portland cement on:

[Wikipedia]

[Google]

[Amazon]

Portland cement is the most common type of

Portland cement is the most common type of

The name ''portland cement'' is recorded in a directory published in 1823 being associated with a William Lockwood and possibly others. In his 1824 cement patent, Joseph Aspdin called his invention "portland cement" because of its resemblance to Portland stone. Aspdin's cement was nothing like modern portland cement, but a first step in the development of modern portland cement, and has been called a "proto-portland cement".

The name ''portland cement'' is recorded in a directory published in 1823 being associated with a William Lockwood and possibly others. In his 1824 cement patent, Joseph Aspdin called his invention "portland cement" because of its resemblance to Portland stone. Aspdin's cement was nothing like modern portland cement, but a first step in the development of modern portland cement, and has been called a "proto-portland cement".

William Aspdin had left his father's company, to form his own cement manufactury. In the 1840s William Aspdin, apparently accidentally, produced

William Aspdin had left his father's company, to form his own cement manufactury. In the 1840s William Aspdin, apparently accidentally, produced

To achieve the desired setting qualities in the finished product, a quantity (2–8%, but typically 5%) of calcium sulphate (usually

To achieve the desired setting qualities in the finished product, a quantity (2–8%, but typically 5%) of calcium sulphate (usually

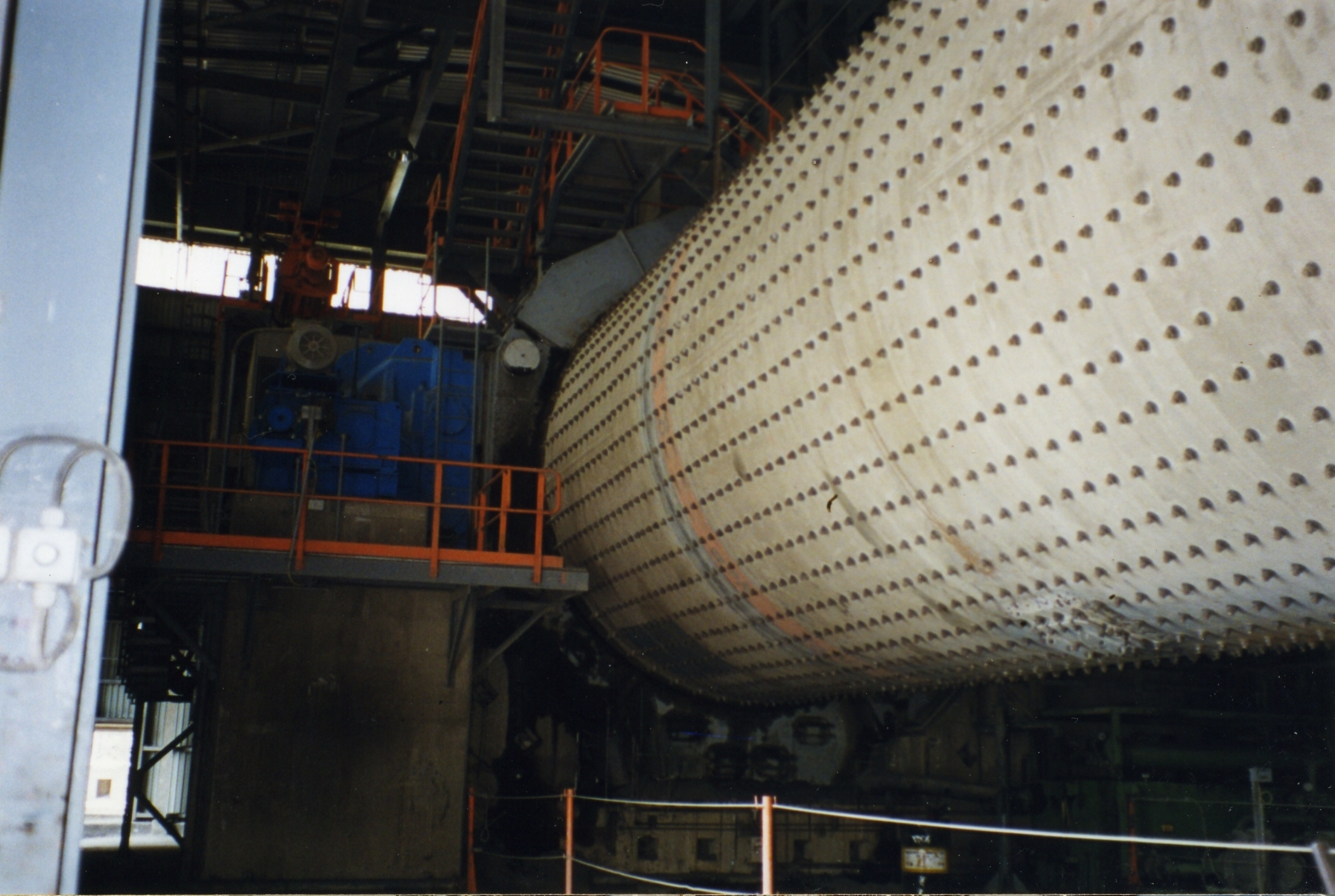

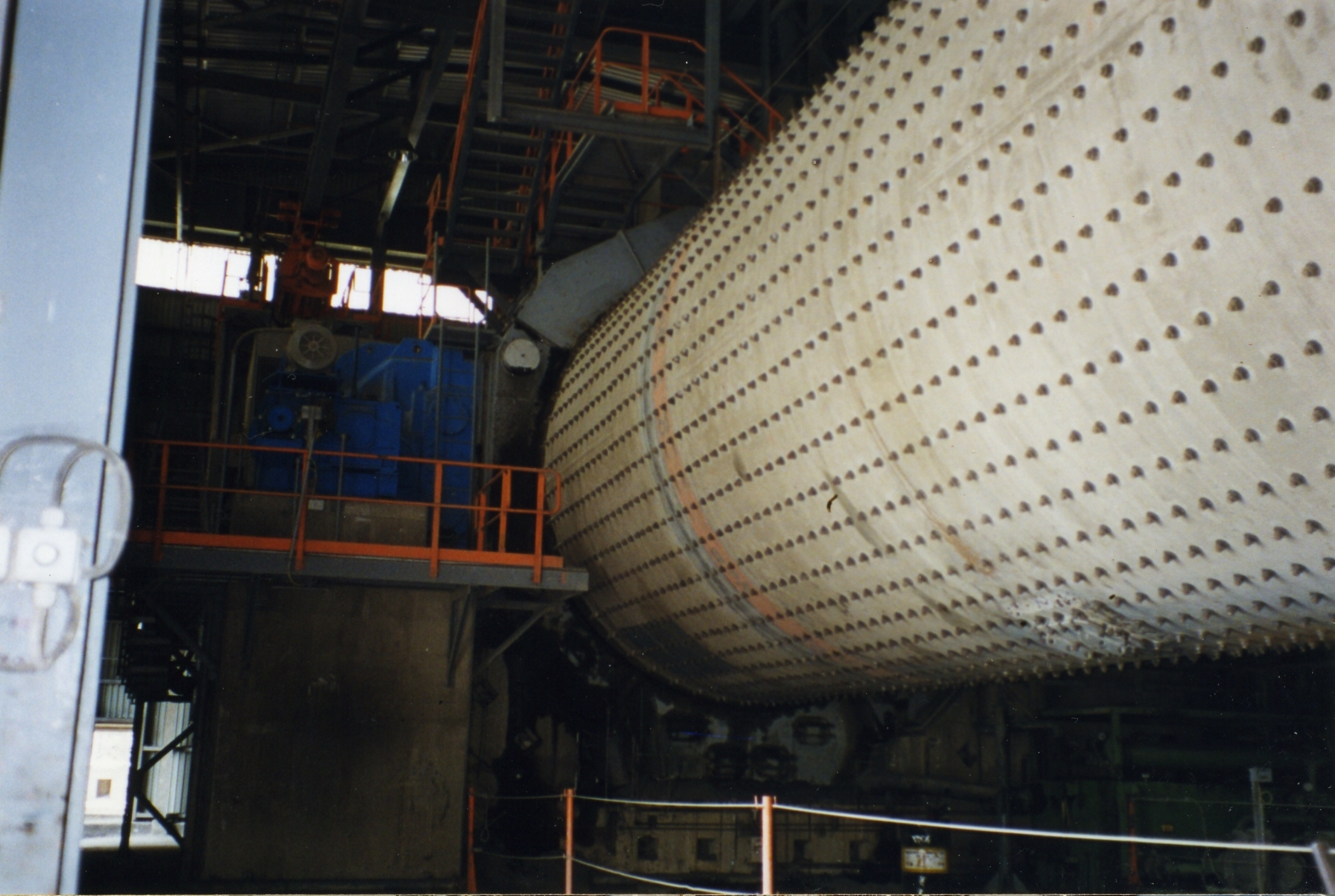

Due to the high temperatures inside

Due to the high temperatures inside

World Production of Hydraulic Cement, by CountryAlpha The Guaranteed Portland Cement Company: 1917 Trade Literature from Smithsonian Institution Libraries

*

*Aerial views of the world's largest concentration of cement manufacturing capacity, Saraburi Province, Thailand, at *

CDC – NIOSH Pocket Guide to Chemical Hazards

cement

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel ( aggregate) together. Cement mi ...

in general use around the world as a basic ingredient of concrete

Concrete is a composite material composed of aggregate bound together with a fluid cement that cures to a solid over time. It is the second-most-used substance (after water), the most–widely used building material, and the most-manufactur ...

, mortar, stucco

Stucco or render is a construction material made of aggregates, a binder, and water. Stucco is applied wet and hardens to a very dense solid. It is used as a decorative coating for walls and ceilings, exterior walls, and as a sculptural and ...

, and non-specialty grout. It was developed from other types of hydraulic lime

Hydraulic lime (HL) is a general term for a variety of lime different from calcium oxide (quicklime), that sets by hydration and consists of calcium silicate and calcium aluminate, compounds that can harden in contact with water. This contras ...

in England in the early 19th century by Joseph Aspdin, and is usually made from limestone

Limestone is a type of carbonate rock, carbonate sedimentary rock which is the main source of the material Lime (material), lime. It is composed mostly of the minerals calcite and aragonite, which are different Polymorphism (materials science) ...

. It is a fine powder, produced by heating limestone and clay minerals in a kiln

A kiln is a thermally insulated chamber, a type of oven, that produces temperatures sufficient to complete some process, such as hardening, drying, or Chemical Changes, chemical changes. Kilns have been used for millennia to turn objects m ...

to form clinker, and then grinding the clinker with the addition of several percent (often around 5%) gypsum

Gypsum is a soft sulfate mineral composed of calcium sulfate Hydrate, dihydrate, with the chemical formula . It is widely mined and is used as a fertilizer and as the main constituent in many forms of plaster, drywall and blackboard or sidewalk ...

. Several types of portland cement are available. The most common, historically called ordinary portland cement (OPC), is grey, but white portland cement is also available.

The cement was so named by Joseph Aspdin, who obtained a patent for it in 1824, because, once hardened, it resembled the fine, pale limestone known as Portland stone, quarried from the windswept cliffs of the Isle of Portland

The Isle of Portland is a tied island, long by wide, in the English Channel. The southern tip, Portland Bill, lies south of the resort of Weymouth, Dorset, Weymouth, forming the southernmost point of the county of Dorset, England. A barrier ...

in Dorset

Dorset ( ; Archaism, archaically: Dorsetshire , ) is a Ceremonial counties of England, ceremonial county in South West England. It is bordered by Somerset to the north-west, Wiltshire to the north and the north-east, Hampshire to the east, t ...

. Portland stone was prized for centuries in British architecture and used in iconic structures such as St Paul’s Cathedral and the British Museum

The British Museum is a Museum, public museum dedicated to human history, art and culture located in the Bloomsbury area of London. Its permanent collection of eight million works is the largest in the world. It documents the story of human cu ...

.

His son William Aspdin is regarded as the inventor of "modern" portland cement due to his developments in the 1840s.

The low cost and widespread availability of the limestone, shale

Shale is a fine-grained, clastic sedimentary rock formed from mud that is a mix of flakes of Clay mineral, clay minerals (hydrous aluminium phyllosilicates, e.g., Kaolinite, kaolin, aluminium, Al2Silicon, Si2Oxygen, O5(hydroxide, OH)4) and tiny f ...

s, and other naturally occurring materials used in portland cement make it a relatively cheap building material. At 4.4 billion tons manufactured (in 2023), Portland cement ranks third in the list (by mass) of manufactured materials, outranked only by sand and gravel. These two are combined, with water, to make the most manufactured material, concrete

Concrete is a composite material composed of aggregate bound together with a fluid cement that cures to a solid over time. It is the second-most-used substance (after water), the most–widely used building material, and the most-manufactur ...

. This is Portland cement's most common use.

History

Portland cement was developed from natural cements made in Britain beginning in the middle of the 18th century. Its name is derived from its similarity to Portland stone, a type of building stone quarried on theIsle of Portland

The Isle of Portland is a tied island, long by wide, in the English Channel. The southern tip, Portland Bill, lies south of the resort of Weymouth, Dorset, Weymouth, forming the southernmost point of the county of Dorset, England. A barrier ...

in Dorset

Dorset ( ; Archaism, archaically: Dorsetshire , ) is a Ceremonial counties of England, ceremonial county in South West England. It is bordered by Somerset to the north-west, Wiltshire to the north and the north-east, Hampshire to the east, t ...

, England. The development of modern portland cement (sometimes called ordinary or normal portland cement) began in 1756, when John Smeaton

John Smeaton (8 June 1724 – 28 October 1792) was an English civil engineer responsible for the design of bridges, canals, harbours and lighthouses. He was also a capable mechanical engineer and an eminent scholar, who introduced various ...

experimented with combinations of different limestones and additives, including trass and pozzolana

Pozzolana or pozzuolana ( , ), also known as pozzolanic ash (), is a natural siliceous or siliceous- aluminous material which reacts with calcium hydroxide in the presence of water at room temperature (cf. pozzolanic reaction). In this reaction ...

s, intended for the construction of a lighthouse,Robert G. Blezard, "The History of Calcareous Cements" in Hewlett, Peter C., ed.. ''Leaʼs chemistry of cement and concrete''. 4. ed. Amsterdam: Elsevier Butterworth-Heinemann, 2004. 1–24. Print. now known as Smeaton's Tower

Smeaton's Tower is a redundant lighthouse, now a memorial to civil engineer John Smeaton, designer of the third and most notable Eddystone Lighthouse#Smeaton.27s lighthouse, Eddystone Lighthouse. A major step forward in lighthouse design, Smeat ...

. In the late 18th century, Roman cement was developed and patented in 1796 by James Parker.Saikia, Mimi Das. Bhargab Mohan Das, Madan Mohan Das. ''Elements of Civil Engineering''. New Delhie: PHI Learning Private Limited. 2010. 30. Print. Roman cement quickly became popular, but was largely replaced by portland cement in the 1850s. In 1811, James Frost produced a cement he called British cement. James Frost is reported to have erected a manufactory for making of an artificial cement in 1826. In 1811 Edgar Dobbs of Southwark patented a cement of the kind invented 7 years later by the French engineer Louis Vicat. Vicat's cement is an artificial hydraulic lime

Hydraulic lime (HL) is a general term for a variety of lime different from calcium oxide (quicklime), that sets by hydration and consists of calcium silicate and calcium aluminate, compounds that can harden in contact with water. This contras ...

, and is considered the "principal forerunner" of portland cement.

The name ''portland cement'' is recorded in a directory published in 1823 being associated with a William Lockwood and possibly others. In his 1824 cement patent, Joseph Aspdin called his invention "portland cement" because of its resemblance to Portland stone. Aspdin's cement was nothing like modern portland cement, but a first step in the development of modern portland cement, and has been called a "proto-portland cement".

The name ''portland cement'' is recorded in a directory published in 1823 being associated with a William Lockwood and possibly others. In his 1824 cement patent, Joseph Aspdin called his invention "portland cement" because of its resemblance to Portland stone. Aspdin's cement was nothing like modern portland cement, but a first step in the development of modern portland cement, and has been called a "proto-portland cement".

William Aspdin had left his father's company, to form his own cement manufactury. In the 1840s William Aspdin, apparently accidentally, produced

William Aspdin had left his father's company, to form his own cement manufactury. In the 1840s William Aspdin, apparently accidentally, produced calcium silicate

Calcium silicate can refer to several silicates of calcium including:

*CaO·SiO2, wollastonite (CaSiO3)

*2CaO·SiO2, larnite (Ca2SiO4)

*3CaO·SiO2, alite or (Ca3SiO5)

*3CaO·2SiO2, (Ca3Si2O7).

This article focuses on Ca2SiO4, also known as calci ...

s which are a middle step in the development of portland cement. In 1848, William Aspdin further improved his cement. Then, in 1853, he moved to Germany, where he was involved in cement making. William Aspdin made what could be called "meso-portland cement" (a mix of portland cement and hydraulic lime). Isaac Charles Johnson further refined the production of "meso-portland cement" (middle stage of development), and claimed to be the real father of portland cement.

In 1859, John Grant of the Metropolitan Board of Works, set out requirements for cement to be used in the London sewer project. This became a specification for portland cement. The next development in the manufacture of portland cement was the introduction of the rotary kiln

A rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process. Materials produced using rotary kilns include:

* Cement

* Lime

* Refractories

* Metakaolin

* Titanium dioxide

* ...

, patented by Frederick Ransome in 1885 (U.K.) and 1886 (U.S.); which allowed a stronger, more homogeneous mixture and a continuous manufacturing process. The Hoffmann "endless" kiln which was said to give "perfect control over combustion" was tested in 1860 and shown to produce a superior grade of cement. This cement was made at the Portland Cementfabrik Stern at Stettin

Szczecin ( , , ; ; ; or ) is the capital and largest city of the West Pomeranian Voivodeship in northwestern Poland. Located near the Baltic Sea and the German border, it is a major seaport, the largest city of northwestern Poland, and se ...

, which was the first to use a Hoffmann kiln. The Association of German Cement Manufacturers issued a standard on portland cement in 1878.

Portland cement had been imported into the United States from England and Germany, and in the 1870s and 1880s, it was being produced by Eagle Portland cement near Kalamazoo, Michigan. In 1875, the first portland cement was produced in the Coplay Cement Company Kilns under the direction of David O. Saylor in Coplay, Pennsylvania, US. By the early 20th century, American-made portland cement had displaced most of the imported portland cement.

Composition

ASTM

ASTM International, formerly known as American Society for Testing and Materials, is a standards organization that develops and publishes voluntary consensus technical international standards for a wide range of materials, products, systems and s ...

C219 defines portland cement as:

The European Standard

European Standards, sometimes called Euronorm (abbreviated EN, from the German name , "European Norm"), are technical standards which have been ratified by one of the three European Standards Organizations (ESO): European Committee for Standardizat ...

EN 197-1 uses the following definition:

(The last two requirements were already set out in the German Standard, issued in 1909).

Clinkers make up more than 90% of the cement, along with a limited amount of calcium sulphate

Calcium sulfate (or calcium sulphate) is an Inorganic compound, inorganic Salt (chemistry), salt with the chemical formula . It occurs in several Hydrate, hydrated forms; the anhydrous state (known as anhydrite) is a white crystalline solid often ...

(CaSO4, which controls the set time), and up to 5% minor constituents (fillers) as allowed by various standards. Clinkers are nodules (diameters, ) of a sintered material that is produced when a raw mixture of predetermined composition is heated to high temperature. The key chemical reaction distinguishing portland cement from other hydraulic limes occurs at these high temperatures (>) as belite

Belite is an industrial mineral important in Portland cement manufacture. Its main constituent is dicalcium silicate, Ca2SiO4, sometimes formulated as 2 CaO · SiO2, SiO2 (C2S in cement chemist notation).

Etymology

The name was given by Alfred E ...

(Ca2SiO4) combines with calcium oxide

Calcium oxide (formula: Ca O), commonly known as quicklime or burnt lime, is a widely used chemical compound. It is a white, caustic, alkaline, crystalline solid at room temperature. The broadly used term '' lime'' connotes calcium-containing ...

(CaO) to form alite

Alite is an impure form of tricalcium silicate, , sometimes formulated as ( in cement chemist notation), typically with 3-4% of substituent oxides. It is the major, and characteristic, phase in Portland cement. The name was given by Alfred Elis ...

(Ca3SiO5).

Manufacturing

Portland cement clinker is made by heating, in acement kiln

Cement kilns are used for the pyroprocessing stage of manufacture of Portland cement, portland and other types of hydraulic cement, in which calcium carbonate reacts with silicon dioxide, silica-bearing minerals to form a mixture of calcium silic ...

, a mixture of raw materials to a calcining

Calcination is thermal treatment of a solid chemical compound (e.g. mixed carbonate ores) whereby the compound is raised to high temperature without melting under restricted supply of ambient oxygen (i.e. gaseous O2 fraction of air), generally fo ...

temperature of above and then a fusion temperature, which is about for modern cements, to sinter the materials into clinker.

The materials in cement clinker are alite, belite, tricalcium aluminate

Tricalcium aluminate Ca3Al2O6, often formulated as 3CaO·Al2O3 to highlight the proportions of the oxides from which it is made, is the most basic of the calcium aluminates. It does not occur in nature, but is an important mineral phase in Port ...

and tetracalcium alumino ferrite. The aluminium, iron and magnesium oxides are present as a flux

Flux describes any effect that appears to pass or travel (whether it actually moves or not) through a surface or substance. Flux is a concept in applied mathematics and vector calculus which has many applications in physics. For transport phe ...

allowing the calcium silicates to form at a lower temperature, and contribute little to the strength. For special cements, such as low heat (LH) and sulphate resistant (SR) types, it is necessary to limit the amount of tricalcium aluminate (3 CaO·Al2O3) formed.

The major raw material for the clinker-making is usually limestone

Limestone is a type of carbonate rock, carbonate sedimentary rock which is the main source of the material Lime (material), lime. It is composed mostly of the minerals calcite and aragonite, which are different Polymorphism (materials science) ...

( CaCO3) mixed with a second material containing clay as source of alumino-silicate. Normally, an impure limestone which contains clay or SiO2 is used. The CaCO3 content of these limestones can be as low as 80%. Secondary raw materials (materials in the raw mix other than limestone) depend on the purity of the limestone. Some of the materials used are clay

Clay is a type of fine-grained natural soil material containing clay minerals (hydrous aluminium phyllosilicates, e.g. kaolinite, ). Most pure clay minerals are white or light-coloured, but natural clays show a variety of colours from impuriti ...

, shale

Shale is a fine-grained, clastic sedimentary rock formed from mud that is a mix of flakes of Clay mineral, clay minerals (hydrous aluminium phyllosilicates, e.g., Kaolinite, kaolin, aluminium, Al2Silicon, Si2Oxygen, O5(hydroxide, OH)4) and tiny f ...

, sand

Sand is a granular material composed of finely divided mineral particles. Sand has various compositions but is usually defined by its grain size. Sand grains are smaller than gravel and coarser than silt. Sand can also refer to a textural ...

, iron ore

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the f ...

, bauxite

Bauxite () is a sedimentary rock with a relatively high aluminium content. It is the world's main source of aluminium and gallium. Bauxite consists mostly of the aluminium minerals gibbsite (), boehmite (γ-AlO(OH)), and diaspore (α-AlO(OH) ...

, fly ash

Coal combustion products (CCPs), also called coal combustion wastes (CCWs) or coal combustion residuals (CCRs), are byproducts of burning coal. They are categorized in four groups, each based on physical and chemical forms derived from coal combust ...

, and slag

The general term slag may be a by-product or co-product of smelting (pyrometallurgical) ores and recycled metals depending on the type of material being produced. Slag is mainly a mixture of metal oxides and silicon dioxide. Broadly, it can be c ...

. When a cement kiln is fired by coal, the ash of the coal acts as a secondary raw material.

Cement grinding

To achieve the desired setting qualities in the finished product, a quantity (2–8%, but typically 5%) of calcium sulphate (usually

To achieve the desired setting qualities in the finished product, a quantity (2–8%, but typically 5%) of calcium sulphate (usually gypsum

Gypsum is a soft sulfate mineral composed of calcium sulfate Hydrate, dihydrate, with the chemical formula . It is widely mined and is used as a fertilizer and as the main constituent in many forms of plaster, drywall and blackboard or sidewalk ...

or anhydrite) is added to the clinker, and the mixture is finely ground to form the finished cement powder. This is achieved in a cement mill. The grinding process is controlled to obtain a powder with a broad particle size range, in which typically 15% by mass consists of particles below 5 μm diameter, and 5% of particles above 45 μm. The measure of fineness usually used is the 'specific surface area

Specific surface area (SSA) is a property of solids defined as the total surface area (SA) of a material per unit mass, (with units of m2/kg or m2/g). Alternatively, it may be defined as SA per solid or bulk volume (units of m2/m3 or m−1).

I ...

', which is the total particle surface area of a unit mass of cement. The rate of initial reaction (up to 24 hours) of the cement on addition of water is directly proportional to the specific surface area. Typical values are 320–380 m2·kg−1 for general purpose cements, and 450–650 m2·kg−1 for 'rapid hardening' cements. The cement is conveyed by belt or powder pump to a silo for storage. Cement plants normally have sufficient silo space for one to 20 weeks of production, depending upon local demand cycles. The cement is delivered to end users either in bags, or as bulk powder blown from a pressure vehicle into the customer's silo. In industrial countries, 80% or more of cement is delivered in bulk.

Setting and hardening

Cement sets when mixed with water by way of a complex series of chemical reactions that are still only partly understood. A brief summary is as follows: The clinker phases—calcium silicates and aluminates—dissolve into the water that is mixed with the cement, which results in a fluid containing relatively high concentrations of dissolvedions

An ion () is an atom or molecule with a net electrical charge. The charge of an electron is considered to be negative by convention and this charge is equal and opposite to the charge of a proton, which is considered to be positive by convent ...

. This reaches supersaturation

In physical chemistry, supersaturation occurs with a solution (chemistry), solution when the concentration of a solute exceeds the concentration specified by the value of solubility at Solubility equilibrium, equilibrium. Most commonly the term ...

with respect to specific mineral phases: usually first ettringite, and then calcium silicate hydrate

Calcium silicate hydrates (CSH or C-S-H) are the main products of the hydration of Portland cement and are primarily responsible for the strength of cement-based materials. They are the main binding phase (the "glue") in most concrete. Only well de ...

(C-S-H)—which precipitate as newly formed solids. The interlocking of the C-S-H (which is crystallographically disordered, and can take on needle or crumpled-foil morphologies) and the ettringite crystals gives cement its initial setting, converting the fluid into a solid, and chemically incorporating much of the water into these new phases.

Gypsum

Gypsum is a soft sulfate mineral composed of calcium sulfate Hydrate, dihydrate, with the chemical formula . It is widely mined and is used as a fertilizer and as the main constituent in many forms of plaster, drywall and blackboard or sidewalk ...

is included in the cement as an inhibitor to prevent flash (or quick) setting; if gypsum is not present, the initial formation of (needle-shaped) ettringite is not possible, and so (plate-shaped) hydrocalumite-group ("AFm") calcium aluminate phases form instead. This premature formation of AFm phases causes a rapid loss of flowability, which is generally not desirable because it means that placement of the cement or concrete is very difficult.

Hardening of the cement then proceeds through further C-S-H formation, as this fills in the spaces between the (still-dissolving) cement grains with newly formed solid phases. Portlandite also precipitates from the pore solution to form part of the solid microstructure, and some of the initially-formed ettringite may be converted to AFm phases, releasing part of the sulfate from its structure to continue reacting with any remaining tricalcium aluminate

Use

The most common use for portland cement is in the production of concrete. Concrete is a composite material consisting of aggregate (gravel

Gravel () is a loose aggregation of rock fragments. Gravel occurs naturally on Earth as a result of sedimentation, sedimentary and erosion, erosive geological processes; it is also produced in large quantities commercially as crushed stone.

Gr ...

and sand

Sand is a granular material composed of finely divided mineral particles. Sand has various compositions but is usually defined by its grain size. Sand grains are smaller than gravel and coarser than silt. Sand can also refer to a textural ...

), cement, and water. As a construction material, concrete can be cast in almost any shape desired, and once hardened, can become a structural (load bearing) element. Concrete can be used in the construction of structural elements like panels, beams, and street furniture

Street furniture is a collective term for objects and pieces of equipment installed along streets and roads for various purposes. It includes bench (furniture), benches, traffic barriers, bollards, post boxes, phone boxes, streetlamps, traffic ...

, or may be cast-''in situ'' for superstructures like roads and dams. These may be supplied with concrete mixed on site, or may be provided with ' ready-mixed' concrete made at permanent mixing sites. Portland cement is also used in mortars (with sand and water only), for plaster

Plaster is a building material used for the protective or decorative coating of walls and ceilings and for moulding and casting decorative elements. In English, "plaster" usually means a material used for the interiors of buildings, while "re ...

s and screed

Screed has three meanings in building construction:

# A flat board (screed board, floating screed) or a purpose-made aluminium tool used to smooth and to "Wikt:true#Verb, true" materials like concrete, stucco and plaster after they have been p ...

s, and in grouts (cement/water mixes squeezed into gaps to consolidate foundations, road-beds, etc.).

When water is mixed with portland cement, the product sets in a few hours and hardens over a period of weeks. These processes can vary widely, depending upon the mix used and the conditions of curing of the product, but a typical concrete sets in about 6 hours and develops a compressive strength

In mechanics, compressive strength (or compression strength) is the capacity of a material or Structural system, structure to withstand Structural load, loads tending to reduce size (Compression (physics), compression). It is opposed to ''tensil ...

of 8 MPa in 24 hours. The strength rises to 15 MPa at 3 days, 23 MPa at 1 week, 35 MPa at 4 weeks, and 41 MPa at 3 months. In principle, the strength continues to rise slowly as long as water is available for continued hydration, but concrete is usually allowed to dry out after a few weeks and this causes strength growth to stop.

Types

General

ASTM C150

Five types of portland cements exist, with variations of the first three according to ASTM C150. ''Type I'' portland cement is known as common or general-purpose cement. It is generally assumed unless another type is specified. It is commonly used for general construction, especially when making precast, and precast-prestressed concrete that is not to be in contact with soils or ground water. The typical compound compositions of this type are: 55% (C3S), 19% (C2S), 10% (C3A), 7% (C4AF), 2.8% MgO, 2.9% (SO3), 1.0% ignition loss, and 1.0% free CaO (utilizingcement chemist notation

Cement chemist notation (CCN) was developed to simplify the formulas cement chemists use on a daily basis. It is a shorthand way of writing the chemical formula of oxides of calcium, silicon, and various metals.

Abbreviations of oxides

The main ...

).

A limitation on the composition is that the (C3A) shall not exceed 15%.

''Type II'' provides moderate sulphate resistance, and gives off less heat during hydration. This type of cement costs about the same as type I. Its typical compound composition is:

51% (C3S), 24% (C2S), 6% (C3A), 11% (C4AF), 2.9% MgO, 2.5% (SO3), 0.8% ignition loss, and 1.0% free CaO.

A limitation on the composition is that the (C3A) shall not exceed 8%, which reduces its vulnerability to sulphates. This type is for general construction exposed to moderate sulphate attack, and is meant for use when concrete is in contact with soils and ground water, especially in the western United States due to the high sulphur content of the soils. Because of similar price to that of type I, type II is much used as a general purpose cement, and the majority of portland cement sold in North America meets this specification.

Note: Cement meeting (among others) the specifications for types I and II has become commonly available on the world market.

''Type III'' has relatively high early strength. Its typical compound composition is:

57% (C3S), 19% (C2S), 10% (C3A), 7% (C4AF), 3.0% MgO, 3.1% (SO3), 0.9% ignition loss, and 1.3% free CaO.

This cement is similar to type I, but ground finer. Some manufacturers make a separate clinker with higher C3S and/or C3A content, but this is increasingly rare, and the general purpose clinker is usually used, ground to a specific surface area

Specific surface area (SSA) is a property of solids defined as the total surface area (SA) of a material per unit mass, (with units of m2/kg or m2/g). Alternatively, it may be defined as SA per solid or bulk volume (units of m2/m3 or m−1).

I ...

typically 50–80% higher. The gypsum level may also be increased a small amount. This gives the concrete using this type of cement a three-day compressive strength equal to the seven-day compressive strength of types I and II. Its seven-day compressive strength is almost equal to 28-day compressive strengths of types I and II. The only downside is that the six-month strength of type III is the same or slightly less than that of types I and II. Therefore, the long-term strength is sacrificed. It is usually used for precast concrete manufacture, where high one-day strength allows fast turnover of molds. It may also be used in emergency construction and repairs, and construction of machine bases and gate installations.

''Type IV'' portland cement is generally known for its low heat of hydration. Its typical compound composition is:

28% (C3S), 49% (C2S), 4% (C3A), 12% (C4AF), 1.8% MgO, 1.9% (SO3), 0.9% ignition loss, and 0.8% free CaO.

The percentages of (C2S) and (C4AF) are relatively high and (C3S) and (C3A) are relatively low. A limitation on this type is that the maximum percentage of (C3A) is seven, and the maximum percentage of (C3S) is thirty-five. This causes the heat given off by the hydration reaction to develop at a slower rate. Consequently, the strength of the concrete develops slowly. After one or two years the strength is higher than the other types after full curing. This cement is used for very large concrete structures, such as dams, which have a low surface to volume ratio. This type of cement is generally not stocked by manufacturers, but some might consider a large special order. This type of cement has not been made for many years, because portland-pozzolan cements and ground granulated blast furnace slag addition offer a cheaper and more reliable alternative.

''Type V'' is used where sulphate resistance is important. Its typical compound composition is:

38% (C3S), 43% (C2S), 4% (C3A), 9% (C4AF), 1.9% MgO, 1.8% (SO3), 0.9% ignition loss, and 0.8% free CaO.

This cement has a very low (C3A) composition which accounts for its high sulphate resistance. The maximum content of (C3A) allowed is 5% for type V portland cement. Another limitation is that the (C4AF) + 2(C3A) composition cannot exceed 20%. This type is used in concrete to be exposed to alkali

In chemistry, an alkali (; from the Arabic word , ) is a basic salt of an alkali metal or an alkaline earth metal. An alkali can also be defined as a base that dissolves in water. A solution of a soluble base has a pH greater than 7.0. The a ...

soil and ground water sulphates which react with (C3A) causing disruptive expansion. It is unavailable in many places, although its use is common in the western United States and Canada. As with type IV, type V portland cement has mainly been supplanted by the use of ordinary cement with added ground granulated blast furnace slag or tertiary blended cements containing slag and fly ash.

''Types Ia'', ''IIa'', and ''IIIa'' have the same composition as types I, II, and III. The only difference is that in Ia, IIa, and IIIa, an air-entraining agent is ground into the mix. The air-entrainment must meet the minimum and maximum optional specification found in the ASTM manual. These types are only available in the eastern United States and Canada, only on a limited basis. They are a poor approach to air-entrainment which improves resistance to freezing under low temperatures.

''Types II(MH)'' and ''II(MH)a'' have a similar composition as types II and IIa, but with a mild heat.

EN 197 norm

The European norm EN 197-1 defines five classes of common cement that comprise portland cement as a main constituent. These classes differ from the ASTM classes. ''Constituents that are permitted in portland-composite cements are artificial pozzolans (blast furnace slag (in fact a latent hydraulic binder), silica fume, and fly ashes), or natural pozzolans (siliceous or siliceous aluminous materials such as volcanic ash glasses, calcined clays and shale).''CSA A3000-08

The Canadian standards describe six main classes of cement, four of which can also be supplied as a blend containing ground limestone (where a suffix L is present in the class names).White portland cement

White portland cement or white ordinary portland cement (WOPC) is similar to ordinary grey portland cement in all respects, except for its high degree of whiteness. Obtaining this colour requires raw materials with lower low Fe2O3 content, and some modification to the method of manufacture, among others a higher kiln temperature required to sinter the clinker in the absence of ferric oxides acting as a flux in normal clinker. As Fe2O3 contributes to decrease the melting point of the clinker (normally 1450 °C), the white cement requires a higher sintering temperature (around 1600 °C). Because of this, it is somewhat more expensive than the grey product. The main requirement is to have a low iron content which should be less than 0.5 wt.% expressed as Fe2O3 for white cement, and less than 0.9 wt.% for off-white cement. It also helps to have the iron oxide as ferrous oxide (FeO) which is obtained via slightly reducing conditions in the kiln, i.e., operating with zero excess oxygen at the kiln exit. This gives the clinker and cement a green tinge. Other metallic oxides such as Cr2O3 (green), MnO (pink), TiO2 (white), etc., in trace content, can also give colour tinges, so for a given project it is best to use cement from a single batch.Safety issues

Bags of cement routinely have health and safety warnings printed on them, because not only is cement highlyalkali

In chemistry, an alkali (; from the Arabic word , ) is a basic salt of an alkali metal or an alkaline earth metal. An alkali can also be defined as a base that dissolves in water. A solution of a soluble base has a pH greater than 7.0. The a ...

ne, but the setting process is also exothermic

In thermodynamics, an exothermic process () is a thermodynamic process or reaction that releases energy from the system to its surroundings, usually in the form of heat, but also in a form of light (e.g. a spark, flame, or flash), electricity (e ...

. As a result, wet cement is strongly caustic and can easily cause severe skin burns if not promptly washed off with water. Similarly, dry cement powder in contact with mucous membrane

A mucous membrane or mucosa is a membrane that lines various cavities in the body of an organism and covers the surface of internal organs. It consists of one or more layers of epithelial cells overlying a layer of loose connective tissue. It ...

s can cause severe eye or respiratory irritation. The reaction of cement dust with moisture in the sinuses and lungs can also cause a chemical burn, as well as headaches, fatigue, and lung cancer.

The production of comparatively low-alkalinity cements (pH<11) is an area of ongoing investigation.

In Scandinavia

Scandinavia is a subregion#Europe, subregion of northern Europe, with strong historical, cultural, and linguistic ties between its constituent peoples. ''Scandinavia'' most commonly refers to Denmark, Norway, and Sweden. It can sometimes also ...

, France, and the United Kingdom, the level of chromium(VI), which is considered to be toxic and a major skin irritant, may not exceed 2 parts per million

In science and engineering, the parts-per notation is a set of pseudo-units to describe the small values of miscellaneous dimensionless quantity, dimensionless quantities, e.g. mole fraction or mass fraction (chemistry), mass fraction.

Since t ...

(ppm).

In the US, the Occupational Safety and Health Administration

The Occupational Safety and Health Administration (OSHA; ) is a regulatory agency of the United States Department of Labor that originally had federal visitorial powers to inspect and examine workplaces. The United States Congress established ...

(OSHA) has set the legal limit (permissible exposure limit

The permissible exposure limit (PEL or OSHA PEL) is a legal limit in the United States for exposure of an employee to a chemical substance or physical agents such as high level noise. Permissible exposure limits were established by the Occupational ...

) for portland cement exposure in the workplace as 50 mppcf (million particles per cubic foot) over an 8-hour workday. The National Institute for Occupational Safety and Health

The National Institute for Occupational Safety and Health (NIOSH, ) is the List of United States federal agencies, United States federal agency responsible for conducting research and making recommendations for the prevention of work-related occ ...

(NIOSH) has set a recommended exposure limit (REL) of 10 mg/m3 total exposure and 5 mg/m3 respiratory exposure over an 8-hour workday. At levels of 5000 mg/m3, portland cement is immediately dangerous to life and health.

Environmental effects

Portland cement manufacture can cause environmental impacts at all stages of the process. These include emissions of airborne pollution in the form of dust; gases; noise and vibration when operating machinery and during blasting in quarries; consumption of large quantities of fuel during manufacture; release of from the raw materials during manufacture, and damage to countryside from quarrying. Equipment to reduce dust emissions during quarrying and manufacture of cement is widely used, and equipment to trap and separate exhaust gases are coming into increased use. Environmental protection also includes the re-integration of quarries into the countryside after they have been closed down by returning them to nature or re-cultivating them. Portland cement is caustic, so it can cause chemical burns. The powder can cause irritation or, with severe exposure, lung cancer, and can contain a number of hazardous components, including crystallinesilica

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , commonly found in nature as quartz. In many parts of the world, silica is the major constituent of sand. Silica is one of the most complex and abundant f ...

and hexavalent chromium

Hexavalent chromium (chromium(VI), Cr(VI), chromium 6) is any chemical compound that contains the element chromium in the +6 oxidation state (thus hexavalent). It has been identified as carcinogenic, which is of concern since approximately of ...

. Environmental concerns are the high energy consumption required to mine, manufacture, and transport the cement, and the related air pollution, including the release of the greenhouse gas

Greenhouse gases (GHGs) are the gases in the atmosphere that raise the surface temperature of planets such as the Earth. Unlike other gases, greenhouse gases absorb the radiations that a planet emits, resulting in the greenhouse effect. T ...

carbon dioxide

Carbon dioxide is a chemical compound with the chemical formula . It is made up of molecules that each have one carbon atom covalent bond, covalently double bonded to two oxygen atoms. It is found in a gas state at room temperature and at norma ...

, dioxin, , , and particulates

Particulate matter (PM) or particulates are microscopic particles of solid or liquid matter suspension (chemistry), suspended in the atmosphere of Earth, air. An ''aerosol'' is a mixture of particulates and air, as opposed to the particulate ...

. Production of portland cement contributes about 10% of world carbon dioxide emissions

Greenhouse gas (GHG) emissions from human activities intensify the greenhouse effect. This contributes to climate change. Carbon dioxide (), from burning fossil fuels such as coal, oil, and natural gas, is the main cause of climate change. The ...

. The International Energy Agency

The International Energy Agency (IEA) is a Paris-based autonomous intergovernmental organization, established in 1974, that provides policy recommendations, analysis and data on the global energy sector. The 31 member countries and 13 associatio ...

has estimated that cement production will increase by between 12 and 23% by 2050 to meet the needs of the world's growing population. There are several ongoing researches targeting a suitable replacement of portland cement by supplementary cementitious materials.

''Epidemiologic Notes and Reports Sulfur Dioxide Exposure in Portland Cement Plants'', from the Centers for Disease Control

The Centers for Disease Control and Prevention (CDC) is the national public health agency of the United States. It is a United States federal agency under the Department of Health and Human Services (HHS), and is headquartered in Atlanta, ...

, states:

An independent research effort of AEA Technology to identify critical issues for the cement industry today concluded the most important environment, health and safety performance issues facing the cement industry are atmospheric releases (including greenhouse gas emissions

Greenhouse gas (GHG) emissions from human activities intensify the greenhouse effect. This contributes to climate change. Carbon dioxide (), from burning fossil fuels such as coal, petroleum, oil, and natural gas, is the main cause of climate chan ...

, dioxin, , , and particulates), accidents, and worker exposure to dust.

The associated with portland cement manufacture comes mainly from four sources:

Overall, with nuclear or hydroelectric power, and efficient manufacturing, generation can be reduced to per kg cement, but can be twice as high. The thrust of innovation for the future is to reduce sources 1 and 2 by modification of the chemistry of cement, by the use of wastes, and by adopting more efficient processes. Although cement manufacturing is clearly a very large emitter, concrete (of which cement makes up about 15%) compares quite favourably with other modern building systems in this regard.. Traditional materials such as lime based mortars as well as timber and earth based construction methods emit significantly less .

Cement plants used for waste disposal or processing

Due to the high temperatures inside

Due to the high temperatures inside cement kiln

Cement kilns are used for the pyroprocessing stage of manufacture of Portland cement, portland and other types of hydraulic cement, in which calcium carbonate reacts with silicon dioxide, silica-bearing minerals to form a mixture of calcium silic ...

s, combined with the oxidising (oxygen-rich) atmosphere and long residence times, cement kilns are used as a processing option for various types of waste streams; indeed, they efficiently destroy many hazardous organic compounds. The waste streams also often contain combustible materials which allow the substitution of part of the fossil fuel normally used in the process.

Waste materials used in cement kilns as a fuel supplement:

*Car and truck tire

A tire (North American English) or tyre (Commonwealth English) is a ring-shaped component that surrounds a Rim (wheel), wheel's rim to transfer a vehicle's load from the axle through the wheel to the ground and to provide Traction (engineeri ...

s – steel belts are easily tolerated in the kilns

*Paint sludge from automobile industries

*Waste solvents and lubricants

* Meat and bone meal – slaughterhouse

In livestock agriculture and the meat industry, a slaughterhouse, also called an abattoir (), is a facility where livestock animals are slaughtered to provide food. Slaughterhouses supply meat, which then becomes the responsibility of a mea ...

waste due to bovine spongiform encephalopathy

Bovine spongiform encephalopathy (BSE), commonly known as mad cow disease, is an incurable and always fatal neurodegenerative disease of cattle. Symptoms include abnormal behavior, trouble walking, and weight loss. Later in the course of th ...

contamination concerns

*Waste plastics

*Sewage sludge

*Rice hulls

Rice hulls or husks are the hard protecting coverings of grains of rice. In addition to protecting rice during the growing season, rice hulls can be put to use as building material, fertilizer, insulation material, or fuel. Rice hulls are part of ...

*Sugarcane

Sugarcane or sugar cane is a species of tall, Perennial plant, perennial grass (in the genus ''Saccharum'', tribe Andropogoneae) that is used for sugar Sugar industry, production. The plants are 2–6 m (6–20 ft) tall with stout, jointed, fib ...

waste

*Used wooden railroad tie

A railroad tie, crosstie (American English), railway tie (Canadian English) or railway sleeper ( Australian and British English) is a rectangular support for the rails in railroad tracks. Generally laid perpendicular to the rails, ties trans ...

s (railway sleepers)

* Spent cell liner from the aluminium smelting industry (also called spent pot liner)

Portland cement manufacture also has the potential to benefit from using industrial byproducts from the waste stream. These include in particular:

*Slag

The general term slag may be a by-product or co-product of smelting (pyrometallurgical) ores and recycled metals depending on the type of material being produced. Slag is mainly a mixture of metal oxides and silicon dioxide. Broadly, it can be c ...

*Fly ash

Coal combustion products (CCPs), also called coal combustion wastes (CCWs) or coal combustion residuals (CCRs), are byproducts of burning coal. They are categorized in four groups, each based on physical and chemical forms derived from coal combust ...

(from power plants)

*Silica fume

Silica fume, also known as microsilica, (CAS number 69012-64-2, EINECS number 273-761-1) is an amorphous (non-crystalline) polymorph of silicon dioxide, silica. It is an ultrafine powder collected as a by-product of the silicon and ferrosilicon a ...

(from steel mills)

*Synthetic gypsum

Gypsum is a soft sulfate mineral composed of calcium sulfate Hydrate, dihydrate, with the chemical formula . It is widely mined and is used as a fertilizer and as the main constituent in many forms of plaster, drywall and blackboard or sidewalk ...

(from desulphurisation)

See also

* * * * * * * * * *References

External links

World Production of Hydraulic Cement, by Country

*

*Aerial views of the world's largest concentration of cement manufacturing capacity, Saraburi Province, Thailand, at *

CDC – NIOSH Pocket Guide to Chemical Hazards

Further reading

* * * * {{DEFAULTSORT:Portland Cement Cement Concrete English inventions LimestoneCement

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel ( aggregate) together. Cement mi ...

Building materials

19th-century inventions

de:Zement#Portlandzement