tensile test on:

[Wikipedia]

[Google]

[Amazon]

Tensile testing, also known as tension testing, is a fundamental materials science and

Tensile testing, also known as tension testing, is a fundamental materials science and

The preparation of test specimens depends on the purposes of testing and on the governing

The preparation of test specimens depends on the purposes of testing and on the governing

Tensile testing is most often carried out at a material testing laboratory. The ASTM D638 is among the most common tensile testing protocols. The ASTM D638 measures plastics tensile properties including ultimate tensile strength, yield strength, elongation and Poisson's ratio.

The most common testing machine used in tensile testing is the '' universal testing machine''. This type of machine has two ''crossheads''; one is adjusted for the length of the specimen and the other is driven to apply tension to the test specimen. There are two types:

Tensile testing is most often carried out at a material testing laboratory. The ASTM D638 is among the most common tensile testing protocols. The ASTM D638 measures plastics tensile properties including ultimate tensile strength, yield strength, elongation and Poisson's ratio.

The most common testing machine used in tensile testing is the '' universal testing machine''. This type of machine has two ''crossheads''; one is adjusted for the length of the specimen and the other is driven to apply tension to the test specimen. There are two types:

Video on the tensile test

Tensile Tester

* ttps://www.micomlab.com/micom-testing/astm-d638/ Learn more about the ASTM D638 Tensile Test

RUBBER BELT TENSILE STRENGTH TEST

{{Authority control Materials testing

Tensile testing, also known as tension testing, is a fundamental materials science and

Tensile testing, also known as tension testing, is a fundamental materials science and engineering

Engineering is the use of scientific method, scientific principles to design and build machines, structures, and other items, including bridges, tunnels, roads, vehicles, and buildings. The discipline of engineering encompasses a broad rang ...

test in which a sample is subjected to a controlled tension until failure. Properties that are directly measured via a tensile test are ultimate tensile strength, breaking strength, maximum elongation and reduction in area. From these measurements the following properties can also be determined: Young's modulus

Young's modulus E, the Young modulus, or the modulus of elasticity in tension or compression (i.e., negative tension), is a mechanical property that measures the tensile or compressive stiffness of a solid material when the force is applied ...

, Poisson's ratio

In materials science and solid mechanics, Poisson's ratio \nu ( nu) is a measure of the Poisson effect, the deformation (expansion or contraction) of a material in directions perpendicular to the specific direction of loading. The value of Po ...

, yield strength

In materials science and engineering, the yield point is the point on a stress-strain curve that indicates the limit of Elasticity (physics), elastic behavior and the beginning of Plasticity (physics), plastic behavior. Below the yield point, ...

, and strain-hardening

In materials science, work hardening, also known as strain hardening, is the strengthening of a metal or polymer by plastic deformation. Work hardening may be desirable, undesirable, or inconsequential, depending on the context.

This strengt ...

characteristics. ''Uniaxial tensile testing'' is the most commonly used for obtaining the mechanical characteristics of isotropic materials. Some materials use biaxial tensile testing

In materials science and solid mechanics, biaxial tensile testing is a versatile technique to address the mechanical Characterization (materials science), characterization of planar materials. It is a generalized form of tensile testing in which t ...

. The main difference between these testing machines being how load is applied on the materials.

Purposes of tensile testing

Tensile testing might have a variety of purposes, such as: *Select a material or item for an application *Predict how a material will perform in use: normal and extremeforce

In physics, a force is an influence that can change the motion of an object. A force can cause an object with mass to change its velocity (e.g. moving from a state of rest), i.e., to accelerate. Force can also be described intuitively as a ...

s.

* Determine if, or verify that, the requirements of a specification

A specification often refers to a set of documented requirements to be satisfied by a material, design, product, or service. A specification is often a type of technical standard.

There are different types of technical or engineering specificat ...

, regulation

Regulation is the management of complex systems according to a set of rules and trends. In systems theory, these types of rules exist in various fields of biology

Biology is the scientific study of life. It is a natural science with a ...

, or contract

A contract is a legally enforceable agreement between two or more parties that creates, defines, and governs mutual rights and obligations between them. A contract typically involves the transfer of goods, services, money, or a promise to ...

are met

* Decide if a new product development program is on track

* Demonstrate proof of concept

Proof of concept (POC or PoC), also known as proof of principle, is a realization of a certain method or idea in order to demonstrate its feasibility, or a demonstration in principle with the aim of verifying that some concept or theory has prac ...

* Demonstrate the utility of a proposed patent

A patent is a type of intellectual property that gives its owner the legal right to exclude others from making, using, or selling an invention for a limited period of time in exchange for publishing an sufficiency of disclosure, enabling disclo ...

* Provide standard data

In the pursuit of knowledge, data (; ) is a collection of discrete values that convey information, describing quantity, quality, fact, statistics, other basic units of meaning, or simply sequences of symbols that may be further interpret ...

for other scientific, engineering, and quality assurance functions

* Provide a basis for Technical communication

Technical communication is used to convey scientific, engineering, or other technical information. Individuals in a variety of contexts and with varied professional credentials engage in technical communication. Some individuals are designated as ...

* Provide a technical means of comparison of several options

* Provide evidence

Evidence for a proposition is what supports this proposition. It is usually understood as an indication that the supported proposition is true. What role evidence plays and how it is conceived varies from field to field.

In epistemology, eviden ...

in legal proceedings

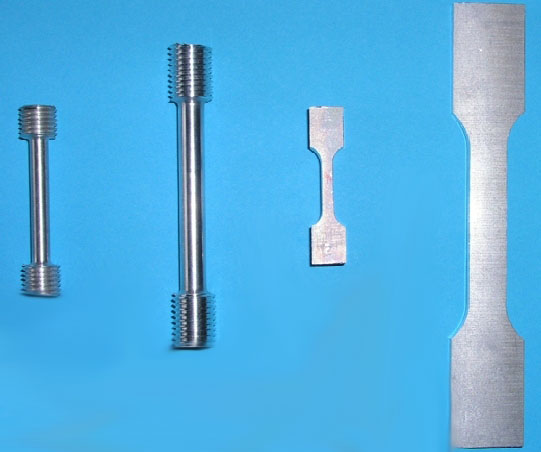

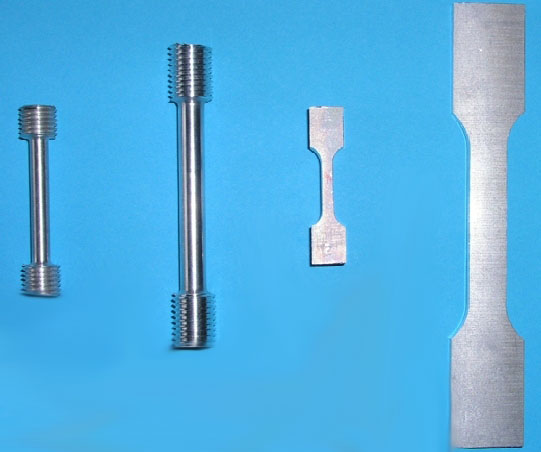

Tensile specimen

The preparation of test specimens depends on the purposes of testing and on the governing

The preparation of test specimens depends on the purposes of testing and on the governing test method

A test method is a method for a test in science or engineering, such as a physical test, chemical test, or statistical test. It is a definitive procedure that produces a test result. In order to ensure accurate and relevant test results, a test ...

or specification

A specification often refers to a set of documented requirements to be satisfied by a material, design, product, or service. A specification is often a type of technical standard.

There are different types of technical or engineering specificat ...

. A tensile specimen usually has a standardized sample cross-section. It has two shoulders and a gauge (section) in between. The shoulders and grip section are generally larger than the gauge section by 33% so they can be easily gripped. The gauge section's smaller diameter also allows the deformation and failure to occur in this area..

The shoulders of the test specimen can be manufactured in various ways to mate to various grips in the testing machine (see the image below). Each system has advantages and disadvantages; for example, shoulders designed for serrated grips are easy and cheap to manufacture, but the alignment of the specimen is dependent on the skill of the technician. On the other hand, a pinned grip assures good alignment. Threaded shoulders and grips also assure good alignment, but the technician must know to thread each shoulder into the grip at least one diameter's length, otherwise the threads can strip before the specimen fractures.

In large castings and forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at whi ...

s it is common to add extra material, which is designed to be removed from the casting so that test specimens can be made from it. These specimens may not be exact representation of the whole workpiece because the grain structure may be different throughout. In smaller workpieces or when critical parts of the casting must be tested, a workpiece may be sacrificed to make the test specimens.. For workpieces that are machined from bar stock, the test specimen can be made from the same piece as the bar stock.

