|

Nanofilms

Nanofilms are thin films ranging from 1 to 100 nanometers in thickness. These materials exhibit unique chemical and physical properties, largely influenced by quantum behavior and surface effects. Their low surface energy, reduced friction coefficient, and high selectivity make them valuable across various industries, including solar energy, medicine, and food packaging. The properties of nanofilms are highly dependent on their chemical composition and molecular structure. Nanofilms are characterized using a range of instrumental techniques, including Scanning electron microscope, scanning electron microscopy (SEM], X-ray diffraction (XRD), transmission electron microscopy (TEM), Energy-dispersive X-ray spectroscopy, energy dispersive X-ray analysis (EDX), Raman spectroscopy, Raman spectroscopy, and UV-Vis absorption spectroscopy. The nanofilm market has gained significant economic importance, with a market size of $2.06 billion, projected to grow to $7.09 billion by 2027. This gro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thin Film

A thin film is a layer of materials ranging from fractions of a nanometer ( monolayer) to several micrometers in thickness. The controlled synthesis of materials as thin films (a process referred to as deposition) is a fundamental step in many applications. A familiar example is the household mirror, which typically has a thin metal coating on the back of a sheet of glass to form a reflective interface. The process of silvering was once commonly used to produce mirrors, while more recently the metal layer is deposited using techniques such as sputtering. Advances in thin film deposition techniques during the 20th century have enabled a wide range of technological breakthroughs in areas such as magnetic recording media, electronic semiconductor devices, integrated passive devices, light-emitting diodes, optical coatings (such as antireflective coatings), hard coatings on cutting tools, and for both energy generation (e.g. thin-film solar cells) and storage ( thin-film bat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrospinning

Electrospinning is a fiber production method that uses Electrostatics, electrical force (based on electrohydrodynamic principles) to draw charged threads of polymer solutions for producing nanofibers with diameters ranging from nanometers to micrometers. Electrospinning shares characteristics of both electrospraying and conventional solution spinning (polymers)#Dry spinning, dry spinning of fibers.Ziabicki, A. (1976) ''Fundamentals of fiber formation'', John Wiley and Sons, London, . The process does not require the use of coagulation chemistry or high temperatures to produce solid threads from solution. This makes the process particularly suited to the production of fibers using large and complex molecules. Electrospinning from molten precursors is also practiced; this method ensures that no solvent can be carried over into the final product. Process When a sufficiently high voltage is applied to a liquid droplet, the body of the liquid becomes charged, and electrostatic repuls ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanotechnology

Nanotechnology is the manipulation of matter with at least one dimension sized from 1 to 100 nanometers (nm). At this scale, commonly known as the nanoscale, surface area and quantum mechanical effects become important in describing properties of matter. This definition of nanotechnology includes all types of research and technologies that deal with these special properties. It is common to see the plural form "nanotechnologies" as well as "nanoscale technologies" to refer to research and applications whose common trait is scale. An earlier understanding of nanotechnology referred to the particular technological goal of precisely manipulating atoms and molecules for fabricating macroscale products, now referred to as molecular nanotechnology. Nanotechnology defined by scale includes fields of science such as surface science, organic chemistry, molecular biology, semiconductor physics, energy storage, engineering, microfabrication, and molecular engineering. The associated rese ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Photovoltaic Thermal Hybrid Solar Collector

Photovoltaic thermal collectors, typically abbreviated as PVT collectors and also known as hybrid solar collectors, photovoltaic thermal solar collectors, PV/T collectors or solar cogeneration systems, are power generation technologies that convert solar radiation into usable thermal and electrical energy. PVT collectors combine photovoltaic solar cells (often arranged in solar panels), which convert sunlight into electricity, with a solar thermal collector, which transfers the otherwise unused waste heat from the PV module to a heat transfer fluid. By combining electricity and heat generation within the same component, these technologies can reach a higher overall efficiency than solar photovoltaic (PV) or solar thermal (T) alone. Significant research has gone into developing a diverse range of PVT technologies since the 1970s. The different PVT collector technologies differ substantially in their collector design and heat transfer fluid and address different applications rangin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanotube (15112442038)

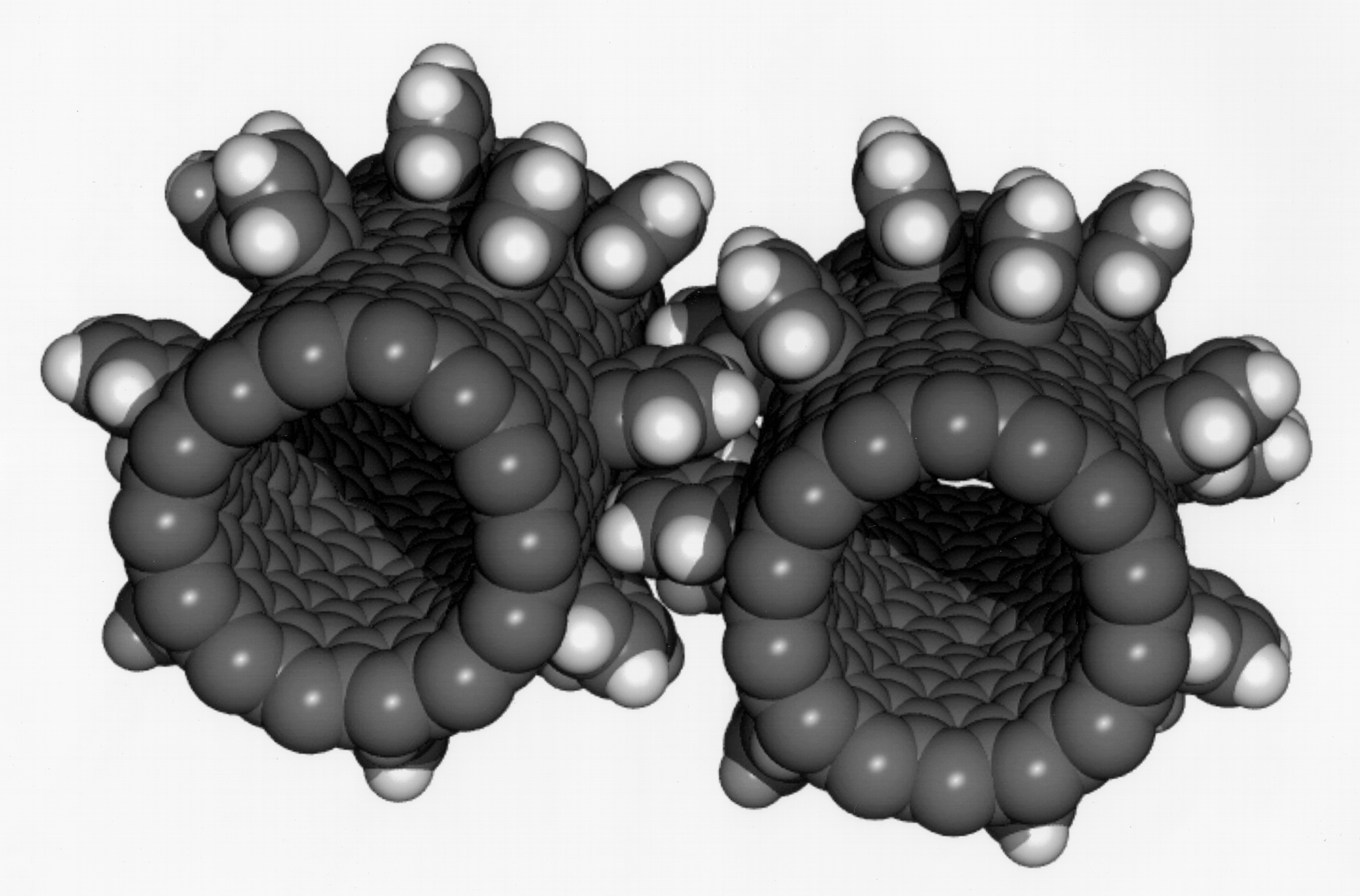

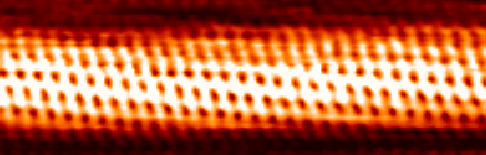

A nanotube is a nanoscale cylindrical structure with a hollow core, typically composed of carbon atoms, though other materials can also form nanotubes. Carbon nanotubes (CNTs) are the most well-known and widely studied type, consisting of rolled-up sheets of graphene with diameters ranging from about 1 to tens of nanometers and lengths up to millimeters. These structures exhibit remarkable physical, chemical, and electrical properties, including high tensile strength, excellent thermal and electrical conductivity, and unique quantum effects due to their one-dimensional nature. Nanotubes can be classified into two main categories: single-walled nanotubes (SWNTs) and multi-walled nanotubes (MWNTs), each with distinct characteristics and potential applications. Since their discovery in 1991, nanotubes have been the subject of intense research and development, with promising applications in fields such as electronics, materials science, energy storage, and medicine. Types * BCN na ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Nanotube

A carbon nanotube (CNT) is a tube made of carbon with a diameter in the nanometre range ( nanoscale). They are one of the allotropes of carbon. Two broad classes of carbon nanotubes are recognized: * ''Single-walled carbon nanotubes'' (''SWCNTs'') have diameters around 0.5–2.0 nanometres, about 100,000 times smaller than the width of a human hair. They can be idealised as cutouts from a two-dimensional graphene sheet rolled up to form a hollow cylinder. * ''Multi-walled carbon nanotubes'' (''MWCNTs'') consist of nested single-wall carbon nanotubes in a nested, tube-in-tube structure. Double- and triple-walled carbon nanotubes are special cases of MWCNT. Carbon nanotubes can exhibit remarkable properties, such as exceptional tensile strength and thermal conductivity because of their nanostructure and strength of the bonds between carbon atoms. Some SWCNT structures exhibit high electrical conductivity while others are semiconductors. In addition, carbon nanotubes can b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Biosensors And Molecule Delivery

A biosensor is an analytical device, used for the detection of a chemical substance, that combines a biological component with a physicochemical detector. The ''sensitive biological element'', e.g. tissue, microorganisms, organelles, cell receptors, enzymes, antibodies, nucleic acids, etc., is a biologically derived material or biomimetic component that interacts with, binds with, or recognizes the analyte under study. The biologically sensitive elements can also be created by biological engineering. The ''transducer'' or the ''detector element'', which transforms one signal into another one, works in a physicochemical way: optical, piezoelectric, electrochemical, electrochemiluminescence etc., resulting from the interaction of the analyte with the biological element, to easily measure and quantify. The biosensor reader device connects with the associated electronics or signal processors that are primarily responsible for the display of the results in a user-friendly way. This s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Biosensor

A biosensor is an analytical device, used for the detection of a chemical substance, that combines a biological component with a physicochemical detector. The ''sensitive biological element'', e.g. tissue, microorganisms, organelles, cell receptors, enzymes, antibodies, nucleic acids, etc., is a biologically derived material or biomimetic component that interacts with, binds with, or recognizes the analyte under study. The biologically sensitive elements can also be created by biological engineering. The ''transducer'' or the ''detector element'', which transforms one signal into another one, works in a physicochemical way: optical, piezoelectric, electrochemical, electrochemiluminescence etc., resulting from the interaction of the analyte with the biological element, to easily measure and quantify. The biosensor reader device connects with the associated electronics or signal processors that are primarily responsible for the display of the results in a user-friendly way. Thi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Physical Vapor Deposition

Physical vapor deposition (PVD), sometimes called physical vapor transport (PVT), describes a variety of vacuum deposition methods which can be used to produce thin films and coatings on substrates including metals, ceramics, glass, and polymers. PVD is characterized by a process in which the material transitions from a condensed phase to a vapor phase and then back to a thin film condensed phase. The most common PVD processes are Sputter coating, sputtering and Evaporation (deposition), evaporation. PVD is used in the manufacturing of items which require thin films for optical, mechanical, electrical, acoustic or chemical functions. Examples include semiconductor devices such as thin-film solar cells, microelectromechanical devices such as thin film bulk acoustic resonator, aluminized Polyethylene terephthalate, PET film for food packaging and balloons, and titanium nitride coated cutting tools for metalworking. Besides PVD tools for fabrication, special smaller tools used mai ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Atomic Layer Deposition

Atomic layer deposition (ALD) is a thin-film deposition technique based on the sequential use of a gas-phase chemical process; it is a subclass of chemical vapour deposition. The majority of ALD reactions use two chemicals called wiktionary:precursor, precursors (also called "reactants"). These precursors react with the surface of a material one at a time in a sequential, self-limiting, manner. A thin film is slowly deposited through repeated exposure to separate precursors. ALD is a key process in semiconductor device fabrication, fabricating semiconductor devices, and part of the set of tools for synthesizing nanomaterials. Introduction During atomic layer deposition, a film is grown on a substrate by exposing its surface to alternate gaseous species (typically referred to as Precursor (chemistry), precursors or reactants). In contrast to chemical vapor deposition, the precursors are never present simultaneously in the reactor, but they are inserted as a series of sequential, no ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrospinning Image For Wikipedia

Electrospinning is a fiber production method that uses electrical force (based on electrohydrodynamic principles) to draw charged threads of polymer solutions for producing nanofibers with diameters ranging from nanometers to micrometers. Electrospinning shares characteristics of both electrospraying and conventional solution dry spinning of fibers.Ziabicki, A. (1976) ''Fundamentals of fiber formation'', John Wiley and Sons, London, . The process does not require the use of coagulation chemistry or high temperatures to produce solid threads from solution. This makes the process particularly suited to the production of fibers using large and complex molecules. Electrospinning from molten precursors is also practiced; this method ensures that no solvent can be carried over into the final product. Process When a sufficiently high voltage is applied to a liquid droplet, the body of the liquid becomes charged, and electrostatic repulsion counteracts the surface tension and the dro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |