|

Laminated Steel Blade

A laminated steel blade or piled steel is a knife, sword, or other tool blade made out of layers of differing types of steel, rather than a single homogeneous alloy. The earliest steel blades were laminated out of necessity, due to the early bloomery method of smelting iron, which made production of steel expensive and inconsistent. Laminated steel offered both a way to average out the properties of the steel, as well as a way to restrict high carbon steel to the areas that needed it most. Laminated steel blades are still produced today for specialized applications, where different requirements at different points in the blade are met by use of different alloys, forged together into a single blade. Technique Piled steel developed out of the necessarily complex process of making blades that were both hard and tough from the erratic and unsuitable output from early iron smelting in bloomeries. The bloomery does not generate temperatures high enough to melt iron and steel, but instea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Knife

A knife ( : knives; from Old Norse 'knife, dirk') is a tool or weapon with a cutting edge or blade, usually attached to a handle or hilt. One of the earliest tools used by humanity, knives appeared at least 2.5 million years ago, as evidenced by the Oldowan tools. Originally made of wood, bone, and stone (such as flint and obsidian), over the centuries, in step with improvements in both metallurgy and manufacturing, knife blades have been made from copper, bronze, iron, steel, ceramic, and titanium. Most modern knives have either fixed or folding blades; blade patterns and styles vary by maker and country of origin. Knives can serve various purposes. Hunters use a hunting knife, soldiers use the combat knife, scouts, campers, and hikers carry a pocket knife; there are kitchen knives for preparing foods (the chef's knife, the paring knife, bread knife, cleaver), table knives (butter knives and steak knives), weapons ( daggers or switchblades), knives for throwing or juggl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Case Hardening

Case-hardening or surface hardening is the process of hardening the surface of a metal object while allowing the metal deeper underneath to remain soft, thus forming a thin layer of harder metal at the surface. For iron or steel with low carbon content, which has poor to no hardenability of its own, the case-hardening process involves infusing additional carbon or nitrogen into the surface layer. Case-hardening is usually done after the part has been formed into its final shape, but can also be done to increase the hardening element content of bars to be used in a pattern welding or similar process. The term face hardening is also used to describe this technique, when discussing modern armour. Hardening is desirable for metal components that are subject to sliding contact with hard or abrasive materials, as the hardened metal is more resistant to surface wear. However, because hardened metal is usually more brittle than softer metal, through-hardening (that is, hardening the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Toledo Steel

Toledo steel, historically known for being unusually hard, is from Toledo, Spain, which has been a traditional sword-making, metal-working center since about the Roman period, and came to the attention of Rome when used by Hannibal in the Punic Wars. It soon became a standard source of weaponry for Roman legions. Toledo steel was famed for its high quality alloy. History The name "Toledo steel" comes from the city where these special steel products were most-notably crafted: Toledo, Spain. Toledo steel forging techniques were developed from ancient Spanish customs and used to forge many different types of weapons over the course of many centuries. In simple terms, the Toledo steel technique consisted of a steel blade that enveloped a wrought iron strip, thus preventing the steel from bending or cracking. As such, the strong and durable Toledo steel weapons were said to have had a "soul of iron". In ancient Iberia, blacksmiths in Toledo applied their unique method of forging ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Japanese Swordsmithing

Japanese swordsmithing is the labour-intensive bladesmithing process developed in Japan for forging traditionally made bladed weapons ( ''nihonto'') including ''katana'', '' wakizashi'', ''tantō'', '' yari'', ''naginata'', '' nagamaki'', ''tachi'', '' nodachi'', '' ōdachi'', '' kodachi'', and ''ya'' (arrow). Japanese sword blades were often forged with different profiles, different blade thicknesses, and varying amounts of grind. ''Wakizashi'' and ''tantō'' were not simply scaled-down ''katana'' but were often forged without a ridge (''hira-zukuri'') or other such forms which were very rare on ''katana''. Traditional methods Steel production The steel used in sword production is known as , or "jewel steel" (''tama'' – ball or jewel, ''hagane'' – steel). ''Tamahagane'' is produced from iron sand, a source of iron ore, and mainly used to make samurai swords, such as the ''katana'', and some tools. The smelting process used is different from the modern mass production o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Damascus Steel

Damascus steel was the forged steel of the blades of swords smithed in the Near East from ingots of Wootz steel either imported from Southern India or made in production centres in Sri Lanka, or Khorasan, Iran. These swords are characterized by distinctive patterns of banding and mottling reminiscent of flowing water, sometimes in a "ladder" or "rose" pattern. Such blades were reputed to be tough, resistant to shattering, and capable of being honed to a sharp, resilient edge. Wootz (Indian), Pulad (Persian), Fuladh (Arabic), Bulat (Russian) and Bintie (Chinese) are all names for historical ultra-high carbon crucible steel typified by carbide segregation. "Wootz" is an erroneous transliteration of "utsa" or "fountain" in Sanskrit, however since 1794 it has been the primary word used to refer to historical hypereutectoid crucible steel. History Origins The origin of the name "Damascus Steel" is contentious: the Islamic scholars al-Kindi (full name Abu Ya'qub ibn Ishaq al-Ki ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mokume-gane

is a Japanese metalworking procedure which produces a mixed-metal laminate with distinctive layered patterns; the term is also used to refer to the resulting laminate itself. The term translates closely to "wood grain metal" or "wood eye metal" and describes the way metal takes on the appearance of natural wood grain. fuses several layers of differently coloured precious metals together to form a sandwich of alloys called a "billet." The billet is then manipulated in such a way that a pattern resembling wood grain emerges over its surface. Numerous ways of working create diverse patterns. Once the metal has been rolled into a sheet or bar, several techniques are used to produce a range of effects. has been used to create many artistic objects. Though the technique was first developed for production of decorative sword fittings, the craft is today mostly used in the production of jewelry and hollowware. History Origins First developed in 17th-century Japan, was originally ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pattern Welding

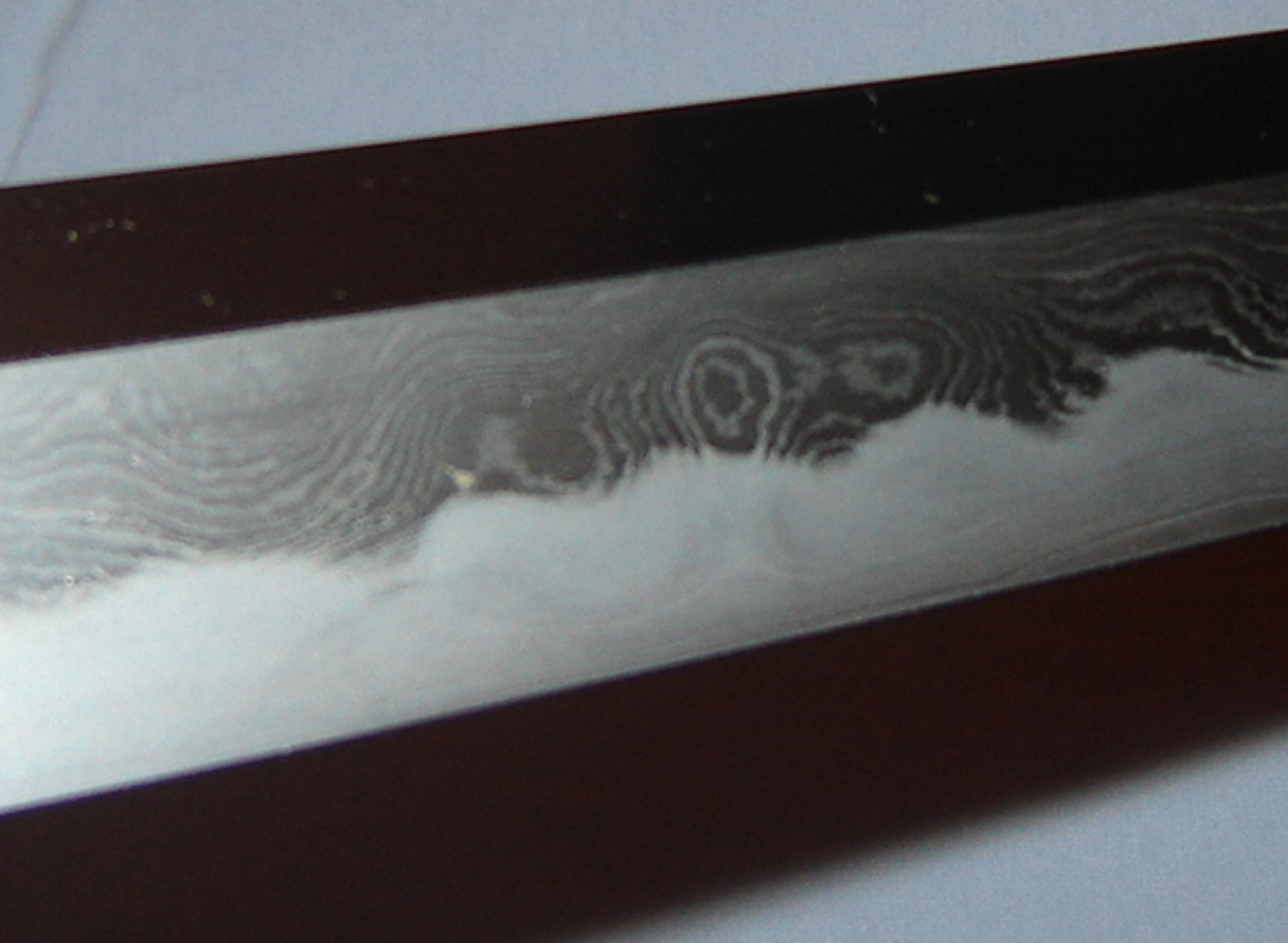

Pattern welding is the practice in sword and knife making of forming a blade of several metal pieces of differing composition that are forge welding, forge-welded together and twisted and manipulated to form a pattern. Often mistakenly called Damascus steel, blades forged in this manner often display bands of slightly different patterning along their entire length. These bands can be highlighted for cosmetic purposes by proper polishing or acid industrial etching, etching. Pattern welding was an outgrowth of laminated steel blade, laminated or piled steel, a similar technique used to combine steels of different carbon contents, providing a desired mix of hardness and toughness. Although modern steelmaking processes negate the need to blend different steels, pattern welded steel is still used by custom knifemakers for the cosmetic effects it produces. History Pattern welding developed out of the necessarily complex process of making blades that were both hardness, hard and tough ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pattern Welding

Pattern welding is the practice in sword and knife making of forming a blade of several metal pieces of differing composition that are forge welding, forge-welded together and twisted and manipulated to form a pattern. Often mistakenly called Damascus steel, blades forged in this manner often display bands of slightly different patterning along their entire length. These bands can be highlighted for cosmetic purposes by proper polishing or acid industrial etching, etching. Pattern welding was an outgrowth of laminated steel blade, laminated or piled steel, a similar technique used to combine steels of different carbon contents, providing a desired mix of hardness and toughness. Although modern steelmaking processes negate the need to blend different steels, pattern welded steel is still used by custom knifemakers for the cosmetic effects it produces. History Pattern welding developed out of the necessarily complex process of making blades that were both hardness, hard and tough ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Viking

Vikings ; non, víkingr is the modern name given to seafaring people originally from Scandinavia (present-day Denmark, Norway and Sweden), who from the late 8th to the late 11th centuries raided, pirated, traded and settled throughout parts of Europe.Roesdahl, pp. 9–22. They also voyaged as far as the Mediterranean, North Africa, Volga Bulgaria, the Middle East, and North America. In some of the countries they raided and settled in, this period is popularly known as the Viking Age, and the term "Viking" also commonly includes the inhabitants of the Scandinavian homelands as a collective whole. The Vikings had a profound impact on the early medieval history of Scandinavia, the British Isles, France, Estonia, and Kievan Rus'. Expert sailors and navigators aboard their characteristic longships, Vikings established Norse settlements and governments in the British Isles, the Faroe Islands, Iceland, Greenland, Normandy, and the Baltic coast, as well as alon ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Katana

A is a Japanese sword characterized by a curved, single-edged blade with a circular or squared guard and long grip to accommodate two hands. Developed later than the '' tachi'', it was used by samurai in feudal Japan and worn with the edge facing upward. Since the Muromachi period, many old '' tachi'' were cut from the root and shortened, and the blade at the root was crushed and converted into ''katana''. The specific term for ''katana'' in Japan is ''uchigatana'' (打刀) and the term ''katana'' (刀) often refers to single-edged swords from around the world. Etymology and loanwords The word ''katana'' first appears in Japanese in the '' Nihon Shoki'' of 720. The term is a compound of ''kata'' ("one side, one-sided") + ''na'' ("blade"), in contrast to the double-sided '' tsurugi''. See more at the Wiktionary entry. The ''katana'' belongs to the ''nihontō'' family of swords, and is distinguished by a blade length (''nagasa'') of more than 2 '' shaku'', approximately . ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laminate

Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materials, such as plastic. A laminate is a permanently assembled object created using heat, pressure, welding, or adhesives. Various coating machines, machine presses and calendering equipment are used. Materials There are different lamination processes, depending primarily on the type or types of materials to be laminated. The materials used in laminates can be identical or different, depending on the process and the object to be laminated. Textile Laminated fabric are widely used in different fields of human activity, including medical and military. Woven fabrics (organic and inorganic based) are usually laminated by different chemical polymers to give them useful properties like chemical resistance, dust, grease, windproofness, photo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.png)