|

Strain Gauge

A strain gauge (also spelled strain gage) is a device used to measure Deformation (mechanics)#Strain, strain on an object. Invented by Edward E. Simmons and Arthur C. Ruge in 1938, the most common type of strain gauge consists of an Electrical insulation, insulating flexible backing which supports a metallic foil pattern. The gauge is attached to the object by a suitable adhesive, such as cyanoacrylate. As the object is deformed, the foil is deformed, causing its electrical resistance to change. This resistance change, usually measured using a Wheatstone bridge, is related to the strain by the quantity known as the gauge factor. History Edward E. Simmons and Professor Arthur C. Ruge independently invented the strain gauge. Simmons was involved in a research project by Dätwyler and Clark at Caltech between 1936 and 1938. They researched the stress-strain behavior of metals under shock loads. Simmons came up with an original way to measure the force introduced into the sample b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piezoresistive Effect

The piezoresistive effect is a change in the electrical resistivity and conductivity, electrical resistivity of a semiconductor or metal when deformation (mechanics), mechanical strain is applied. In contrast to the piezoelectricity, piezoelectric effect, the piezoresistive effect causes a change only in electrical resistance, not in electric potential. History The change of electrical resistance in metal devices due to an applied mechanical load was first discovered in 1856 by Lord Kelvin. With single crystal silicon becoming the material of choice for the design of analog and digital circuits, the large piezoresistive effect in silicon and germanium was first discovered in 1954 (Smith 1954). Mechanism In conducting and semi-conducting materials, changes in inter-atomic spacing resulting from strain affect the bandgaps, making it easier (or harder depending on the material and strain) for electrons to be raised into the conduction band. This results in a change in resistiv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strain Gauge Geometries

Strain may refer to: Science and technology * Strain (biology), variants of biological organisms * Strain (chemistry), a chemical stress of a molecule * Strain (general relativity), measure of spacetime stretching in linearized gravity * Strain (injury), an injury to a muscle * Strain (mechanics), a measure of deformation * Filtration, separating fluids from solids by passing through a filter * Percolation, of fluids through porous materials * Psychological stress Other uses * straining, in cooking, by a strainer or sieve. * Strain, a term in contract bridge Proper names * Strain (surname) Arts and media * ''Strain'' (manga), 1996 * Strain (music), phrases of a piece * ''Strain'' (album), 2004, by Flesh Field * '' Strain: Strategic Armored Infantry'', a 2006 anime * ''Strain'' (film), a 2020 Nigerian drama Places * Strain, Arkansas, US, an unincorporated community * Strain, Missouri, US, an unincorporated community See also * Overwork * S Train (other) * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Non-intrusive Stress Measurement System

Non-intrusive stress measurement (system), or NSMS, is a method for determining dynamic blade stresses in rotating turbomachinery. NSMS is also known by the names "blade tip timing" (BTT), "arrival time analysis" (ATA), "blade vibration monitoring" (BVM), ''Beruehrungslose Schaufel Schwingungsmessung'' (BSSM), and "blade health monitoring" (BHM). NSMS uses externally mounted sensors to determine the passing times of turbomachinery blades. The passing times after conversion to deflections, can be used to measure each blade's vibratory response characteristics such as amplitude/ stress, phase, frequency and damping. Since every blade is measured, stage effects such as flutter, blade mistuning, and nodal diameter can also be characterized. The measurement method has been used successfully in all stages of the gas turbine engine (fan, compressor, and turbine) and on other turbo-machinery equipment ranging from turbochargers to rocket pumps. The ability to apply the technology to a g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Voltage-controlled Oscillator

A voltage-controlled oscillator (VCO) is an electronic oscillator whose oscillation frequency is controlled by a voltage input. The applied input voltage determines the instantaneous oscillation frequency. Consequently, a VCO can be used for frequency modulation (FM) or phase modulation (PM) by applying a modulation, modulating signal to the control input. A VCO is also an integral part of a phase-locked loop. VCOs are used in synthesizers to generate a waveform whose Pitch (music), pitch can be adjusted by a voltage determined by a musical keyboard or other input. A voltage-to-frequency converter (VFC) is a special type of VCO designed to be very linear in frequency control over a wide range of input control voltages. Types VCOs can be generally categorized into two groups based on the type of waveform produced. * ''Linear'' or ''harmonic oscillators'' generate a sinusoidal waveform. Harmonic oscillators in electronics usually consist of a resonator with an amplifier that re ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aviation

Aviation includes the activities surrounding mechanical flight and the aircraft industry. ''Aircraft'' include fixed-wing and rotary-wing types, morphable wings, wing-less lifting bodies, as well as lighter-than-air aircraft such as hot air balloons and airships. Aviation began in the 18th century with the development of the hot air balloon, an apparatus capable of atmospheric displacement through buoyancy. Clément Ader built the "Ader Éole" in France and made an uncontrolled, powered hop in 1890. This was the first powered aircraft, although it did not achieve controlled flight. Some of the most significant advancements in aviation technology came with the controlled gliding flying of Otto Lilienthal in 1896. A major leap followed with the construction of the '' Wright Flyer'', the first powered airplane by the Wright brothers in the early 1900s. Since that time, aviation has been technologically revolutionized by the introduction of the jet engine which enabl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Creep (deformation)

In materials science, creep (sometimes called cold flow) is the tendency of a solid material to undergo slow deformation while subject to persistent mechanical stresses. It can occur as a result of long-term exposure to high levels of stress that are still below the yield strength of the material. Creep is more severe in materials that are subjected to heat for long periods and generally increases as they near their melting point. The rate of deformation is a function of the material's properties, exposure time, exposure temperature and the applied structural load. Depending on the magnitude of the applied stress and its duration, the deformation may become so large that a component can no longer perform its function – for example creep of a turbine blade could cause the blade to contact the casing, resulting in the failure of the blade. Creep is usually of concern to engineers and metallurgists when evaluating components that operate under high stresses or high temperatures ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Structural Health Monitoring

Structural health monitoring (SHM) involves the observation and analysis of a system over time using periodically sampled response measurements to monitor changes to the material and geometric properties of engineering structures such as bridges and buildings. In an operational environment, structures degrade with age and use. Long term SHM outputs periodically updated information regarding the ability of the structure to continue performing its intended function. After extreme events, such as earthquakes or blast loading, SHM is used for rapid condition screening. SHM is intended to provide reliable information regarding the integrity of the structure in near real time. The SHM process involves selecting the excitation methods, the sensor types, number and locations, and the data acquisition/storage/transmittal hardware commonly called health and usage monitoring systems. Measurements may be taken to either directly detect any degradation or damage that may occur to a system o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

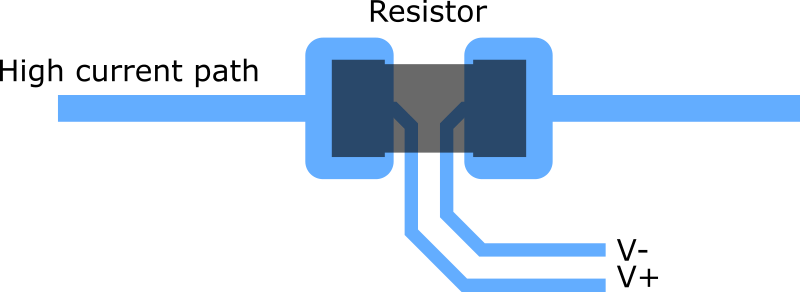

Kelvin Connection

In electrical engineering, four-terminal sensing (4T sensing), 4-wire sensing, or 4-point probes method is an electrical impedance measuring technique that uses separate pairs of current-carrying and voltage-sensing electrodes to make more accurate measurements than the simpler and more usual two-terminal (2T) sensing. Four-terminal sensing is used in some ohmmeters and impedance analyzers, and in wiring for strain gauges and resistance thermometers. Four-point probes are also used to measure sheet resistance of thin films (particularly semiconductor thin films). Separation of current and voltage electrodes eliminates the lead and contact resistance from the measurement. This is an advantage for precise measurement of low resistance values. For example, an LCR bridge instruction manual recommends the four-terminal technique for accurate measurement of resistance below 100 ohms.Manual for the Racal-Dana Databridge 9343M: "If the resistance value is low, less than 100 ohms, ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Murphy's Law

Murphy's law is an adage or epigram that is typically stated as: "Anything that can go wrong will go wrong." Though similar statements and concepts have been made over the course of history, the law itself was coined by, and named after, American aerospace engineer Edward A. Murphy Jr.; its exact origins are debated, but it is generally agreed it originated from Murphy and his team following a mishap during rocket sled tests some time between 1948 and 1949, and was finalized and first popularized by testing project head John Stapp during a later press conference. Murphy's original quote was the precautionary design advice that "If there are two or more ways to do something and one of those results in a catastrophe, then someone will do it that way." The law entered wider public knowledge in the late 1970s with the publication of Arthur Bloch's 1977 book ''Murphy's Law, and Other Reasons Why Things Go WRONG'', which included other variations and Corollary, corollaries of the law. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |