|

Boilers

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation. Heat sources In a fossil fuel power plant using a steam cycle for power generation, the primary heat source will be combustion of coal, oil, or natural gas. In some cases byproduct fuel such as the carbon monoxide rich offgasses of a coke battery can be burned to heat a boiler; biofuels such as bagasse, where economically available, can also be used. In a nuclear power plant, boilers called steam generators are heated by the heat produced by nuclear fission. Where a large volume of hot gas is available from some process, a heat recovery steam generator or recovery boiler can use the heat to produce steam, with little or no extra fuel consumed; such a configuration is commo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pulverized Coal-fired Boiler

A pulverized coal-fired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal (also known as powdered coal or coal dust since it is as fine as face powder in cosmetic makeup) that is blown into the firebox. The basic idea of a firing system using pulverised fuel is to use the whole volume of the furnace for the combustion of solid fuels. Coal is ground to the size of a fine grain, mixed with air and burned in the flue gas flow. Biomass and other materials can also be added to the mixture. Coal contains mineral matter which is converted to ash during combustion. The ash is removed as bottom ash and fly ash. The bottom ash is removed at the furnace bottom. This type of boiler dominates coal-fired power stations, providing steam to drive large turbines. History Prior to the developments leading to the use of pulverized coal, most boilers utilized grate firing where the fuel was mechanically distributed onto a moving grate at the botto ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steam Generator (nuclear Power)

A steam generator (aka nuclear steam raising plant ('NSRP')) is a heat exchanger used to convert water into steam from heat produced in a nuclear reactor core. It is used in pressurized water reactors (PWRs), between the primary and secondary coolant loops. It is also used in liquid metal cooled reactors (LMRs), pressurized heavy-water reactors (PHWRs), and gas-cooled reactors (GCRs). In typical PWR designs, the primary coolant is high-purity water, kept under high pressure so it cannot boil. This primary coolant is pumped through the reactor core where it absorbs heat from the fuel rods. It then passes through the steam generator, where it transfers its heat (via conduction through metal) to lower-pressure water which is allowed to boil. Purpose Unlike PWRs, boiling water reactors (BWRs) do not use steam generators. The primary coolant is allowed to boil directly in the reactor core, and the steam is simply passed through a steam turbine. While theoretically simple, this has a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Recovery Steam Generator

A heat recovery steam generator (HRSG) is a heat exchanger that recovers heat from a hot gas stream, such as a combustion turbine or other waste gas stream. It produces steam that can be used in a process (cogeneration) or used to drive a steam turbine (combined cycle). HRSGs HRSGs consist of four major components: the economizer, evaporator, superheater and water preheater. The different components are put together to meet the operating requirements of the unit. See the attached illustration of a Modular HRSG General Arrangement. Modular HRSGs can be categorized by a number of ways such as direction of exhaust gas flow or number of pressure levels. Based on the flow of exhaust gases, HRSGs are categorized into vertical and horizontal types. In horizontal type HRSGs, exhaust gas flows horizontally over vertical tubes whereas in vertical type HRSGs, exhaust gas flows vertically over horizontal tubes. Based on pressure levels, HRSGs can be categorized into single pressure and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boiler (water Heating)

The term boiler may refer to an appliance for heating water. Applications include water heating and central heating. Operation The boiler heats water to a temperature controlled by a thermostat. The water then flows (either by natural circulation or by a pump) to radiators in the rooms which are to be heated. Water also flows through a coil in the hot water tank to heat a separate mass of water for bathing, etc. Condensing boiler Back boiler A back boiler is a device which is fitted to a residential heating stove or open fireplace to enable it to provide both room heat and domestic hot water or central heating. See also * Electric water boiler * Heat-only boiler station * Multi-fuel stove A multi-fuel stove is similar to a wood-burning stove in appearance and design. Multifuel refers to the capability of the stove to burn wood and also coal, wood pellets, or peat. Stoves that have a grate for the fire to burn on and a removable ash ... References Heating, ventilation, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Firebox (locomotive)

In a steam engine, the firebox is the area where the fuel is burned, producing heat to boil the water in the boiler. Most are somewhat box-shaped, hence the name. The hot gases generated in the firebox are pulled through a rack of tubes running through the boiler. Steam locomotive fire tube firebox In the standard steam locomotive fire-tube boiler, the firebox is surrounded by water space on five sides. The bottom of the firebox is open to atmospheric pressure, but covered by fire grates (solid fuel) or a firing pan (liquid fuel). If the engine burns solid fuel, like wood or coal, there is a grate covering most of the bottom of the firebox to hold the fire. An ashpan, mounted underneath the firebox and below the grates, catches and collects hot embers, ashes, and other solid combustion waste as it falls through the grates. In a coal-burning locomotive, the grates may be shaken to clean dead ash from the bottom of the fire. They are shaken either manually or (in larger locomoti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steam Locomotive

A steam locomotive is a locomotive that provides the force to move itself and other vehicles by means of the expansion of steam. It is fuelled by burning combustible material (usually coal, Fuel oil, oil or, rarely, Wood fuel, wood) to heat water in the locomotive's Boiler (power generation), boiler to the point where it becomes gaseous and its volume increases 1,700 times. Functionally, it is a steam engine on wheels. In most locomotives, the steam is admitted alternately to each end of its Steam locomotive components, cylinders in which pistons are mechanically connected to the locomotive's main wheels. Fuel and water supplies are usually carried with the locomotive, either on the locomotive itself or in a Tender (rail), tender coupled to it. #Variations, Variations in this general design include electrically powered boilers, turbines in place of pistons, and using steam generated externally. Steam locomotives were first developed in the United Kingdom of Great Britain an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Recovery Boiler

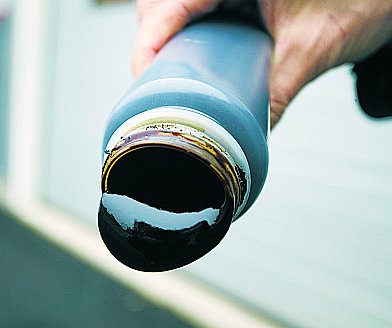

Recovery boiler is the part of kraft process of wood pulp, pulping where chemicals for white liquor are recovered and reformed from black liquor, which contains lignin from previously processed wood. The black liquor is burned, generating heat, which is usually used in the process of making electricity, much as in a conventional steam power plant. The invention of the recovery boiler by G.H. Tomlinson in the early 1930s was a milestone in the advancement of the kraft process. Recovery boilers are also used in the (less common) sulfite process of wood pulping; this article deals only with recovery boiler use in the kraft process. Function of recovery boilers Concentrated black liquor contains organic dissolved wood residue in addition to sodium sulfate from the cooking chemicals added at the digester. Combustion of the organic portion of chemicals produces heat. In the recovery boiler, heat is used to produce high pressure steam, which is used to generate electricity in a turbin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Live Steam

Live steam is steam under pressure, obtained by heating water in a boiler. The steam may be used to operate stationary or moving equipment. A live steam machine or device is one powered by steam, but the term is usually reserved for those that are replicas, scale models, toys, or otherwise used for heritage, museum, entertainment, or recreational purposes, to distinguish them from similar devices powered by electricity, internal combustion, or some other more convenient method but designed to look as if they are steam-powered. Revenue-earning steam-powered machines such as mainline and narrow gauge steam locomotives, full-sized steamships, and the worldwide electric power-generating industry steam turbines are not normally referred to as "live steam". Steamrollers and traction engines are popular, in 1:4 or 1:3 scale, as are model stationary steam engines, ranging from pocket-size to 1:2 scale. Railroads or railways Ridable, large-scale live steam railroading on a ba ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scale Model

A scale model is a physical model that is geometrically similar to an object (known as the ''prototype''). Scale models are generally smaller than large prototypes such as vehicles, buildings, or people; but may be larger than small prototypes such as anatomical structures or subatomic particles. Models built to the same scale as the prototype are called '' mockups''. Scale models are used as tools in engineering design and testing, promotion and sales, filmmaking special effects, military strategy, and hobbies such as rail transport modeling, wargaming and racing; and as toys. Model building is also pursued as a hobby for the sake of artisanship. Scale models are constructed of plastic, wood, or metal. They are usually painted with enamel, lacquer, or acrylics. Model prototypes include all types of vehicles (railroad trains, cars, trucks, military vehicles, aircraft, and spacecraft), buildings, people, and science fiction themes (spaceships and robots). Methods M ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rivet

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylinder (geometry), cylindrical shaft with a head on one end. The end opposite the head is called the ''tail''. On installation, the deformed end is called the ''shop head'' or buck-tail. Because there is effectively a head on each end of an installed rivet, it can support Tension (physics), tension loads. However, it is much more capable of supporting Shear force, shear loads (loads perpendicular to the axis of the shaft). Fastenings used in traditional wooden boat building, such as copper nails and clinch bolts, work on the same principle as the rivet but were in use long before the term ''rivet'' was introduced and, where they are remembered, are usually classified among nails and bolts respectively. History Solid rivets are one of the oldest and most reliable types of fasteners, having been found in archeology, archaeological findings dating back to the Bronze Age. Rivet ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stress Corrosion Cracking

Stress corrosion cracking (SCC) is the growth of crack formation in a corrosive environment. It can lead to unexpected and sudden failure of normally ductile metal alloys subjected to a tensile stress, especially at elevated temperature. SCC is highly chemically specific in that certain alloys are likely to undergo SCC only when exposed to a small number of chemical environments. The chemical environment that causes SCC for a given alloy is often one which is only mildly corrosive to the metal. Hence, metal parts with severe SCC can appear bright and shiny, while being filled with microscopic cracks. This factor makes it common for SCC to go undetected prior to failure. SCC often progresses rapidly, and is more common among alloys than pure metals. The specific environment is of crucial importance, and only very small concentrations of certain highly active chemicals are needed to produce catastrophic cracking, often leading to devastating and unexpected failure. The stresse ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |