineers, led by Charles Dudley, formed ASTM in 1898 to address the frequent rail breaks affecting the fast-growing railroad industry. The group developed a standard for the steel used to fabricate rails. Originally called the "American Society for Testing Materials" in 1902, it became the "American Society for Testing And Materials" in 1961. In 2001, ASTM off ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hex Cap Screw-ASTM A490M 10S3

Hex or HEX may refer to: Magic * Hex, a curse or supposed real and potentially supernaturally realized malicious wish * Hex sign, a barn decoration originating in Pennsylvania Dutch regions of the United States * Hex work, a Pennsylvania Dutch (German) folk magic system also known as pow-wow Web colors * Hex triplet, a six-digit, three-byte hexadecimal number used in computing applications to represent colors Engineering and technology * Hex key, a tool also known as a hex wrench or Allen wrench, used to drive fasteners * Hex key, a number sign (#) key on telephones (regional term used in Singapore and Malaysia) * High-energy X-rays, sometimes abbreviated "HEX-rays" * Hexadecimal, a base-16 number system often used in computer nomenclature * Hexcentric, an item of climbing protection equipment * Heat exchanger, a device for heat transfer * Hypersonic Flight Experiment, a planned mission of the Indian Space Research Organisation * Intel HEX, a computer file format * U ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electroplating

Electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the redox, reduction of cations of that metal by means of a direct current, direct electric current. The part to be coated acts as the cathode (negative electrode) of an electrolytic cell; the electrolyte is a solution (chemistry), solution of a salt (chemistry), salt of the metal to be coated; and the anode (positive electrode) is usually either a block of that metal, or of some inert electrical conductor, conductive material. The current is provided by an external power supply. Electroplating is widely used in industry and decorative arts to improve the surface qualities of objects—such as resistance to abrasion (mechanical), abrasion and corrosion, lubrication, lubricity, reflectivity, electrical conductivity, or appearance. It is used to build up thickness on undersized or worn-out parts, or to manufacture metal plates with ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bolt (fastener)

A bolt is a form of threaded fastener with an external male thread requiring a matching pre-formed female thread such as a nut. Bolts are very closely related to screws. Bolts vs. screws The distinction between a bolt and a screw is poorly-defined. The academic distinction, per '' Machinery's Handbook'', is in their intended design: bolts are designed to pass through an unthreaded hole in a component and be fastened with the aid of a nut, although such a fastener can be used without a nut to tighten into a threaded component such as a nut-plate or tapped housing. Screws in contrast are used in components which contain their own thread, or to cut its own internal thread into them. This definition allows ambiguity in the description of a fastener depending on the application it is actually used for, and the terms screw and bolt are widely used by different people or in different countries to apply to the same or varying fastener. Bolts are often used to make a bolted jo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanical Deposition

Mechanical plating, also known as peen plating, mechanical deposition, or impact plating, is a plating process that imparts the coating by cold welding fine metal particles to a workpiece. Mechanical galvanization is the same process, but applies to coatings that are thicker than .. It is commonly used to overcome hydrogen embrittlement problems. Commonly plated workpieces include nails, screws, nuts, washers, stampings, springs, clips, and sintered iron components.. The process involves tumbling the workpieces with a mixture of water, metal powder, media, and additives. Common coating materials are zinc, cadmium, tin, copper, and aluminium.. Invented by the Tainton Company in the 1950s, it was further developed by the 3M company. Process The process begins with a descaling and removing soil from the workpiece. This can be done in the tumbler or in a separate cleaning system. After cleaning, the parts are prepared by combining them with water, medium, and a surface ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |