A lithium-ion or Li-ion battery is a type of

rechargeable battery

A rechargeable battery, storage battery, or secondary cell (formally a type of energy accumulator), is a type of electrical battery which can be charged, discharged into a load, and recharged many times, as opposed to a disposable or prima ...

that uses the reversible

intercalation of Li

+ ions into electronically

conducting

Conducting is the art of directing a musical performance, such as an orchestral or Choir, choral concert. It has been defined as "the art of directing the simultaneous performance of several players or singers by the use of gesture." The primary d ...

solids to store energy. Li-ion batteries are characterized by higher

specific energy

Specific energy or massic energy is energy per unit mass. It is also sometimes called gravimetric energy density, which is not to be confused with energy density, which is defined as energy per unit volume. It is used to quantify, for example, st ...

,

energy density

In physics, energy density is the quotient between the amount of energy stored in a given system or contained in a given region of space and the volume of the system or region considered. Often only the ''useful'' or extractable energy is measure ...

, and

energy efficiency and a longer

cycle life

A charge cycle is the process of charging a rechargeable battery and discharging it as required into a load. The term is typically used to specify a battery's expected life, as the number of charge cycles affects life more than the mere passage o ...

and calendar life than other types of rechargeable batteries. Also noteworthy is a dramatic improvement in lithium-ion battery properties after their market introduction in 1991; over the following 30 years, their volumetric energy density increased threefold while their cost dropped tenfold. In late 2024 global demand passed per year, while production capacity was more than twice that.

The invention and commercialization of Li-ion batteries

has had a large impact on technology, as recognized by the 2019

Nobel Prize in Chemistry

The Nobel Prize in Chemistry () is awarded annually by the Royal Swedish Academy of Sciences to scientists in the various fields of chemistry. It is one of the five Nobel Prizes established by the will of Alfred Nobel in 1895, awarded for outst ...

.

Li-ion batteries have enabled portable

consumer electronics

Consumer electronics, also known as home electronics, are electronic devices intended for everyday household use. Consumer electronics include those used for entertainment, Communication, communications, and recreation. Historically, these prod ...

,

laptop computers

A laptop computer or notebook computer, also known as a laptop or notebook, is a small, portable personal computer (PC). Laptops typically have a clamshell form factor with a flat-panel screen on the inside of the upper lid and an alph ...

,

cellular phones

A mobile phone or cell phone is a portable telephone that allows users to make and receive calls over a radio frequency link while moving within a designated telephone service area, unlike fixed-location phones ( landline phones). This radio ...

, and

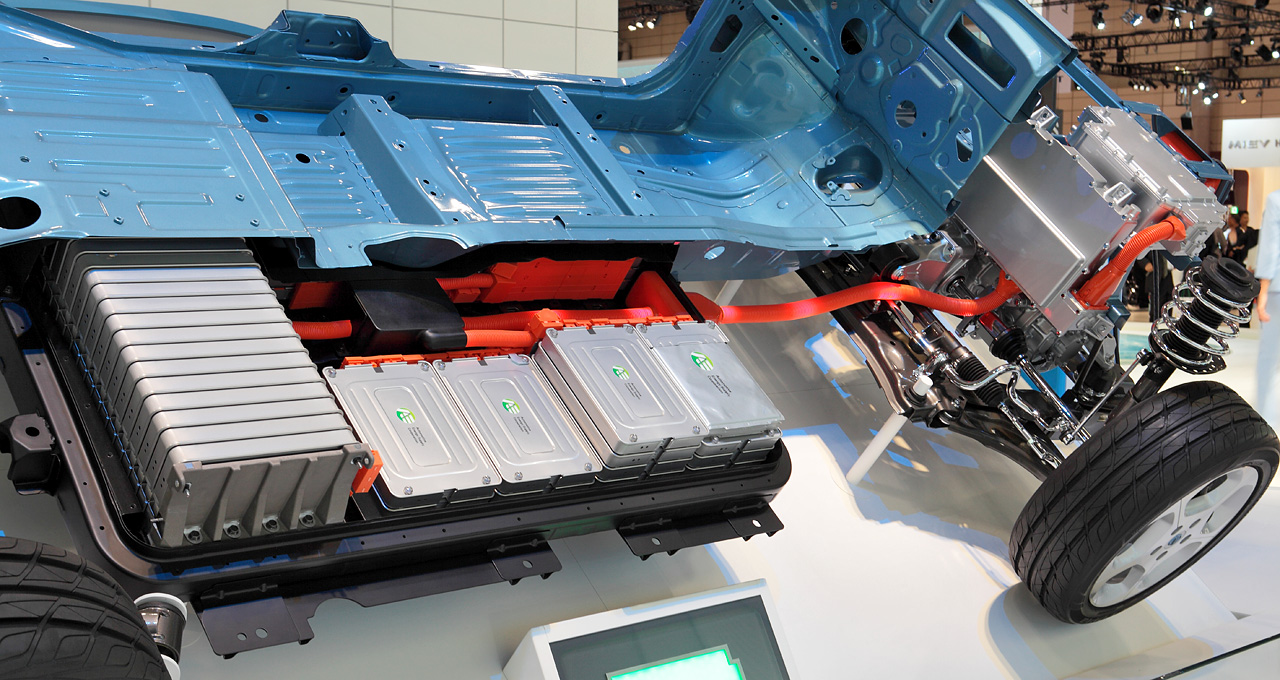

electric cars. Li-ion batteries also see significant use for

grid-scale energy storage as well as military and aerospace applications.

M. Stanley Whittingham conceived intercalation electrodes in the 1970s and created the first rechargeable lithium-ion battery, based on a

titanium disulfide cathode and a lithium-aluminium anode, although it suffered from safety problems and was never commercialized.

expanded on this work in 1980 by using

lithium cobalt oxide as a cathode.

The first prototype of the modern Li-ion battery, which uses a carbonaceous anode rather than lithium metal, was developed by

Akira Yoshino

is a Japanese chemist. He is a fellow of Asahi Kasei, Asahi Kasei Corporation and a professor at Meijo University in Nagoya. He created the first safe, production-viable lithium-ion battery, which became used widely in cellular phones and noteb ...

in 1985 and commercialized by a

Sony

is a Japanese multinational conglomerate (company), conglomerate headquartered at Sony City in Minato, Tokyo, Japan. The Sony Group encompasses various businesses, including Sony Corporation (electronics), Sony Semiconductor Solutions (i ...

and

Asahi Kasei

is a multinational Japanese chemical company. Its main products are chemicals and materials.

It was founded in May 1931, using the paid-in capital of Nobeoka Ammonia Fiber Co., Ltd, a Nobeoka, Miyazaki-based producer of ammonia, nitric acid ...

team led by Yoshio Nishi in 1991.

Whittingham, Goodenough, and Yoshino were awarded the 2019 Nobel Prize in Chemistry for their contributions to the development of lithium-ion batteries.

Lithium-ion batteries can be a fire or explosion hazard as they contain flammable electrolytes. Progress has been made in the development and manufacturing of safer lithium-ion batteries. Lithium-ion

solid-state batteries are being developed to eliminate the flammable electrolyte.

Recycled batteries can create toxic waste, including from toxic metals, and are a fire risk. Both

lithium

Lithium (from , , ) is a chemical element; it has chemical symbol, symbol Li and atomic number 3. It is a soft, silvery-white alkali metal. Under standard temperature and pressure, standard conditions, it is the least dense metal and the ...

and other minerals can have significant issues in mining, with lithium being water intensive in often arid regions and other minerals used in some Li-ion chemistries potentially being

conflict minerals

The eastern Democratic Republic of the Congo (DRC) has a Kivu conflict, history of conflict, where various armies, rebel groups, and outside actors have profited from mining while contributing to violence and exploitation during wars in the regio ...

such as

cobalt

Cobalt is a chemical element; it has Symbol (chemistry), symbol Co and atomic number 27. As with nickel, cobalt is found in the Earth's crust only in a chemically combined form, save for small deposits found in alloys of natural meteoric iron. ...

.

Environmental issues

Environmental issues are disruptions in the usual function of ecosystems. Further, these issues can be caused by humans (human impact on the environment) or they can be natural. These issues are considered serious when the ecosystem cannot recov ...

have encouraged some researchers to improve mineral efficiency and find alternatives such as

lithium iron phosphate

Lithium iron phosphate or lithium ferro-phosphate (LFP) is an inorganic compound with the formula . It is a gray, red-grey, brown or black solid that is insoluble in water. The material has attracted attention as a component of lithium iron phosp ...

lithium-ion chemistries or non-lithium-based battery chemistries such as

sodium-ion and

iron-air batteries.

"Li-ion battery" can be considered a generic term involving at least 12 different chemistries; see

List of battery types

This list is a summary of notable electric battery types composed of one or more electrochemical cells. Three lists are provided in the table. The primary (non-rechargeable) and secondary (rechargeable) cell lists are lists of battery chemistry. ...

. Lithium-ion cells can be manufactured to optimize energy density or power density. Handheld electronics mostly use

lithium polymer batteries

A lithium polymer battery, or more correctly, lithium-ion polymer battery (abbreviated as LiPo, LIP, Li-poly, lithium-poly, and others), is a rechargeable battery derived from lithium-ion battery, lithium-ion and lithium-metal battery technology ...

(with a polymer gel as an electrolyte), a lithium cobalt oxide () cathode material, and a

graphite

Graphite () is a Crystallinity, crystalline allotrope (form) of the element carbon. It consists of many stacked Layered materials, layers of graphene, typically in excess of hundreds of layers. Graphite occurs naturally and is the most stable ...

anode, which together offer high energy density.

Lithium iron phosphate

Lithium iron phosphate or lithium ferro-phosphate (LFP) is an inorganic compound with the formula . It is a gray, red-grey, brown or black solid that is insoluble in water. The material has attracted attention as a component of lithium iron phosp ...

(),

lithium manganese oxide (

spinel

Spinel () is the magnesium/aluminium member of the larger spinel group of minerals. It has the formula in the cubic crystal system. Its name comes from the Latin word , a diminutive form of ''spine,'' in reference to its pointed crystals.

Prop ...

, or -based lithium-rich layered materials, LMR-NMC), and

lithium nickel manganese cobalt oxide ( or NMC) may offer longer life and a higher discharge rate. NMC and its derivatives are widely used in the

electrification of transport, one of the main technologies (combined with

renewable energy

Renewable energy (also called green energy) is energy made from renewable resource, renewable natural resources that are replenished on a human lifetime, human timescale. The most widely used renewable energy types are solar energy, wind pow ...

) for reducing

greenhouse gas emissions

Greenhouse gas (GHG) emissions from human activities intensify the greenhouse effect. This contributes to climate change. Carbon dioxide (), from burning fossil fuels such as coal, petroleum, oil, and natural gas, is the main cause of climate chan ...

from vehicles.

History

Research on rechargeable Li-ion batteries dates to the 1960s; one of the earliest examples is a /Li battery developed by

NASA

The National Aeronautics and Space Administration (NASA ) is an independent agencies of the United States government, independent agency of the federal government of the United States, US federal government responsible for the United States ...

in 1965. The breakthrough that produced the earliest form of the modern Li-ion battery was made by British chemist

M. Stanley Whittingham in 1974, who first used

titanium disulfide () as a cathode material, which has a layered structure that can

take in lithium ions without significant changes to its

crystal structure

In crystallography, crystal structure is a description of ordered arrangement of atoms, ions, or molecules in a crystalline material. Ordered structures occur from intrinsic nature of constituent particles to form symmetric patterns that repeat ...

.

Exxon

Exxon Mobil Corporation ( ) is an American multinational oil and gas corporation headquartered in Spring, Texas, a suburb of Houston. Founded as the largest direct successor of John D. Rockefeller's Standard Oil, the modern company was form ...

tried to commercialize this battery in the late 1970s, but found the synthesis expensive and complex, as is sensitive to moisture and releases toxic

hydrogen sulfide () gas on contact with water. More prohibitively, the batteries were also prone to spontaneously catch fire due to the presence of metallic lithium in the cells. For this, and other reasons, Exxon discontinued the development of Whittingham's lithium-titanium disulfide battery.

In 1980, working in separate groups Ned A. Godshall et al., and, shortly thereafter,

Koichi Mizushima and

John B. Goodenough, after testing a range of alternative materials, replaced with

lithium cobalt oxide (, or LCO), which has a similar layered structure but offers a higher voltage and is much more stable in air. This material would later be used in the first commercial Li-ion battery, although it did not, on its own, resolve the persistent issue of flammability.

These early attempts to develop rechargeable Li-ion batteries used lithium metal anodes, which were ultimately abandoned due to safety concerns, as lithium metal is unstable and prone to

dendrite

A dendrite (from Ancient Greek language, Greek δένδρον ''déndron'', "tree") or dendron is a branched cytoplasmic process that extends from a nerve cell that propagates the neurotransmission, electrochemical stimulation received from oth ...

formation, which can cause

short-circuiting. The eventual solution was to use an intercalation anode, similar to that used for the cathode, which prevents the formation of lithium metal during battery charging. The first to demonstrate lithium ion reversible intercalation into graphite anodes was

Jürgen Otto Besenhard in 1974.

Besenhard used organic solvents such as carbonates, however these solvents decomposed rapidly providing short battery cycle life. Later, in 1980,

Rachid Yazami used a solid organic electrolyte,

polyethylene oxide

Polyethylene glycol (PEG; ) is a polyether compound derived from petroleum with many applications, from industrial manufacturing to medicine. PEG is also known as polyethylene oxide (PEO) or polyoxyethylene (POE), depending on its molecular we ...

, which was more stable.

In 1985,

Akira Yoshino

is a Japanese chemist. He is a fellow of Asahi Kasei, Asahi Kasei Corporation and a professor at Meijo University in Nagoya. He created the first safe, production-viable lithium-ion battery, which became used widely in cellular phones and noteb ...

at

Asahi Kasei

is a multinational Japanese chemical company. Its main products are chemicals and materials.

It was founded in May 1931, using the paid-in capital of Nobeoka Ammonia Fiber Co., Ltd, a Nobeoka, Miyazaki-based producer of ammonia, nitric acid ...

Corporation discovered that

petroleum coke

Petroleum coke, abbreviated coke, pet coke or petcoke, is a final carbon-rich solid material that derives from oil refinery, oil refining, and is one type of the group of fuels referred to as Coke (fuel), cokes. Petcoke is the coke that, in parti ...

, a less graphitized form of carbon, can reversibly intercalate Li-ions at a low potential of ~0.5 V relative to Li+ /Li without structural degradation. Its structural stability originates from its

amorphous carbon

Amorphous carbon is free, reactive carbon that has no crystalline structure. Amorphous carbon materials may be stabilized by terminating dangling-π bonds with hydrogen. As with other amorphous solids, some short-range order can be observed. Amo ...

regions, which serving as covalent joints to pin the layers together. Although it has a lower capacity compared to graphite (~Li0.5C6, 186 mAh g–1), it became the first commercial intercalation anode for Li-ion batteries owing to its cycling stability. In 1987, Yoshino patented what would become the first commercial lithium-ion battery using this anode. He used Goodenough's previously reported

LiCoO2 as the cathode and a

carbonate ester

In organic chemistry, a carbonate ester (organic carbonate or organocarbonate) is an ester of carbonic acid. This functional group consists of a carbonyl group flanked by two alkoxy groups. The general structure of these carbonates is and they a ...

-based electrolyte. The battery was assembled in the discharged state, which made it safer and cheaper to manufacture. In 1991, using Yoshino's design,

Sony

is a Japanese multinational conglomerate (company), conglomerate headquartered at Sony City in Minato, Tokyo, Japan. The Sony Group encompasses various businesses, including Sony Corporation (electronics), Sony Semiconductor Solutions (i ...

began producing and selling the world's first rechargeable lithium-ion batteries. The following year, a

joint venture

A joint venture (JV) is a business entity created by two or more parties, generally characterized by shared ownership, shared returns and risks, and shared governance. Companies typically pursue joint ventures for one of four reasons: to acce ...

between

Toshiba

is a Japanese multinational electronics company headquartered in Minato, Tokyo. Its diversified products and services include power, industrial and social infrastructure systems, elevators and escalators, electronic components, semiconductors ...

and Asahi Kasei Co. also released a lithium-ion battery.

Significant improvements in energy density were achieved in the 1990s by replacing Yoshino's soft carbon anode first with

hard carbon and later with graphite. In 1990,

Jeff Dahn and two colleagues at

Dalhousie University

Dalhousie University (commonly known as Dal) is a large public research university in Nova Scotia, Canada, with three campuses in Halifax, Nova Scotia, Halifax, a fourth in Bible Hill, Nova Scotia, Bible Hill, and a second medical school campus ...

(Canada) reported reversible intercalation of lithium ions into graphite in the presence of

ethylene carbonate

Ethylene carbonate (sometimes abbreviated EC) is the organic compound with the formula (CH2O)2CO. It is classified as the cyclic carbonate ester of ethylene glycol and carbonic acid. At room temperature (25 °C) ethylene carbonate is a tra ...

solvent (which is solid at room temperature and is mixed with other solvents to make a liquid). This represented the final innovation of the era that created the basic design of the modern lithium-ion battery.

In 2010, global lithium-ion battery production capacity was 20 gigawatt-hours. By 2016, it was 28 GWh, with 16.4 GWh in China. Global production capacity was 767 GWh in 2020, with China accounting for 75%. Production in 2021 is estimated by various sources to be between 200 and 600 GWh, and predictions for 2023 range from 400 to 1,100 GWh.

In 2012, John B. Goodenough,

Rachid Yazami and

Akira Yoshino

is a Japanese chemist. He is a fellow of Asahi Kasei, Asahi Kasei Corporation and a professor at Meijo University in Nagoya. He created the first safe, production-viable lithium-ion battery, which became used widely in cellular phones and noteb ...

received the 2012 IEEE Medal for Environmental and Safety Technologies for developing the lithium-ion battery; Goodenough, Whittingham, and Yoshino were awarded the 2019

Nobel Prize in Chemistry

The Nobel Prize in Chemistry () is awarded annually by the Royal Swedish Academy of Sciences to scientists in the various fields of chemistry. It is one of the five Nobel Prizes established by the will of Alfred Nobel in 1895, awarded for outst ...

"for the development of lithium-ion batteries".

Jeff Dahn received the ECS Battery Division Technology Award (2011) and the Yeager award from the International Battery Materials Association (2016).

In April 2023,

CATL announced that it would begin scaled-up production of its semi-solid condensed matter battery that produces a then record 500

Wh/kg. They use electrodes made from a gelled material, requiring fewer binding agents. This in turn shortens the manufacturing cycle. One potential application is in battery-powered airplanes.

Another new development of lithium-ion batteries are

flow batteries with redox-targeted solids, that use no binders or electron-conducting additives, and allow for completely independent scaling of energy and power.

Design

Generally, the negative electrode of a conventional lithium-ion cell is made from

graphite

Graphite () is a Crystallinity, crystalline allotrope (form) of the element carbon. It consists of many stacked Layered materials, layers of graphene, typically in excess of hundreds of layers. Graphite occurs naturally and is the most stable ...

. The positive electrode is typically a metal

oxide

An oxide () is a chemical compound containing at least one oxygen atom and one other element in its chemical formula. "Oxide" itself is the dianion (anion bearing a net charge of −2) of oxygen, an O2− ion with oxygen in the oxidation st ...

or phosphate. The

electrolyte

An electrolyte is a substance that conducts electricity through the movement of ions, but not through the movement of electrons. This includes most soluble Salt (chemistry), salts, acids, and Base (chemistry), bases, dissolved in a polar solven ...

is a

lithium

Lithium (from , , ) is a chemical element; it has chemical symbol, symbol Li and atomic number 3. It is a soft, silvery-white alkali metal. Under standard temperature and pressure, standard conditions, it is the least dense metal and the ...

salt

In common usage, salt is a mineral composed primarily of sodium chloride (NaCl). When used in food, especially in granulated form, it is more formally called table salt. In the form of a natural crystalline mineral, salt is also known as r ...

in an

organic solvent

A solvent (from the Latin language, Latin ''wikt:solvo#Latin, solvō'', "loosen, untie, solve") is a substance that dissolves a solute, resulting in a Solution (chemistry), solution. A solvent is usually a liquid but can also be a solid, a gas ...

.

[Silberberg, M. (2006). ''Chemistry: The Molecular Nature of Matter and Change'', 4th Ed. New York (NY): McGraw-Hill Education. p. 935, .] The negative electrode (which is the

anode

An anode usually is an electrode of a polarized electrical device through which conventional current enters the device. This contrasts with a cathode, which is usually an electrode of the device through which conventional current leaves the devic ...

when the cell is discharging) and the positive electrode (which is the

cathode

A cathode is the electrode from which a conventional current leaves a polarized electrical device such as a lead-acid battery. This definition can be recalled by using the mnemonic ''CCD'' for ''Cathode Current Departs''. Conventional curren ...

when discharging) are prevented from shorting by a separator.

The electrodes are connected to the powered circuit through two pieces of metal called current collectors.

The negative and positive electrodes swap their electrochemical roles (anode and

cathode

A cathode is the electrode from which a conventional current leaves a polarized electrical device such as a lead-acid battery. This definition can be recalled by using the mnemonic ''CCD'' for ''Cathode Current Departs''. Conventional curren ...

) when the cell is charged. Despite this, in discussions of battery design the negative electrode of a rechargeable cell is often just called "the anode" and the positive electrode "the cathode".

In its fully lithiated state of LiC

6, graphite correlates to a theoretical capacity of 1339

coulomb

The coulomb (symbol: C) is the unit of electric charge in the International System of Units (SI).

It is defined to be equal to the electric charge delivered by a 1 ampere current in 1 second, with the elementary charge ''e'' as a defining c ...

s per gram (372 mAh/g).

[G. Shao et al.: Polymer-Derived SiOC Integrated with a Graphene Aerogel As a Highly Stable Li-Ion Battery Anode](_blank)

ACS Appl. Mater. Interfaces 2020, 12, 41, 46045–46056 The positive electrode is generally one of three materials: a layered

oxide

An oxide () is a chemical compound containing at least one oxygen atom and one other element in its chemical formula. "Oxide" itself is the dianion (anion bearing a net charge of −2) of oxygen, an O2− ion with oxygen in the oxidation st ...

(such as

lithium cobalt oxide), a

polyanion (such as

lithium iron phosphate

Lithium iron phosphate or lithium ferro-phosphate (LFP) is an inorganic compound with the formula . It is a gray, red-grey, brown or black solid that is insoluble in water. The material has attracted attention as a component of lithium iron phosp ...

) or a

spinel

Spinel () is the magnesium/aluminium member of the larger spinel group of minerals. It has the formula in the cubic crystal system. Its name comes from the Latin word , a diminutive form of ''spine,'' in reference to its pointed crystals.

Prop ...

(such as lithium

manganese oxide). More experimental materials include

graphene

Graphene () is a carbon allotrope consisting of a Single-layer materials, single layer of atoms arranged in a hexagonal lattice, honeycomb planar nanostructure. The name "graphene" is derived from "graphite" and the suffix -ene, indicating ...

-containing electrodes, although these remain far from commercially viable due to their high cost.

Lithium reacts vigorously with water to form

lithium hydroxide

Lithium hydroxide is an inorganic compound with the formula LiOH. It can exist as anhydrous or hydrated, and both forms are white hygroscopic solids. They are soluble in water and slightly soluble in ethanol. Both are available commercially. While ...

(LiOH) and

hydrogen

Hydrogen is a chemical element; it has chemical symbol, symbol H and atomic number 1. It is the lightest and abundance of the chemical elements, most abundant chemical element in the universe, constituting about 75% of all baryon, normal matter ...

gas. Thus, a non-aqueous electrolyte is typically used, and a sealed container rigidly excludes moisture from the battery pack. The non-aqueous electrolyte is typically a mixture of organic carbonates such as

ethylene carbonate

Ethylene carbonate (sometimes abbreviated EC) is the organic compound with the formula (CH2O)2CO. It is classified as the cyclic carbonate ester of ethylene glycol and carbonic acid. At room temperature (25 °C) ethylene carbonate is a tra ...

and

propylene carbonate

Propylene carbonate (often abbreviated PC) is an organic compound with the formula C4H6O3. It is a cyclic carbonate ester derived from propylene glycol. This colorless and odorless liquid is useful as a polar, aprotic solvent. Propylene carbon ...

containing

complexes of lithium ions.

Ethylene carbonate

Ethylene carbonate (sometimes abbreviated EC) is the organic compound with the formula (CH2O)2CO. It is classified as the cyclic carbonate ester of ethylene glycol and carbonic acid. At room temperature (25 °C) ethylene carbonate is a tra ...

is essential for making solid electrolyte interphase on the carbon anode, but since it is solid at room temperature, a liquid

solvent

A solvent (from the Latin language, Latin ''wikt:solvo#Latin, solvō'', "loosen, untie, solve") is a substance that dissolves a solute, resulting in a Solution (chemistry), solution. A solvent is usually a liquid but can also be a solid, a gas ...

(such as

propylene carbonate

Propylene carbonate (often abbreviated PC) is an organic compound with the formula C4H6O3. It is a cyclic carbonate ester derived from propylene glycol. This colorless and odorless liquid is useful as a polar, aprotic solvent. Propylene carbon ...

or

diethyl carbonate) is added.

The electrolyte salt is almost always

lithium hexafluorophosphate (), which combines good

ionic conductivity with chemical and electrochemical stability. The

hexafluorophosphate

Hexafluorophosphate is an fluoroanion, anion with chemical formula of . It is an Octahedral molecular geometry, octahedral species that imparts no color to its salts. is isoelectronic with sulfur hexafluoride, , and the Hexafluorosilicic acid, h ...

anion

An ion () is an atom or molecule with a net electrical charge. The charge of an electron is considered to be negative by convention and this charge is equal and opposite to the charge of a proton, which is considered to be positive by conven ...

is essential for

passivating the aluminium current collector used for the positive electrode. A titanium tab is ultrasonically

welded to the aluminium current collector.

Other salts like

lithium perchlorate (),

lithium tetrafluoroborate (), and

lithium bis(trifluoromethanesulfonyl)imide () are frequently used in research in tab-less

coin cells, but are not usable in larger format cells, often because they are not compatible with the aluminium current collector. Copper (with a

spot-welded nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slo ...

tab) is used as the current collector at the negative electrode.

Current collector design and surface treatments may take various forms: foil, mesh, foam (dealloyed), etched (wholly or selectively), and coated (with various materials) to improve electrical characteristics.

Depending on materials choices, the

voltage

Voltage, also known as (electrical) potential difference, electric pressure, or electric tension, is the difference in electric potential between two points. In a Electrostatics, static electric field, it corresponds to the Work (electrical), ...

,

energy density

In physics, energy density is the quotient between the amount of energy stored in a given system or contained in a given region of space and the volume of the system or region considered. Often only the ''useful'' or extractable energy is measure ...

, life, and safety of a lithium-ion cell can change dramatically. Current effort has been exploring the use of

novel architectures using

nanotechnology

Nanotechnology is the manipulation of matter with at least one dimension sized from 1 to 100 nanometers (nm). At this scale, commonly known as the nanoscale, surface area and quantum mechanical effects become important in describing propertie ...

to improve performance. Areas of interest include nano-scale electrode materials and alternative electrode structures.

Electrochemistry

The reactants in the electrochemical reactions in a lithium-ion cell are the materials of the electrodes, both of which are compounds containing lithium atoms. Although many thousands of different materials have been investigated for use in lithium-ion batteries, only a very small number are commercially usable. All commercial Li-ion cells use intercalation compounds as active materials. The negative electrode is usually graphite, although

silicon

Silicon is a chemical element; it has symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic lustre, and is a tetravalent metalloid (sometimes considered a non-metal) and semiconductor. It is a membe ...

is often mixed in to increase the capacity. The electrolyte is usually

lithium hexafluorophosphate, dissolved in a mixture of

organic carbonates. A number of different materials are used for the positive electrode, such as

LiCoO2,

LiFePO4, and

lithium nickel manganese cobalt oxides.

During cell discharge the negative electrode is the anode and the positive electrode the cathode: electrons flow from the anode to the cathode through the external circuit. An oxidation

half-reaction

In chemistry, a half reaction (or half-cell reaction) is either the oxidation or reduction reaction component of a redox reaction. A half reaction is obtained by considering the change in oxidation states of individual substances involved in the r ...

at the anode produces positively charged lithium ions and negatively charged electrons. The oxidation half-reaction may also produce uncharged material that remains at the anode. Lithium ions move through the electrolyte; electrons move through the external circuit toward the cathode where they recombine with the cathode material in a reduction half-reaction. The electrolyte provides a conductive medium for lithium ions but does not partake in the electrochemical reaction. The reactions during discharge lower the chemical potential of the cell, so discharging transfers

energy

Energy () is the physical quantity, quantitative physical property, property that is transferred to a physical body, body or to a physical system, recognizable in the performance of Work (thermodynamics), work and in the form of heat and l ...

from the cell to wherever the electric current dissipates its energy, mostly in the external circuit.

During charging these reactions and transports go in the opposite direction: electrons move from the positive electrode to the negative electrode through the external circuit. To charge the cell the external circuit has to provide electrical energy. This energy is then stored as chemical energy in the cell (with some loss, e. g., due to

coulombic efficiency lower than 1).

Both electrodes allow lithium ions to move in and out of their structures with a process called ''insertion'' (''intercalation'') or ''extraction'' (''deintercalation''), respectively.

As the lithium ions "rock" back and forth between the two electrodes, these batteries are also known as "rocking-chair batteries" or "swing batteries" (a term given by some European industries).

The following equations exemplify the chemistry (left to right: discharging, right to left: charging).

The negative electrode half-reaction for the graphite is

:

LiC6 <=> C6 + Li+ + e^-

The positive electrode half-reaction in the lithium-doped cobalt oxide substrate is

:

CoO2 + Li+ + e- <=> LiCoO2

The full reaction being

:

LiC6 + CoO2 <=> C6 + LiCoO2

The overall reaction has its limits. Overdischarging supersaturates

lithium cobalt oxide, leading to the production of

lithium oxide

Lithium oxide (Lithium, Oxygen, O) or lithia is an Inorganic compound, inorganic chemical compound. It is a white or pale yellow solid. Although not specifically important, many materials are assessed on the basis of their Li2O content. For examp ...

, possibly by the following irreversible reaction:

:

Li+ + e^- + LiCoO2 -> Li2O + CoO

Overcharging up to 5.2

volts

The volt (symbol: V) is the unit of electric potential, electric potential difference (voltage), and electromotive force in the International System of Units (SI).

Definition

One volt is defined as the electric potential between two point ...

leads to the synthesis of cobalt (IV) oxide, as evidenced by

x-ray diffraction

X-ray diffraction is a generic term for phenomena associated with changes in the direction of X-ray beams due to interactions with the electrons around atoms. It occurs due to elastic scattering, when there is no change in the energy of the waves. ...

:

:

LiCoO2 -> Li+ + CoO2 + e^-

The

transition metal

In chemistry, a transition metal (or transition element) is a chemical element in the d-block of the periodic table (groups 3 to 12), though the elements of group 12 (and less often group 3) are sometimes excluded. The lanthanide and actinid ...

in the positive electrode, cobalt (

Co), is reduced from to during discharge, and oxidized from to during charge. The participation of

oxygen redox reactions in lithium-ion battery cathodes has been explored as a mechanism to enhance capacity beyond the limits set by transition metal oxidation states. Computational studies, primarily using

density functional theory

Density functional theory (DFT) is a computational quantum mechanical modelling method used in physics, chemistry and materials science to investigate the electronic structure (or nuclear structure) (principally the ground state) of many-body ...

, have provided insights into anionic redox activity and its implications for battery performance, helping researchers design materials that optimize capacity while mitigating issues like oxygen loss and structural degradation. Advances in understanding anionic redox have led to strategies such as surface fluorination to stabilize cathode materials, thereby improving their long-term cycling stability and safety.

The cell's energy is equal to the voltage times the charge. Each gram of lithium represents

Faraday's constant/6.941, or 13,901 coulombs. At 3 V, this gives 41.7 kJ per gram of lithium, or 11.6 kWh per kilogram of lithium. This is slightly more than the

heat of combustion

The heating value (or energy value or calorific value) of a substance, usually a fuel or food (see food energy), is the amount of heat released during the combustion of a specified amount of it.

The ''calorific value'' is the total energy relea ...

of

gasoline

Gasoline ( North American English) or petrol ( Commonwealth English) is a petrochemical product characterized as a transparent, yellowish, and flammable liquid normally used as a fuel for spark-ignited internal combustion engines. When for ...

; however, lithium-ion batteries as a whole are still significantly heavier per unit of energy due to the additional materials used in production.

Note that the cell voltages involved in these reactions are larger than the potential at which an

aqueous solution

An aqueous solution is a solution in which the solvent is water. It is mostly shown in chemical equations by appending (aq) to the relevant chemical formula. For example, a solution of table salt, also known as sodium chloride (NaCl), in water ...

s would

electrolyze.

Discharging and charging

During discharge, lithium ions () carry the

current within the battery cell from the negative to the positive electrode, through the non-

aqueous

An aqueous solution is a solution in which the solvent is water. It is mostly shown in chemical equations by appending (aq) to the relevant chemical formula. For example, a solution of table salt, also known as sodium chloride (NaCl), in wat ...

electrolyte

An electrolyte is a substance that conducts electricity through the movement of ions, but not through the movement of electrons. This includes most soluble Salt (chemistry), salts, acids, and Base (chemistry), bases, dissolved in a polar solven ...

and separator diaphragm.

[Linden, David and Reddy, Thomas B. (eds.) (2002). ''Handbook of Batteries 3rd Edition''. McGraw-Hill, New York. chapter 35. .]

During charging, an external electrical power source applies an over-voltage (a voltage greater than the cell's own voltage) to the cell, forcing electrons to flow from the positive to the negative electrode. The lithium ions also migrate (through the electrolyte) from the positive to the negative electrode where they become embedded in the porous electrode material in a process known as intercalation.

Energy losses arising from electrical

contact resistance

Electrical contact resistance (ECR, or simply contact resistance) is resistance to the flow of electric current caused by incomplete contact of the surfaces through which the current is flowing, and by films or oxide layers on the contacting sur ...

at interfaces between

electrode

An electrode is an electrical conductor used to make contact with a nonmetallic part of a circuit (e.g. a semiconductor, an electrolyte, a vacuum or a gas). In electrochemical cells, electrodes are essential parts that can consist of a varie ...

layers and at contacts with current collectors can be as high as 20% of the entire energy flow of batteries under typical operating conditions.

The charging procedures for single Li-ion cells, and complete Li-ion batteries, are slightly different:

* A single Li-ion cell is charged in two stages:

#

Constant current (CC)

#

Constant voltage (CV)

* A Li-ion battery (a set of Li-ion cells in series) is charged in three stages:

#

Constant current

# Balance (only required when cell groups become unbalanced during use)

#

Constant voltage

During the ''constant current'' phase, the charger applies a constant current to the battery at a steadily increasing voltage, until the top-of-charge voltage limit per cell is reached.

During the ''balance'' phase, the charger/battery reduces the charging current (or cycles the charging on and off to reduce the average current) while the

state of charge

State of charge (SOC) quantifies the remaining capacity available in a battery at a given time and in relation to a given state of ageing. It is usually expressed as percentage (0% = empty; 100% = full). An alternative form of the same measure i ...

of individual cells is brought to the same level by a balancing circuit until the battery is balanced. Balancing typically occurs whenever one or more cells reach their top-of-charge voltage before the other(s), as it is generally inaccurate to do so at other stages of the charge cycle. This is most commonly done by passive balancing, which

dissipates excess charge as heat via

resistor

A resistor is a passive two-terminal electronic component that implements electrical resistance as a circuit element. In electronic circuits, resistors are used to reduce current flow, adjust signal levels, to divide voltages, bias active e ...

s connected momentarily across the cells to be balanced. Active balancing is less common, more expensive, but more efficient, returning excess energy to other cells (or the entire pack) via a

DC-DC converter or other circuitry. Balancing most often occurs during the constant voltage stage of charging, switching between charge modes until complete. The pack is usually fully charged only when balancing is complete, as even a single cell group lower in charge than the rest will limit the entire battery's usable capacity to that of its own. Balancing can last hours or even days, depending on the magnitude of the imbalance in the battery.

During the ''constant voltage'' phase, the charger applies a voltage equal to the maximum cell voltage times the number of cells in series to the battery, as the current gradually declines towards 0, until the current is below a set threshold of about 3% of initial constant charge current.

Periodic topping charge about once per 500 hours. Top charging is recommended to be initiated when voltage goes below

Failure to follow current and voltage limitations can result in an explosion.

Charging temperature limits for Li-ion are stricter than the operating limits. Lithium-ion chemistry performs well at elevated temperatures but prolonged exposure to heat reduces battery life. Li‑ion batteries offer good charging performance at cooler temperatures and may even allow "fast-charging" within a temperature range of .

Charging should be performed within this temperature range. At temperatures from 0 to 5 °C charging is possible, but the charge current should be reduced. During a low-temperature (under 0 °C) charge, the slight temperature rise above ambient due to the internal cell resistance is beneficial. High temperatures during charging may lead to battery degradation and charging at temperatures above 45 °C will degrade battery performance, whereas at lower temperatures the internal resistance of the battery may increase, resulting in slower charging and thus longer charging times.

Batteries gradually self-discharge even if not connected and delivering current. Li-ion rechargeable batteries have a

self-discharge rate typically stated by manufacturers to be 1.5–2% per month.

The rate increases with temperature and state of charge. A 2004 study found that for most cycling conditions self-discharge was primarily time-dependent; however, after several months of stand on open circuit or float charge, state-of-charge dependent losses became significant. The self-discharge rate did not increase monotonically with state-of-charge, but dropped somewhat at intermediate states of charge. Self-discharge rates may increase as batteries age.

In 1999, self-discharge per month was measured at 8% at 21 °C, 15% at 40 °C, 31% at 60 °C. By 2007, monthly self-discharge rate was estimated at 2% to 3%, and 2

–3% by 2016.

By comparison, the self-discharge rate for

NiMH batteries dropped, as of 2017, from up to 30% per month for previously common cells

to about 0.08–0.33% per month for

low self-discharge NiMH batteries, and is about 10% per month in

NiCd batteries.

Cathode

Transition metal oxides (TMOs) are widely used as cathode materials in lithium-ion batteries as the variable oxidation state of transition metal cations allows oxides of these metals to reversibly host lithium ions (Li⁺) and undergo efficient redox (reduction-oxidation) reactions. Their layered or framework structures allow Li⁺ insertion/extraction during charging/discharging, while their transition metals and oxygen anions participate in electron transfer, enabling high energy density and stability.

There are three classes of commercial cathode materials in lithium-ion batteries: (1) layered oxides, (2) spinel oxides and (3) oxoanion complexes. All of them were discovered by John Goodenough and his collaborators.

Layered Oxides

LiCoO2 was used in the first commercial lithium-ion battery made by Sony in 1991. The layered oxides have a pseudo-

tetrahedral

In geometry, a tetrahedron (: tetrahedra or tetrahedrons), also known as a triangular pyramid, is a polyhedron composed of four triangular Face (geometry), faces, six straight Edge (geometry), edges, and four vertex (geometry), vertices. The tet ...

structure comprising layers made of MO

6 octahedra separated by interlayer spaces that allow for two-dimensional lithium-ion

diffusion

Diffusion is the net movement of anything (for example, atoms, ions, molecules, energy) generally from a region of higher concentration to a region of lower concentration. Diffusion is driven by a gradient in Gibbs free energy or chemical p ...

. The

band structure of Li

xCoO

2 allows for true

electronic (rather than

polaronic) conductivity. However, due to an overlap between the Co

4+ t

2g d-band with the O

2- 2p-band, the x must be >0.5, otherwise O

2 evolution occurs. This limits the charge capacity of this material to ~140 mA h g

−1.

Several other first-row (3d)

transition metal

In chemistry, a transition metal (or transition element) is a chemical element in the d-block of the periodic table (groups 3 to 12), though the elements of group 12 (and less often group 3) are sometimes excluded. The lanthanide and actinid ...

s also form layered LiMO

2 salts. Some can be directly prepared from

lithium oxide

Lithium oxide (Lithium, Oxygen, O) or lithia is an Inorganic compound, inorganic chemical compound. It is a white or pale yellow solid. Although not specifically important, many materials are assessed on the basis of their Li2O content. For examp ...

and M

2O

3 (e.g. for M=Ti, V, Cr, Co, Ni), while others (M= Mn or Fe) can be prepared by

ion exchange

Ion exchange is a reversible interchange of one species of ion present in an insoluble solid with another of like charge present in a solution surrounding the solid. Ion exchange is used in softening or demineralizing of water, purification of ch ...

from NaMO

2. LiVO

2, LiMnO

2 and LiFeO

2 suffer from structural instabilities (including mixing between M and Li sites) due to a low energy difference between octahedral and tetrahedral environments for the metal ion M. For this reason, they are not used in lithium-ion batteries.

However, Na

+ and Fe

3+ have sufficiently different sizes that NaFeO

2 can be used in

sodium-ion batteries.

Similarly, LiCrO

2 shows reversible lithium (de)intercalation around 3.2 V with 170–270 mAh/g. However, its

cycle life is short, because of

disproportionation of Cr

4+ followed by translocation of Cr

6+ into tetrahedral sites. On the other hand, NaCrO

2 shows a much better cycling stability. LiTiO

2 shows Li+ (de)intercalation at a voltage of ~1.5 V, which is too low for a cathode material.

These problems leave and as the only practical layered oxide materials for lithium-ion battery cathodes. The cobalt-based cathodes show high theoretical specific (per-mass) charge capacity, high volumetric capacity, low self-discharge, high discharge voltage, and good cycling performance. Unfortunately, they suffer from a high cost of the material.

For this reason, the current trend among lithium-ion battery manufacturers is to switch to cathodes with higher Ni content and lower Co content.

In addition to a lower (than cobalt) cost, nickel-oxide based materials benefit from the two-electron redox chemistry of Ni: in layered oxides comprising nickel (such as nickel-cobalt-manganese

NCM and nickel-cobalt-aluminium oxides

NCA), Ni cycles between the oxidation states +2 and +4 (in one step between +3.5 and +4.3 V),

cobalt- between +2 and +3, while Mn (usually >20%) and Al (typically, only 5% is needed) remain in +4 and 3+, respectively. Thus increasing the Ni content increases the cyclable charge. For example, NCM111 shows 160 mAh/g, while (NCM811) and (NCA) deliver a higher capacity of ~200 mAh/g. NCM and NCA batteries are collectively called Ternary Lithium Batteries.

It is worth mentioning so-called "lithium-rich" cathodes, that can be produced from traditional NCM (, where M=Ni, Co, Mn) layered cathode materials upon cycling them to voltages/charges corresponding to Li:M<0.5. Under such conditions a new semi-reversible redox transition at a higher voltage with ca. 0.4-0.8 electrons/metal site charge appears. This transition involves non-binding electron orbitals centered mostly on O atoms. Despite significant initial interest, this phenomenon did not result in marketable products because of the fast structural degradation (O2 evolution and lattice rearrangements) of such "lithium-rich" phases.

Cubic oxides (spinels)

LiMn2O4 adopts a cubic lattice, which allows for three-dimensional lithium-ion diffusion.

Manganese cathodes are attractive because manganese is less expensive than cobalt or nickel. The operating voltage of Li-LiMn

2O

4 battery is 4 V, and ca. one lithium per two Mn ions can be reversibly extracted from the tetrahedral sites, resulting in a practical capacity of <130 mA h g–1. However, Mn

3+ is not a stable oxidation state, as it tends to

disporportionate into insoluble Mn

4+ and soluble Mn

2+.

[A reflection on lithium-ion battery cathode chemistry. 2020. Nature Communications. 11/1, 9. A. Manthiram. doi: 10.1038/s41467-020-15355-0] LiMn

2O

4 can also intercalate more than 0.5 Li per Mn at a lower voltage around +3.0 V. However, this results in an irreversible

phase transition

In physics, chemistry, and other related fields like biology, a phase transition (or phase change) is the physical process of transition between one state of a medium and another. Commonly the term is used to refer to changes among the basic Sta ...

due to

Jahn-Teller distortion in Mn3+:t2g3eg1, as well as

disproportionation and dissolution of Mn

3+.

An important improvement of Mn spinel are related cubic structures of the LiMn

1.5Ni

0.5O

4 type, where Mn exists as Mn4+ and Ni cycles reversibly between the

oxidation states

In chemistry, the oxidation state, or oxidation number, is the hypothetical charge of an atom if all of its bonds to other atoms are fully ionic. It describes the degree of oxidation (loss of electrons) of an atom in a chemical compound. Concep ...

+2 and +4.

This materials show a reversible Li-ion capacity of ca. 135 mAh/g around 4.7 V. Although such high voltage is beneficial for increasing the

specific energy

Specific energy or massic energy is energy per unit mass. It is also sometimes called gravimetric energy density, which is not to be confused with energy density, which is defined as energy per unit volume. It is used to quantify, for example, st ...

of batteries, the adoption of such materials is currently hindered by the lack of suitable high-voltage electrolytes. In general, materials with a high

nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slo ...

content are favored in 2023, because of the possibility of a 2-electron cycling of Ni between the

oxidation states

In chemistry, the oxidation state, or oxidation number, is the hypothetical charge of an atom if all of its bonds to other atoms are fully ionic. It describes the degree of oxidation (loss of electrons) of an atom in a chemical compound. Concep ...

+2 and +4.

LiV

2O

4 (lithium vanadium oxide) operates as a lower (ca. +3.0 V) voltage than

LiMn2O4, suffers from similar durability issues, is more expensive, and thus is not considered of practical interest.

Oxoanionic/olivins

Around 1980

Manthiram discovered that

oxoanions (

molybdates and

tungstates in that particular case) cause a substantial positive shift in the redox potential of the metal-ion compared to oxides. In addition, these oxoanionic cathode materials offer better stability/safety than the corresponding oxides. However, they also suffer from poor electronic conductivity due to the long distance between redox-active metal centers, which slows down the electron transport. This necessitates the use of small (less than 200 nm) cathode particles and coating each particle with a layer of electronically-

conducting carbon. This reduces the

packing density of these materials.

Although numerous combinations of oxoanions (

sulfate

The sulfate or sulphate ion is a polyatomic anion with the empirical formula . Salts, acid derivatives, and peroxides of sulfate are widely used in industry. Sulfates occur widely in everyday life. Sulfates are salts of sulfuric acid and many ...

,

phosphate

Phosphates are the naturally occurring form of the element phosphorus.

In chemistry, a phosphate is an anion, salt, functional group or ester derived from a phosphoric acid. It most commonly means orthophosphate, a derivative of orthop ...

,

silicate

A silicate is any member of a family of polyatomic anions consisting of silicon and oxygen, usually with the general formula , where . The family includes orthosilicate (), metasilicate (), and pyrosilicate (, ). The name is also used ...

) with various metals (mostly Mn, Fe, Co, Ni) have been studied,

LiFePO4 is the only one that has been commercialized. Although it was originally used primarily for

stationary energy storage due to its lower energy density compared to layered oxides,

it has begun to be widely used in electric vehicles since the 2020s.

Anode

Negative electrode materials are traditionally constructed from graphite and other carbon materials, although newer silicon-based materials are being increasingly used (see

Nanowire battery). In 2016, 89% of lithium-ion batteries contained graphite (43% artificial and 46% natural), 7% contained amorphous carbon (either soft carbon or

hard carbon), 2% contained lithium titanate (LTO) and 2% contained silicon or tin-based materials.

These materials are used because they are abundant, electrically conducting and can intercalate lithium ions to store electrical charge with modest volume expansion (~10%).

Graphite is the dominant material because of its low intercalation voltage and excellent performance. Various alternative materials with higher capacities have been proposed, but they usually have higher voltages, which reduces energy density. Low voltage is the key requirement for anodes; otherwise, the excess capacity is useless in terms of energy density.

As graphite is limited to a maximum capacity of 372 mAh/g

much research has been dedicated to the development of materials that exhibit higher theoretical capacities and overcoming the technical challenges that presently encumber their implementation. The extensive 2007 Review Article by Kasavajjula et al.

summarizes early research on silicon-based anodes for lithium-ion secondary cells. In particular, Hong Li et al.

showed in 2000 that the electrochemical insertion of lithium ions in silicon

nanoparticle

A nanoparticle or ultrafine particle is a particle of matter 1 to 100 nanometres (nm) in diameter. The term is sometimes used for larger particles, up to 500 nm, or fibers and tubes that are less than 100 nm in only two directions. At ...

s and silicon nanowires leads to the formation of an amorphous Li-Si alloy. The same year, Bo Gao and his doctoral advisor, Professor Otto Zhou described the cycling of electrochemical cells with anodes comprising silicon nanowires, with a reversible capacity ranging from at least approximately 900 to 1500 mAh/g.

Diamond-like carbon coatings can increase retention capacity by 40% and cycle life by 400% for lithium based batteries.

To improve the stability of the lithium anode, several approaches to installing a protective layer have been suggested.

Silicon is beginning to be looked at as an anode material because it can accommodate significantly more lithium ions, storing up to 10 times the electric charge, however this alloying between lithium and silicon results in significant volume expansion (ca. 400%),

which causes catastrophic failure for the cell. Silicon has been used as an anode material but the insertion and extraction of

\scriptstyle Li+ can create cracks in the material. These cracks expose the Si surface to an electrolyte, causing decomposition and the formation of a solid electrolyte interphase (SEI) on the new Si surface (crumpled graphene encapsulated Si nanoparticles). This SEI will continue to grow thicker, deplete the available

\scriptstyle Li+, and degrade the capacity and cycling stability of the anode.

