|

Piston Pulse Duplicator

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod. In a pump, the function is reversed and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder. In some engines, the piston also acts as a valve by covering and uncovering ports in the cylinder. __TOC__ Piston engines Internal combustion engines An internal combustion engine is acted upon by the pressure of the expanding combustion gases in the combustion chamber space at the top of the cylinder. This force then acts downwards through the connecting rod and onto the crankshaft. The connecting rod is attached t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Combustion Piston Engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons (piston engine), turbine blades (gas turbine), a rotor (Wankel engine), or a nozzle (jet engine). This force moves the component over a distance. This process transforms chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. The first commercially successful internal combustion engines were invented in the mid-19th century. The first modern internal combustion engine, the Otto engine, was designed in 1876 by the German engineer Nicolaus Otto. The term ''internal combustion engine'' usually ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hiduminium

The Hiduminium alloys or R.R. alloys are a series of high-strength, high-temperature aluminium alloys, developed for aircraft use by Rolls-Royce Limited, Rolls-Royce ("RR") before World War II. They were manufactured and later developed by #High Duty Alloys Ltd., High Duty Alloys Ltd. The name ''Hi''-''Du''-Minium is derived from that of ''Hi''gh ''Du''ty Alu''minium'' Alloys. The first of these Hiduminium alloys was termed '''R.R.50' ''. This alloy was first developed for motor-racing pistons, and was only later adopted for aircraft engine use. It was a development of the earlier Y alloy, the first of the nickel-containing light aluminium alloys. These alloys are one of the three main groups of high-strength aluminium alloys, the nickel-aluminium alloys having the advantage of retaining strength at high temperatures, making them particularly useful for pistons. Early adoption The alloys were in limited use for aircraft by 1929, being used in the Rolls-Royce R engine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Y Alloy

Y alloy is a nickel-containing aluminium alloy. It was developed by the British National Physical Laboratory during World War I, in an attempt to find an aluminium alloy that would retain its strength at high temperatures. Duralumin, an aluminium alloy containing 4% copper was already known at this time. Its strength, and its previously unknown age hardening behaviour had made it a popular choice for zeppelins. Aircraft of the period were largely constructed of wood, but there was a need for an aluminium alloy suitable for making engines, particularly pistons, that would have the strength of duralumin but could retain this when in service at high temperatures for long periods. The National Physical Laboratory began a series of experiments to study new aluminium alloys. Experimental series "Y" was successful, and gave its name to the new alloy. Like duralumin, this was a 4% copper alloy, but with the addition of 2% nickel and 1.5% magnesium. This addition of nickel was an innova ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cast Iron

Cast iron is a class of iron–carbon alloys with a carbon content of more than 2% and silicon content around 1–3%. Its usefulness derives from its relatively low melting temperature. The alloying elements determine the form in which its carbon appears: Cast iron#White cast iron, white cast iron has its carbon combined into an iron carbide named cementite, which is very hard, but brittle, as it allows cracks to pass straight through; Grey iron, grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and Ductile iron, ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing. Carbon (C), ranging from 1.8 to 4 wt%, and silicon (Si), 1–3 wt%, are the main alloying elements of cast iron. Iron alloys with lower carbon content are known as steel. Cast iron tends to be brittle, except for malleable iron, malleable cast irons. With its relatively low melting point, g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminium Alloy

An aluminium alloy ( UK/IUPAC) or aluminum alloy ( NA; see spelling differences) is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to their low melting points, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.I. J. Polmear, ''Light Alloys'', A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forging

Forging is a manufacturing process involving the shaping of metal using localized compression (physics), compressive forces. The blows are delivered with a hammer (often a power hammer) or a die (manufacturing), die. Forging is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging, or hot forging (a type of hot working). For the latter two, the metal is heated, usually in a forge. Forged parts can range in weight from less than a kilogram to hundreds of metric tons.Degarmo, p. 389 Forging has been done by metalsmith, smiths for millennia; the traditional products were kitchenware, household hardware, hardware, hand tools, edged weapons, cymbals, and jewellery. Since the Industrial Revolution, forged parts are widely used in mechanism (engineering), mechanisms and machines wherever a component requires high strength of materials, strength; such forgings usually require further processing (such as machining) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting (metalworking)

In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a Mold (manufacturing), mold (usually by a crucible) that contains a negative impression (i.e., a three-dimensional negative image) of the intended shape. The metal is poured into the mold through a hollow channel called a Sprue (manufacturing), sprue. The metal and mold are then cooled, and the metal part (the ''casting'') is extracted. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods. Casting processes have been known for thousands of years, and have been widely used for sculpture (especially in bronze), jewelry in precious metals, and weapons and tools. Highly engineered castings are found in 90 percent of durable goods, including cars, trucks, aerospace, trains, mining and construction equipment, oil wells, appliances, pipes, hydrants, wind turbines, nuclear plants, medical devices, defense products, toys, an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Circlip

A circlip (a portmanteau of "circle" and "clip"), also known as a C-clip, snap ring, or Jesus clip, is a type of fastener or retaining ring that consists of a semi-flexible metal ring with open ends that can be snapped into place into a Machining, machined Groove (machining), groove on a dowel pin or other part to permit rotation but to prevent axial Motion (physics), movement. There are two basic types of circlips: internal (fitted into a bore) and external (fitted over a shaft). Circlips are used to secure pinned connections. Details The term "Jesus clip" is a comical reference given to it due to its tendency to come loose and launch itself at high speed while removing or installing it, often leading to the remark "Oh Jesus, where did it go?" E-clip Common examples include e-clips (e-rings) and the snap ring (both internal and external) or circlip. These general types of fasteners are sized to provide an interference fit onto (or into, in the case of an internal fastener) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cooling Chanel

Cooling is removal of heat, usually resulting in a lower temperature and/or phase change. Temperature lowering achieved by any other means may also be called cooling. The transfer of thermal energy may occur via thermal radiation, heat conduction or convection. Examples can be as simple as reducing temperature of a coffee. Devices *Coolant *Cooling towers, as used in large industrial plants and power stations *Daytime passive radiative cooler *Evaporative cooler *Heat exchanger *Heat pipe *Heat sink *HVAC (Heating, Ventilation and Air Conditioning) *Intercooler *Radiative cooling in Heat shields *Radiators in automobiles *Pumpable ice technology *Thermoelectric cooling *Vortex tube, as used in industrial spot cooling See also * Computer cooling * Refridgeration Refrigeration is any of various types of cooling of a space, substance, or system to lower and/or maintain its temperature below the ambient one (while the removed heat is ejected to a place of higher temperature). ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

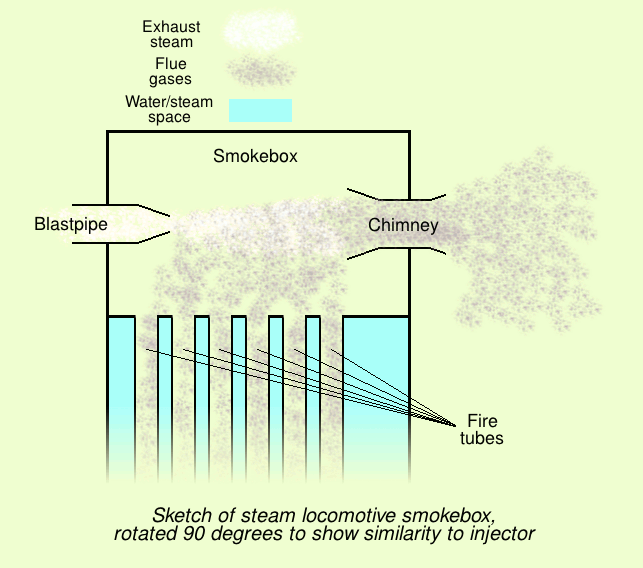

Injector

An injector is a system of ducting and nozzles used to direct the flow of a high-pressure fluid in such a way that a lower pressure fluid is Entrainment (hydrodynamics), entrained in the jet and carried through a duct to a region of higher pressure. It is a fluid-dynamic pump with no moving parts except a valve to control inlet flow. Depending on the application, an injector can also take the form of an ''eductor-jet pump'', a ''water eductor'' or an ''aspirator''. An ''Vacuum ejector, ejector'' operates on similar principles to create a vacuum feed connection for braking systems etc. The motive fluid may be a liquid, steam or any other gas. The entrained suction fluid may be a gas, a liquid, a slurry, or a dust-laden gas stream. Steam injector The steam injector is a common device used for delivering water to steam boilers, especially in steam locomotives. It is a typical application of the injector principle used to deliver cold boiler feedwater, water to a boiler against ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel Engines

The diesel engine, named after the German engineer Rudolf Diesel, is an internal combustion engine in which ignition of diesel fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is called a compression-ignition engine (CI engine). This contrasts with engines using spark plug-ignition of the air-fuel mixture, such as a petrol engine (gasoline engine) or a gas engine (using a gaseous fuel like natural gas or liquefied petroleum gas). Introduction Diesel engines work by compressing only air, or air combined with residual combustion gases from the exhaust (known as exhaust gas recirculation, "EGR"). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases air temperature inside the cylinder so that atomised diesel fuel injected into the combustion chamber ignites. The torque a diesel engine produces is controlled by manipulating the air-fue ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |