Recycled Plastic on:

[Wikipedia]

[Google]

[Amazon]

Plastic recycling is the processing of

"How Big Oil Misled The Public Into Believing Plastic Would Be Recycled"

/ref>PBS, Frontline, 31 March 2020

"Plastics Industry Insiders Reveal the Truth About Recycling"

/ref> This has resulted in occasions where plastic waste dropped into recycling bins has not been recycled, and been treated as general waste.

As regulations expanded, the plastics industry responded with lobbying to preserve their business interests. In the U.S., the 1970 Resource Recovery Act directed the nation towards recycling and energy recovery. More than a thousand attempts to pass legislation to ban or tax packaging, including plastics, came by 1976. The plastics industry responded by lobbying for plastic to be recycled. A $50 million per year campaign was run by organisations such as Keep America Beautiful with the message that plastic could and would be recycled, as well as lobbying for the establishment of curbside recycling.

However, plastic could not be economically recycled using the technology of the time. For example, an April 1973 report written by industry scientists stated that, "There is no recovery from obsolete products" and that, "A degradation of resin properties and performance occurs during the initial fabrication, through aging, and in any reclamation process." The report concluded that sorting the plastic is "infeasible". Contemporary scientific reports highlighted numerous technical barriers.

Globally, plastic waste was almost entirely disposed of via

As regulations expanded, the plastics industry responded with lobbying to preserve their business interests. In the U.S., the 1970 Resource Recovery Act directed the nation towards recycling and energy recovery. More than a thousand attempts to pass legislation to ban or tax packaging, including plastics, came by 1976. The plastics industry responded by lobbying for plastic to be recycled. A $50 million per year campaign was run by organisations such as Keep America Beautiful with the message that plastic could and would be recycled, as well as lobbying for the establishment of curbside recycling.

However, plastic could not be economically recycled using the technology of the time. For example, an April 1973 report written by industry scientists stated that, "There is no recovery from obsolete products" and that, "A degradation of resin properties and performance occurs during the initial fabrication, through aging, and in any reclamation process." The report concluded that sorting the plastic is "infeasible". Contemporary scientific reports highlighted numerous technical barriers.

Globally, plastic waste was almost entirely disposed of via

The total amount of plastic ever produced worldwide, until 2015, is estimated to be 8.3 billion tonnes (Bt). Approximately 6.3 Bt of this was discarded as waste, of which around 79% accumulated in landfills or the natural environment, 12% was incinerated, and 9% was recycled - only ~1% of all plastic has been recycled more than once. More recently, as of 2017, still only 9% of the 9 Bt of plastic produced was recycled.

By 2015 global production had reached some 381 million tonnes (Mt) per year. The recycling rate that year was 19.5%, while 25.5% was incinerated and the remaining 55% disposed of, largely to landfill. These rates lag behind those of other recyclables, such as paper, metal and glass. Although the percentage of recycled or incinerated material is increasing each year, the tonnage of waste left-over also continues to rise. Production could reach ~800 Mt per year by 2040, although implementing all feasible interventions could reduce plastic pollution by 40% from 2016 rates.

Recycling rates vary among types of plastic. Several types are in common use, each with distinct chemical and physical properties. This affects sorting and reprocessing costs; which affects the value and market size for recovered materials.

The total amount of plastic ever produced worldwide, until 2015, is estimated to be 8.3 billion tonnes (Bt). Approximately 6.3 Bt of this was discarded as waste, of which around 79% accumulated in landfills or the natural environment, 12% was incinerated, and 9% was recycled - only ~1% of all plastic has been recycled more than once. More recently, as of 2017, still only 9% of the 9 Bt of plastic produced was recycled.

By 2015 global production had reached some 381 million tonnes (Mt) per year. The recycling rate that year was 19.5%, while 25.5% was incinerated and the remaining 55% disposed of, largely to landfill. These rates lag behind those of other recyclables, such as paper, metal and glass. Although the percentage of recycled or incinerated material is increasing each year, the tonnage of waste left-over also continues to rise. Production could reach ~800 Mt per year by 2040, although implementing all feasible interventions could reduce plastic pollution by 40% from 2016 rates.

Recycling rates vary among types of plastic. Several types are in common use, each with distinct chemical and physical properties. This affects sorting and reprocessing costs; which affects the value and market size for recovered materials.

Commission Decision (97/129/EC)

establishing the ID system for packaging materials pursuant to European Parliament & Council Directive 94/62/EC RICs are based on the

Recycling begins with the collection and sorting of waste. Curbside collection operates in many countries. Waste is sent to a materials recovery facility or MBT plant where the plastic is separated, cleaned and sorted for sale. Unsuitable materials are sent to a landfill or incinerator. These operations account for a large proportion of the financial and energy costs associated with recycling.

Sorting plastic is more complicated than other recyclable materials because it comes in a greater range of forms. For example, glass is separated into three streams (clear, green and amber), metals are usually either steel or aluminum and can be separated using magnets or eddy current separators, and paper is usually sorted into a single stream.

Six types of commodity polymer account for about 75% of plastics waste, with the rest comprising a myriad of polymer types, including polyurethanes and

Recycling begins with the collection and sorting of waste. Curbside collection operates in many countries. Waste is sent to a materials recovery facility or MBT plant where the plastic is separated, cleaned and sorted for sale. Unsuitable materials are sent to a landfill or incinerator. These operations account for a large proportion of the financial and energy costs associated with recycling.

Sorting plastic is more complicated than other recyclable materials because it comes in a greater range of forms. For example, glass is separated into three streams (clear, green and amber), metals are usually either steel or aluminum and can be separated using magnets or eddy current separators, and paper is usually sorted into a single stream.

Six types of commodity polymer account for about 75% of plastics waste, with the rest comprising a myriad of polymer types, including polyurethanes and

This approach is largely automated and involves various sensors linked to a computer, which analyses items and directs them into appropriate chutes or belts. Near-infrared spectroscopy can be used to distinguish polymer types, although black/strongly-coloured plastics, as well as composite materials like plastic-coated paper and multilayered packaging, which can give misleading readings.

This approach is largely automated and involves various sensors linked to a computer, which analyses items and directs them into appropriate chutes or belts. Near-infrared spectroscopy can be used to distinguish polymer types, although black/strongly-coloured plastics, as well as composite materials like plastic-coated paper and multilayered packaging, which can give misleading readings.

The majority of plastic waste is made of thermosoftening polymers, which can be re-melted and reformed into new items via mechanical recycling. Globally, this is by far the most common form of recycling and in many countries it is the only type practised. It is the simplest and most economical technique. It has a lower

The majority of plastic waste is made of thermosoftening polymers, which can be re-melted and reformed into new items via mechanical recycling. Globally, this is by far the most common form of recycling and in many countries it is the only type practised. It is the simplest and most economical technique. It has a lower

plastic waste

Plastic pollution is the accumulation of plastic objects and particles (e.g. plastic bottles, bags and microbeads) in the Earth's environment that adversely affects humans, wildlife and their habitat. Plastics that act as pollutants are cate ...

into other products. Recycling can reduce dependence on landfills, conserve resources and protect the environment from plastic pollution

Plastic pollution is the accumulation of plastic objects and particles (e.g. plastic bottles, bags and microbeads) in the Earth's environment that adversely affects humans, wildlife and their habitat. Plastics that act as pollutants are catego ...

and greenhouse gas

Greenhouse gases (GHGs) are the gases in the atmosphere that raise the surface temperature of planets such as the Earth. Unlike other gases, greenhouse gases absorb the radiations that a planet emits, resulting in the greenhouse effect. T ...

emissions. Recycling rates lag behind those of other recoverable materials, such as aluminium

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has ...

, glass

Glass is an amorphous (non-crystalline solid, non-crystalline) solid. Because it is often transparency and translucency, transparent and chemically inert, glass has found widespread practical, technological, and decorative use in window pane ...

and paper

Paper is a thin sheet material produced by mechanically or chemically processing cellulose fibres derived from wood, Textile, rags, poaceae, grasses, Feces#Other uses, herbivore dung, or other vegetable sources in water. Once the water is dra ...

. From the start of plastic production through to 2015, the world produced around 6.3 billion tonnes of plastic waste, only 9% of which has been recycled and only ~1% has been recycled more than once. Of the remaining waste, 12% was incinerated and 79% was either sent to landfills or lost to the environment as pollution.

Almost all plastic is non- biodegradable and without recycling, spreads across the environment where it causes plastic pollution

Plastic pollution is the accumulation of plastic objects and particles (e.g. plastic bottles, bags and microbeads) in the Earth's environment that adversely affects humans, wildlife and their habitat. Plastics that act as pollutants are catego ...

. For example, as of 2015, approximately 8 million tonnes of waste plastic enters the oceans annually, damaging oceanic ecosystems and forming ocean garbage patches.

Almost all recycling is mechanical and involves the melting and reforming of plastic into other items. This can cause polymer degradation at the molecular level, and requires that waste be sorted by colour and polymer

A polymer () is a chemical substance, substance or material that consists of very large molecules, or macromolecules, that are constituted by many repeat unit, repeating subunits derived from one or more species of monomers. Due to their br ...

type before processing, which is often complicated and expensive. Errors can lead to material with inconsistent properties, rendering it unappealing to industry. Though filtration in mechanical recycling reduces microplastic release, even the most efficient filtration systems cannot prevent the release of microplastics

Microplastics are "synthetic solid particles or polymeric matrices, with regular or irregular shape and with size ranging from 1 μm to 5 mm, of either primary or secondary manufacturing origin, which are insoluble in water." Microplastics a ...

into wastewater.

In feedstock recycling, waste plastic is converted into its starting chemicals, which can then become fresh plastic. This involves higher energy and capital costs. Alternatively, plastic can be burned in place of fossil fuel

A fossil fuel is a flammable carbon compound- or hydrocarbon-containing material formed naturally in the Earth's crust from the buried remains of prehistoric organisms (animals, plants or microplanktons), a process that occurs within geolog ...

s in energy recovery facilities, or biochemically converted into other useful chemicals for industry. In some countries, burning is the dominant form of plastic waste disposal, particularly where landfill diversion policies are in place.

Plastic recycling is low in the waste hierarchy

The waste management hierarchy, waste hierarchy, or "hierarchy of waste management options", is a tool#Non-material usage, tool used in the evaluation of processes that Environmental protection, protect the environment alongside resource consu ...

, meaning that reduction and reuse

Reuse is the action or practice of using an item, whether for its original purpose (conventional reuse) or to fulfill a different function (creative reuse or repurposing). It should be distinguished from recycling, which is the breaking down of ...

are more favourable and long-term solutions for sustainability

Sustainability is a social goal for people to co-exist on Earth over a long period of time. Definitions of this term are disputed and have varied with literature, context, and time. Sustainability usually has three dimensions (or pillars): env ...

.

It has been advocated since the early 1970s, but due to economic and technical challenges, did not impact the management of plastic waste to any significant extent until the late 1980s. The plastics industry has been criticised for lobbying for expansion of recycling programmes, even while research showed that most plastic could not be economically recycled.National Public Radio, 12 September 202"How Big Oil Misled The Public Into Believing Plastic Would Be Recycled"

/ref>PBS, Frontline, 31 March 2020

"Plastics Industry Insiders Reveal the Truth About Recycling"

/ref> This has resulted in occasions where plastic waste dropped into recycling bins has not been recycled, and been treated as general waste.

History

Although plastics were discovered before the 20th century, large-scale production was not realised untilWorld War II

World War II or the Second World War (1 September 1939 – 2 September 1945) was a World war, global conflict between two coalitions: the Allies of World War II, Allies and the Axis powers. World War II by country, Nearly all of the wo ...

. Nylon

Nylon is a family of synthetic polymers characterised by amide linkages, typically connecting aliphatic or Polyamide#Classification, semi-aromatic groups.

Nylons are generally brownish in color and can possess a soft texture, with some varieti ...

replaced silk

Silk is a natural fiber, natural protein fiber, some forms of which can be weaving, woven into textiles. The protein fiber of silk is composed mainly of fibroin and is most commonly produced by certain insect larvae to form cocoon (silk), c ...

in parachutes, while Perspex was a light-weight alternative to glass in aeroplanes. After the war these materials were commercialized. The plastic age began around 1950, part of the post-war economic boom.

Global environmental movements in the 1960s and 1970s led to the formation of environmental agencies in the US ( EPA, 1970), EU ( DG ENV, 1973) Australia ( EPA, 1971) and Japan ( JEA 1971). Environmental awareness put plastic waste under scrutiny. The earliest effort to abate plastic pollution was arguably the 1973 and 1978 MARPOL agreements, whose Annex V banned dumping plastics in the oceans.

Industry lobbying

As regulations expanded, the plastics industry responded with lobbying to preserve their business interests. In the U.S., the 1970 Resource Recovery Act directed the nation towards recycling and energy recovery. More than a thousand attempts to pass legislation to ban or tax packaging, including plastics, came by 1976. The plastics industry responded by lobbying for plastic to be recycled. A $50 million per year campaign was run by organisations such as Keep America Beautiful with the message that plastic could and would be recycled, as well as lobbying for the establishment of curbside recycling.

However, plastic could not be economically recycled using the technology of the time. For example, an April 1973 report written by industry scientists stated that, "There is no recovery from obsolete products" and that, "A degradation of resin properties and performance occurs during the initial fabrication, through aging, and in any reclamation process." The report concluded that sorting the plastic is "infeasible". Contemporary scientific reports highlighted numerous technical barriers.

Globally, plastic waste was almost entirely disposed of via

As regulations expanded, the plastics industry responded with lobbying to preserve their business interests. In the U.S., the 1970 Resource Recovery Act directed the nation towards recycling and energy recovery. More than a thousand attempts to pass legislation to ban or tax packaging, including plastics, came by 1976. The plastics industry responded by lobbying for plastic to be recycled. A $50 million per year campaign was run by organisations such as Keep America Beautiful with the message that plastic could and would be recycled, as well as lobbying for the establishment of curbside recycling.

However, plastic could not be economically recycled using the technology of the time. For example, an April 1973 report written by industry scientists stated that, "There is no recovery from obsolete products" and that, "A degradation of resin properties and performance occurs during the initial fabrication, through aging, and in any reclamation process." The report concluded that sorting the plastic is "infeasible". Contemporary scientific reports highlighted numerous technical barriers.

Globally, plastic waste was almost entirely disposed of via landfill

A landfill is a site for the disposal of waste materials. It is the oldest and most common form of waste disposal, although the systematic burial of waste with daily, intermediate and final covers only began in the 1940s. In the past, waste was ...

until the 1980s when rates of incineration increased. Although better technology was known, these early incinerators often lacked advanced combustors or emission-control systems, leading to the release of dioxins and dioxin-like compounds

Dioxins and dioxin-like compounds (DLCs) are a group of chemical compounds that are persistent organic pollutants (POPs) in the environmental pollutant, environment. They are mostly by-products of burning or various industrial processes or, in the ...

.

In the late 1980s plastic recycling began in earnest. In 1988 the U.S. Society of the Plastics Industry created the Council for Solid Waste Solutions as a trade association

A trade association, also known as an industry trade group, business association, sector association or industry body, is an organization founded and funded by businesses that operate in a specific Industry (economics), industry. Through collabor ...

to promote the idea of plastic recycling to the public. The association lobbied American municipalities to launch or expand plastic waste collection programmes and lobbied U.S. states to require the labelling of plastic containers and products with recycling symbols.

The industry introduced resin identification code

The Resin Identification Code (RIC) is a technical standard with a set of symbols appearing on plastic products that identify the Synthetic resin, plastic resin out of which the product is made. It was developed in 1988 by the Society of the P ...

s in 1988, which provided a standard system for the identification of various polymer types at materials recovery facilities.

Global recycling trade

Globalisation

Globalization is the process of increasing interdependence and integration among the economies, markets, societies, and cultures of different countries worldwide. This is made possible by the reduction of barriers to international trade, th ...

during the 1990s included the export of plastic waste from advanced economies to developing and middle-income ones, where it could be sorted and recycled less expensively. The annual trade in plastic waste increased rapidly from 1993 onwards as part of the global waste trade.

Many governments count items as recycled if they have been exported for that purpose, regardless of the actual outcome. The practice has been labeled environmental dumping, as environmental laws and enforcement are generally weaker in less developed economies. By 2016 about 14 Mt of plastic waste was exported, with China taking 7.35 Mt. Much of this was low quality mixed plastic that ended up in landfills. However, recycled plastic is used extensively in manufacturing in China, and imported plastic waste was predominantly processed using low-technology processing. High-income countries such as Germany, Japan, the United Kingdom and the United States were the top exporters.

In 2017, China began restricting waste plastics imports via Operation National Sword. Exporters eventually exported to other countries mostly in Southeast Asia, such as Vietnam and Malaysia, but also Turkey and India. Indonesia, Malaysia, and Thailand reacted to illegal plastic waste imports by reinforcing border controls. Illegally imported containers were repatriated or refused entry. Consequently, plastic waste containers accumulated in ports.

Given limited export options, attention turned to local solutions. Proposed extended producer responsibility would tax plastic producers to subsidise recyclers.

In 2019, international trade in plastic waste became regulated under the Basel Convention. Under the convention, any Party can decide to prohibit imports of hazardous plastic waste and, since 1 January 2021, of some mixed plastic wastes. Parties to the convention are required to ensure environmentally sound management of their refuse either through alternative importers or by increasing capacity.

The COVID-19 pandemic

The COVID-19 pandemic (also known as the coronavirus pandemic and COVID pandemic), caused by severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2), began with an disease outbreak, outbreak of COVID-19 in Wuhan, China, in December ...

temporarily reduced trade in plastic waste, due in part to reduced activity at waste management facilities, shipping disruptions, and low oil prices that reduced the cost of virgin plastic and made recycling less profitable.

European Union strategic developments

TheEuropean Commission

The European Commission (EC) is the primary Executive (government), executive arm of the European Union (EU). It operates as a cabinet government, with a number of European Commissioner, members of the Commission (directorial system, informall ...

's "Action Plan" for a circular economy, adopted in December 2015, saw plastics as a strategic priority for developing circular economy actions. In 2017, the Commission further adopted a focus on plastic production and use, targeting the achievement of all plastic packaging being recyclable by 2030. The Commission then issued a strategic document in January 2018 which set out an "ambitious vision" and an opportunity for global action on plastic recycling.

Production and recycling rates

The total amount of plastic ever produced worldwide, until 2015, is estimated to be 8.3 billion tonnes (Bt). Approximately 6.3 Bt of this was discarded as waste, of which around 79% accumulated in landfills or the natural environment, 12% was incinerated, and 9% was recycled - only ~1% of all plastic has been recycled more than once. More recently, as of 2017, still only 9% of the 9 Bt of plastic produced was recycled.

By 2015 global production had reached some 381 million tonnes (Mt) per year. The recycling rate that year was 19.5%, while 25.5% was incinerated and the remaining 55% disposed of, largely to landfill. These rates lag behind those of other recyclables, such as paper, metal and glass. Although the percentage of recycled or incinerated material is increasing each year, the tonnage of waste left-over also continues to rise. Production could reach ~800 Mt per year by 2040, although implementing all feasible interventions could reduce plastic pollution by 40% from 2016 rates.

Recycling rates vary among types of plastic. Several types are in common use, each with distinct chemical and physical properties. This affects sorting and reprocessing costs; which affects the value and market size for recovered materials.

The total amount of plastic ever produced worldwide, until 2015, is estimated to be 8.3 billion tonnes (Bt). Approximately 6.3 Bt of this was discarded as waste, of which around 79% accumulated in landfills or the natural environment, 12% was incinerated, and 9% was recycled - only ~1% of all plastic has been recycled more than once. More recently, as of 2017, still only 9% of the 9 Bt of plastic produced was recycled.

By 2015 global production had reached some 381 million tonnes (Mt) per year. The recycling rate that year was 19.5%, while 25.5% was incinerated and the remaining 55% disposed of, largely to landfill. These rates lag behind those of other recyclables, such as paper, metal and glass. Although the percentage of recycled or incinerated material is increasing each year, the tonnage of waste left-over also continues to rise. Production could reach ~800 Mt per year by 2040, although implementing all feasible interventions could reduce plastic pollution by 40% from 2016 rates.

Recycling rates vary among types of plastic. Several types are in common use, each with distinct chemical and physical properties. This affects sorting and reprocessing costs; which affects the value and market size for recovered materials. PET

A pet, or companion animal, is an animal kept primarily for a person's company or entertainment rather than as a working animal, livestock, or a laboratory animal. Popular pets are often considered to have attractive/ cute appearances, inte ...

and HDPE have the highest recycling rates, whereas polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It i ...

and polyurethane

Polyurethane (; often abbreviated PUR and PU) is a class of polymers composed of organic chemistry, organic units joined by carbamate (urethane) links. In contrast to other common polymers such as polyethylene and polystyrene, polyurethane term ...

are rarely recycled.

One of the reasons for low levels of plastic recycling is weak demand, given the materials' poor/inconsistent properties. The percentage of plastic that can be fully recycled, rather than downcycled or go to waste, can be increased when manufacturers minimise mixing of packaging materials and eliminate contaminants. The Association of Plastics Recyclers has issued a "Design Guide for Recyclability".

The most commonly produced plastic consumer products include packaging made from LDPE (e.g. bags, containers, food packaging film), containers made from HDPE (e.g. milk bottles, shampoo bottles, ice cream tubs), and PET

A pet, or companion animal, is an animal kept primarily for a person's company or entertainment rather than as a working animal, livestock, or a laboratory animal. Popular pets are often considered to have attractive/ cute appearances, inte ...

(e.g. bottles for water and other drinks). Together these products account for around 36% of plastic production. The use of plastics in building and construction, textiles, transportation and electrical equipment accounts for another substantial share of the plastics market.

Regional data

Plastic consumption differs among countries and communities, although it is found almost everywhere. As of 2022 North American countries ( NAFTA) accounted for 21% of global plastic consumption, closely followed by China (20%) and Western Europe (18%). In North America and Europe per capita plastic consumption was 94 kg and 85 kg/capita/year, respectively. China reached 58 kg/capita/year. In 2012, 25.2 Mt of post-consumer plastic waste was collected in the European Union. Of this, more than 60% (15.6 Mt) was recovered and 40% (9.6 Mt) was disposed of as municipal solid waste (MSW). Of the 15.6 Mt of recovered plastic waste, about 6.6 Mt was recycled, while the remainder was likely used as refuse-derived fuel (RDF) or incinerated in MSW incinerators with energy recovery (about 9 Mt). Europe leads in plastics recycling, reusing about 26%. The recycling activities of the largest producers of plastic waste have the greatest effect on global averages. These are a mix of advanced economies and large developing nations. Some publish official statistics on their plastic recycling rates. Others may release partial data, usually limited to population centres. This makes it difficult to draw accurate comparisons, especially as the published recycling rates vary. * Although not formally a country, legislation affecting recycling is often made at the EU levelIdentification codes

Many plastic items bear symbols identifying the type ofpolymer

A polymer () is a chemical substance, substance or material that consists of very large molecules, or macromolecules, that are constituted by many repeat unit, repeating subunits derived from one or more species of monomers. Due to their br ...

from which they are made. These resin identification codes (RIC), are used internationally. They were developed in 1988 by the Society of the Plastics Industry (now the Plastics Industry Association) in the United States, but since 2008 have been administered by standards organisation ASTM International

ASTM International, formerly known as American Society for Testing and Materials, is a standards organization that develops and publishes voluntary consensus technical international standards for a wide range of materials, products, systems and s ...

.

RICs are not mandatory in all countries, but many producers voluntarily mark their products. More than half of U.S. states have enacted laws that require plastic products be identifiable. The seven codes include six for the most common commodity plastics and one as a catch-all. The EU maintains a similar nine-code list that also includes ABS and polyamides.Official Journal of the ECCommission Decision (97/129/EC)

establishing the ID system for packaging materials pursuant to European Parliament & Council Directive 94/62/EC RICs are based on the

recycling symbol

The universal recycling symbol ( or in Unicode) is a symbol consisting of three chasing arrows folded in a Möbius strip. It is an internationally recognized symbol for recycling. The symbol originated on the first Earth Day in 1970, created ...

, but have drawn criticism, as they imply that marked items are always recyclable when this may not be true.

RICs are not particularly important for single-stream recycling, as these operations are increasingly automated. However, in some countries citizens are required to separate their plastic waste according to polymer type before collection. For instance, in Japan PET bottles are collected separately for recycling.

Waste composition

Plastic waste consists of various polymer types.Polyolefin

A polyolefin is a type of polymer with the general formula (CH2CHR)n where R is an alkyl group. They are usually derived from a small set of simple olefins (alkenes). Dominant in a commercial sense are polyethylene and polypropylene. More speciali ...

s make up nearly 50% of all plastic waste and more than 90% of waste is made of thermosoftening polymers, which can be remelted

Collecting and sorting

Recycling begins with the collection and sorting of waste. Curbside collection operates in many countries. Waste is sent to a materials recovery facility or MBT plant where the plastic is separated, cleaned and sorted for sale. Unsuitable materials are sent to a landfill or incinerator. These operations account for a large proportion of the financial and energy costs associated with recycling.

Sorting plastic is more complicated than other recyclable materials because it comes in a greater range of forms. For example, glass is separated into three streams (clear, green and amber), metals are usually either steel or aluminum and can be separated using magnets or eddy current separators, and paper is usually sorted into a single stream.

Six types of commodity polymer account for about 75% of plastics waste, with the rest comprising a myriad of polymer types, including polyurethanes and

Recycling begins with the collection and sorting of waste. Curbside collection operates in many countries. Waste is sent to a materials recovery facility or MBT plant where the plastic is separated, cleaned and sorted for sale. Unsuitable materials are sent to a landfill or incinerator. These operations account for a large proportion of the financial and energy costs associated with recycling.

Sorting plastic is more complicated than other recyclable materials because it comes in a greater range of forms. For example, glass is separated into three streams (clear, green and amber), metals are usually either steel or aluminum and can be separated using magnets or eddy current separators, and paper is usually sorted into a single stream.

Six types of commodity polymer account for about 75% of plastics waste, with the rest comprising a myriad of polymer types, including polyurethanes and synthetic fibers

Synthetic fibers or synthetic fibres (in British English; see spelling differences) are fibers made by humans through chemical synthesis, as opposed to natural fibers that are directly derived from living organisms, such as plants like cotton ...

with a range of chemical structures. Items made from the same type of polymer may be incompatible with each other depending on the additives they contain. Additives are compounds blended into plastics to enhance performance and include stabilisers, fillers

In animal feed, a filler is an ingredient added to provide dietary fiber, bulk or some other non-nutritive purpose. Products like corn fiber (corncobs), fruit fibers (pulp), rice bran, and whole grains are possible fillers.

Purpose

As source ...

and, most significantly, dyes

Juan de Guillebon, better known by his stage name DyE, is a French musician. He is known for the music video of the single "Fantasy (DyE song), Fantasy" from his first album ''Taki 183 (album), Taki 183''. This video became popular, attracting ...

. Clear plastics hold the highest value as they may be dyed after recycling, while black or strongly coloured plastic is much less valuable, because they affect the color of the downstream product. Thus, plastic is typically sorted by both polymer type and colour.

Various sorting approaches and technologies have been developed. They can be combined in various ways. In practice no approach is 100% effective. Sorting accuracy varies between recyclers, producing a market where products are poorly standardised. This inconsistency is another barrier to recycling.

Manual separation

Sorting by hand is the oldest and simplest method. In developing countries this may be done bywaste picker

A waste picker also known as waste collector or garbage collector is a person who salvages reusable or recyclable materials thrown away by others to sell or for personal consumption. There are millions of waste pickers worldwide, predominantly ...

s, while in a recycling center, workers pick items off a conveyor-belt. It requires low levels of technology and investment, but has high labor costs. Although many plastic items have identification codes workers rarely have time to look for them, so leaving problems of inefficiency and inconsistency. Even advanced facilities retain manual pickers to troubleshoot and correct sorting errors. Working conditions can be unsanitary.

Density separation

Plastics can be separated by exploiting differences in their densities. In this approach the plastic is first ground into flakes of a similar size, washed and subjected to gravity separation. This can be achieved using either an air classifier or hydrocyclone, or via wet float-sink method. These approaches provide partial sorting, as some polymers have similar density. Polypropylene (PP) andpolyethylene

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging (plastic bags, plastic films, geomembranes and containers including bott ...

(PE) are similar as are polyethylene terephthalate (PET), polystyrene (PS), and PVC. In addition, if the plastic contains fillers

In animal feed, a filler is an ingredient added to provide dietary fiber, bulk or some other non-nutritive purpose. Products like corn fiber (corncobs), fruit fibers (pulp), rice bran, and whole grains are possible fillers.

Purpose

As source ...

, this may affect its density. The lighter PP and PE fraction is known as mixed polyolefin (MPO) and can be sold as a low-value product, the heavier mixed plastics fraction is usually unrecyclable.

Electrostatic separation

In electrostatic separators, thetriboelectric effect

The triboelectric effect (also known as triboelectricity, triboelectric charging, triboelectrification, or tribocharging) describes electric charge transfer between two objects when they contact or slide against each other. It can occur with d ...

is used to charge plastic particles electrically; with different polymers charged to different extents. They are then blown through an electric field, which deflects them depending on their charge, directing them into appropriate collectors. As with density separation, the particles need to be dry, be uniform in size and shape. Electrostatic separation can be complementary to density separation, allowing full separation of polymers, albeit of mixed colours.

Sensor-based separation

This approach is largely automated and involves various sensors linked to a computer, which analyses items and directs them into appropriate chutes or belts. Near-infrared spectroscopy can be used to distinguish polymer types, although black/strongly-coloured plastics, as well as composite materials like plastic-coated paper and multilayered packaging, which can give misleading readings.

This approach is largely automated and involves various sensors linked to a computer, which analyses items and directs them into appropriate chutes or belts. Near-infrared spectroscopy can be used to distinguish polymer types, although black/strongly-coloured plastics, as well as composite materials like plastic-coated paper and multilayered packaging, which can give misleading readings. Optical sorting

Optical sorting (sometimes called digital sorting) is the automated process of sorting solid products using cameras and/or lasers.

Depending on the types of sensors used and the software-driven intelligence of the image processing system, optical ...

such as colour sorters or hyperspectral imaging

Hyperspectral imaging collects and processes information from across the electromagnetic spectrum. The goal of hyperspectral imaging is to obtain the spectrum for each pixel in the image of a scene, with the purpose of finding objects, identifyi ...

can then split by colour. Sensor based separation is more expensive to install but has the best recovery rates and produces more high-quality products.

Scrap

Plastic waste is either industrialscrap

Scrap consists of recyclable materials, usually metals, left over from product manufacturing and consumption, such as parts of vehicles, building supplies, and surplus materials. Unlike waste, scrap can have monetary value, especially recover ...

(sometimes referred to as post industrial resin) or consumer waste. Scrap is generated during production and is usually handled differently. It can include flashings, trimmings, sprues and rejects. As it is collected at the point of manufacture it is clean, and of a known type and grade, and is valuable. As scrap is mostly privately traded, it is often not included in official statistics.

Mechanical recycling

The majority of plastic waste is made of thermosoftening polymers, which can be re-melted and reformed into new items via mechanical recycling. Globally, this is by far the most common form of recycling and in many countries it is the only type practised. It is the simplest and most economical technique. It has a lower

The majority of plastic waste is made of thermosoftening polymers, which can be re-melted and reformed into new items via mechanical recycling. Globally, this is by far the most common form of recycling and in many countries it is the only type practised. It is the simplest and most economical technique. It has a lower carbon footprint

A carbon footprint (or greenhouse gas footprint) is a calculated value or index that makes it possible to compare the total amount of greenhouse gases that an activity, product, company or country Greenhouse gas emissions, adds to the atmospher ...

than other processes. However, several factors can reduce output quality, which limits its applicability.

Plastics are melted at anywhere between , depending on polymer type. This is sufficient to cause unwanted chemical reactions that degrade the output. This can produce volatile, low-molecular weight

A molecule is a group of two or more atoms that are held together by Force, attractive forces known as chemical bonds; depending on context, the term may or may not include ions that satisfy this criterion. In quantum physics, organic chemi ...

compounds, which may impart undesirable taste or odour, as well as discolouration. Additives can accelerate this degradation. For instance, oxo-biodegradable

Oxo-degradation refers to the breakdown mechanism caused by heat, light or oxygen on plastics that contain additives that accelerate the process of breaking them into smaller fragments called microplastics. These plastics contrast biodegradable ...

additives, intended to improve the biodegradability of plastic, also increase the degree of thermal degradation. Flame retardants

Flame retardants are a diverse group of chemicals that are added to manufactured materials, such as plastics and textiles, and surface finishes and coatings. Flame retardants are activated by the presence of an combustion, ignition source and pr ...

can similarly have unwanted effects. Product quality also depends strongly on how well the plastic was sorted. Many polymers are immiscible with each other when molten and phase separate (like oil and water) during reprocessing. Products made from such blends contain boundaries between the different polymers with weak cohesion across these boundaries, compromising mechanical properties. In more extreme cases the polymers may degrade each other, particularly with PVC, as it can generate hydrogen chloride

The Chemical compound, compound hydrogen chloride has the chemical formula and as such is a hydrogen halide. At room temperature, it is a colorless gas, which forms white fumes of hydrochloric acid upon contact with atmospheric water vapor. Hyd ...

which strongly affects condensation polymers such as PET.

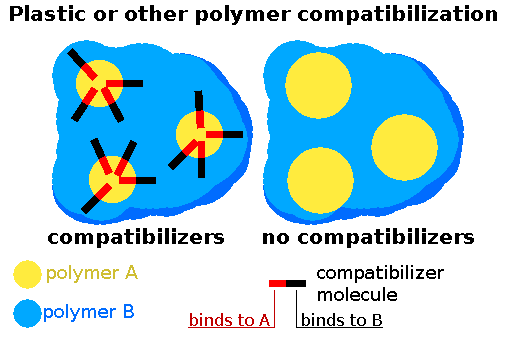

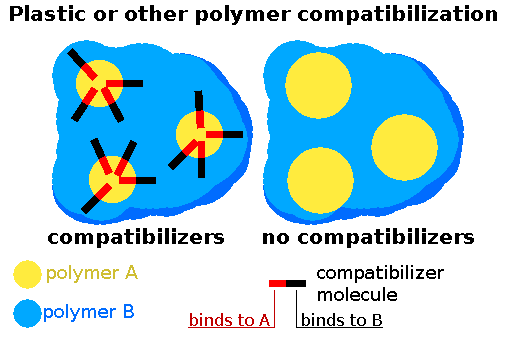

Many of these problems have technological solutions, though they bear a financial cost. Advanced polymer stabilisers and can be used to protect plastics from the stress of thermal reprocessing. Volatile degradation products can be removed by a range of devolatilisation techniques. Flame retardants can be removed by chemical treatment, while damaging metallic additives can be rendered inert with deactivators. Finally, the properties of mixed plastics can be improved by using compatibilisers. These are compounds that improve miscibility between polymer types to give a more homogeneous

Homogeneity and heterogeneity are concepts relating to the uniformity of a substance, process or image. A homogeneous feature is uniform in composition or character (i.e., color, shape, size, weight, height, distribution, texture, language, i ...

product, with better internal cohesion and improved mechanical properties. They are small-molecules possessing two chemical regions, each of which is compatible with a certain polymer. This allows them to act like molecular-nails or screws, anchoring the polymers to one another. As a result, compatibilisers are normally limited to systems dominated by two particular types of plastic and are not cost-effective for heterogeneous mixtures. No compatibiliser solves all plastic combinations. Even with these technologies, it is particularly challenging to recycle plastic so that it can meet food contact standards.

Closed-loop recycling

In closed-loop, or primary recycling, used plastic is endlessly recycled back into new items of the same quality and type. For instance, turning drinks bottles back into drinks bottles. It can be considered an example of acircular economy

A circular economy (also referred to as circularity or CE) is a model of resource Production (economics), production and Resource consumption, consumption in any economy that involves sharing, leasing, Reuse, reusing, repairing, refurbishing, and ...

. The continual mechanical recycling of plastic without reduction in quality is challenging due to cumulative polymer degradation and risk of contaminant build-up. In 2013 only 2% of plastic packaging was recycled in a closed loop. Although closed-loop recycling has been investigated for many polymers, to-date the only industrial success is with PET bottle recycling. This is because polymer degradation in PET is often repairable. PET's polymer chains tend to cleave at their ester

In chemistry, an ester is a compound derived from an acid (either organic or inorganic) in which the hydrogen atom (H) of at least one acidic hydroxyl group () of that acid is replaced by an organyl group (R). These compounds contain a distin ...

groups and the alcohol and carboxyl groups left by this can be joined back together by the use of chemical agents called chain extenders. Pyromellitic dianhydride is one such compound.

Open-loop recycling

In open-loop recycling, also known as secondary recycling, ordowncycling

Downcycling, or cascading, is the recycling of waste where the recycled material is of lower quality and functionality than the original material. Often, this is due to the accumulation of tramp elements in secondary metals, which may exclude th ...

, the quality of the plastic is reduced each time it is recycled, so that the material eventually becomes unrecyclable. It is the most common type. Recycling PET bottles into fleece or other fibres is a common example, and accounts for the majority of PET recycling. Life-cycle assessment

Life cycle assessment (LCA), also known as life cycle analysis, is a methodology for assessing the impacts associated with all the stages of the life cycle of a commercial product, process, or service. For instance, in the case of a manufact ...

shows it to be of ecological benefit. Recycling can displace demand for fresh plastic. However, if it is used to produce items that would not otherwise have been made, then it is not displacing production and is of little or no benefit to the environment.

The reduction in polymer quality can be offset by mixing recycled and new materials. Compatibilised plastics can be used as a replacement for virgin material, as it is possible to produce them with the right melt flow index needed for good results. Low quality mixed plastics can be recycled in an open-loop, although demand for such products is limited. When these are mixed during reprocessing the result is usually an unappealing dark-brown. These blends find use as outdoor furniture or plastic lumber. As the material is weak, but of low cost, it is produced in thick planks to provide material strength.

Thermosets

Althoughthermoset

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening (" curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and ...

polymers do not melt, technologies have been developed for their mechanical recycling. This usually involves breaking the material down to small particles (crumbs), which can then be mixed with a binding agent to form a composite material. For instance, polyurethanes

Polyurethane (; often abbreviated PUR and PU) is a class of polymers composed of organic chemistry, organic units joined by carbamate (urethane) links. In contrast to other common polymers such as polyethylene and polystyrene, polyurethane term ...

can be recycled as reconstituted crumb foam.

Feedstock recycling

In feedstock recycling, also called chemical recycling or tertiary recycling, polymers are reduced to their chemical building-blocks (monomers

A monomer ( ; ''wikt:mono-, mono-'', "one" + ''wikt:-mer, -mer'', "part") is a molecule that can chemical reaction, react together with other monomer molecules to form a larger polymer chain or two- or three-dimensional network in a process called ...

), which can then be polymerised back into fresh plastics. In theory, this allows for near infinite recycling; as impurities, additives, dyes and chemical defects are completely removed with each cycle. In practice, chemical recycling is far less common than mechanical recycling. Implementation is limited because technologies do not yet exist to reliably depolymerise all polymers on an industrial scale and also because the equipment and operating costs are much higher. In 2018 Japan had one of the highest rates in the world at ~4%, compared to 23% mechanical recycling, in the same period Germany, another major recycler, reported a feedstock recycling rate of 0.2%. Depolymerising, purifying and re-polymerising the plastic can also be energy intensive, leading to the carbon footprint

A carbon footprint (or greenhouse gas footprint) is a calculated value or index that makes it possible to compare the total amount of greenhouse gases that an activity, product, company or country Greenhouse gas emissions, adds to the atmospher ...

of feedstock recycling normally being higher than that of mechanical recycling. PET, PU and PS are depolymerised commercially to varying extents, but the feedstock recycling of polyolefins, which make-up nearly half of all plastics, is much more limited.

Thermal depolymerisation

Certain polymers likePTFE

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene, and has numerous applications because it is chemically inert. The commonly known brand name of PTFE-based composition is Teflon by Chemours, a spin-off fro ...

, polystyrene, nylon 6, and polymethylmethacrylate (PMMA) undergo thermal depolymerisation when heated to sufficiently high temperatures. The reactions are sensitive to impurities and require clean and well sorted waste to produce a good product. Even then, not all depolymerisation reactions are completely efficient and some competitive pyrolysis

Pyrolysis is a process involving the Bond cleavage, separation of covalent bonds in organic matter by thermal decomposition within an Chemically inert, inert environment without oxygen. Etymology

The word ''pyrolysis'' is coined from the Gree ...

is often observed; the monomers, therefore, require purification before reuse. The feedstock recycling of polystyrene has been commercialised, but global capacity remains fairly limited.

Chemical depolymerisation

Condensation polymers bearing cleavable groups such asesters

In chemistry, an ester is a chemical compound, compound derived from an acid (either organic or inorganic) in which the hydrogen atom (H) of at least one acidic hydroxyl group () of that acid is replaced by an organyl group (R). These compounds c ...

and amides can be completely depolymerised by hydrolysis

Hydrolysis (; ) is any chemical reaction in which a molecule of water breaks one or more chemical bonds. The term is used broadly for substitution reaction, substitution, elimination reaction, elimination, and solvation reactions in which water ...

or solvolysis

In chemistry, solvolysis is a type of nucleophilic substitution (S1/S2) or elimination reaction, elimination where the nucleophile is a solvent molecule. Characteristic of S1 reactions, solvolysis of a chirality (chemistry), chiral reactant affor ...

. This can be a purely chemical process but may also be promoted by enzymes such as PETase. Such technologies have lower energy costs than thermal depolymerisation but are not available for all polymers. Polyethylene terephthalate has been the most heavily studied polymer, and has reached commercial scale.

Energy recovery

Energy recovery, also called energy recycling or quaternary recycling, involves burning waste plastic in place offossil fuels

A fossil fuel is a flammable carbon compound- or hydrocarbon-containing material formed naturally in the Earth's crust from the buried remains of prehistoric organisms (animals, plants or microplanktons), a process that occurs within geologica ...

for energy production. It is included in the recycling data reported by many countries, although it is not considered recycling by the EU. It is distinct from incineration without energy recovery, which is historically more common, but which does not reduce either plastic production or fossil fuel use.

Energy recovery is often the waste management method of last resort, a position previously held by landfill. In urban areas a lack of suitable sites for new landfills can drive this, but it is also driven by regulation, such as the EU's Landfill Directive or other landfill diversion policies. Compared to the other recycling options, its appeal is largely economic. If the correct technologies are used, then the plastics do not need to be separated, or from other municipal solid waste

Municipal solid waste (MSW), commonly known as trash or garbage in the American English, United States and rubbish in British English, Britain, is a List of waste types, waste type consisting of everyday items that are discarded by the public. ...

(garbage), which reduces costs. Compared to the sometimes variable market for recyclables, demand for electricity is universal and better understood, reducing the perceived financial risk

Financial risk is any of various types of risk associated with financing, including financial transactions that include company loans in risk of default. Often it is understood to include only downside risk, meaning the potential for financi ...

. As a means of waste management, it is highly effective, reducing the volume of waste by about 90%, with the residues sent to landfill or used to make cinder block

A concrete block, also known as a cinder block in North American English, breeze block in British English, or concrete masonry unit (CMU), or by #Naming, various other terms, is a standard-size rectangular block used in building constructio ...

. Although its CO2 emissions are high, comparing its overall ecological desirability to other recycling technologies is difficult. For instance, while recycling greatly reduces greenhouse gas emissions compared to incineration, it is an expensive way of achieving these reductions when compared to investing in renewable energy

Renewable energy (also called green energy) is energy made from renewable resource, renewable natural resources that are replenished on a human lifetime, human timescale. The most widely used renewable energy types are solar energy, wind pow ...

.

Plastic waste may be burnt as refuse-derived fuel

Refuse-derived fuel (RDF) is a Waste-to-energy, fuel produced from various types of waste such as municipal solid waste (MSW), industrial waste or commercial waste.

The World Business Council for Sustainable Development provides a definition:

' ...

(RDF), or it may be chemically converted to a synthetic fuel first. In either approach PVC must be excluded or compensated for by installing dechlorination technologies, as it generates large amounts of hydrogen chloride

The Chemical compound, compound hydrogen chloride has the chemical formula and as such is a hydrogen halide. At room temperature, it is a colorless gas, which forms white fumes of hydrochloric acid upon contact with atmospheric water vapor. Hyd ...

(HCl) when burnt. This can corrode equipment and cause undesirable chlorination of fuel products. Burning has long been associated with the release of harmful dioxins and dioxin-like compounds

Dioxins and dioxin-like compounds (DLCs) are a group of chemical compounds that are persistent organic pollutants (POPs) in the environmental pollutant, environment. They are mostly by-products of burning or various industrial processes or, in the ...

, however these hazards can be abated by the use of advanced combustors and emission control systems. Incineration with energy recovery remains the most common method, with more advanced waste-to-fuel technologies such as pyrolysis

Pyrolysis is a process involving the Bond cleavage, separation of covalent bonds in organic matter by thermal decomposition within an Chemically inert, inert environment without oxygen. Etymology

The word ''pyrolysis'' is coined from the Gree ...

hindered by technical and cost hurdles.

Waste-to-fuel

Mixed plastic waste can be depolymerised to give a synthetic fuel. This has a higher heating value than the starting plastic and can be burnt more efficiently, although it remains less efficient than fossil fuels. Various conversion technologies have been investigated, of which pyrolysis is the most common. Conversion can take place as part of incineration in an IGC cycle, but often the aim is to collect the fuel to sell it. Pyrolysis of mixed plastics can give a fairly broad mix of chemical products (between 1 and 15 carbon atoms) including gases andaromatic

In organic chemistry, aromaticity is a chemical property describing the way in which a conjugated system, conjugated ring of unsaturated bonds, lone pairs, or empty orbitals exhibits a stabilization stronger than would be expected from conjugati ...

liquids. Catalysts can give a better-defined product with a higher value. Liquid products can be used as synthetic diesel fuel, with commercial production in several countries. Life-cycle analysis

Life cycle assessment (LCA), also known as life cycle analysis, is a methodology for assessing the impacts associated with all the stages of the life cycle of a commercial product, process, or service. For instance, in the case of a manufact ...

shows that plastic-to-fuel can displace fossil fuels and lower net greenhouse gas

Greenhouse gases (GHGs) are the gases in the atmosphere that raise the surface temperature of planets such as the Earth. Unlike other gases, greenhouse gases absorb the radiations that a planet emits, resulting in the greenhouse effect. T ...

emissions (~15% reduction).

Compared to the widespread practise of incineration, plastic-to-fuel technologies have struggled to become economically viable.

Other Uses

Coke replacement

Many kinds of plastic can be used as acarbon

Carbon () is a chemical element; it has chemical symbol, symbol C and atomic number 6. It is nonmetallic and tetravalence, tetravalent—meaning that its atoms are able to form up to four covalent bonds due to its valence shell exhibiting 4 ...

source (in place of coke) in scrap steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength a ...

recycling, with roughly 200,000 tonnes of waste plastics processed each year in Japan.

Construction and concrete

The use of recovered plastics in engineering materials is gaining ground. Ground plastic may be used as aconstruction aggregate

Construction aggregate, or simply aggregate, is a broad category of coarse- to medium-grained particulate material used in construction. Traditionally, it includes natural materials such as sand, gravel, crushed stone. As with other types of ag ...

or filler material in certain applications. While generally unsuitable in structural concrete, plastic's inclusion in asphalt concrete

Asphalt concrete (commonly called asphalt, blacktop, or pavement in North America, and Tarmacadam, tarmac or bitumen macadam in the United Kingdom and the Republic of Ireland) is a composite material commonly used to surface road surface, roads ...

, (forming rubberised asphalt), subbase and recycled insulation can be beneficial. An example of this is the construction of plastic roads. These may be made entirely of plastic or can incorporate significant amounts of plastic. The practice is popular in India, which by 2021 had constructed some 700 km (435 miles) of highways. It may allow the leaching of plastic additives into the environment. Research is ongoing to use plastics in various forms in cementitious materials such as concrete. Densifying plastic materials such as PET and plastic bags and then using them to partially replace aggregate and depolymerizing PET to use as a polymeric binder to enhance concrete are under study.

See also

* Economics of plastics processing *Electronic waste

Electronic waste (or e-waste) describes discarded electrical or electronics, electronic devices. It is also commonly known as waste electrical and electronic equipment (WEEE) or end-of-life (EOL) electronics. Used electronics which are destined ...

* Microplastics

Microplastics are "synthetic solid particles or polymeric matrices, with regular or irregular shape and with size ranging from 1 μm to 5 mm, of either primary or secondary manufacturing origin, which are insoluble in water." Microplastics a ...

* Mobro 4000

* Phase-out of lightweight plastic bags

A plastic bag ban or charge is a law that restricts the use of lightweight plastic bags at retail establishments. In the early 21st century, there has been a global trend towards the phase-out of lightweight plastic bags. Single-use plastic shopp ...

* Plastics 2020 Challenge

Sources

References

External links

* ISF's Plastics Recovery Manual {{Plastics Recycling by material Energy conservation