In addition to carbon- and silicon- based anode materials for lithium-ion batteries, high-entropy metal oxide materials are being developed. These conversion (rather than intercalation) materials comprise an alloy (or subnanometer mixed phases) of several metal oxides performing different functions. For example, Zn and Co can act as electroactive charge-storing species, Cu can provide an electronically conducting support phase and MgO can prevent pulverization.

Electrolyte

Liquid

Liquid is a state of matter with a definite volume but no fixed shape. Liquids adapt to the shape of their container and are nearly incompressible, maintaining their volume even under pressure. The density of a liquid is usually close to th ...

electrolytes in lithium-ion batteries consist of lithium

salts

In chemistry, a salt or ionic compound is a chemical compound consisting of an assembly of positively charged ions ( cations) and negatively charged ions (anions), which results in a compound with no net electric charge (electrically neutral). ...

, such as

,

or

in an

organic solvent

A solvent (from the Latin language, Latin ''wikt:solvo#Latin, solvō'', "loosen, untie, solve") is a substance that dissolves a solute, resulting in a Solution (chemistry), solution. A solvent is usually a liquid but can also be a solid, a gas ...

, such as

ethylene carbonate

Ethylene carbonate (sometimes abbreviated EC) is the organic compound with the formula (CH2O)2CO. It is classified as the cyclic carbonate ester of ethylene glycol and carbonic acid. At room temperature (25 °C) ethylene carbonate is a tra ...

,

dimethyl carbonate

Dimethyl carbonate (DMC) is an organic compound with the formula OC(OCH3)2. It is a colourless, flammable liquid. It is classified as a carbonate ester. This compound has found use as a methylating agent and as a co-solvent in lithium-ion ba ...

, and

diethyl carbonate. A liquid electrolyte acts as a conductive pathway for the movement of cations passing from the negative to the positive electrodes during discharge. Typical conductivities of liquid electrolyte at room temperature () are in the range of 10

mS/cm, increasing by approximately 30–40% at and decreasing slightly at . The combination of linear and cyclic carbonates (e.g.,

ethylene carbonate

Ethylene carbonate (sometimes abbreviated EC) is the organic compound with the formula (CH2O)2CO. It is classified as the cyclic carbonate ester of ethylene glycol and carbonic acid. At room temperature (25 °C) ethylene carbonate is a tra ...

(EC) and

dimethyl carbonate

Dimethyl carbonate (DMC) is an organic compound with the formula OC(OCH3)2. It is a colourless, flammable liquid. It is classified as a carbonate ester. This compound has found use as a methylating agent and as a co-solvent in lithium-ion ba ...

(DMC)) offers high conductivity and

solid electrolyte interphase (SEI)-forming ability. While EC forms a stable SEI, it is not a liquid at room temperature, only becoming a liquid with the addition of additives such as the previously mentioned DMC or

diethyl carbonate (DEC) or

ethyl methyl carbonate (EMC). Organic solvents easily decompose on the negative electrodes during charge. When appropriate

organic solvent

A solvent (from the Latin '' solvō'', "loosen, untie, solve") is a substance that dissolves a solute, resulting in a solution. A solvent is usually a liquid but can also be a solid, a gas, or a supercritical fluid. Water is a solvent for p ...

s are used as the electrolyte, the solvent decomposes on initial charging and forms a solid layer called the solid electrolyte interphase, which is electrically insulating, yet provides significant ionic conductivity, behaving as a solid electrolyte. The interphase prevents further decomposition of the electrolyte after the second charge as it grows thick enough to prevent electron tunneling after the first charge cycle. For example,

ethylene carbonate

Ethylene carbonate (sometimes abbreviated EC) is the organic compound with the formula (CH2O)2CO. It is classified as the cyclic carbonate ester of ethylene glycol and carbonic acid. At room temperature (25 °C) ethylene carbonate is a tra ...

is decomposed at a relatively high voltage, 0.7 V vs. lithium, and forms a dense and stable interface. Composite electrolytes based on POE (poly(oxyethylene)) provide a relatively stable interface. It can be either solid (high molecular weight) and be applied in dry Li-polymer cells, or liquid (low molecular weight) and be applied in regular Li-ion cells.

Room-temperature ionic liquids (RTILs) are another approach to limiting the flammability and volatility of organic electrolytes.

Solid Electrolyte Interphase (SEI)

The term solid electrolyte interphase was first coined by Peled in 1979 to describe the layer of insoluble products deposited on alkali and alkaline earth cathodes in non-aqueous batteries (NAB). However, Dey and Sullivan had noted previously in 1970 that graphite, in a lithium metal half cell using

propylene carbonate (PC), reduced the electrolyte during discharge at a rate which linearly increased with the current. They proposed that the following reaction was taking place:

:

C4H6O3 + 2e- -> CH3-CH=CH2 + CO3^

The same reaction was later proposed by Fong et al in 1990, where they theorized that the carbonate ion was reacting with the lithium to form

lithium carbonate

Lithium carbonate is an inorganic compound, the lithium salt of carbonic acid with the chemical formula, formula . This white Salt (chemistry), salt is widely used in processing metal oxides. It is on the WHO Model List of Essential Medicines, Wor ...

, which was then forming a passivating layer on the surface of the graphite. PC is no longer used in batteries today as the molecules can intercalate into the graphite layers and react with the lithium there to form propylene and acts to delaminate the graphite.

The insulating properties of the SEI allow the battery to reach more extreme voltage gaps without simply reducing the electrolyte. This ability of the SEI to improve the voltage window of batteries was discovered almost on accident, but plays a vital role in high voltage batteries today.

Solid Electrolytes

Recent advances in battery technology involve using a solid as the electrolyte material. The most promising of these are ceramics. Solid ceramic electrolytes are mostly lithium metal

oxide

An oxide () is a chemical compound containing at least one oxygen atom and one other element in its chemical formula. "Oxide" itself is the dianion (anion bearing a net charge of −2) of oxygen, an O2− ion with oxygen in the oxidation st ...

s, which allow lithium-ion transport through the solid more readily due to the intrinsic lithium. The main benefit of solid electrolytes is that there is no risk of

leaks, which is a serious safety issue for batteries with liquid electrolytes. Solid ceramic electrolytes can be further broken down into two main categories: ceramic and glassy.

Ceramic

A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcela ...

solid electrolytes are highly ordered compounds with

crystal structure

In crystallography, crystal structure is a description of ordered arrangement of atoms, ions, or molecules in a crystalline material. Ordered structures occur from intrinsic nature of constituent particles to form symmetric patterns that repeat ...

s that usually have ion transport channels. Common ceramic electrolytes are lithium

super ion conductors (LISICON) and

perovskites

A perovskite is a crystalline material of formula ABX3 with a crystal structure similar to that of Perovskite, the mineral perovskite, this latter consisting of calcium titanium oxide (CaTiO3). The mineral was first discovered in the Ural Moun ...

.

Glass

Glass is an amorphous (non-crystalline solid, non-crystalline) solid. Because it is often transparency and translucency, transparent and chemically inert, glass has found widespread practical, technological, and decorative use in window pane ...

y solid electrolytes are

amorphous

In condensed matter physics and materials science, an amorphous solid (or non-crystalline solid) is a solid that lacks the long-range order that is a characteristic of a crystal. The terms "glass" and "glassy solid" are sometimes used synonymousl ...

atomic structures made up of similar elements to ceramic solid electrolytes but have higher

conductivities overall due to higher conductivity at grain boundaries. Both glassy and ceramic electrolytes can be made more ionically conductive by substituting sulfur for oxygen. The larger radius of sulfur and its higher ability to be

polarized allow higher conductivity of lithium. This contributes to conductivities of solid electrolytes are nearing parity with their liquid counterparts, with most on the order of 0.1 mS/cm and the best at 10 mS/cm. An efficient and economic way to tune targeted electrolytes properties is by adding a third component in small concentrations, known as an additive. By adding the additive in small amounts, the bulk properties of the electrolyte system will not be affected whilst the targeted property can be significantly improved. The numerous additives that have been tested can be divided into the following three distinct categories: (1) those used for SEI chemistry modifications; (2) those used for enhancing the ion conduction properties; (3) those used for improving the safety of the cell (e.g. prevent overcharging).

Electrolyte alternatives have also played a significant role, for example the

lithium polymer battery

A lithium polymer battery, or more correctly, lithium-ion polymer battery (abbreviated as LiPo, LIP, Li-poly, lithium-poly, and others), is a rechargeable battery derived from lithium-ion and lithium-metal battery technology. The primary differ ...

. Polymer electrolytes are promising for minimizing the dendrite formation of lithium. Polymers are supposed to prevent short circuits and maintain conductivity.

The ions in the electrolyte diffuse because there are small changes in the electrolyte concentration. Linear diffusion is only considered here. The change in concentration ''c'', as a function of time ''t'' and distance ''x'', is

:

In this equation, ''D'' is the

diffusion coefficient

Diffusivity, mass diffusivity or diffusion coefficient is usually written as the proportionality constant between the molar flux due to molecular diffusion and the negative value of the gradient in the concentration of the species. More accurate ...

for the lithium ion. It has a value of in the electrolyte. The value for ''ε'', the porosity of the electrolyte, is 0.724.

Battery designs and formats

Lithium-ion batteries may have multiple levels of structure. Small batteries consist of a single battery cell. Larger batteries connect cells

in parallel into a module and connect modules

in series and parallel into a pack. Multiple packs may be connected

in series to increase the voltage.

Batteries may be equipped with temperature sensors, heating/cooling systems,

voltage regulator

A voltage regulator is a system designed to automatically maintain a constant voltage. It may use a simple feed-forward design or may include negative feedback. It may use an electromechanical mechanism or electronic components. Depending on the ...

circuits,

voltage taps, and charge-state monitors. These components address safety risks like overheating and

short circuit

A short circuit (sometimes abbreviated to short or s/c) is an electrical circuit that allows a current to travel along an unintended path with no or very low electrical impedance. This results in an excessive current flowing through the circuit ...

ing.

Electrode layers and electrolyte

On the macrostructral level (length scale 0.1–5 mm) almost all commercial lithium-ion batteries comprise foil current collectors (aluminium for cathode and copper for anode). Copper is selected for the anode, because lithium does not alloy with it. Aluminum is used for the cathode, because it passivates in LiPF

6 electrolytes.

Cells

Li-ion cells are available in various form factors, which can generally be divided into four types:

* Coin cells have a rugged design with metal (stainless steel, usually) casing. Because of their poor

specific energy

Specific energy or massic energy is energy per unit mass. It is also sometimes called gravimetric energy density, which is not to be confused with energy density, which is defined as energy per unit volume. It is used to quantify, for example, st ...

(in Wh/kg) and small energy (Wh) per cell, their use is limited to

handwatches,

portable calculators and research. Notably, coin format cells are more commonly used for primary

lithium-metal batteries.

* Small cylindrical (solid body without terminals, such as those used in most

e-bikes and most

electric vehicle battery

An electric vehicle battery is a rechargeable battery used to power the electric motors of a battery electric vehicle (BEV) or hybrid electric vehicle (HEV).

They are typically lithium-ion batteries that are designed for high power-to-weigh ...

and older laptop batteries); they typically come in

standard sizes.

* Large cylindrical (solid body with large threaded terminals)

* Flat or pouch (soft, flat body, such as those used in cell phones and newer laptops; these are

lithium-ion polymer batteries.

* Rigid plastic case with large threaded terminals (such as electric vehicle traction packs)

Cells with a cylindrical shape are made in a characteristic "

swiss roll" manner (known as a "jelly roll" in the US), which means it is a single long "sandwich" of the positive electrode, separator, negative electrode, and separator rolled into a single spool. The result is encased in a container. One advantage of cylindrical cells is faster production speed. One disadvantage can be a large radial temperature gradient at high discharge rates.

The absence of a case gives pouch cells the highest gravimetric energy density; however, many applications require containment to prevent expansion when their

state of charge

State of charge (SOC) quantifies the remaining capacity available in a battery at a given time and in relation to a given state of ageing. It is usually expressed as percentage (0% = empty; 100% = full). An alternative form of the same measure i ...

(SOC) level is high, and for general structural stability. Both rigid plastic and pouch-style cells are sometimes referred to as

prismatic

An optical prism is a transparent optics, optical element with flat, polished surfaces that are designed to refraction, refract light. At least one surface must be angled—elements with two parallel surfaces are ''not'' prisms. The most fami ...

cells due to their rectangular shapes. Three basic battery types are used in 2020s-era electric vehicles: cylindrical cells (e.g., Tesla), prismatic pouch (e.g., from

LG), and prismatic can cells (e.g., from LG,

Samsung

Samsung Group (; stylised as SΛMSUNG) is a South Korean Multinational corporation, multinational manufacturing Conglomerate (company), conglomerate headquartered in the Samsung Town office complex in Seoul. The group consists of numerous a ...

,

Panasonic

is a Japanese multinational electronics manufacturer, headquartered in Kadoma, Osaka, Kadoma, Japan. It was founded in 1918 as in Fukushima-ku, Osaka, Fukushima by Kōnosuke Matsushita. The company was incorporated in 1935 and renamed and c ...

, and others).

have been demonstrated that suspend the cathode or anode material in an aqueous or organic solution.

As of 2014, the smallest Li-ion cell was

pin-shaped with a diameter of 3.5 mm and a weight of 0.6 g, made by

Panasonic

is a Japanese multinational electronics manufacturer, headquartered in Kadoma, Osaka, Kadoma, Japan. It was founded in 1918 as in Fukushima-ku, Osaka, Fukushima by Kōnosuke Matsushita. The company was incorporated in 1935 and renamed and c ...

. A

coin cell form factor is available for LiCoO

2 cells, usually designated with a "LiR" prefix.

Electrode Layers

Cell voltage

The average voltage of LCO (lithium cobalt oxide) chemistry is 3.6v if made with hard carbon cathode and 3.7v if made with graphite cathode. Comparatively, the latter has a flatter discharge voltage curve.

Uses

Lithium ion batteries are used in a multitude of applications, including

consumer electronics

Consumer electronics, also known as home electronics, are electronic devices intended for everyday household use. Consumer electronics include those used for entertainment, Communication, communications, and recreation. Historically, these prod ...

, toys, power tools, and electric vehicles.

More niche uses include backup power in telecommunications applications. Lithium-ion batteries are also frequently discussed as a potential option for

grid energy storage

Grid energy storage, also known as large-scale energy storage, are technologies connected to the electrical power grid that store energy for later use. These systems help balance supply and demand by storing excess electricity from variabl ...

, although as of 2020, they were not yet cost-competitive at scale.

Performance

Because lithium-ion batteries can have a variety of positive and negative electrode materials, the energy density and voltage vary accordingly.

The

open-circuit voltage

Open-circuit voltage (abbreviated as OCV or VOC) is the voltage, difference of electrical potential between two Terminal (electronics), terminals of an electronic device when disconnected from any Electric Circuit, circuit. There is no External ...

is higher than in

aqueous batteries (such as

lead–acid,

nickel–metal hydride and

nickel–cadmium).

Internal resistance

In electrical engineering, a practical electric power source which is a linear circuit may, according to Thévenin's theorem, be represented as an ideal voltage source in series with an impedance. This impedance is termed the internal resis ...

increases with both cycling and age, although this depends strongly on the voltage and temperature the batteries are stored at. Rising internal resistance causes the voltage at the terminals to drop under load, which reduces the maximum current draw. Eventually, increasing resistance will leave the battery in a state such that it can no longer support the normal discharge currents requested of it without unacceptable voltage drop or overheating.

Batteries with a lithium iron phosphate positive and graphite negative electrodes have a nominal open-circuit voltage of 3.2 V and a typical charging voltage of 3.6 V. Lithium nickel manganese cobalt (NMC) oxide positives with graphite negatives have a 3.7 V nominal voltage with a 4.2 V maximum while charging. The charging procedure is performed at constant voltage with current-limiting circuitry (i.e., charging with constant current until a voltage of 4.2 V is reached in the cell and continuing with a constant voltage applied until the current drops close to zero). Typically, the charge is terminated at 3% of the initial charge current. In the past, lithium-ion batteries could not be fast-charged and needed at least two hours to fully charge. Current-generation cells can be fully charged in 45 minutes or less. In 2015 researchers demonstrated a small 600 mAh capacity battery charged to 68 percent capacity in two minutes and a 3,000 mAh battery charged to 48 percent capacity in five minutes. The latter battery has an energy density of 620 W·h/L. The device employed heteroatoms bonded to graphite molecules in the anode.