For soft and porous materials, like electrospun nonwovens made of nanofibers, the specimen is usually a sample strip supported by a paper frame to favour its mounting on the machine and to avoid membrane damaging.

The repeatability of a testing machine can be found by using special test specimens meticulously made to be as similar as possible.

A standard specimen is prepared in a round or a square section along the gauge length, depending on the standard used. Both ends of the

specimens should have sufficient length and a surface condition such that they are firmly gripped

during testing. The initial gauge length Lo is standardized (in several countries) and varies with the

diameter (Do) or the cross-sectional area (Ao) of the specimen as listed

The following tables gives examples of test specimen dimensions and tolerances per standard ASTM

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, a ...

E8.

Equipment

Tensile testing is most often carried out at a material testing laboratory. The ASTM D638 is among the most common tensile testing protocols. The ASTM D638 measures plastics tensile properties including ultimate tensile strength, yield strength, elongation and Poisson's ratio.

The most common testing machine used in tensile testing is the '' universal testing machine''. This type of machine has two ''crossheads''; one is adjusted for the length of the specimen and the other is driven to apply tension to the test specimen. There are two types:

Tensile testing is most often carried out at a material testing laboratory. The ASTM D638 is among the most common tensile testing protocols. The ASTM D638 measures plastics tensile properties including ultimate tensile strength, yield strength, elongation and Poisson's ratio.

The most common testing machine used in tensile testing is the '' universal testing machine''. This type of machine has two ''crossheads''; one is adjusted for the length of the specimen and the other is driven to apply tension to the test specimen. There are two types: hydraulic

Hydraulics (from Greek: Υδραυλική) is a technology and applied science using engineering, chemistry, and other sciences involving the mechanical properties and use of liquids. At a very basic level, hydraulics is the liquid counter ...

powered and electromagnet

An electromagnet is a type of magnet in which the magnetic field is produced by an electric current. Electromagnets usually consist of wire wound into a coil. A current through the wire creates a magnetic field which is concentrated in the ...

ically powered machines.

The electromechanical machine uses an electric motor, gear reduction system and one, two or four screws to move the crosshead up or down. A range of crosshead speeds can be achieved by changing the speed of the motor. The speed of the crosshead, and consequently the load rate, can be controlled by a microprocessor in the closed-loop servo controller. A hydraulic testing machine uses either a single- or dual-acting piston to move the crosshead up or down. Manually operated testing systems are also available. Manual configurations require the operator to adjust a needle valve in order to control the load rate. A general comparison shows that the electromechanical machine is capable of a wide range of test speeds and long crosshead displacements, whereas the hydraulic machine is a cost-effective solution for generating high forces.

The machine must have the proper capabilities for the test specimen being tested. There are four main parameters: force capacity, speed, precision and accuracy

Accuracy and precision are two measures of ''observational error''.

''Accuracy'' is how close a given set of measurements ( observations or readings) are to their ''true value'', while ''precision'' is how close the measurements are to each oth ...

. Force capacity refers to the fact that the machine must be able to generate enough force to fracture the specimen. The machine must be able to apply the force quickly or slowly enough to properly mimic the actual application. Finally, the machine must be able to accurately and precisely measure the gauge length and forces applied; for instance, a large machine that is designed to measure long elongations may not work with a brittle material that experiences short elongations prior to fracturing..

Alignment of the test specimen in the testing machine is critical, because if the specimen is misaligned, either at an angle or offset to one side, the machine will exert a bending force on the specimen. This is especially bad for brittle materials, because it will dramatically skew the results. This situation can be minimized by using spherical seats or U-joint

A universal joint (also called a universal coupling or U-joint) is a joint or coupling connecting rigid shafts whose axes are inclined to each other. It is commonly used in shafts that transmit rotary motion. It consists of a pair of hinges l ...

s between the grips and the test machine. If the initial portion of the stress–strain curve is curved and not linear, it indicates the specimen is misaligned in the testing machine.

The strain measurements are most commonly measured with an extensometer, but strain gauges are also frequently used on small test specimen or when Poisson's ratio

In materials science and solid mechanics, Poisson's ratio \nu ( nu) is a measure of the Poisson effect, the deformation (expansion or contraction) of a material in directions perpendicular to the specific direction of loading. The value of Po ...

is being measured. Newer test machines have digital time, force, and elongation measurement systems consisting of electronic sensors connected to a data collection device (often a computer) and software to manipulate and output the data. However, analog machines continue to meet and exceed ASTM, NIST, and ASM metal tensile testing accuracy requirements, continuing to be used today.

Process

The test process involves placing the test specimen in the testing machine and slowly extending it until it fractures. During this process, the elongation of the gauge section is recorded against the applied force. The data is manipulated so that it is not specific to the geometry of the test sample. The elongation measurement is used to calculate the ''engineering strain'', ''ε'', using the following equation: : where Δ''L'' is the change in gauge length, ''L''0 is the initial gauge length, and ''L'' is the final length. The force measurement is used to calculate the ''engineering stress'', σ, using the following equation: : where F is the tensile force and A is the nominal cross-section of the specimen. The machine does these calculations as the force increases, so that the data points can be graphed into a '' stress–strain curve''. When dealing with porous and soft materials, as electrospun nanofibrous membranes, the application of the above stress formula is problematic. The membrane thickness, indeed, is dependent on the pressure applied during its measurement, leading to variable thicknesses value. As a consequence, the obtained stress-strain curves show high variability. In this case, the normalization of load with respect to the specimen mass instead of the cross-section area (A) is recommended to obtain reliable tensile results.Tensile testing creep

Tensile testing can be used to testcreep

Creep, Creeps or CREEP may refer to:

People

* Creep, a creepy person

Politics

* Committee for the Re-Election of the President (CRP), mockingly abbreviated as CREEP, an fundraising organization for Richard Nixon's 1972 re-election campaign

Art ...

in materials, a slow plastic deformation of the material from constant applied stresses over extended periods of time. Creep is generally aided by diffusion and dislocation movement. While there are many ways to test creep, tensile testing is useful for materials such as concrete and ceramics that behave differently in tension and compression, and thus possess different tensile and compressive creep rates. As such, understanding the tensile creep is important in the design of concrete for structures that experience tension, such as water holding containers, or for general structural integrity.

Tensile testing of creep generally follows the same testing process as standard testing albeit generally at lower stresses to remain in the creep domain rather than plastic deformation. Additionally, specialized tensile creep testing equipment may include incorporated high temperature furnace components to aid diffusion. The sample is held at constant temperature and tension, and strain on the material is measured using strain gauges or laser gauges. The measured strain can be fitted with equations governing different mechanisms of creep, such as power law creep or diffusion creep (see creep

Creep, Creeps or CREEP may refer to:

People

* Creep, a creepy person

Politics

* Committee for the Re-Election of the President (CRP), mockingly abbreviated as CREEP, an fundraising organization for Richard Nixon's 1972 re-election campaign

Art ...

for more information). Further analysis can be obtained from examining the sample post fracture. Understanding the creep mechanism and rate be able to aid materials selection and design.

It is important to note that sample alignment is important for tensile testing creep. Off centered loading will result in a bending stress being applied to the sample. Bending can be measured by tracking strain on all sides of the sample. The percent bending can then be defined as the difference between strain on one face () and the average strain ():

Percent bending should be under 1% on the wider face of loaded samples, and under 2% on the thinner face. Bending can caused by misalignment on the loading clamp and asymmetric machining of samples.

Standards

Metals

*ASTM

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, a ...

E8/E8M-13: "Standard Test Methods for Tension Testing of Metallic Materials" (2013)

* ISO 6892-1: "Metallic materials. Tensile testing. Method of test at ambient temperature" (2009)

* ISO 6892-2: "Metallic materials. Tensile testing. Method of test at elevated temperature" (2011)

* JIS Z2241 Method of tensile test for metallic materials

* MPIF Test Standard 10: "Method for the Tensile Properties of Powder Metallurgy (PM) Materials" Standard Test Methods for Tension Testing of Metallic Materials" (2015)

Composites

*ASTM

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, a ...

D 3039/D 3039M: "Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials"

Flexible materials

*ASTM

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, a ...

D638 Standard Test Method for Tensile Properties of Plastics

*ASTM

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, a ...

D828 Standard test method for tensile properties of paper and paperboard using constant-rate-of-elongation apparatus

*ASTM

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, a ...

D882 Standard test method for tensile properties of thin plastic sheeting

* ISO 37 rubber, vulcanized or thermoplastic—determination of tensile stress–strain properties

References

External links

Video on the tensile test

Tensile Tester

* ttps://www.micomlab.com/micom-testing/astm-d638/ Learn more about the ASTM D638 Tensile Test

RUBBER BELT TENSILE STRENGTH TEST

{{Authority control Materials testing