|

Spot Welding

Spot welding (or resistance spot welding) is a type of electric resistance welding used to weld various sheet metal products, through a process in which contacting metal surface points are joined by the heat obtained from resistance to electric current. The process uses two shaped copper alloy electrodes to concentrate welding current into a small "spot" and to simultaneously clamp the sheets together. Work-pieces are held together under pressure exerted by electrodes. Typically the sheets are in the thickness range. Forcing a large current through the spot will melt the metal and form the weld. The attractive feature of spot welding is that a large amount of energy can be delivered to the spot in a very short time (approximately 10–100 milliseconds). This permits the welding to occur without excessive heating of the remainder of the sheet. The amount of heat (energy) delivered to the spot is determined by the resistance between the electrodes and the magnitude and duration ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spot Welder (Miller 12,000 Amp Model)

Spot welding (or resistance spot welding) is a type of electric resistance welding used to weld various sheet metal products, through a process in which contacting metal surface points are joined by the heat obtained from resistance to electric current. The process uses two shaped List of copper alloys, copper alloy electrodes to concentrate welding current into a small "spot" and to simultaneously clamp the sheets together. Work-pieces are held together under pressure exerted by electrodes. Typically the sheets are in the thickness range. Forcing a large current through the spot will melt the metal and form the weld. The attractive feature of spot welding is that a large amount of energy can be delivered to the spot in a very short time (approximately 10–100 milliseconds). This permits the welding to occur without excessive heating of the remainder of the sheet. The amount of heat (energy) delivered to the spot is determined by the resistance between the electrodes and the ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrical Conductivity

Electrical resistivity (also called volume resistivity or specific electrical resistance) is a fundamental specific property of a material that measures its electrical resistance or how strongly it resists electric current. A low resistivity indicates a material that readily allows electric current. Resistivity is commonly represented by the Greek alphabet, Greek letter (Rho (letter), rho). The SI unit of electrical resistivity is the ohm-metre (Ω⋅m). For example, if a solid cube of material has sheet contacts on two opposite faces, and the Electrical resistance, resistance between these contacts is , then the resistivity of the material is . Electrical conductivity (or specific conductance) is the reciprocal of electrical resistivity. It represents a material's ability to conduct electric current. It is commonly signified by the Greek letter (Sigma (letter), sigma), but (kappa) (especially in electrical engineering) and (gamma) are sometimes used. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

List Of Welding Processes

This is a list of welding processes, separated into their respective categories. The associated ''N reference numbers'' (second column) are specified in ISO 4063 (in the European Union published as ''EN ISO 4063''). Numbers in parentheses are obsolete and were removed from the current (1998) version of ISO 4063. The AWS reference codes of the American Welding Society are commonly used in North America."Welding Inspection Handbook", 3rd edition, American Welding Society, , Miami, FL, pp. 10-11 (2000) Arc welding ''Overview article: arc welding'' Oxyfuel gas welding ''Overview article: Oxy-fuel welding and cutting'' Resistance welding ''Overview article: electric resistance welding'' Solid-state welding Other types of welding Notes and references *Cary, Howard B. and Scott C. Helzer (2005). Modern Welding Technology. Upper Saddle River, New Jersey: Pearson Education. . *Lincoln Electric (1994). The Procedure Handbook of Arc Welding. Cleveland: Lincoln Electric. . ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Clinching (metalworking)

In metalworking, clinching or press-joining is a bulk sheet metal forming process aimed at joining thin metal sheets without additional components, using special tools to Deformation (engineering), plastically form an interlock between two or more sheets. The process is generally performed at room temperature, but in some special cases the sheets can be pre-heated to improve the material ductility and thereby avoid the formation of cracks during the process. Clinching is characterized by a series of advantages over competitive technologies: * Reduced joining time (the joining time is less than a second) * Reduced cost and weight: the process does not involve additional elements such as screws, rivets or adhesives * Reduced cost of the machine * No Pilot hole, pre-holes are required * Can be adopted to join different materials including metals, polymers, wood, and composite materials * Can be easily automated and does not require qualified workers * Eco-friendly: it does not requi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stud Welding

Stud welding is a technique similar to flash welding where a fastener or specially formed nut is welded onto another metal part, typically a base metal or substrate. The fastener can take different forms, but typically fall under threaded, unthreaded, or tapped. The bolts may be automatically fed into the stud welder. Weld nuts generally have a flange with small nubs that melt to form the weld. ''Weld studs'' are used in stud welding systems. Manufacturers create weld studs for the two main forms of stud welding: capacitor discharge stud welding and drawn arc stud welding Drawn arc stud welding Drawn arc stud welding joins a stud and another piece of metal together by heating both parts with an arc. The stud is usually joined to a flat plate by using the stud as one of the electrodes. The polarity used in stud welding depends on the type of metal being used. Welding aluminium, for example, would usually require direct-current electrode positive (DCEP). Welding steel would re ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Soldering

Soldering (; ) is a process of joining two metal surfaces together using a filler metal called solder. The soldering process involves heating the surfaces to be joined and melting the solder, which is then allowed to cool and solidify, creating a strong and durable joint. Soldering is commonly used in the electronics industry for the manufacture and repair of Printed circuit board, printed circuit boards (PCBs) and other electronic components. It is also used in plumbing and Metalworking, metalwork, as well as in the manufacture of jewelry and other decorative items. The solder used in the process can vary in composition, with different alloys used for different applications. Common solder alloys include tin-lead, tin-silver, and tin-copper, among others. Lead-free solder has also become more widely used in recent years due to health and environmental concerns associated with the use of lead. In addition to the type of solder used, the temperature and method of heating also p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lithium-ion

A lithium-ion or Li-ion battery is a type of rechargeable battery that uses the reversible Intercalation (chemistry), intercalation of Li+ ions into electronically Electrical conductor, conducting solids to store energy. Li-ion batteries are characterized by higher specific energy, energy density, and Energy efficiency (physics), energy efficiency and a longer cycle life and calendar life than other types of rechargeable batteries. Also noteworthy is a dramatic improvement in lithium-ion battery properties after their market introduction in 1991; over the following 30 years, their volumetric energy density increased threefold while their cost dropped tenfold. In late 2024 global demand passed per year, while production capacity was more than twice that. The invention and commercialization of Li-ion batteries Timeline of historic inventions, has had a large impact on technology, as recognized by the 2019 Nobel Prize in Chemistry. Li-ion batteries have enabled portable consumer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nickel–metal Hydride Battery

A nickel–metal hydride battery (NiMH or Ni–MH) is a type of rechargeable battery. The chemical reaction at the positive electrode is similar to that of the nickel–cadmium cell (NiCd), with both using nickel oxide hydroxide (NiOOH). However, the negative electrodes use a hydrogen-absorbing alloy instead of cadmium. NiMH batteries can have two to three times the capacity of NiCd batteries of the same size, with significantly higher energy density, although only about half that of lithium-ion batteries. They are typically used as a substitute for similarly shaped non-rechargeable alkaline batteries, as they feature a slightly lower but generally compatible cell voltage and are less prone to leaking. History Work on NiMH batteries began at the Battelle-Geneva Research Center following the technology's invention in 1967. It was based on sintered Ti2Ni+TiNi+x alloys and NiOOH electrodes. Development was sponsored over nearly two decades by Daimler-Benz and by Volkswa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nickel–cadmium Battery

The nickel–cadmium battery (Ni–Cd battery or NiCad battery) is a type of rechargeable battery using nickel oxide hydroxide and metallic cadmium as electrodes. The abbreviation ''Ni–Cd'' is derived from the chemical symbols of nickel (Ni) and cadmium (Cd): the abbreviation ''NiCad'' is a registered trademark of Saft Groupe S.A., SAFT Corporation, although this brand name is genericized trademark, commonly used to describe all Ni–Cd batteries. Battery (electricity)#Wet cell, Wet-cell nickel–cadmium batteries were invented in 1899. A Ni–Cd battery has a terminal voltage during discharge of around 1.2 volts which decreases little until nearly the end of discharge. The maximum electromotive force offered by a Ni–Cd cell is 1.3V. Ni–Cd batteries are made in a wide range of sizes and capacities, from portable sealed types interchangeable with carbon–zinc dry cells, to large ventilated cells used for standby power and motive power. Compared with other types of rechargeab ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Orthodontics

Orthodontics (also referred to as orthodontia) is a dentistry specialty that addresses the diagnosis, prevention, management, and correction of mal-positioned teeth and jaws, as well as misaligned bite patterns. It may also address the modification of facial growth, known as dentofacial orthopedics. Abnormal alignment of the teeth and jaws is very common. The approximate worldwide prevalence of malocclusion was as high as 56%. However, conclusive evidence-based medicine, scientific evidence for the Health benefit (medicine), health benefits of orthodontic treatment is lacking, although patients with completed treatment have reported a higher quality of life than that of untreated patients undergoing orthodontic treatment. The main reason for the prevalence of these malocclusions is diets with less fresh fruit and vegetables and overall softer foods in childhood, causing smaller jaws with less room for the teeth to erupt. Treatment may require several months to a few years and enta ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Assembly Line

An assembly line, often called ''progressive assembly'', is a manufacturing process where the unfinished product moves in a direct line from workstation to workstation, with parts added in sequence until the final product is completed. By mechanically moving parts to workstations and transferring the unfinished product from one workstation to another, a finished product can be assembled faster and with less labor than having workers carry parts to a stationary product. Assembly lines are common methods of assembling complex items such as automobiles and other transportation equipment, household appliances and Consumer electronics, electronic goods. Workers in charge of the works of assembly line are called assemblers. Concepts Assembly lines are designed for the sequential organization of workers, tools or machines, and parts. The motion of workers is minimized to the extent possible. All parts or assemblies are handled either by conveyors or motorized vehicles such as forklif ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

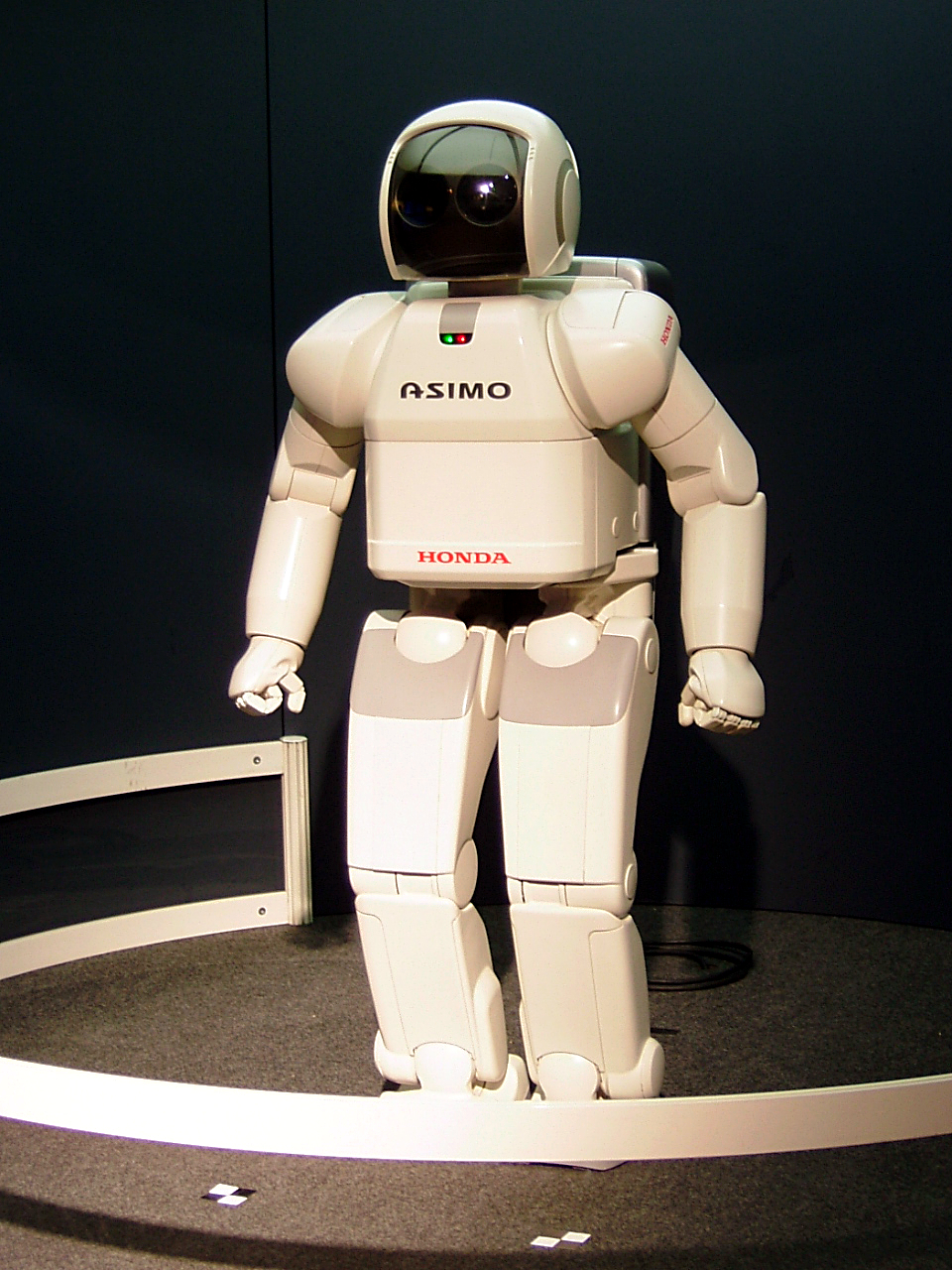

Robot

A robot is a machine—especially one Computer program, programmable by a computer—capable of carrying out a complex series of actions Automation, automatically. A robot can be guided by an external control device, or the robot control, control may be embedded within. Robots may be constructed to evoke Humanoid robot, human form, but most robots are task-performing machines, designed with an emphasis on stark functionality, rather than expressive aesthetics. Robots can be autonomous robot, autonomous or semi-autonomous and range from humanoids such as Honda's ''Advanced Step in Innovative Mobility'' (ASIMO) and TOSY's ''TOSY Ping Pong Playing Robot'' (TOPIO) to industrial robots, robot-assisted surgery, medical operating robots, patient assist robots, dog therapy robots, collectively programmed Swarm robotics, ''swarm'' robots, UAV drones such as General Atomics MQ-1 Predator, and even microscopic Nanorobotics, nanorobots. By mimicking a lifelike appearance or automating mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |