|

Physical Vapour Deposition

Physical vapor deposition (PVD), sometimes called physical vapor transport (PVT), describes a variety of vacuum deposition methods which can be used to produce thin films and coatings on substrates including metals, ceramics, glass, and polymers. PVD is characterized by a process in which the material transitions from a condensed phase to a vapor phase and then back to a thin film condensed phase. The most common PVD processes are sputtering and evaporation. PVD is used in the manufacturing of items which require thin films for optical, mechanical, electrical, acoustic or chemical functions. Examples include semiconductor devices such as thin-film solar cells, microelectromechanical devices such as thin film bulk acoustic resonator, aluminized PET film for food packaging and balloons, and titanium nitride coated cutting tools for metalworking. Besides PVD tools for fabrication, special smaller tools used mainly for scientific purposes have been developed. The source material ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plasma Spray-Physical Vapor Deposition

Plasma or plasm may refer to: Science * Plasma (physics), one of the four fundamental states of matter * Plasma (mineral), a green translucent silica mineral * Quark–gluon plasma, a state of matter in quantum chromodynamics Biology * Blood plasma, the yellow-colored liquid component of blood, in which blood cells are suspended * Cytoplasm, a jelly-like substance that fills cells, suspends and protects organelles * Germ plasm, a zone in the cytoplasm determining germ cells * Germplasm, describes a collection of genetic resources for an organism * Milk plasma or whey, the liquid remaining after milk has been curdled and strained * Nucleoplasm, a highly viscous liquid that surrounds the chromosomes and nucleoli * Plasma cell, white blood cells that secrete large volumes of antibodies * Protoplasm, the entire living substance inside the cell membrane or cell wall Technology * Plasma (engine), a real-time 3D game engine from Cyan Worlds * Plasma display, a flat-panel electronic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining proc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cutting Tool (machining)

In the context of machining, a cutting tool or cutter is typically a hardened metal tool that is used to cut, shape, and remove material from a workpiece by means of machining tools as well as abrasive tools by way of shear deformation. The majority of these tools are designed exclusively for metals. There are several different types of single edge cutting tools that are made from a variety of hardened metal alloys that are ground to a specific shape in order to perform a specific part of the turning process resulting in a finished machined part. Single edge cutting tools are used mainly in the turning operations performed by a lathe in which they vary in size as well as alloy composition depending on the size and the type of material being turned. These cutting tools are held stationary by what is known as a tool post which is what manipulates the tools to cut the material into the desired shape. Single edge cutting tools are also the means of cutting material performed by metal s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wear Resistance

Wear is the damaging, gradual removal or deformation of material at solid surfaces. Causes of wear can be mechanical (e.g., erosion) or chemical (e.g., corrosion). The study of wear and related processes is referred to as tribology. Wear in machine elements, together with other processes such as fatigue and creep, causes functional surfaces to degrade, eventually leading to material failure or loss of functionality. Thus, wear has large economic relevance as first outlined in the Jost Report. Abrasive wear alone has been estimated to cost 1-4% of the gross national product of industrialized nations. Wear of metals occurs by plastic displacement of surface and near-surface material and by detachment of particles that form wear debris. The particle size may vary from millimeters to nanometers. This process may occur by contact with other metals, nonmetallic solids, flowing liquids, solid particles or liquid droplets entrained in flowing gasses. The wear rate is affected by fa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

The Bund

The Bund or Waitan (, Shanghainese romanization: ''Nga3thae1'', , ) is a waterfront area and a protected historical district in central Shanghai. The area centers on a section of Zhongshan Road (East Zhongshan Road No.1) within the former Shanghai International Settlement, which runs along the western bank of the Huangpu River in the eastern part of Huangpu District. The area along the river faces the modern skyscrapers of Lujiazui in the Pudong District. The Bund usually refers to the buildings and wharves on this section of the road, as well as some adjacent areas. From the 1860s to the 1930s, it was the rich and powerful center of the foreign establishment in Shanghai, operating as a legally protected treaty port. Name The term "bund" was borrowed into English from Hindustani and originally referred to a dyke or embankment. Within the Chinese treaty ports, it was applied specifically to an embanked quay which ran along the shore. The Chinese name for the Bund is unrelate ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vessel (sculpture)

''Vessel'' (TKA) is a structure and visitor attraction built as part of the Hudson Yards (development), Hudson Yards Redevelopment Project in Manhattan, New York City, New York (state), New York. Built to plans by the British designer Thomas Heatherwick, the elaborate honeycomb-like structure rises 16 stories and consists of 154 flights of stairs, 2,500 steps, and 80 landings for visitors to climb. ''Vessel'' is the main feature of the Hudson Yards Public Square. Funded by Hudson Yards developer Related Companies, its final cost is estimated at $200 million. The concept of ''Vessel'' was unveiled to the public on September 14, 2016. Construction began in April 2017, with the pieces being manufactured in Italy and shipped to the United States. ''Vessel'' Topping out, topped out in December 2017 with the installation of its highest piece, and it opened to the public on March 15, 2019. In January 2021, following three suicides at the ''Vessel'', it was indefinitely closed to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Physical Vapor Deposition (PVD)

Physical vapor deposition (PVD), sometimes called physical vapor transport (PVT), describes a variety of vacuum deposition methods which can be used to produce thin films and coatings on substrates including metals, ceramics, glass, and polymers. PVD is characterized by a process in which the material transitions from a condensed phase to a vapor phase and then back to a thin film condensed phase. The most common PVD processes are sputtering and evaporation. PVD is used in the manufacturing of items which require thin films for optical, mechanical, electrical, acoustic or chemical functions. Examples include semiconductor devices such as thin-film solar cells, microelectromechanical devices such as thin film bulk acoustic resonator, aluminized PET film for food packaging and balloons, and titanium nitride coated cutting tools for metalworking. Besides PVD tools for fabrication, special smaller tools used mainly for scientific purposes have been developed. The source material ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electroplating

Electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. The part to be coated acts as the cathode (negative electrode) of an electrolytic cell; the electrolyte is a solution of a salt of the metal to be coated; and the anode (positive electrode) is usually either a block of that metal, or of some inert conductive material. The current is provided by an external power supply. Electroplating is widely used in industry and decorative arts to improve the surface qualities of objects—such as resistance to abrasion and corrosion, lubricity, reflectivity, electrical conductivity, or appearance. It is used to build up thickness on undersized or worn-out parts, or to manufacture metal plates with complex shape, a process called electroforming. It is used to deposit copper and other conductors in forming pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

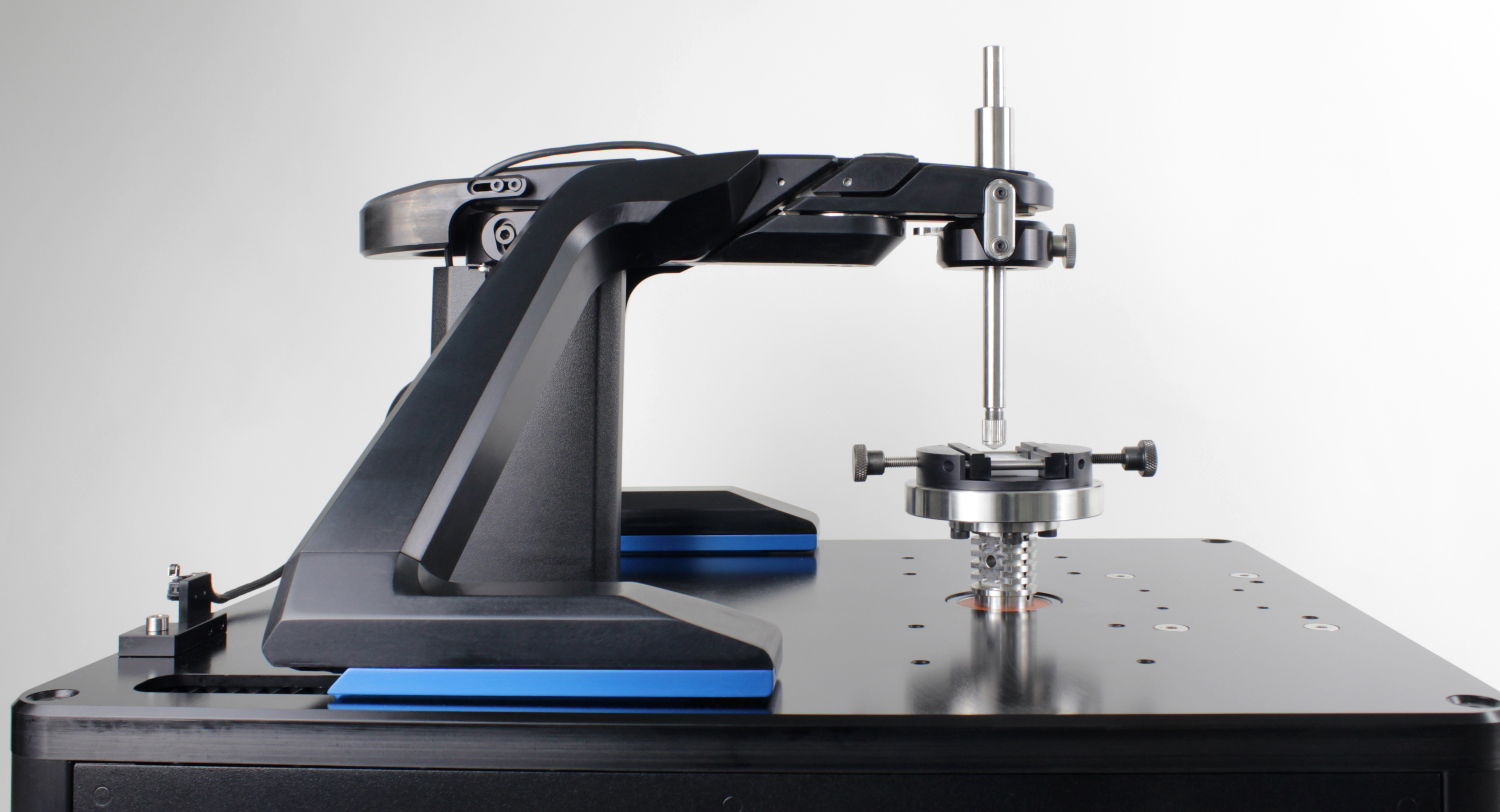

Scratch Tester

Scratch or scratching may refer to: Science and technology * Scratch (programming language), an educational programming language developed by MIT Media Lab * Scratch space, space on the hard disk drive that is dedicated for only temporary storage * Scratching, a technique used in recrystallization * Scratch reflex, a response to activation of sensory neurons * "Scratches", a synonym for mud fever, an infection occurring in horses Arts, entertainment, and media Fictional characters * Scratch (robot), in the TV show ''Adventures of Sonic the Hedgehog'' * Scratch, a fictional character from the ''Gobots'' series * Scratch, a fictional character (who is the titular ghost) in the animated series television '' The Ghost and Molly McGee'' Films * ''Scratch'' (2001 film), a documentary about disc jockeys and hip-hop culture * ''Scratch'' (2008 film), a Polish drama film * ''Scratch'' (2010 film), a short film produced by Breakthru Films * ''Scratch'' (2015 film), a Canadian ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pin On Disc Tribometer

A tribometer is an instrument that measures tribological quantities, such as coefficient of friction, friction force, and wear volume, between two surfaces in contact. It was invented by the 18th century Dutch scientist Musschenbroek A tribotester is the general name given to a machine or device used to perform tests and simulations of wear, friction and lubrication which are the subject of the study of tribology. Often tribotesters are extremely specific in their function and are fabricated by manufacturers who desire to test and analyze the long-term performance of their products. An example is that of orthopedic implant manufacturers who have spent considerable sums of money to develop tribotesters that accurately reproduce the motions and forces that occur in human hip joints so that they can perform accelerated wear tests of their products. Theory A simple tribometer is described by a hanging mass and a mass resting on a horizontal surface, connected to each other vi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

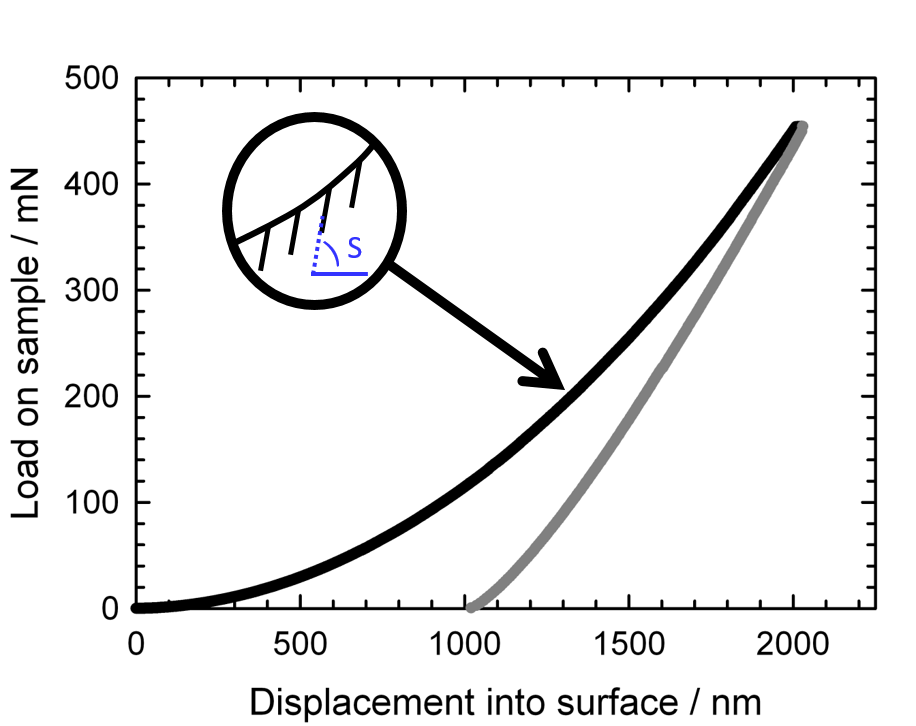

Nanoindentation

Nanoindentation, also called instrumented indentation testing, is a variety of indentation hardness tests applied to small volumes. Indentation is perhaps the most commonly applied means of testing the mechanical properties of materials. The nanoindentation technique was developed in the mid-1970s to measure the hardness of small volumes of material. Background In a traditional indentation test (macro or micro indentation), a hard tip whose mechanical properties are known (frequently made of a very hard material like diamond) is pressed into a sample whose properties are unknown. The load placed on the indenter tip is increased as the tip penetrates further into the specimen and soon reaches a user-defined value. At this point, the load may be held constant for a period or removed. The area of the residual indentation in the sample is measured and the hardness, H, is defined as the maximum load, P_, divided by the residual indentation area, A_r: :H=\frac . For most techniques, t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)

.jpg)