|

Microextrusion

Microextrusion is a microforming extrusion process performed at the submillimeter range. Like extrusion, material is pushed through a die orifice, but the resulting product's cross section can fit through a 1mm square. Several microextrusion processes have been developed since microforming was envisioned in 1990. Forward (ram and billet move in the same direction) and backward (ram and billet move in the opposite direction) microextrusion were first introduced, with forward rod-backward cup and double cup extrusion methods developing later. Regardless of method, one of the greatest challenges of creating a successful microextrusion machine is the manufacture of the die and ram. "The small size of the die and ram, along with the stringent accuracy requirement, needs suitable manufacturing processes." Additionally, as Fu and Chan pointed out in a 2013 state-of-the-art technology review, several issues must still be resolved before microextrusion and other microforming technologies can ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extrusion

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal bars and tubes are also often drawn. Extrusion may be continuous (theoretically producing indefinitely long material) or semi-continuous (producing many pieces). It can be done with hot or cold material. Commonly extruded ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microfabrication

Microfabrication is the process of fabricating miniature structures of micrometre scales and smaller. Historically, the earliest microfabrication processes were used for integrated circuit fabrication, also known as "semiconductor manufacturing" or "semiconductor device fabrication". In the last two decades microelectromechanical systems (MEMS), microsystems (European usage), micromachines (Japanese terminology) and their subfields, microfluidics/lab-on-a-chip, optical MEMS (also called MOEMS), RF MEMS, PowerMEMS, BioMEMS and their extension into nanoscale (for example NEMS, for nano electro mechanical systems) have re-used, adapted or extended microfabrication methods. Flat-panel displays and solar cells are also using similar techniques. Miniaturization of various devices presents challenges in many areas of science and engineering: physics, chemistry, materials science, computer science, ultra-precision engineering, fabrication processes, and equipment design. It is also gi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forming Processes

Some of example of forming processes are: * Forging * Extrusion * Rolling * Sheet metal working * Rotary swaging * Thread rolling * Explosive forming * Electromagnetic forming * Plastic extrusion * Die_forming_(plastics)#Process * Food_extrusion#Process See also * * * Pedogenesis Soil formation, also known as pedogenesis, is the process of soil genesis as regulated by the effects of place, environment, and history. Biogeochemical processes act to both create and destroy order ( anisotropy) within soils. These alterations ... - soil forming processes {{metalworking-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Database

In computing, a database is an organized collection of data stored and accessed electronically. Small databases can be stored on a file system, while large databases are hosted on computer clusters or cloud storage. The design of databases spans formal techniques and practical considerations, including data modeling, efficient data representation and storage, query languages, security and privacy of sensitive data, and distributed computing issues, including supporting concurrent access and fault tolerance. A database management system (DBMS) is the software that interacts with end users, applications, and the database itself to capture and analyze the data. The DBMS software additionally encompasses the core facilities provided to administer the database. The sum total of the database, the DBMS and the associated applications can be referred to as a database system. Often the term "database" is also used loosely to refer to any of the DBMS, the database system or an app ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engineering Tolerance

Engineering tolerance is the permissible limit or limits of variation in: # a physical dimension; # a measured value or physical property of a material, manufactured object, system, or service; # other measured values (such as temperature, humidity, etc.); # in engineering and safety, a physical distance or space (tolerance), as in a truck (lorry), train or boat under a bridge as well as a train in a tunnel (see structure gauge and loading gauge); # in mechanical engineering, the space between a bolt and a nut or a hole, etc. Dimensions, properties, or conditions may have some variation without significantly affecting functioning of systems, machines, structures, etc. A variation beyond the tolerance (for example, a temperature that is too hot or too cold) is said to be noncompliant, rejected, or exceeding the tolerance. Considerations when setting tolerances A primary concern is to determine how wide the tolerances may be without affecting other factors or the outcome of a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drug Delivery

Drug delivery refers to approaches, formulations, manufacturing techniques, storage systems, and technologies involved in transporting a pharmaceutical compound to its target site to achieve a desired therapeutic effect. Principles related to drug preparation, route of administration, site-specific targeting, metabolism, and toxicity are used to optimize efficacy and safety, and to improve patient convenience and compliance. Drug delivery is aimed at altering a drug's pharmacokinetics and specificity by formulating it with different excipients, drug carriers, and medical devices. There is additional emphasis on increasing the bioavailability and duration of action of a drug to improve therapeutic outcomes. Some research has also been focused on improving safety for the person administering the medication. For example, several types of microneedle patches have been developed for administering vaccines and other medications to reduce the risk of needlestick injury. Drug deli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bioresorbable Stents

In medicine, a stent is any device which is inserted into a blood vessel or other internal duct to expand it to prevent or alleviate a blockage. Traditionally, such devices are fabricated from metal mesh and remain in the body permanently or until removed through further surgical intervention. A bioresorbable stent (also called bioresorbable scaffold, biodegradable stent or naturally-dissolving stent) serves the same purpose, but is manufactured from a material that may dissolve or be absorbed in the body. Background The use of metal drug-eluting stents presents some potential drawbacks. These include a predisposition to late stent thrombosis, prevention of late vessel adaptive or expansive remodeling, hindrance of surgical revascularization, and impairment of imaging with multislice CT. To overcome some of these potential drawbacks, several companies are pursuing the development of bioresorbable scaffolds or bioabsorbable stents. Like metal stents, placement of a bioresorbabl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Medical Device

A medical device is any device intended to be used for medical purposes. Significant potential for hazards are inherent when using a device for medical purposes and thus medical devices must be proved safe and effective with reasonable assurance before regulating governments allow marketing of the device in their country. As a general rule, as the associated risk of the device increases the amount of testing required to establish safety and efficacy also increases. Further, as associated risk increases the potential benefit to the patient must also increase. Discovery of what would be considered a medical device by modern standards dates as far back as c. 7000 BC in Baluchistan where Neolithic dentists used flint-tipped drills and bowstrings. Study of archeology and Roman medical literature also indicate that many types of medical devices were in widespread use during the time of ancient Rome. In the United States it wasn't until the Federal Food, Drug, and Cosmetic Act (FD&C ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

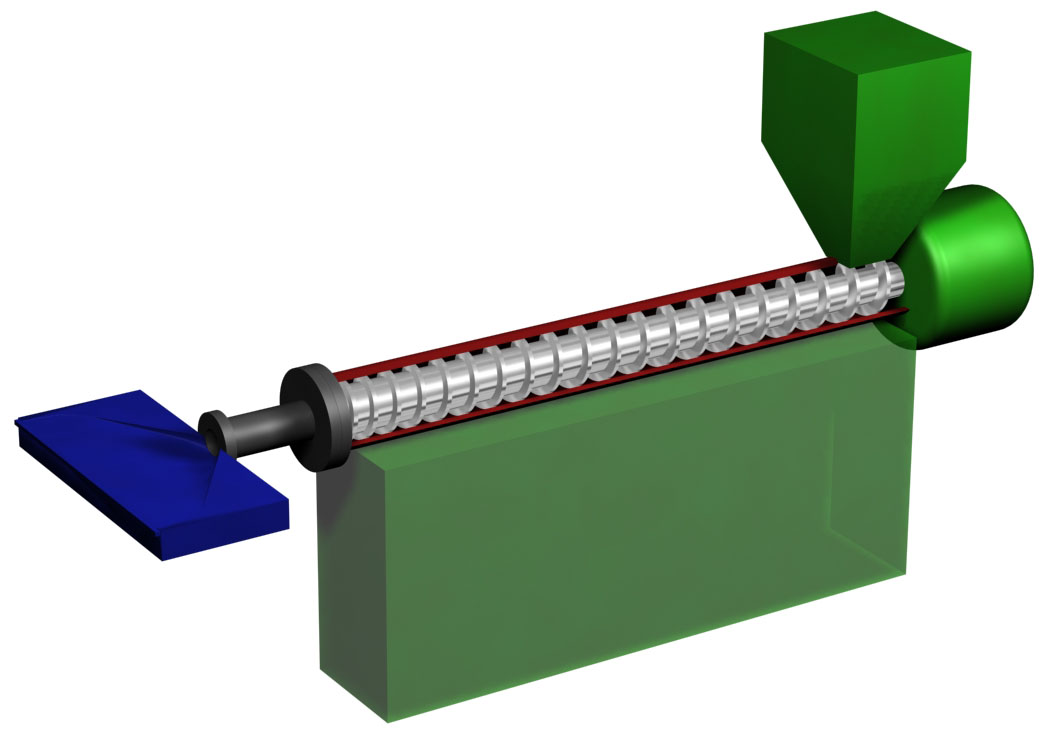

Plastic Extrusion

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted by the mechanical energy generated by turning screws and by heaters arranged along the barrel. The molten polymer is then forced into a die, which shapes the polymer into a shape that hardens during cooling. History The first precursors to the modern extruder were developed in the early 19th century. In 1820, Thomas Hancock invented a rubber "masticator" designed to reclaim processed rubber scraps, and in 1836 Edwin Chaffee developed a two-roller machine to mix additives into rubber. The first thermoplastic extrus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Implant (medicine)

An implant is a medical device manufactured to replace a missing biological structure, support a damaged biological structure, or enhance an existing biological structure. Medical implants are man-made devices, in contrast to a transplant, which is a transplanted biomedical tissue. The surface of implants that contact the body might be made of a biomedical material such as titanium, silicone, or apatite depending on what is the most functional. In some cases implants contain electronics, e.g. artificial pacemaker and cochlear implants. Some implants are bioactive, such as subcutaneous drug delivery devices in the form of implantable pills or drug-eluting stents. Applications Implants can roughly be categorized into groups by application: Sensory and neurological Sensory and neurological implants are used for disorders affecting the major senses and the brain, as well as other neurological disorders. They are predominately used in the treatment of conditions such as c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

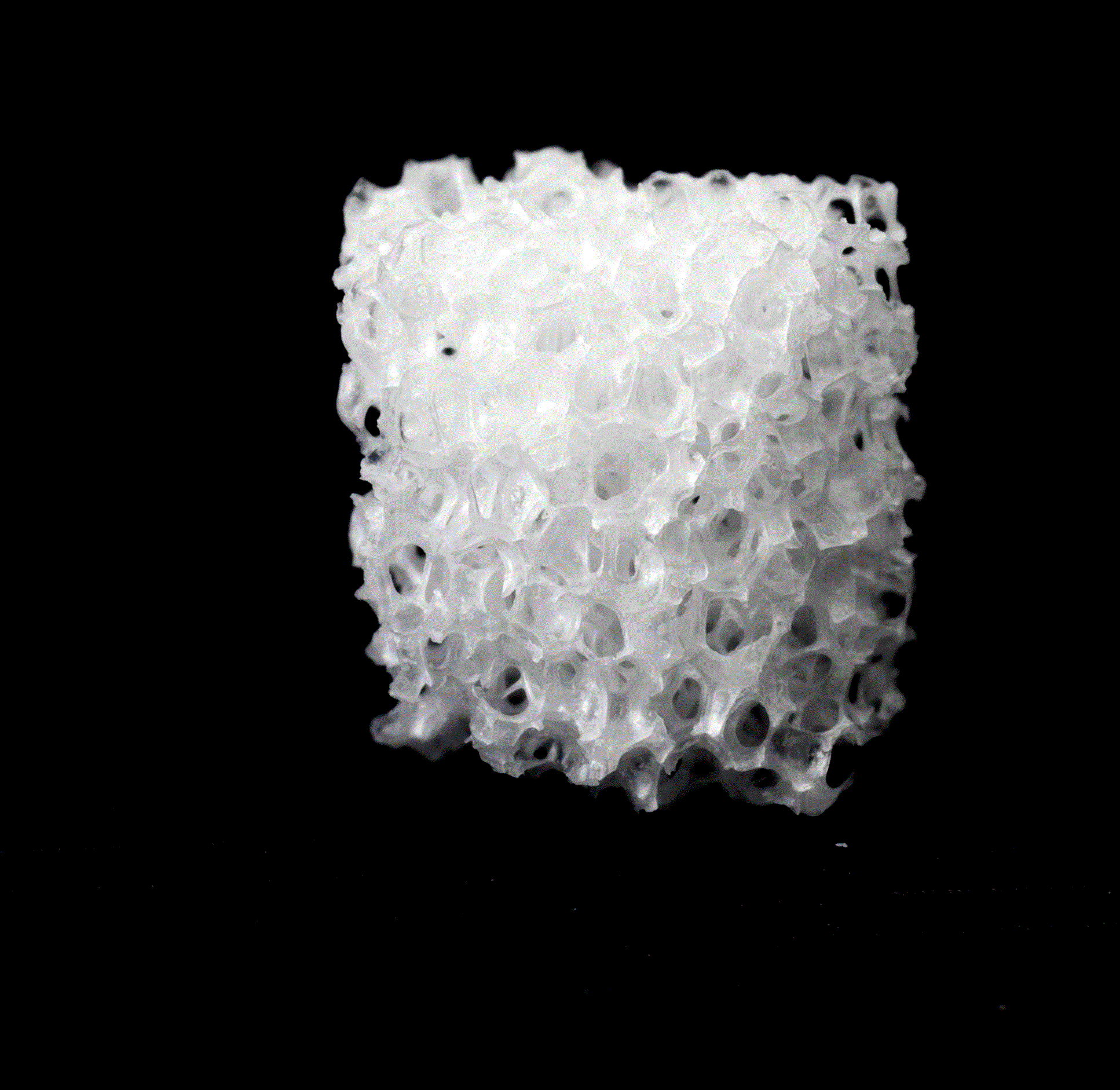

Bioceramic

Bioceramics and bioglasses are ceramic materials that are biocompatibility, biocompatible. Bioceramics are an important subset of biomaterials.J. F. Shackelford (editor)(1999) ''MSF bioceramics applications of ceramic and glass materials in medicine'' Bioceramics range in biocompatibility from the ceramic oxides, which are inert in the body, to the other extreme of resorbable materials, which are eventually replaced by the body after they have assisted repair. Bioceramics are used in many types of medical procedures. Bioceramics are typically used as rigid materials in Implant (medicine), surgical implants, though some bioceramics are flexible. The ceramic materials used are not the same as porcelain type ceramic materials. Rather, bioceramics are closely related to either the body's own materials or are extremely durable Mixed metal oxide, metal oxides. History Prior to 1925, the materials used in implant surgery were primarily relatively pure metals. The success of these material ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |