heat recovery steam generator on:

[Wikipedia]

[Google]

[Amazon]

A heat recovery steam generator (HRSG) is a

A heat recovery steam generator (HRSG) is a

HRSGs consist of four major components: the

HRSGs consist of four major components: the

/ref>

Innovative Steam Technologies

/ref>

HRSG Users

{{Webarchive, url=https://web.archive.org/web/20210226085712/https://hrsgusers.org/ , date=2021-02-26 Steam power Energy recovery

heat exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contac ...

that recovers heat from a hot gas stream, such as a combustion turbine or other waste gas stream. It produces steam

Steam is water vapor, often mixed with air or an aerosol of liquid water droplets. This may occur due to evaporation or due to boiling, where heat is applied until water reaches the enthalpy of vaporization. Saturated or superheated steam is inv ...

that can be used in a process (cogeneration

Cogeneration or combined heat and power (CHP) is the use of a heat engine or power station to generate electricity and useful heat at the same time.

Cogeneration is a more efficient use of fuel or heat, because otherwise- wasted heat from elec ...

) or used to drive a steam turbine

A steam turbine or steam turbine engine is a machine or heat engine that extracts thermal energy from pressurized steam and uses it to do mechanical work utilising a rotating output shaft. Its modern manifestation was invented by Sir Charles Par ...

(combined cycle

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas turb ...

).

HRSGs

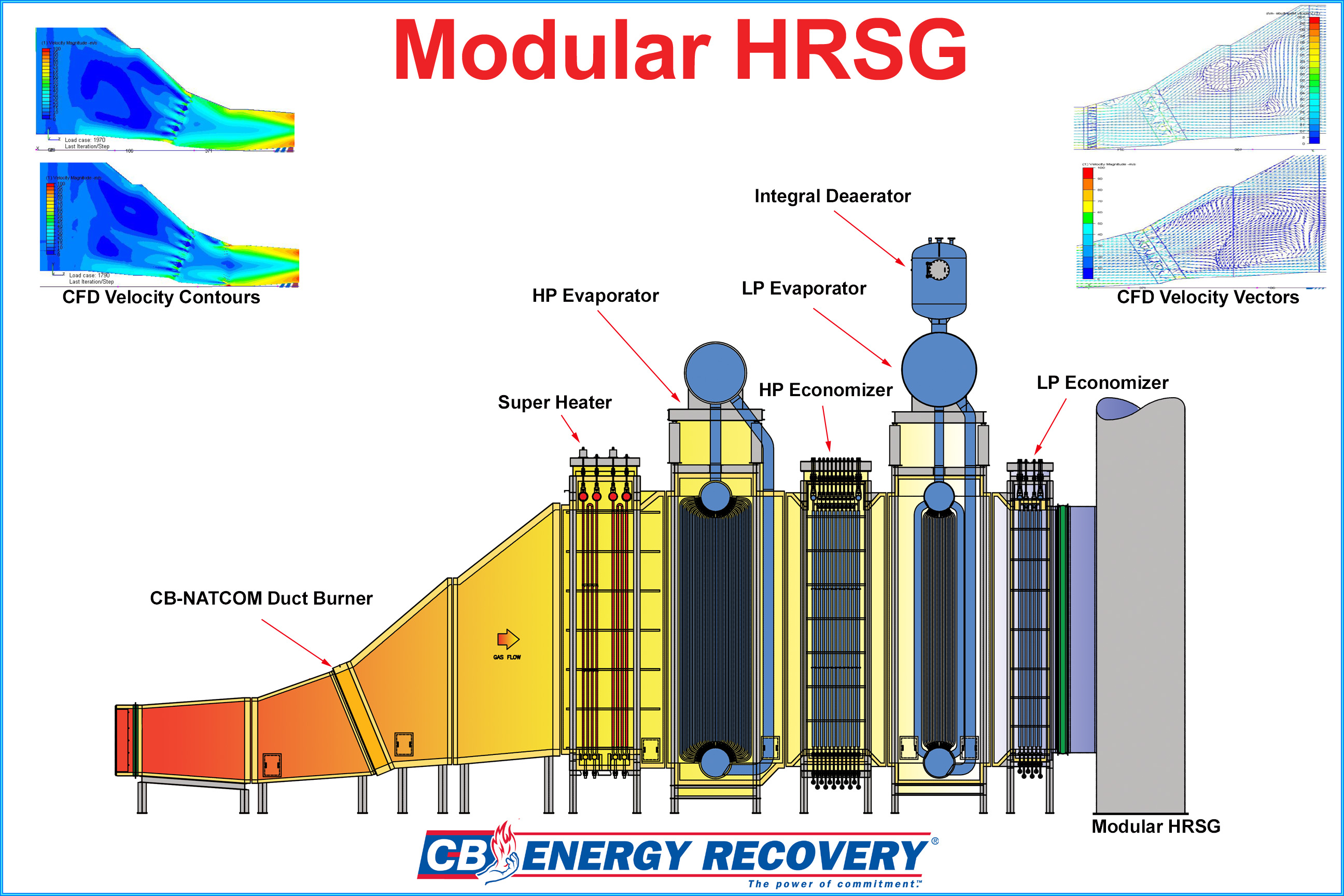

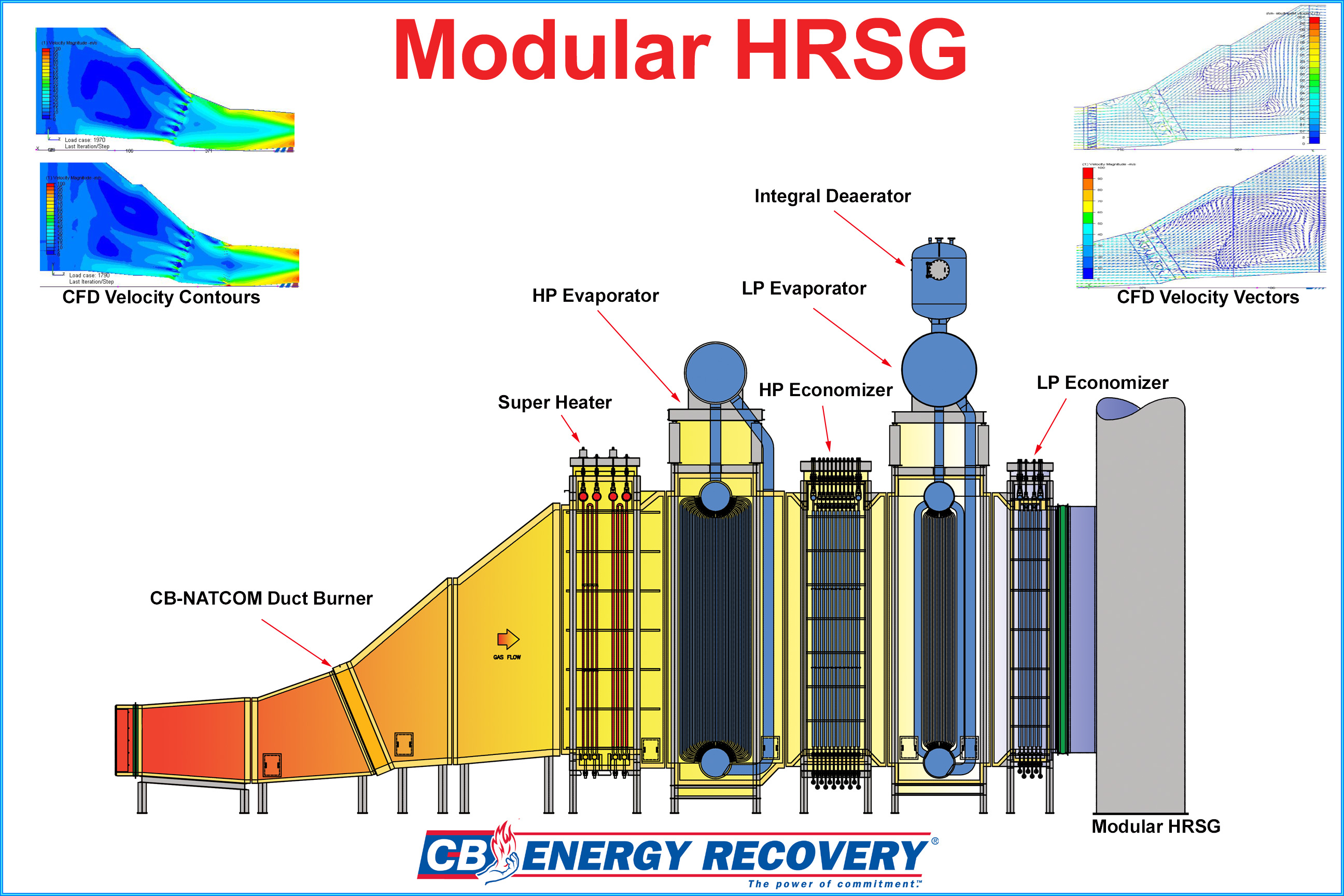

HRSGs consist of four major components: the

HRSGs consist of four major components: the economizer

Economizers (US and Oxford spelling), or economisers (UK), are mechanical devices intended to reduce energy consumption, or to perform useful function such as preheating a fluid. The term economizer is used for other purposes as well. Boiler, p ...

, evaporator

An evaporator is a type of heat exchanger device that facilitates evaporation by utilizing conductive and convective heat transfer, which provides the necessary thermal energy for phase transition from liquid to vapour. Within evaporators, a ci ...

, superheater

A superheater is a device used to convert saturated steam or wet steam into superheated steam or dry steam. Superheated steam is used in steam turbines for electricity generation, in some steam engines, and in processes such as steam reforming. ...

and water preheater. The different components are put together to meet the operating requirements of the unit. See the attached illustration of a Modular HRSG General Arrangement.

Modular HRSGs can be categorized by a number of ways such as direction of exhaust gas

Exhaust gas or flue gas is emitted as a result of the combustion of fuels such as natural gas, gasoline (petrol), diesel fuel, fuel oil, biodiesel blends, or coal. According to the type of engine, it is discharged into the atmosphere through ...

flow or number of pressure levels. Based on the flow of exhaust gases, HRSGs are categorized into vertical and horizontal types. In horizontal type HRSGs, exhaust gas flows horizontally over vertical tubes whereas in vertical type HRSGs, exhaust gas flows vertically over horizontal tubes. Based on pressure levels, HRSGs can be categorized into single pressure and multi pressure. Single pressure HRSGs have only one steam drum and steam is generated at a single pressure level, whereas multi pressure HRSGs employ two (double pressure) or three (triple pressure) steam drums. As such, triple pressure HRSGs consist of three sections: an LP (low pressure) section, a reheat/IP (intermediate pressure) section, and an HP (high pressure) section. Each section has a steam drum and an evaporator

An evaporator is a type of heat exchanger device that facilitates evaporation by utilizing conductive and convective heat transfer, which provides the necessary thermal energy for phase transition from liquid to vapour. Within evaporators, a ci ...

section where water is converted to steam. This steam then passes through superheaters to raise the temperature beyond the saturation point.

The steam and water pressure parts of an HRSG are subjected to a wide range of degradation mechanisms, for example creep, thermal fatigue

Fatigue is a state of tiredness (which is not sleepiness), exhaustion or loss of energy. It is a signs and symptoms, symptom of any of various diseases; it is not a disease in itself.

Fatigue (in the medical sense) is sometimes associated wit ...

, creep-fatigue, mechanical fatigue, Flow Accelerated Corrosion (FAC), corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engine ...

and corrosion fatigue, amongst others.

Additionally, HRSGs can include cold water heat exchangers designed to condense moisture in flue gases, reducing emissions and increasing efficiency.AITESA. Heat Recovery Steam Generators & Waste Heat Recovery Boilers/ref>

Packaged HRSGs

Packaged HRSGs are designed to be shipped as a fully assembled unit from the factory. They can be used inwaste heat

Waste heat is heat that is produced by a machine, or other process that uses energy, as a byproduct of doing work. All such processes give off some waste heat as a fundamental result of the laws of thermodynamics. Waste heat has lower utility ...

or turbine (usually under 20 MW) applications. The packaged HRSG can have a water-cooled furnace, which allows for higher supplemental firing and better overall efficiency.

Variations

Some HRSGs include supplemental, or duct firing. These additional burners provide additional energy to the HRSG, which produces more steam and hence increases the output of thesteam turbine

A steam turbine or steam turbine engine is a machine or heat engine that extracts thermal energy from pressurized steam and uses it to do mechanical work utilising a rotating output shaft. Its modern manifestation was invented by Sir Charles Par ...

. Generally, duct firing provides electrical output at lower capital cost. It is therefore often utilized for peaking operations.

HRSGs can also have diverter valves to regulate the inlet flow into the HRSG. This allows the gas turbine to continue to operate when there is no steam demand or if the HRSG needs to be taken offline.

Emissions controls may also be located in the HRSG. Some may contain a selective catalytic reduction system to reduce nitrogen oxides

In atmospheric chemistry, is shorthand for nitric oxide () and nitrogen dioxide (), the nitrogen oxides that are most relevant for air pollution.

These gases contribute to the formation of smog and acid rain, as well as affecting tr ...

(a large contributor to the formation of smog and acid rain) or a catalyst to remove carbon monoxide

Carbon monoxide (chemical formula CO) is a poisonous, flammable gas that is colorless, odorless, tasteless, and slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the si ...

. The inclusion of an SCR dramatically affects the layout of the HRSG. NOx catalyst performs best in temperatures between . This usually means that the evaporator section of the HRSG will have to be split and the SCR placed in between the two sections. Some low-temperature NOx catalysts have recently come to market that allow for the SCR to be placed between the evaporator and economizer sections ().

Once-through steam generator (OTSG)

A specialized type of HRSG without boiler drums is the once-through steam generator. In this design, the inlet feedwater follows a continuous path without segmented sections for economizers, evaporators, and superheaters. This provides a high degree of flexibility as the sections are allowed to grow or contract based on the heat load being received from the gas turbine. The absence of drums allows for quick changes in steam production and fewer variables to control, and is ideal for cycling and base load operation. With proper material selection, an OTSG can be run dry, meaning the hot exhaust gases can pass over the tubes with no water flowing inside the tubes. This eliminates the need for a bypass stack and exhaust gas diverter system which is required to operate a combustion turbine with a drum-type HRSG out of service./ref>

Applications

* Heat recovery can be used extensively in energy projects. * In the energy-richPersian Gulf

The Persian Gulf, sometimes called the Arabian Gulf, is a Mediterranean seas, mediterranean sea in West Asia. The body of water is an extension of the Arabian Sea and the larger Indian Ocean located between Iran and the Arabian Peninsula.Un ...

region, the steam from the HRSG is used for desalination

Desalination is a process that removes mineral components from saline water. More generally, desalination is the removal of salts and minerals from a substance. One example is Soil salinity control, soil desalination. This is important for agric ...

plants.

* Universities are ideal candidates for HRSG applications. They can use a gas turbine to produce high-reliability electricity for campus use. The HRSG can recover the heat from the gas turbine to produce steam/hot water for district heating

District heating (also known as heat networks) is a system for distributing heat generated in a centralized location through a system of insulated pipes for residential and commercial heating requirements such as space heater, space heating and w ...

or cooling.

* Large ocean vessels (e.g., Emma Maersk) make use of heat recovery so that their oil-fired boilers can be shut down while underway.

Block diagram

See also

* Exhaust heat recovery system * BMW Turbosteamer * Oxygenated treatment * Monotube steam generatorReferences

External links

HRSG Users

{{Webarchive, url=https://web.archive.org/web/20210226085712/https://hrsgusers.org/ , date=2021-02-26 Steam power Energy recovery