Crystal growth on:

[Wikipedia]

[Google]

[Amazon]

Crystal growth is a major stage of a crystallization process, and consists of the addition of new atoms, ions, or

Nucleation can be either

Nucleation can be either

The interface between a crystal and its vapor can be molecularly sharp at temperatures well below the melting point. An ideal crystalline surface grows by the spreading of single layers, or equivalently, by the lateral advance of the growth steps bounding the layers. For perceptible growth rates, this mechanism requires a finite driving force (or degree of supercooling) in order to lower the nucleation barrier sufficiently for nucleation to occur by means of thermal fluctuations. In the theory of crystal growth from the melt, Keith Burton and Nicolás Cabrera have distinguished between two major mechanisms:

The interface between a crystal and its vapor can be molecularly sharp at temperatures well below the melting point. An ideal crystalline surface grows by the spreading of single layers, or equivalently, by the lateral advance of the growth steps bounding the layers. For perceptible growth rates, this mechanism requires a finite driving force (or degree of supercooling) in order to lower the nucleation barrier sufficiently for nucleation to occur by means of thermal fluctuations. In the theory of crystal growth from the melt, Keith Burton and Nicolás Cabrera have distinguished between two major mechanisms:

It is generally believed that the mechanical and other properties of the crystal are also pertinent to the subject matter, and that crystal morphology provides the missing link between growth kinetics and physical properties. The necessary thermodynamic apparatus was provided by

It is generally believed that the mechanical and other properties of the crystal are also pertinent to the subject matter, and that crystal morphology provides the missing link between growth kinetics and physical properties. The necessary thermodynamic apparatus was provided by

Very commonly when the supersaturation (or degree of supercooling) is high, and sometimes even when it is not high, growth kinetics may be diffusion-controlled, which means the transport of atoms or molecules to the growing nucleus is limiting the velocity of crystal growth. Assuming the nucleus in such a diffusion-controlled system is a perfect sphere, the growth velocity, corresponding to the change of the radius with time , can be determined with Fick’s Laws.

1. Fick' s Law: ,

where is the flux of atoms in the dimension of , is the diffusion coefficient and is the concentration gradient.

2. Fick' s Law: ,

where is the change of the concentration with time.

The first Law can be adjusted to the flux of matter onto a specific surface, in this case the surface of the spherical nucleus:

,

where now is the flux onto the spherical surface in the dimension of and being the area of the spherical nucleus. can also be expressed as the change of number of atoms in the nucleus over time, with the number of atoms in the nucleus being:

,

where is the volume of the spherical nucleus and is the atomic volume. Therefore, the change if number of atoms in the nucleus over time will be:

Combining both equations for the following expression for the growth velocity is obtained:

From second Fick’s Law for spheres the equation below can be obtained:

Assuming that the diffusion profile does not change over time but is only shifted with the growing radius it can be said that , which leads to being constant. This constant can be indicated with the letter and integrating will result in the following equation:

,

where is the radius of the nucleus, is the distance from the nucleus where the equilibrium concentration is recovered and is the concentration right at the surface of the nucleus. Now the expression for can be found by:

Therefore, the growth velocity for a diffusion-controlled system can be described as:

Very commonly when the supersaturation (or degree of supercooling) is high, and sometimes even when it is not high, growth kinetics may be diffusion-controlled, which means the transport of atoms or molecules to the growing nucleus is limiting the velocity of crystal growth. Assuming the nucleus in such a diffusion-controlled system is a perfect sphere, the growth velocity, corresponding to the change of the radius with time , can be determined with Fick’s Laws.

1. Fick' s Law: ,

where is the flux of atoms in the dimension of , is the diffusion coefficient and is the concentration gradient.

2. Fick' s Law: ,

where is the change of the concentration with time.

The first Law can be adjusted to the flux of matter onto a specific surface, in this case the surface of the spherical nucleus:

,

where now is the flux onto the spherical surface in the dimension of and being the area of the spherical nucleus. can also be expressed as the change of number of atoms in the nucleus over time, with the number of atoms in the nucleus being:

,

where is the volume of the spherical nucleus and is the atomic volume. Therefore, the change if number of atoms in the nucleus over time will be:

Combining both equations for the following expression for the growth velocity is obtained:

From second Fick’s Law for spheres the equation below can be obtained:

Assuming that the diffusion profile does not change over time but is only shifted with the growing radius it can be said that , which leads to being constant. This constant can be indicated with the letter and integrating will result in the following equation:

,

where is the radius of the nucleus, is the distance from the nucleus where the equilibrium concentration is recovered and is the concentration right at the surface of the nucleus. Now the expression for can be found by:

Therefore, the growth velocity for a diffusion-controlled system can be described as:

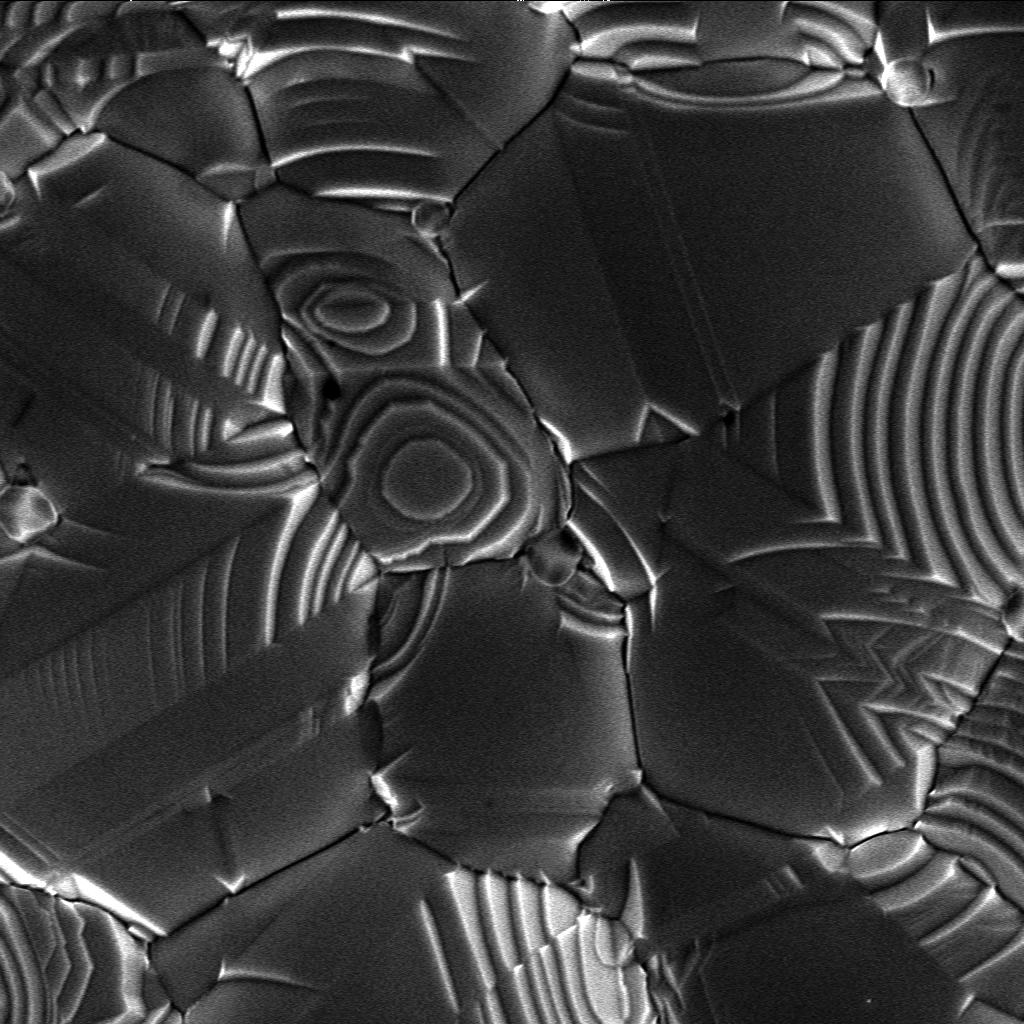

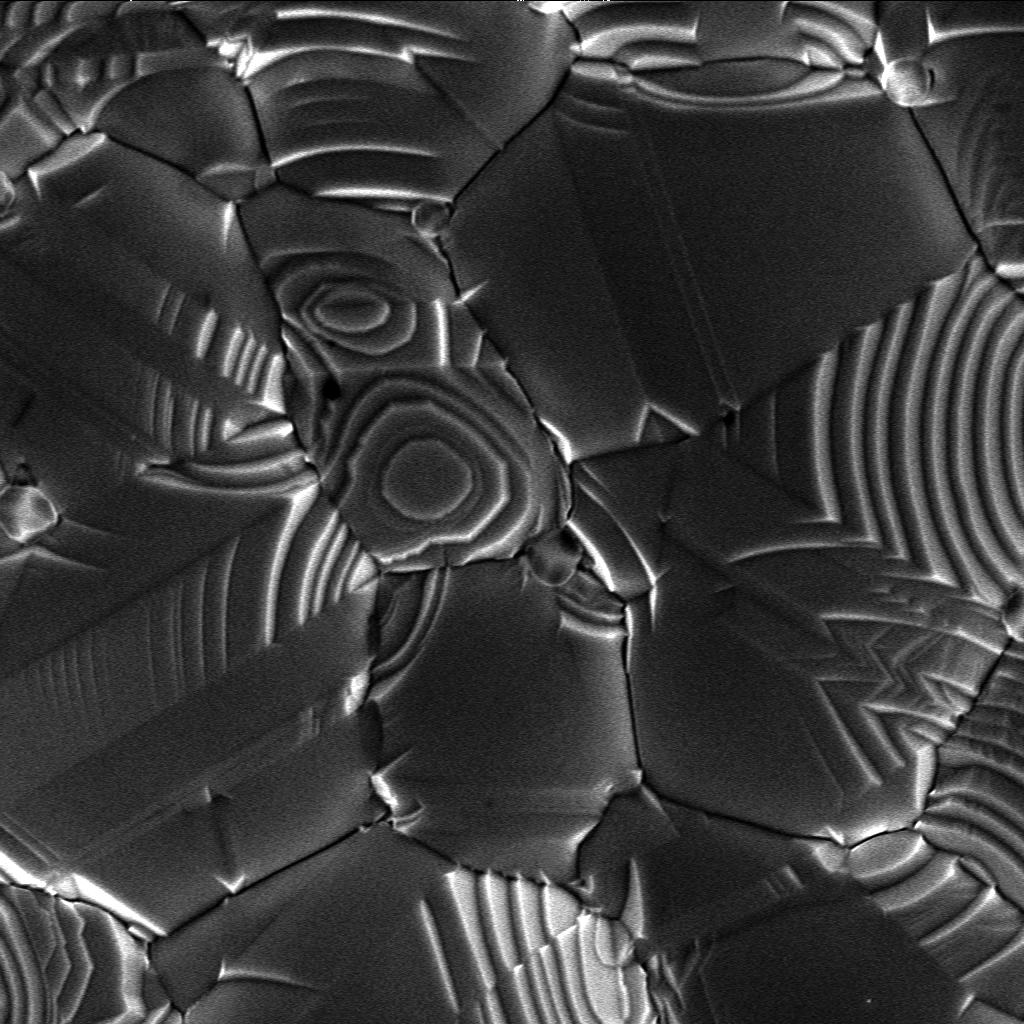

Under such diffusion controlled conditions, the polyhedral crystal form will be unstable, it will sprout protrusions at its corners and edges where the degree of supersaturation is at its highest level. The tips of these protrusions will clearly be the points of highest supersaturation. It is generally believed that the protrusion will become longer (and thinner at the tip) until the effect of interfacial free energy in raising the chemical potential slows the tip growth and maintains a constant value for the tip thickness.

In the subsequent tip-thickening process, there should be a corresponding instability of shape. Minor bumps or "bulges" should be exaggerated—and develop into rapidly growing side branches. In such an unstable (or metastable) situation, minor degrees of anisotropy should be sufficient to determine directions of significant branching and growth. The most appealing aspect of this argument, of course, is that it yields the primary morphological features of dendritic growth.

Under such diffusion controlled conditions, the polyhedral crystal form will be unstable, it will sprout protrusions at its corners and edges where the degree of supersaturation is at its highest level. The tips of these protrusions will clearly be the points of highest supersaturation. It is generally believed that the protrusion will become longer (and thinner at the tip) until the effect of interfacial free energy in raising the chemical potential slows the tip growth and maintains a constant value for the tip thickness.

In the subsequent tip-thickening process, there should be a corresponding instability of shape. Minor bumps or "bulges" should be exaggerated—and develop into rapidly growing side branches. In such an unstable (or metastable) situation, minor degrees of anisotropy should be sufficient to determine directions of significant branching and growth. The most appealing aspect of this argument, of course, is that it yields the primary morphological features of dendritic growth.

polymer

A polymer () is a chemical substance, substance or material that consists of very large molecules, or macromolecules, that are constituted by many repeat unit, repeating subunits derived from one or more species of monomers. Due to their br ...

strings into the characteristic arrangement of the crystalline lattice. The growth typically follows an initial stage of either homogeneous or heterogeneous (surface catalyzed) nucleation

In thermodynamics, nucleation is the first step in the formation of either a new Phase (matter), thermodynamic phase or Crystal structure, structure via self-assembly or self-organization within a substance or mixture. Nucleation is typically def ...

, unless a "seed" crystal, purposely added to start the growth, was already present.

The action of crystal growth yields a crystalline solid whose atoms or molecules are close packed, with fixed positions in space

Space is a three-dimensional continuum containing positions and directions. In classical physics, physical space is often conceived in three linear dimensions. Modern physicists usually consider it, with time, to be part of a boundless ...

relative to each other.

The crystalline state of matter

In physics, a state of matter is one of the distinct forms in which matter can exist. Four states of matter are observable in everyday life: solid, liquid, gas, and Plasma (physics), plasma.

Different states are distinguished by the ways the ...

is characterized by a distinct structural rigidity

In discrete geometry and mechanics, structural rigidity is a combinatorial theory for predicting the flexibility of ensembles formed by rigid bodies connected by flexible linkages or hinges.

Definitions

Rigidity is the property of a structu ...

and very high resistance to deformation (i.e. changes of shape and/or volume). Most crystalline solids have high values both of Young's modulus

Young's modulus (or the Young modulus) is a mechanical property of solid materials that measures the tensile or compressive stiffness when the force is applied lengthwise. It is the modulus of elasticity for tension or axial compression. Youn ...

and of the shear modulus

In materials science, shear modulus or modulus of rigidity, denoted by ''G'', or sometimes ''S'' or ''μ'', is a measure of the Elasticity (physics), elastic shear stiffness of a material and is defined as the ratio of shear stress to the shear s ...

of elasticity. This contrasts with most liquid

Liquid is a state of matter with a definite volume but no fixed shape. Liquids adapt to the shape of their container and are nearly incompressible, maintaining their volume even under pressure. The density of a liquid is usually close to th ...

s or fluid

In physics, a fluid is a liquid, gas, or other material that may continuously motion, move and Deformation (physics), deform (''flow'') under an applied shear stress, or external force. They have zero shear modulus, or, in simpler terms, are M ...

s, which have a low shear modulus, and typically exhibit the capacity for macroscopic viscous flow.

Overview

After successful formation of a stable nucleus, a growth stage ensues in which free particles (atoms or molecules) adsorb onto the nucleus and propagate its crystalline structure outwards from the nucleating site. This process is significantly faster than nucleation. The reason for such rapid growth is that real crystals contain dislocations and other defects, which act as a catalyst for the addition of particles to the existing crystalline structure. By contrast, perfect crystals (lacking defects) would grow exceedingly slowly. On the other hand, impurities can act as crystal growth inhibitors and can also modifycrystal habit

In mineralogy, crystal habit is the characteristic external shape of an individual crystal or aggregate of crystals. The habit of a crystal is dependent on its crystallographic form and growth conditions, which generally creates irregularities d ...

.

Nucleation

Nucleation can be either

Nucleation can be either homogeneous

Homogeneity and heterogeneity are concepts relating to the uniformity of a substance, process or image. A homogeneous feature is uniform in composition or character (i.e., color, shape, size, weight, height, distribution, texture, language, i ...

, without the influence of foreign particles, or heterogeneous, with the influence of foreign particles. Generally, heterogeneous nucleation takes place more quickly since the foreign particles act as a scaffold for the crystal to grow on, thus eliminating the necessity of creating a new surface and the incipient surface energy requirements.

Heterogeneous nucleation can take place by several methods. Some of the most typical are small inclusions, or cuts, in the container the crystal is being grown on. This includes scratches on the sides and bottom of glassware. A common practice in crystal growing is to add a foreign substance, such as a string or a rock, to the solution, thereby providing nucleation sites for facilitating crystal growth and reducing the time to fully crystallize.

The number of nucleating sites can also be controlled in this manner. If a brand-new piece of glassware or a plastic container is used, crystals may not form because the container surface is too smooth to allow heterogeneous nucleation. On the other hand, a badly scratched container will result in many lines of small crystals. To achieve a moderate number of medium-sized crystals, a container which has a few scratches works best. Likewise, adding small previously made crystals, or seed crystals, to a crystal growing project will provide nucleating sites to the solution. The addition of only one seed crystal should result in a larger single crystal.

Mechanisms of growth

The interface between a crystal and its vapor can be molecularly sharp at temperatures well below the melting point. An ideal crystalline surface grows by the spreading of single layers, or equivalently, by the lateral advance of the growth steps bounding the layers. For perceptible growth rates, this mechanism requires a finite driving force (or degree of supercooling) in order to lower the nucleation barrier sufficiently for nucleation to occur by means of thermal fluctuations. In the theory of crystal growth from the melt, Keith Burton and Nicolás Cabrera have distinguished between two major mechanisms:

The interface between a crystal and its vapor can be molecularly sharp at temperatures well below the melting point. An ideal crystalline surface grows by the spreading of single layers, or equivalently, by the lateral advance of the growth steps bounding the layers. For perceptible growth rates, this mechanism requires a finite driving force (or degree of supercooling) in order to lower the nucleation barrier sufficiently for nucleation to occur by means of thermal fluctuations. In the theory of crystal growth from the melt, Keith Burton and Nicolás Cabrera have distinguished between two major mechanisms:

Non-uniform lateral growth

The surface advances by the lateral motion of steps which are one interplanar spacing in height (or some integral multiple thereof). An element of surface undergoes no change and does not advance normal to itself except during the passage of a step, and then it advances by the step height. It is useful to consider the step as the transition between two adjacent regions of a surface which are parallel to each other and thus identical in configuration—displaced from each other by an integral number of lattice planes. Note here the distinct possibility of a step in a diffuse surface, even though the step height would be much smaller than the thickness of the diffuse surface.Uniform normal growth

The surface advances normal to itself without the necessity of a stepwise growth mechanism. This means that in the presence of a sufficient thermodynamic driving force, every element of surface is capable of a continuous change contributing to the advancement of the interface. For a sharp or discontinuous surface, this continuous change may be more or less uniform over large areas for each successive new layer. For a more diffuse surface, a continuous growth mechanism may require changes over several successive layers simultaneously. Non-uniform lateral growth is a geometrical motion of steps—as opposed to motion of the entire surface normal to itself. Alternatively, uniform normal growth is based on the time sequence of an element of surface. In this mode, there is no motion or change except when a step passes via a continual change. The prediction of which mechanism will be operative under any set of given conditions is fundamental to the understanding of crystal growth. Two criteria have been used to make this prediction: Whether or not the surface is ''diffuse'': a diffuse surface is one in which the change from one phase to another is continuous, occurring over several atomic planes. This is in contrast to a sharp surface for which the major change in property (e.g. density or composition) is discontinuous, and is generally confined to a depth of one interplanar distance. Whether or not the surface is ''singular'': a singular surface is one in which the surface tension as a function of orientation has a pointed minimum. Growth of singular surfaces is known to requires steps, whereas it is generally held that non-singular surfaces can continuously advance normal to themselves.Driving force

Consider next the necessary requirements for the appearance of lateral growth. It is evident that the lateral growth mechanism will be found when any area in the surface can reach a metastable equilibrium in the presence of a driving force. It will then tend to remain in such an equilibrium configuration until the passage of a step. Afterward, the configuration will be identical except that each part of the step will have advanced by the step height. If the surface cannot reach equilibrium in the presence of a driving force, then it will continue to advance without waiting for the lateral motion of steps. Thus, Cahn concluded that the distinguishing feature is the ability of the surface to reach an equilibrium state in the presence of the driving force. He also concluded that for every surface or interface in a crystalline medium, there exists a critical driving force, which, if exceeded, will enable the surface or interface to advance normal to itself, and, if not exceeded, will require the lateral growth mechanism. Thus, for sufficiently large driving forces, the interface can move uniformly without the benefit of either a heterogeneous nucleation or screw dislocation mechanism. What constitutes a sufficiently large driving force depends upon the diffuseness of the interface, so that for extremely diffuse interfaces, this critical driving force will be so small that any measurable driving force will exceed it. Alternatively, for sharp interfaces, the critical driving force will be very large, and most growth will occur by the lateral step mechanism. Note that in a typicalsolidification

Freezing is a phase transition in which a liquid turns into a solid when its temperature is lowered below its freezing point.

For most substances, the melting and freezing points are the same temperature; however, certain substances possess dif ...

or crystallization

Crystallization is a process that leads to solids with highly organized Atom, atoms or Molecule, molecules, i.e. a crystal. The ordered nature of a crystalline solid can be contrasted with amorphous solids in which atoms or molecules lack regu ...

process, the thermodynamic driving force is dictated by the degree of supercooling

Supercooling, also known as undercooling, is the process of lowering the temperature of a liquid below its freezing point without it becoming a solid. Per the established international definition, supercooling means ''‘cooling a substance be ...

.

Morphology

It is generally believed that the mechanical and other properties of the crystal are also pertinent to the subject matter, and that crystal morphology provides the missing link between growth kinetics and physical properties. The necessary thermodynamic apparatus was provided by

It is generally believed that the mechanical and other properties of the crystal are also pertinent to the subject matter, and that crystal morphology provides the missing link between growth kinetics and physical properties. The necessary thermodynamic apparatus was provided by Josiah Willard Gibbs

Josiah Willard Gibbs (; February 11, 1839 – April 28, 1903) was an American mechanical engineer and scientist who made fundamental theoretical contributions to physics, chemistry, and mathematics. His work on the applications of thermodynami ...

' study of heterogeneous equilibrium. He provided a clear definition of surface energy, by which the concept of surface tension is made applicable to solids as well as liquids. He also appreciated that ''an anisotropic surface free energy implied a non-spherical equilibrium shape'', which should be thermodynamically defined as ''the shape which minimizes the total surface free energy''.

It may be instructional to note that whisker growth provides the link between the mechanical phenomenon of high strength in whiskers and the various growth mechanisms which are responsible for their fibrous morphologies. (Prior to the discovery of carbon nanotubes, single-crystal whiskers had the highest tensile strength of any materials known). Some mechanisms produce defect-free whiskers, while others may have single screw dislocations along the main axis of growth—producing high strength whiskers.

The mechanism behind whisker growth is not well understood, but seems to be encouraged by compressive mechanical stresses including mechanically induced stresses, stresses induced by diffusion

Diffusion is the net movement of anything (for example, atoms, ions, molecules, energy) generally from a region of higher concentration to a region of lower concentration. Diffusion is driven by a gradient in Gibbs free energy or chemical p ...

of different elements, and thermally induced stresses. Metal whiskers differ from metallic dendrite

A dendrite (from Ancient Greek language, Greek δένδρον ''déndron'', "tree") or dendron is a branched cytoplasmic process that extends from a nerve cell that propagates the neurotransmission, electrochemical stimulation received from oth ...

s in several respects. Dendrites are fern

The ferns (Polypodiopsida or Polypodiophyta) are a group of vascular plants (plants with xylem and phloem) that reproduce via spores and have neither seeds nor flowers. They differ from mosses by being vascular, i.e., having specialized tissue ...

-shaped like the branches of a tree, and grow across the surface of the metal. In contrast, whiskers are fibrous and project at a right angle to the surface of growth, or substrate.

Diffusion-control

Very commonly when the supersaturation (or degree of supercooling) is high, and sometimes even when it is not high, growth kinetics may be diffusion-controlled, which means the transport of atoms or molecules to the growing nucleus is limiting the velocity of crystal growth. Assuming the nucleus in such a diffusion-controlled system is a perfect sphere, the growth velocity, corresponding to the change of the radius with time , can be determined with Fick’s Laws.

1. Fick' s Law: ,

where is the flux of atoms in the dimension of , is the diffusion coefficient and is the concentration gradient.

2. Fick' s Law: ,

where is the change of the concentration with time.

The first Law can be adjusted to the flux of matter onto a specific surface, in this case the surface of the spherical nucleus:

,

where now is the flux onto the spherical surface in the dimension of and being the area of the spherical nucleus. can also be expressed as the change of number of atoms in the nucleus over time, with the number of atoms in the nucleus being:

,

where is the volume of the spherical nucleus and is the atomic volume. Therefore, the change if number of atoms in the nucleus over time will be:

Combining both equations for the following expression for the growth velocity is obtained:

From second Fick’s Law for spheres the equation below can be obtained:

Assuming that the diffusion profile does not change over time but is only shifted with the growing radius it can be said that , which leads to being constant. This constant can be indicated with the letter and integrating will result in the following equation:

,

where is the radius of the nucleus, is the distance from the nucleus where the equilibrium concentration is recovered and is the concentration right at the surface of the nucleus. Now the expression for can be found by:

Therefore, the growth velocity for a diffusion-controlled system can be described as:

Very commonly when the supersaturation (or degree of supercooling) is high, and sometimes even when it is not high, growth kinetics may be diffusion-controlled, which means the transport of atoms or molecules to the growing nucleus is limiting the velocity of crystal growth. Assuming the nucleus in such a diffusion-controlled system is a perfect sphere, the growth velocity, corresponding to the change of the radius with time , can be determined with Fick’s Laws.

1. Fick' s Law: ,

where is the flux of atoms in the dimension of , is the diffusion coefficient and is the concentration gradient.

2. Fick' s Law: ,

where is the change of the concentration with time.

The first Law can be adjusted to the flux of matter onto a specific surface, in this case the surface of the spherical nucleus:

,

where now is the flux onto the spherical surface in the dimension of and being the area of the spherical nucleus. can also be expressed as the change of number of atoms in the nucleus over time, with the number of atoms in the nucleus being:

,

where is the volume of the spherical nucleus and is the atomic volume. Therefore, the change if number of atoms in the nucleus over time will be:

Combining both equations for the following expression for the growth velocity is obtained:

From second Fick’s Law for spheres the equation below can be obtained:

Assuming that the diffusion profile does not change over time but is only shifted with the growing radius it can be said that , which leads to being constant. This constant can be indicated with the letter and integrating will result in the following equation:

,

where is the radius of the nucleus, is the distance from the nucleus where the equilibrium concentration is recovered and is the concentration right at the surface of the nucleus. Now the expression for can be found by:

Therefore, the growth velocity for a diffusion-controlled system can be described as:

Under such diffusion controlled conditions, the polyhedral crystal form will be unstable, it will sprout protrusions at its corners and edges where the degree of supersaturation is at its highest level. The tips of these protrusions will clearly be the points of highest supersaturation. It is generally believed that the protrusion will become longer (and thinner at the tip) until the effect of interfacial free energy in raising the chemical potential slows the tip growth and maintains a constant value for the tip thickness.

In the subsequent tip-thickening process, there should be a corresponding instability of shape. Minor bumps or "bulges" should be exaggerated—and develop into rapidly growing side branches. In such an unstable (or metastable) situation, minor degrees of anisotropy should be sufficient to determine directions of significant branching and growth. The most appealing aspect of this argument, of course, is that it yields the primary morphological features of dendritic growth.

Under such diffusion controlled conditions, the polyhedral crystal form will be unstable, it will sprout protrusions at its corners and edges where the degree of supersaturation is at its highest level. The tips of these protrusions will clearly be the points of highest supersaturation. It is generally believed that the protrusion will become longer (and thinner at the tip) until the effect of interfacial free energy in raising the chemical potential slows the tip growth and maintains a constant value for the tip thickness.

In the subsequent tip-thickening process, there should be a corresponding instability of shape. Minor bumps or "bulges" should be exaggerated—and develop into rapidly growing side branches. In such an unstable (or metastable) situation, minor degrees of anisotropy should be sufficient to determine directions of significant branching and growth. The most appealing aspect of this argument, of course, is that it yields the primary morphological features of dendritic growth.

See also

* Abnormal grain growth * Chvorinov's rule * Cloud condensation nuclei *Crystal structure

In crystallography, crystal structure is a description of ordered arrangement of atoms, ions, or molecules in a crystalline material. Ordered structures occur from intrinsic nature of constituent particles to form symmetric patterns that repeat ...

* Czochralski process

*Dendrite (metal)

A dendrite in metallurgy is a characteristic tree-like structure of crystals growing as molten metal solidifies, the shape produced by faster growth along energetically favourable crystallographic directions. This dendritic growth has larg ...

* Diana's Tree

* Fractional crystallization

* Ice nucleus

* Laser-heated pedestal growth

* Manganese nodule

* Micro-pulling-down

* Monocrystalline whisker

* Protocrystalline

*Recrystallization (chemistry)

Recrystallization is a broad class of List of purification methods in chemistry , chemical purification techniques characterized by the dissolution of an impure sample in a solvent or solvent mixture, followed by some change in conditions that en ...

* Seed crystal

*Single crystal

In materials science, a single crystal (or single-crystal solid or monocrystalline solid) is a material in which the crystal lattice of the entire sample is continuous and unbroken to the edges of the sample, with no Grain boundary, grain bound ...

*Whisker (metallurgy)

Metal whiskering is a phenomenon that occurs in electrical devices when metals form long whisker-like projections over time. Tin whiskers were noticed and documented in the vacuum tube era of electronics early in the 20th century in equipment tha ...

Simulation

* Kinetic Monte Carlo surface growth methodReferences

{{DEFAULTSORT:Crystal Growth Crystallography Crystals Materials science Mineralogy Articles containing video clips