Variable-frequency drive on:

[Wikipedia]

[Google]

[Amazon]

A variable-frequency drive (VFD, or adjustable-frequency drive, adjustable-speed drive, variable-speed drive, AC drive, micro drive, inverter drive, variable voltage variable frequency drive, or drive) is a type of AC motor drive (system incorporating a motor) that controls

A variable-frequency drive (VFD, or adjustable-frequency drive, adjustable-speed drive, variable-speed drive, AC drive, micro drive, inverter drive, variable voltage variable frequency drive, or drive) is a type of AC motor drive (system incorporating a motor) that controls

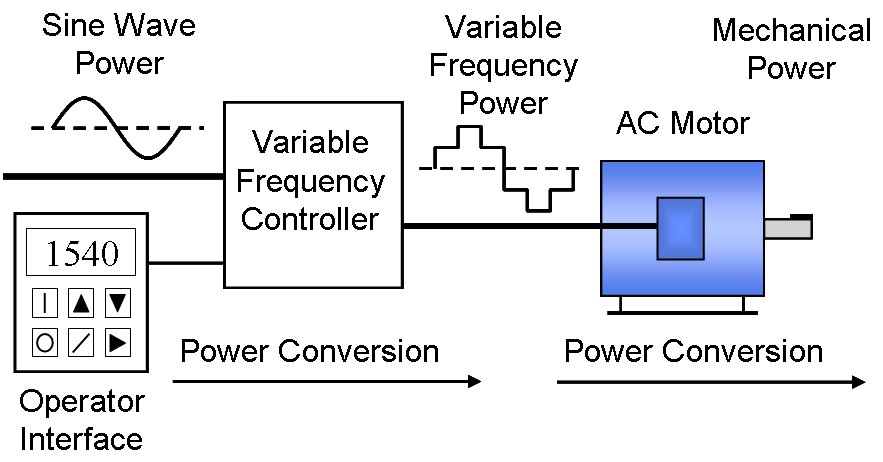

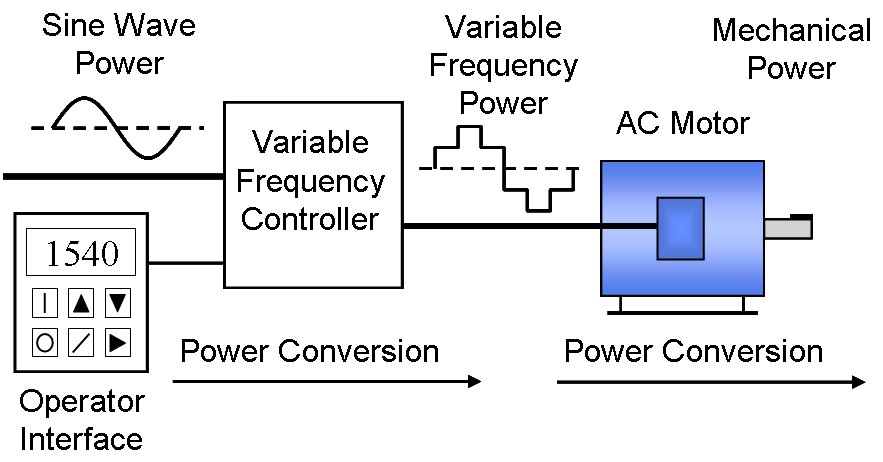

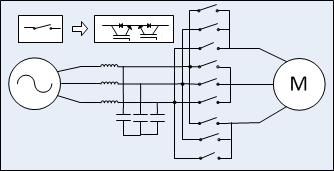

A variable-frequency drive is a device used in a drive system consisting of the following three main sub-systems: AC motor, main drive controller assembly, and drive/operator interface.

A variable-frequency drive is a device used in a drive system consisting of the following three main sub-systems: AC motor, main drive controller assembly, and drive/operator interface.

An embedded

An embedded

AC drives can be classified according to the following generic topologies:

* Voltage-source inverter (VSI) drive topologies (see image): In a VSI drive, the DC output of the

AC drives can be classified according to the following generic topologies:

* Voltage-source inverter (VSI) drive topologies (see image): In a VSI drive, the DC output of the

File:2LI Topology.svg, Simplified 2-Level Inverter Topology

File:3LI Topology.jpg, Simplified Neutral Point Clamped 3-Level Inverter Topology

File:CHBI Topology.jpg, Simplified Cascaded H-bridge Inverter Topology

File:FCI Topology.jpg, Simplified Flying Capacitor Inverter 4-Level Topology

File:NPC-HBI Topology.jpg, Simplified Neutral Point Clamped H-bridge Inverter Topology

Regenerative AC drives have the capacity to recover the braking energy of a load moving faster than the designated motor speed (an ''overhauling'' load) and return it to the power system.

Cycloconverter, Scherbius, matrix, CSI, and LCI drives inherently allow return of energy from the load to the line, while voltage-source inverters require an additional converter to return energy to the supply.

Regeneration is useful in VFDs only where the value of the recovered energy is large compared to the extra cost of a regenerative system, and if the system requires frequent braking and starting. Regenerative VFDs are widely used where speed control of overhauling loads is required.Campbell, pp. 70–190

Some examples:

* Conveyor belt drives for manufacturing, which stop every few minutes. While stopped, parts are assembled; once that is done, the belt moves on.

* A crane, where the hoist motor stops and reverses frequently, and braking is required to slow the load during lowering.

* Plug-in and hybrid electric vehicles of all types (see image and Hybrid Synergy Drive).

Regenerative AC drives have the capacity to recover the braking energy of a load moving faster than the designated motor speed (an ''overhauling'' load) and return it to the power system.

Cycloconverter, Scherbius, matrix, CSI, and LCI drives inherently allow return of energy from the load to the line, while voltage-source inverters require an additional converter to return energy to the supply.

Regeneration is useful in VFDs only where the value of the recovered energy is large compared to the extra cost of a regenerative system, and if the system requires frequent braking and starting. Regenerative VFDs are widely used where speed control of overhauling loads is required.Campbell, pp. 70–190

Some examples:

* Conveyor belt drives for manufacturing, which stop every few minutes. While stopped, parts are assembled; once that is done, the belt moves on.

* A crane, where the hoist motor stops and reverses frequently, and braking is required to slow the load during lowering.

* Plug-in and hybrid electric vehicles of all types (see image and Hybrid Synergy Drive).

A variable-frequency drive (VFD, or adjustable-frequency drive, adjustable-speed drive, variable-speed drive, AC drive, micro drive, inverter drive, variable voltage variable frequency drive, or drive) is a type of AC motor drive (system incorporating a motor) that controls

A variable-frequency drive (VFD, or adjustable-frequency drive, adjustable-speed drive, variable-speed drive, AC drive, micro drive, inverter drive, variable voltage variable frequency drive, or drive) is a type of AC motor drive (system incorporating a motor) that controls speed

In kinematics, the speed (commonly referred to as ''v'') of an object is the magnitude of the change of its position over time or the magnitude of the change of its position per unit of time; it is thus a non-negative scalar quantity. Intro ...

and torque

In physics and mechanics, torque is the rotational analogue of linear force. It is also referred to as the moment of force (also abbreviated to moment). The symbol for torque is typically \boldsymbol\tau, the lowercase Greek letter ''tau''. Wh ...

by varying the frequency

Frequency is the number of occurrences of a repeating event per unit of time. Frequency is an important parameter used in science and engineering to specify the rate of oscillatory and vibratory phenomena, such as mechanical vibrations, audio ...

of the input electricity. Depending on its topology

Topology (from the Greek language, Greek words , and ) is the branch of mathematics concerned with the properties of a Mathematical object, geometric object that are preserved under Continuous function, continuous Deformation theory, deformat ...

, it controls the associated voltage

Voltage, also known as (electrical) potential difference, electric pressure, or electric tension, is the difference in electric potential between two points. In a Electrostatics, static electric field, it corresponds to the Work (electrical), ...

or current variation., quote is per definition on p. 4 of NEMA Standards Publication ICS 7.2-2021.

VFDs are used in applications ranging from small appliances to large compressors. Systems using VFDs can be more efficient than hydraulic systems, such as in systems with pumps and damper control for fans.

Since the 1980s, power electronics technology has reduced VFD cost and size and has improved performance through advances in semiconductor switching devices, drive topologies, simulation and control techniques, and control hardware and software.

VFDs include low- and medium-voltage AC–AC and DC–AC topologies.

History

Pulse-width modulation (PWM) variable-frequency drive projects started in the 1960s at Strömberg in Finland. is regarded as the inventor of this technology. Strömberg managed to sell the idea of PWM drive toHelsinki Metro

The Helsinki Metro (, ) is a rapid transit system serving the Helsinki capital region, Finland. It is the world's most northern, the world's northernmost metro system. It was opened to the general public on 2 August 1982 after 27 years of planni ...

in 1973 and in 1982 the first PWM drive SAMI10 were operational.

System description and operation

A variable-frequency drive is a device used in a drive system consisting of the following three main sub-systems: AC motor, main drive controller assembly, and drive/operator interface.

A variable-frequency drive is a device used in a drive system consisting of the following three main sub-systems: AC motor, main drive controller assembly, and drive/operator interface.

AC motor

The AC electric motor used in a VFD system is usually athree-phase

Three-phase electric power (abbreviated 3ϕ) is a common type of alternating current (AC) used in electricity generation, Electric power transmission, transmission, and Electric power distribution, distribution. It is a type of polyphase system ...

induction motor. Some types of single-phase

In electrical engineering, single-phase electric power (abbreviated 1φ) is the distribution of alternating current electric power using a system in which all the voltages of the supply vary in unison. Single-phase distribution is used when loads ...

motors or synchronous motor

A synchronous electric motor is an AC electric motor in which, at steady state,

the rotation of the shaft is synchronized with the frequency of the supply current; the rotation period is exactly equal to an integer number of AC cycles. Sync ...

s can be advantageous in some situations, but generally three-phase induction motors are preferred as the most economical. Motors that are designed for fixed-speed operation are often used. Elevated-voltage stresses imposed on induction motors that are supplied by VFDs require that such motors be designed for definite-purpose inverter-fed duty in accordance with such requirements as Part 31 of NEMA

The National Electrical Manufacturers Association (NEMA) is the largest trade association of electrical equipment manufacturers in the United States. Founded in 1926, it advocates for the industry and publishes standards for electrical product ...

Standard MG-1.

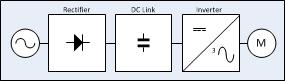

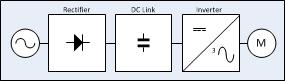

Controller

The VFD controller is a solid-state power electronics conversion system consisting of three distinct sub-systems: arectifier

A rectifier is an electrical device that converts alternating current (AC), which periodically reverses direction, to direct current (DC), which flows in only one direction.

The process is known as ''rectification'', since it "straightens" t ...

bridge converter, a direct current

Direct current (DC) is one-directional electric current, flow of electric charge. An electrochemical cell is a prime example of DC power. Direct current may flow through a conductor (material), conductor such as a wire, but can also flow throug ...

(DC) link, and an inverter. Voltage-source inverter (VSI) drives (see 'Generic topologies' sub-section below) are by far the most common type of drives. Most drives are AC–AC drives in that they convert AC line input to AC inverter output. However, in some applications such as common DC bus or solar applications, drives are configured as DC–AC drives. The most basic rectifier converter for the VSI drive is configured as a three-phase, six-pulse, full-wave diode bridge

A diode bridge is a bridge rectifier circuit of four diodes that is used in the process of converting alternating current (AC) from the input terminals to direct current (DC, i.e. fixed polarity) on the output terminals. Its function is to co ...

. In a VSI drive, the DC link consists of a capacitor

In electrical engineering, a capacitor is a device that stores electrical energy by accumulating electric charges on two closely spaced surfaces that are insulated from each other. The capacitor was originally known as the condenser, a term st ...

which smooths out the converter's DC output ripple and provides a stiff input to the inverter. This filtered DC voltage is converted to quasi-sinusoidal

A sine wave, sinusoidal wave, or sinusoid (symbol: ∿) is a periodic wave whose waveform (shape) is the trigonometric sine function. In mechanics, as a linear motion over time, this is '' simple harmonic motion''; as rotation, it correspond ...

AC voltage output using the inverter's active switching elements. VSI drives provide higher power factor and lower harmonic distortion than phase-controlled current-source inverter (CSI) and load-commutated inverter (LCI) drives (see 'Generic topologies' sub-section below). The drive controller can also be configured as a phase converter having single-phase converter input and three-phase inverter output.

Controller advances have exploited dramatic increases in the voltage and current ratings and switching frequency of solid-state power devices over the past six decades. Introduced in 1983, the insulated-gate bipolar transistor (IGBT) has in the past two decades come to dominate VFDs as an inverter switching device.

In variable-torque

In physics and mechanics, torque is the rotational analogue of linear force. It is also referred to as the moment of force (also abbreviated to moment). The symbol for torque is typically \boldsymbol\tau, the lowercase Greek letter ''tau''. Wh ...

applications suited for Volts-per-Hertz (V/Hz) drive control, AC motor characteristics require that the voltage magnitude of the inverter's output to the motor be adjusted to match the required load torque in a linear

In mathematics, the term ''linear'' is used in two distinct senses for two different properties:

* linearity of a '' function'' (or '' mapping'');

* linearity of a '' polynomial''.

An example of a linear function is the function defined by f(x) ...

V/Hz relationship. For example, for 460 V, 60 Hz motors, this linear V/Hz relationship is 460/60 = 7.67 V/Hz. While suitable in wide-ranging applications, V/Hz control is sub-optimal in high-performance applications involving low speed or demanding, dynamic speed regulation, positioning, and reversing load requirements. Some V/Hz control drives can also operate in quadratic V/Hz mode or can even be programmed to suit special multi-point V/Hz paths.

The two other drive control platforms, vector control

Vector control is any method to limit or eradicate the mammals, birds, insects or other arthropods (here collectively called " vectors") which transmit disease pathogens. The most frequent type of vector control is mosquito control using a varie ...

and direct torque control (DTC), adjust the motor voltage magnitude, angle from reference, and frequency so as to precisely control the motor's magnetic flux and mechanical torque.

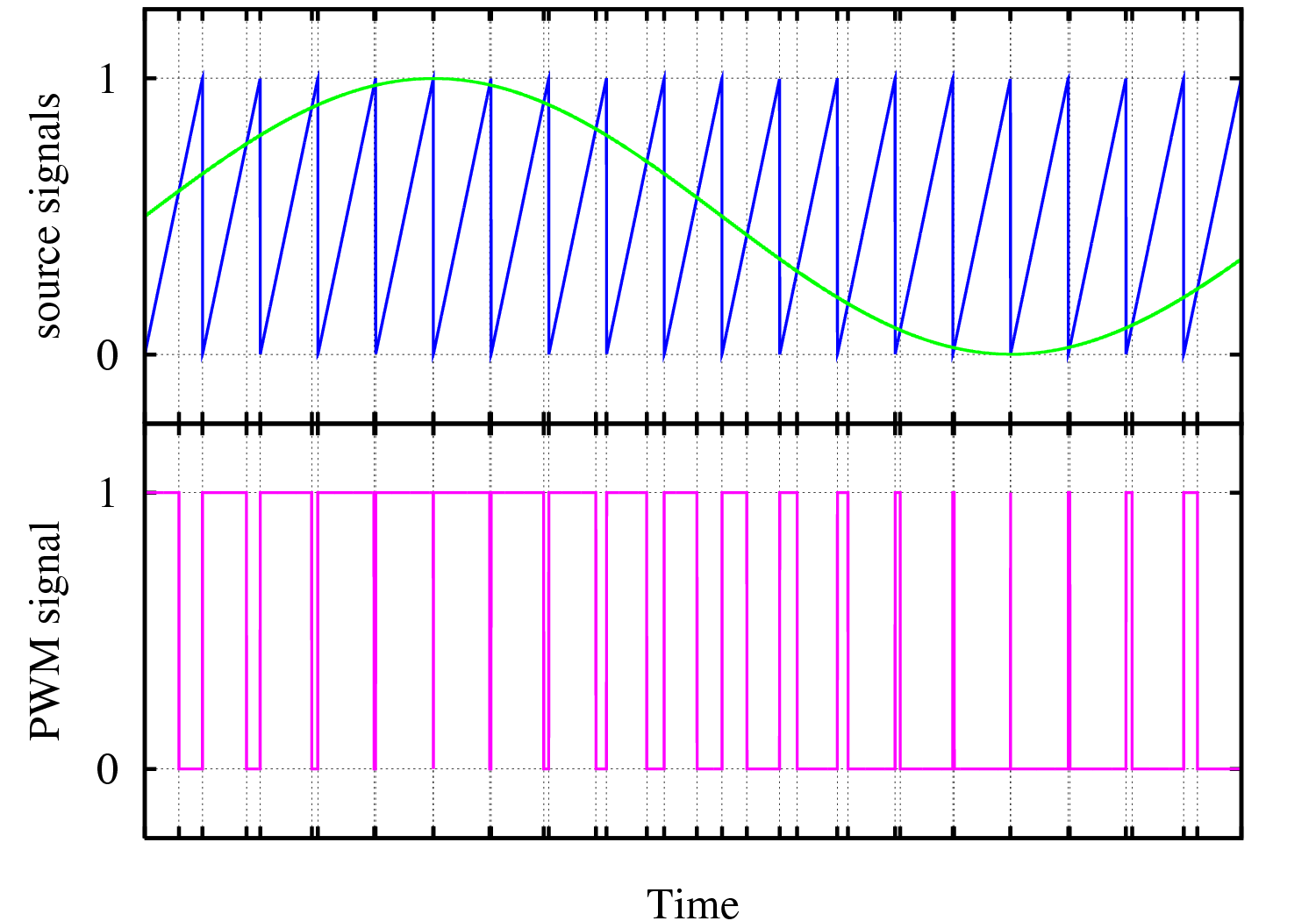

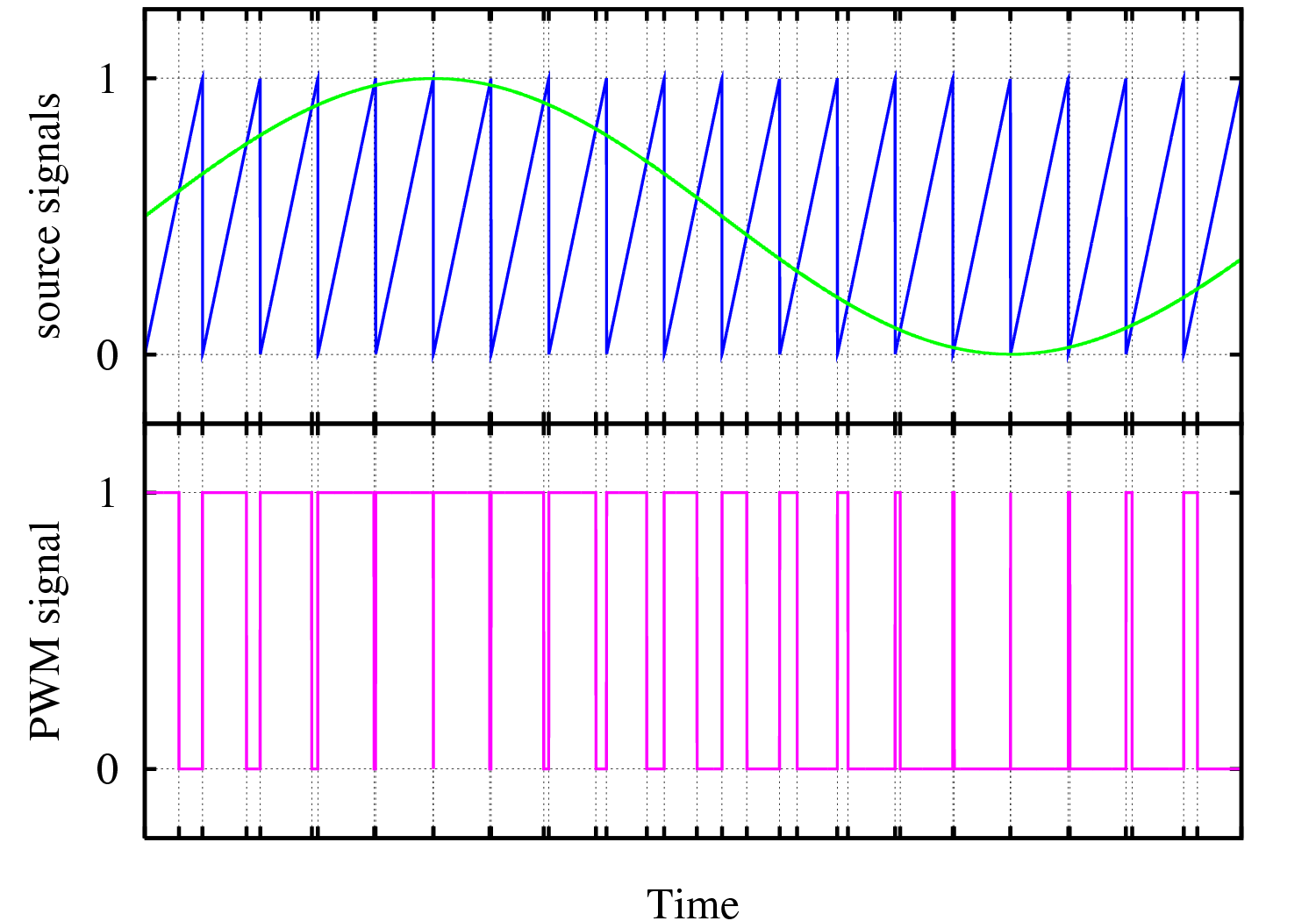

Although space vector pulse-width modulation

Pulse-width modulation (PWM), also known as pulse-duration modulation (PDM) or pulse-length modulation (PLM), is any method of representing a signal as a rectangular wave with a varying duty cycle (and for some methods also a varying peri ...

(SVPWM) is becoming increasingly popular, sinusoidal PWM (SPWM) is the most straightforward method used to vary drives' motor voltage (or current) and frequency. With SPWM control (see Fig. 1), quasi-sinusoidal, variable-pulse-width output is constructed from intersections of a saw-toothed carrier signal

In telecommunications, a carrier wave, carrier signal, or just carrier, is a periodic waveform (usually sinusoidal) that conveys information through a process called ''modulation''. One or more of the wave's properties, such as amplitude or frequ ...

with a modulating sinusoidal signal which is variable in operating frequency as well as in voltage (or current).Bose (2006), p. 183

Operation of the motors above rated nameplate speed (base speed) is possible, but is limited to conditions that do not require more power than the nameplate rating of the motor. This is sometimes called "field weakening" and, for AC motors, means operating at less than rated V/Hz and above rated nameplate speed. Permanent magnet

A magnet is a material or object that produces a magnetic field. This magnetic field is invisible but is responsible for the most notable property of a magnet: a force that pulls on other ferromagnetic materials, such as iron, steel, nickel, c ...

synchronous motors have quite limited field-weakening speed range due to the constant magnet flux linkage. Wound-rotor synchronous motors and induction motors have much wider speed range. For example, a 100 HP, 460 V, 60 Hz, 1775 RPM

Revolutions per minute (abbreviated rpm, RPM, rev/min, r/min, or r⋅min−1) is a unit of rotational speed (or rotational frequency) for rotating machines.

One revolution per minute is equivalent to hertz.

Standards

ISO 80000-3:2019 def ...

(4-pole) induction motor supplied with 460 V, 75 Hz (6.134 V/Hz), would be limited to 60/75 = 80% torque at 125% speed (2218.75 RPM) = 100% power. At higher speeds, the induction motor torque has to be limited further due to the lowering of the breakaway torque of the motor. Thus, rated power can be typically produced only up to 130–150% of the rated nameplate speed. Wound-rotor synchronous motors can be run at even higher speeds. In rolling mill drives, often 200–300% of the base speed is used. The mechanical strength of the rotor limits the maximum speed of the motor.

An embedded

An embedded microprocessor

A microprocessor is a computer processor (computing), processor for which the data processing logic and control is included on a single integrated circuit (IC), or a small number of ICs. The microprocessor contains the arithmetic, logic, a ...

governs the overall operation of the VFD controller. Basic programming of the microprocessor is provided as user-inaccessible firmware

In computing

Computing is any goal-oriented activity requiring, benefiting from, or creating computer, computing machinery. It includes the study and experimentation of algorithmic processes, and the development of both computer hardware, h ...

. User programming of display, variable, and function block parameters is provided to control, protect, and monitor the VFD, motor, and driven equipment.

The basic drive controller can be configured to selectively include such optional power components and accessories as follows:

* Connected upstream of converter – circuit breaker

A circuit breaker is an electrical safety device designed to protect an Electrical network, electrical circuit from damage caused by current in excess of that which the equipment can safely carry (overcurrent). Its basic function is to interr ...

or fuses, isolation contactor, EMC filter, line reactor, passive filter

* Connected to DC link – braking chopper, braking resistor

A resistor is a passive two-terminal electronic component that implements electrical resistance as a circuit element. In electronic circuits, resistors are used to reduce current flow, adjust signal levels, to divide voltages, bias active e ...

* Connected downstream of inverter—output reactor, sine wave filter, dV/dt filter.

Operator interface

The operator interface provides a means for an operator to start and stop the motor and adjust the operating speed. The VFD may also be controlled by aprogrammable logic controller

A programmable logic controller (PLC) or programmable controller is an industrial computer that has been ruggedized and adapted for the control of manufacturing processes, such as assembly lines, machines, robotic devices, or any activity that ...

through Modbus

Modbus (or MODBUS) is a client/server data communications protocol in the application layer. It was originally designed for use with programmable logic controllers (PLCs), but has become a ''de facto'' standardization, standard communication pr ...

or another similar interface. Additional operator control functions might include reversing, and switching between manual speed adjustment and automatic control from an external process control

Industrial process control (IPC) or simply process control is a system used in modern manufacturing which uses the principles of control theory and physical industrial control systems to monitor, control and optimize continuous Industrial processe ...

signal. The operator interface often includes an alphanumeric

Alphanumericals or alphanumeric characters are any collection of number characters and letters in a certain language. Sometimes such characters may be mistaken one for the other.

Merriam-Webster suggests that the term "alphanumeric" may often ...

display or indication lights and meters to provide information about the operation of the drive. An operator interface keypad and display unit is often provided on the front of the VFD controller as shown in the photograph above. The keypad display can often be cable-connected and mounted a short distance from the VFD controller. Most are also provided with input and output

In computing, input/output (I/O, i/o, or informally io or IO) is the communication between an information processing system, such as a computer, and the outside world, such as another computer system, peripherals, or a human operator. Inputs ar ...

(I/O) terminals for connecting push buttons, switches, and other operator interface devices or control signals. A serial communications

In telecommunication and data transmission, serial communication is the process of sending data one bit at a time, sequentially, over a communication channel or computer bus. This is in contrast to parallel communication, where several bits ar ...

port

A port is a maritime facility comprising one or more wharves or loading areas, where ships load and discharge cargo and passengers. Although usually situated on a sea coast or estuary, ports can also be found far inland, such as Hamburg, Manch ...

is also often available to allow the VFD to be configured, adjusted, monitored, and controlled using a computer.

Speed control

There are two main ways to control the speed of a VFD; networked or hardwired. Networked involves transmitting the intended speed over a communication protocol such asModbus

Modbus (or MODBUS) is a client/server data communications protocol in the application layer. It was originally designed for use with programmable logic controllers (PLCs), but has become a ''de facto'' standardization, standard communication pr ...

, Modbus

Modbus (or MODBUS) is a client/server data communications protocol in the application layer. It was originally designed for use with programmable logic controllers (PLCs), but has become a ''de facto'' standardization, standard communication pr ...

/ TCP, EtherNet/IP

EtherNet/IP (IP = Industrial Protocol) is an industrial network protocol that adapts the Common Industrial Protocol (CIP) to standard Ethernet. EtherNet/IP is one of the leading industrial protocols in the United States and is widely used in a r ...

, or via a keypad using Display Serial Interface while hardwired involves a pure electrical means of communication. Typical means of hardwired communication are: 4-20mA, 0-10VDC, or using the internal 24VDC power supply with a potentiometer. Speed control can be performed either remotely or locally, depending on the application's requirements. Remote control instructs the VFD to ignore speed commands from the keypad while local control instructs the VFD to ignore external control and only abide by the keypad.

Programming a VFD

Depending on the model a VFD's operating parameters can be programmed via: dedicated programming software, internal keypad, external keypad, or SD card. VFDs will often block out most programming changes while running. Typical parameters that need to be set include: motor nameplate information, speed reference source, on/off control source and braking control. It is also common for VFDs to provide debugging information such as fault codes and the states of the input signals.Starting and software behavior

Most VFDs allow auto-starting, which will drive the output to a designated frequency after a power cycle, after a fault has been cleared, or after the emergency stop signal has been restored (generally emergency stops are active low logic). One popular way to control a VFD is to enable auto-start and place L1, L2, and L3 into a contactor. Powering on the contactor thus turns on the drive and has it output to a designated speed. Depending on the sophistication of the drive multiple auto-starting behavior can be developed e.g. the drive auto-starts on power up but does not auto-start from clearing an emergency stop until a reset has been cycled.Drive operation

Referring to the accompanying chart, drive applications can be categorized as single-quadrant, two-quadrant, or four-quadrant; the chart's four quadrants are defined as follows:Basics of AC Drives, pp. Hardware – Part 1: slides 9–10 of 11 * Quadrant I – Driving or motoring, forward accelerating quadrant with positive speed and torque * Quadrant II – Generating or braking, forward braking- decelerating quadrant with positive speed and negative torque * Quadrant III – Driving or motoring, reverse accelerating quadrant with negative speed and torque * Quadrant IV – Generating or braking, reverse braking-decelerating quadrant with negative speed and positive torque. Most applications involve single-quadrant loads operating in quadrant I, such as in variable-torque (e.g. centrifugal pumps or fans) and certain constant-torque (e.g. extruders) loads. Certain applications involve two-quadrant loads operating in quadrant I and II where the speed is positive but the torque changes polarity as in case of a fan decelerating faster than natural mechanical losses. Some sources define two-quadrant drives as loads operating in quadrants I and III where the speed and torque is same (positive or negative) polarity in both directions. Certain high-performance applications involve four-quadrant loads (Quadrants I to IV) where the speed and torque can be in any direction such as in hoists, elevators, and hilly conveyors. Regeneration can occur only in the drive's DC link bus when inverter voltage is smaller in magnitude than the motor back- EMF and inverter voltage and back-EMF are the same polarity. In starting a motor, a VFD initially applies a low frequency and voltage, thus avoiding high inrush-current associated with direct-on-line starting. After the start of the VFD, the applied frequency and voltage are increased at a controlled rate or ramped up to accelerate the load. This starting method typically allows a motor to develop 150% of its rated torque while the VFD is drawing less than 50% of its rated current from the mains in the low-speed range. A VFD can be adjusted to produce a steady 150% starting torque from standstill right up to full speed. However, motor cooling deteriorates and can result in overheating as speed decreases such that prolonged low-speed operation with significant torque is not usually possible without separately motorized fan ventilation. With a VFD, the stopping sequence is just the opposite as the starting sequence. The frequency and voltage applied to the motor are ramped down at a controlled rate. When the frequency approaches zero, the motor is shut off. A small amount of braking torque is available to help decelerate the load a little faster than it would stop if the motor were simply switched off and allowed to coast. Additional braking torque can be obtained by adding a braking circuit (resistor controlled by a transistor) to dissipate the braking energy. With a four-quadrant rectifier (active front-end), the VFD is able to brake the load by applying a reverse torque and injecting the energy back to the AC line.Benefits

Energy savings

Many fixed-speed motor load applications that are supplied direct from AC line power can save energy when they are operated at variable speed by means of VFD. Such energy cost savings are especially pronounced in variable-torque centrifugal fan and pump applications, where the load's torque and power vary with the square andcube

A cube or regular hexahedron is a three-dimensional space, three-dimensional solid object in geometry, which is bounded by six congruent square (geometry), square faces, a type of polyhedron. It has twelve congruent edges and eight vertices. It i ...

, respectively, of the speed. This change gives a large power reduction compared to fixed-speed operation for a relatively small reduction in speed. For example, at 63% speed a motor load consumes only 25% of its full-speed power. This reduction is in accordance with affinity laws that define the relationship between various centrifugal load variables.

In the United States, an estimated 60–65% of electrical energy is used to supply motors, 75% of which are variable-torque fan, pump, and compressor loads. Eighteen percent of the energy used in the 40 million motors in the U.S. could be saved by efficient energy improvement technologies such as VFDs.

Only about 3% of the total installed base of AC motors are provided with AC drives. However, it is estimated that drive technology is adopted in as many as 30–40% of all newly installed motors.

An energy consumption breakdown of the global population of AC motor installations is as shown in the following table:

Control performance

AC drives are used to bring about process and quality improvements in industrial and commercial applications' acceleration, flow, monitoring, pressure, speed, temperature, tension, and torque. Fixed-speed loads subject the motor to a high starting torque and to current surges that are up to eight times the full-load current. AC drives instead gradually ramp the motor up to operating speed to lessen mechanical and electrical stress, reducing maintenance and repair costs, and extending the life of the motor and the driven equipment. Variable-speed drives can also run a motor in specialized patterns to further minimize mechanical and electrical stress. For example, an S-curve pattern can be applied to a conveyor application for smoother deceleration and acceleration control, which reduces the backlash that can occur when a conveyor is accelerating or decelerating. Performance factors tending to favor the use of DC drives over AC drives include such requirements as continuous operation at low speed, four-quadrant operation with regeneration, frequent acceleration and deceleration routines, and need for the motor to be protected for a hazardous area. The following table compares AC and DC drives according to certain key parameters: ^ High-frequency injectionVFD types and ratings

Generic topologies

AC drives can be classified according to the following generic topologies:

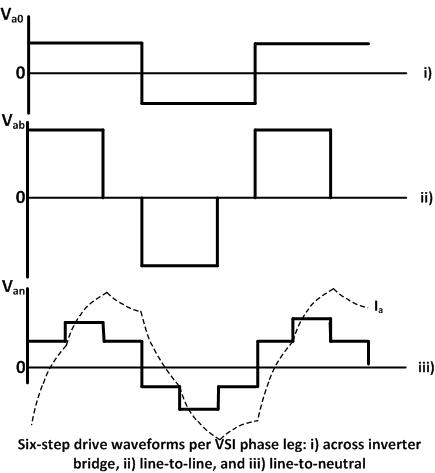

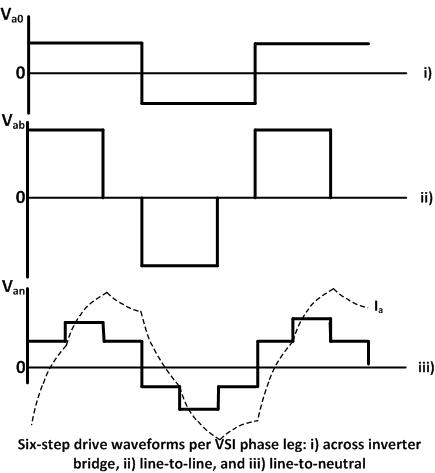

* Voltage-source inverter (VSI) drive topologies (see image): In a VSI drive, the DC output of the

AC drives can be classified according to the following generic topologies:

* Voltage-source inverter (VSI) drive topologies (see image): In a VSI drive, the DC output of the diode

A diode is a two-Terminal (electronics), terminal electronic component that conducts electric current primarily in One-way traffic, one direction (asymmetric electrical conductance, conductance). It has low (ideally zero) Electrical resistance ...

-bridge converter stores energy in the capacitor bus to supply stiff voltage input to the inverter. The vast majority of drives are VSI type with PWM voltage output.

* Current-source inverter (CSI) drive topologies (see image): In a CSI drive, the DC output of the SCR-bridge converter stores energy in series-Inductor

An inductor, also called a coil, choke, or reactor, is a Passivity (engineering), passive two-terminal electronic component, electrical component that stores energy in a magnetic field when an electric current flows through it. An inductor typic ...

connection to supply stiff current input to the inverter. CSI drives can be operated with either PWM or six-step waveform output.

* Six-step inverter drive topologies (see image): Now largely obsolete, six-step drives can be either VSI or CSI type and are also referred to as variable-voltage inverter drives, pulse-amplitude modulation

Pulse-amplitude modulation (PAM) is a form of signal modulation in which the message information is encoded in the amplitude of a pulse train interrupting the carrier frequency. Demodulation is performed by detecting the amplitude level of th ...

(PAM) drives, square-wave drives or DC chopper inverter drives. In a six-step drive, the DC output of the SCR-bridge converter is smoothed via capacitor bus and series-reactor connection to supply via Darlington Pair or IGBT inverter quasi-sinusoidal, six-step voltage or current input to an induction motor.

* Load commutated inverter (LCI) drive topologies: In an LCI drive (a special CSI case), the DC output of the SCR-bridge converter stores energy via DC link inductor circuit to supply stiff quasi-sinusoidal six-step current output of a second SCR-bridge's inverter and an over-excited synchronous machine. Low-cost SCR-thyristor-based LCI fed synchronous motor drives are often used in high-power low-dynamic-performance fan, pump and compressor applications rated up to 100 MW. 480 pages, copyright 2017.

* Cycloconverter or matrix converter (MC) topologies (see image): Cycloconverter

A cycloconverter (CCV) or a cycloinverter converts a constant amplitude, constant frequency Alternating current, AC waveform to another AC waveform of a lower frequency by synthesizing the output waveform from segments of the AC supply without an ...

s and MCs are AC–AC converters that have no intermediate DC link for energy storage. A cycloconverter operates as a three-phase current source via three anti-parallel-connected SCR-bridges in six-pulse configuration, each cycloconverter phase acting selectively to convert fixed line-frequency AC voltage to an alternating voltage at a variable load frequency. MC drives are IGBT-based.

* Doubly-fed slip recovery system topologies: A doubly-fed slip recovery system feeds rectified slip power to a smoothing reactor to supply power to the AC supply network

A supply network is a pattern of temporal and spatial processes carried out at facility nodes and over distribution links, which adds value for customers through the manufacturing and delivery of products. It comprises the general state of busi ...

via an inverter, the speed of the motor being controlled by adjusting the DC current.

Control platforms

Most drives use one or more of the following control platforms: * Scalar control *Vector control

Vector control is any method to limit or eradicate the mammals, birds, insects or other arthropods (here collectively called " vectors") which transmit disease pathogens. The most frequent type of vector control is mosquito control using a varie ...

(VC)

** Field-oriented control (FOC)

* Direct torque control (DTC)

Load torque and power characteristics

Variable-frequency drives are also categorized by the following load torque and power characteristics: * Variable torque, such as in centrifugal fan, pump, and blower applications * Constant torque, such as in conveyor and positive-displacement pump applications * Constant power, such as in machine tool and traction applications.Available power ratings

VFDs are available with voltage and current ratings covering a wide range of single-phase and multi-phase AC motors. Low-voltage (LV) drives are designed to operate at output voltages equal to or less than 690 V. While motor-application LV drives are available in ratings of up to the order of 5 or 6 MW, economic considerations typically favor medium-voltage (MV) drives with much lower power ratings. Different MV drive topologies (see Table 2) are configured in accordance with the voltage/current-combination ratings used in different drive controllers' switching devices such that any given voltage rating is greater than or equal to one to the following standard nominal motor voltage ratings: generally either .16 kV (60 Hz) or .6 kV (50 Hz), with one thyristor manufacturer rated for up to 12 kV switching. In some applications a step-uptransformer

In electrical engineering, a transformer is a passive component that transfers electrical energy from one electrical circuit to another circuit, or multiple Electrical network, circuits. A varying current in any coil of the transformer produces ...

is placed between a LV drive and a MV motor load. MV drives are typically rated for motor applications greater than between about . MV drives have historically required considerably more application design effort than required for LV drive applications. The power rating of MV drives can reach , a range of different drive topologies being involved for different rating, performance, power quality, and reliability requirements.

Drives by machines and detailed topologies

It is lastly useful to relate VFDs in terms of the following two classifications: * In terms of various AC machines as shown in Table 1 below * In terms of various detailed AC–AC converter topologies shown in Tables 2 and 3 below.Application considerations

AC line harmonics

Note of clarification:. Whileharmonics

In physics, acoustics, and telecommunications, a harmonic is a sinusoidal wave with a frequency that is a positive integer multiple of the ''fundamental frequency'' of a periodic signal. The fundamental frequency is also called the ''1st harm ...

in the PWM output can easily be filtered by carrier-frequency-related filter inductance to supply near-sinusoidal currents to the motor load, the VFD's diode-bridge rectifier converts AC line voltage to DC voltage output by super-imposing non-linear

In mathematics and science, a nonlinear system (or a non-linear system) is a system in which the change of the output is not proportional to the change of the input. Nonlinear problems are of interest to engineers, biologists, physicists, mathe ...

half-phase current pulses thus creating harmonic current distortion, and hence voltage distortion, of the AC line input. When the VFD loads are relatively small in comparison to the large, stiff power system available from the electric power company, the effects of VFD harmonic distortion of the AC grid can often be within acceptable limits. Furthermore, in low-voltage networks, harmonics caused by single-phase equipment such as computers and TVs are partially cancelled by three-phase diode bridge harmonics because their 5th and 7th harmonics are in counterphase. However, when the proportion of VFD and other non-linear load compared to total load or of non-linear load compared to the stiffness at the AC power supply, or both, is relatively large enough, the load can have a negative impact on the AC power waveform available to other power company customers in the same grid.

When the power company's voltage becomes distorted due to harmonics, losses in other loads such as normal fixed-speed AC motors are increased. This condition may lead to overheating and shorter operating life. Also, substation transformers and compensation capacitors are affected negatively. In particular, capacitors can cause resonance conditions that can unacceptably magnify harmonic levels. To limit the voltage distortion, owners of VFD load may be required to install filtering equipment to reduce harmonic distortion below acceptable limits. Alternatively, the utility may adopt a solution by installing filtering equipment of its own at substations affected by the large amount of VFD equipment being used. In high-power installations, harmonic distortion can be reduced by supplying multi-pulse rectifier-bridge VFDs from transformers with multiple phase-shifted windings.

It is also possible to replace the standard diode-bridge rectifier with a bi-directional IGBT switching device bridge mirroring the standard inverter which uses IGBT switching device output to the motor. Such rectifiers are referred to by various designations including active infeed converter (AIC), active rectifier, IGBT supply unit (ISU), active front end (AFE), or four-quadrant operation. With PWM control and a suitable input reactor, an AFE's AC line current waveform can be nearly sinusoidal. AFE inherently regenerates energy in four-quadrant mode from the DC side to the AC grid. Thus, no braking resistor is needed, and the efficiency of the drive is improved if the drive is frequently required to brake the motor.

Two other harmonics mitigation techniques exploit use of passive or active filters connected to a common bus with at least one VFD branch load on the bus. Passive filters involve the design of one or more low-pass

A low-pass filter is a filter that passes signals with a frequency lower than a selected cutoff frequency and attenuates signals with frequencies higher than the cutoff frequency. The exact frequency response of the filter depends on the filt ...

LC filter traps, each trap being tuned as required to a harmonic frequency (5th, 7th, 11th, 13th, . . . kq+/-1, where k=integer, q=pulse number of converter).

It is very common practice for power companies or their customers to impose harmonic distortion limits based on IEC or IEEE

The Institute of Electrical and Electronics Engineers (IEEE) is an American 501(c)(3) organization, 501(c)(3) public charity professional organization for electrical engineering, electronics engineering, and other related disciplines.

The IEEE ...

standards. For example, IEEE Standard 519 limits at the customer's connection point call for the maximum individual frequency voltage harmonic to be no more than 3% of the fundamental and call for the voltage total harmonic distortion (THD) to be no more than 5% for a general AC power supply system.

Switching frequency foldback

One drive uses a default switching frequency setting of 4 kHz. Reducing the drive's switching frequency (the carrier-frequency) reduces the heat generated by the IGBTs. A carrier frequency of at least ten times the desired output frequency is used to establish the PWM switching intervals. A carrier frequency in the range of 2,000 to 16,000 Hz is common for LV ow voltage, under 600 Volts ACVFDs. A higher carrier frequency produces a better sine wave approximation but incurs higher in the IGBT, decreasing the overall power conversion efficiency.Noise smoothing

Some drives have a noise smoothing feature that can be turned on to introduce a random variation to the switching frequency. This distributes the acoustic noise over a range of frequencies to lower the peak noise intensity.Long-lead effects

The carrier-frequency pulsed output voltage of a PWM VFD causes rapid rise times in these pulses, the transmission line effects of which must be considered. Since the transmission-line impedance of the cable and motor are different, pulses tend to reflect back from the motor terminals into the cable. The resulting reflections can produce overvoltages equal to twice the DC bus voltage or up to 3.1 times the rated line voltage for long cable runs, putting high stress on the cable and motor windings, and eventual insulation failure. Insulation standards for three-phase motors rated 230 V or less adequately protect against such long-lead overvoltages. On 460 V or 575 V systems and inverters with 3rd-generation 0.1-microsecond-rise-time IGBTs, the maximum recommended cable distance between VFD and motor is about 50 m or 150 feet. For emerging SiC MOSFET powered drives, significant overvoltages have been observed at cable lengths as short as 3 meters. Solutions to overvoltages caused by long lead lengths include minimizing cable length, lowering carrier frequency, installing dV/dt filters, using inverter-duty-rated motors (that are rated 600 V to withstand pulse trains with rise time less than or equal to 0.1 microsecond, of 1,600 V peak magnitude), and installing LCR low-pass sine wave filters. Selection of optimum PWM carrier frequency for AC drives involves balancing noise, heat, motor insulation stress, common-mode voltage-induced motor bearing current damage, smooth motor operation, and other factors. Further harmonics attenuation can be obtained by using an LCR low-pass sine wave filter or dV/dt filter.Motor bearing currents

Carrier frequencies above 5 kHz are likely to cause bearing damage unless protective measures are taken. PWM drives are inherently associated with high-frequency common-mode voltages and currents which may cause trouble with motor bearings. When these high-frequency voltages find a path to earth through a bearing, transfer of metal orelectrical discharge machining

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal

fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). Material is ...

(EDM) sparking occurs between the bearing's ball and the bearing's race. Over time, EDM-based sparking causes erosion in the bearing race that can be seen as a fluting pattern. In large motors, the stray capacitance of the windings provides paths for high-frequency currents that pass through the motor shaft ends, leading to a circulating type of bearing current. Poor grounding of motor stators can lead to shaft-to-ground bearing currents. Small motors with poorly grounded driven equipment are susceptible to high-frequency bearing currents.

Prevention of high-frequency bearing current damage uses three approaches: good cabling and grounding practices, interruption of bearing currents, and filtering or damping of common-mode currents through common mode chokes. Good cabling and grounding practices can include use of shielded, symmetrical-geometry power cable to supply the motor, installation of shaft grounding brushes, and conductive bearing grease. Bearing currents can be interrupted by installation of insulated bearings and specially designed electrostatic-shielded induction motors. Filtering and damping high-frequency bearing can be done though inserting soft magnetic cores over the three phases giving a high frequency impedance against the common mode or motor bearing currents. Another approach is to use instead of standard 2-level inverter drives, using either 3-level inverter drives or matrix converters.

Dynamic braking

Torque generated by the drive causes the induction motor to run at synchronous speed less the slip. If the load drives the motor faster than synchronous speed, the motor acts as a generator, converting mechanical power back to electrical power. This power is returned to the drive's DC link element (capacitor or reactor). A DC-link-connected electronic power switch or braking DC chopper controls dissipation of this power as heat in a set of resistors. Cooling fans may be used to prevent resistor overheating. Dynamic braking wastes braking energy by transforming it to heat. By contrast, regenerative drives recover braking energy by injecting this energy into the AC line. The capital cost of regenerative drives is, however, relatively high.Regenerative drives

Regenerative AC drives have the capacity to recover the braking energy of a load moving faster than the designated motor speed (an ''overhauling'' load) and return it to the power system.

Cycloconverter, Scherbius, matrix, CSI, and LCI drives inherently allow return of energy from the load to the line, while voltage-source inverters require an additional converter to return energy to the supply.

Regeneration is useful in VFDs only where the value of the recovered energy is large compared to the extra cost of a regenerative system, and if the system requires frequent braking and starting. Regenerative VFDs are widely used where speed control of overhauling loads is required.Campbell, pp. 70–190

Some examples:

* Conveyor belt drives for manufacturing, which stop every few minutes. While stopped, parts are assembled; once that is done, the belt moves on.

* A crane, where the hoist motor stops and reverses frequently, and braking is required to slow the load during lowering.

* Plug-in and hybrid electric vehicles of all types (see image and Hybrid Synergy Drive).

Regenerative AC drives have the capacity to recover the braking energy of a load moving faster than the designated motor speed (an ''overhauling'' load) and return it to the power system.

Cycloconverter, Scherbius, matrix, CSI, and LCI drives inherently allow return of energy from the load to the line, while voltage-source inverters require an additional converter to return energy to the supply.

Regeneration is useful in VFDs only where the value of the recovered energy is large compared to the extra cost of a regenerative system, and if the system requires frequent braking and starting. Regenerative VFDs are widely used where speed control of overhauling loads is required.Campbell, pp. 70–190

Some examples:

* Conveyor belt drives for manufacturing, which stop every few minutes. While stopped, parts are assembled; once that is done, the belt moves on.

* A crane, where the hoist motor stops and reverses frequently, and braking is required to slow the load during lowering.

* Plug-in and hybrid electric vehicles of all types (see image and Hybrid Synergy Drive).

See also

* Adjustable-speed drive * AC-to-AC converter *Frequency changer

A frequency changer or frequency converter is Electronics, electronic or electromechanical equipment that converts alternating current (Alternating current, AC) of one frequency to alternating current of another frequency. The equipment may also ...

* Vector control (motor)

Vector control, also called field-oriented control (FOC), is a variable-frequency drive (VFD) control method in which the stator currents of a three-phase AC motor are identified as two orthogonal components that can be visualized with a vector. On ...

Notes

References

{{good article Electric motor control Electric power systems components Frequency changers Mechanical power transmission Mechanical power control Electrical power control