|

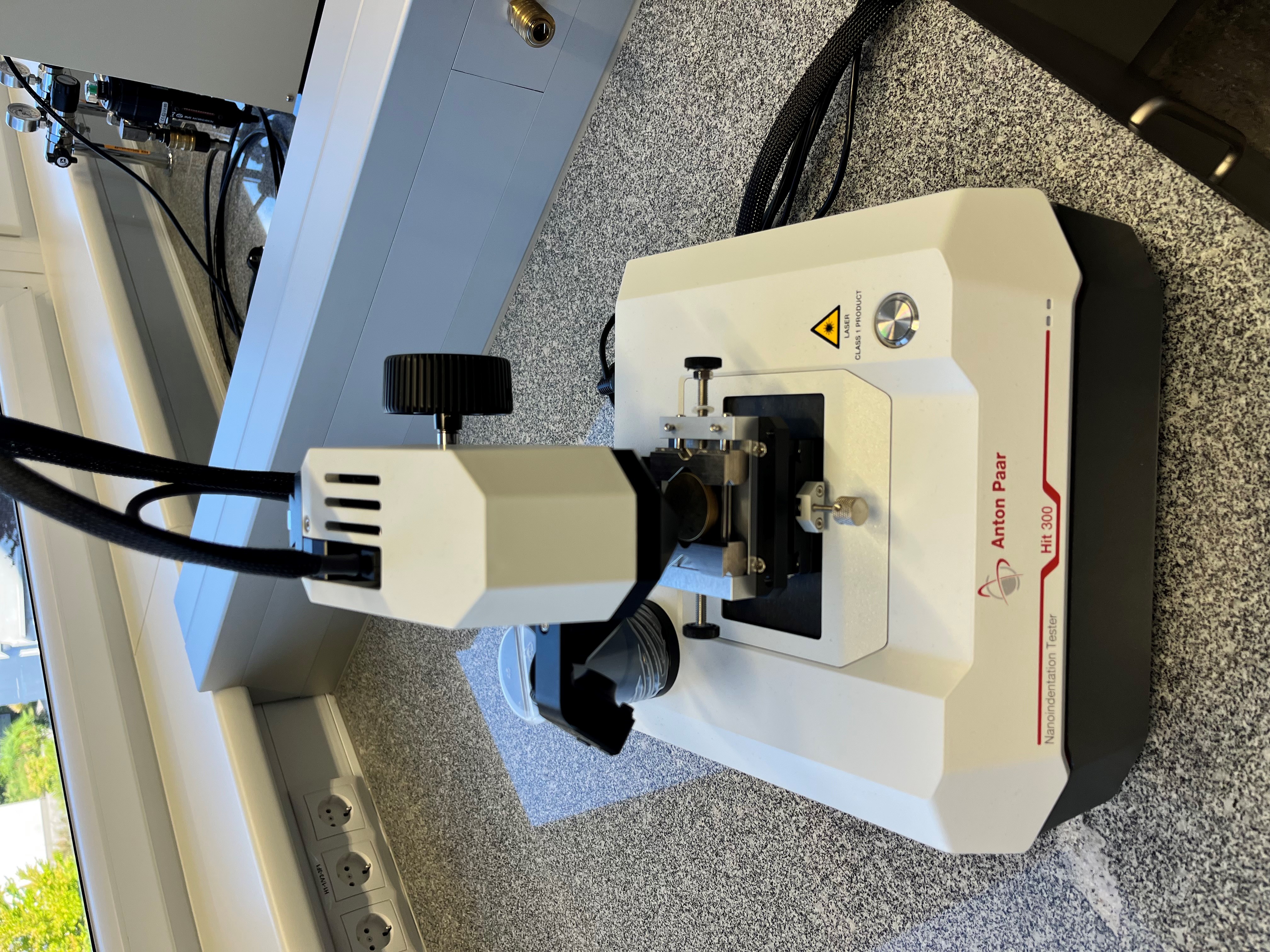

Hardness Test

Indentation hardness tests are used in mechanical engineering to determine the hardness of a material to deformation. Several such tests exist, wherein the examined material is indented until an impression is formed; these tests can be performed on a macroscopic or microscopic scale. When testing metals, indentation hardness correlates roughly linearly with tensile strength, but it is an imperfect correlation often limited to small ranges of strength and hardness for each indentation geometry. This relation permits economically important nondestructive testing of bulk metal deliveries with lightweight, even portable equipment, such as hand-held Rockwell hardness testers. Material hardness Different techniques are used to quantify material characteristics at smaller scales. Measuring mechanical properties for materials, for instance, of thin films, cannot be done using conventional uniaxial tensile testing. As a result, techniques testing material "hardness" by indenting a materia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Knoop Hardness Test

The Knoop hardness test is a microhardness test – a test for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. A pyramidal diamond point is pressed into the polished surface of the test material with a known (often 100 g) load, for a specified dwell time, and the resulting indentation is measured using a microscope. The geometry of this indenter is an extended pyramid with the length to width ratio being 7:1 and respective face angles are 172 degrees for the long edge and 130 degrees for the short edge. The depth of the indentation can be approximated as 1/30 of the long dimension. The Knoop hardness ''HK'' or ''KHN'' is then given by the formula: : HK where: : ''L'' is the length of indentation along its long axis : ''C''p is the correction factor related to the shape of the indenter, ideally 0.070279 : ''P'' is the load HK values are typically in the range from 100 to 1000, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanical Engineering

Mechanical engineering is the study of physical machines and mechanism (engineering), mechanisms that may involve force and movement. It is an engineering branch that combines engineering physics and engineering mathematics, mathematics principles with materials science, to design, analyze, manufacture, and maintain mechanical systems. It is one of the oldest and broadest of the List of engineering branches, engineering branches. Mechanical engineering requires an understanding of core areas including mechanics, Analytical dynamics, dynamics, thermodynamics, materials science, design, structural analysis, and electricity. In addition to these core principles, mechanical engineers use tools such as computer-aided design (CAD), computer-aided manufacturing (CAM), computer-aided engineering (CAE), and product lifecycle management to design and analyze manufacturing plants, industrial equipment and industrial machinery, machinery, HVAC, heating and cooling systems, transport systems, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rockwell Scale

The Rockwell hardness test is a hardness test based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). There are different scales, denoted by a single letter, that use different loads or indenters. The result is a dimensionless number noted as HRA, HRB, HRC, etc., where the last letter is the respective Rockwell scale. Larger numbers correspond to harder materials. When testing metals, indentation hardness correlates linearly with tensile strength. History The differential depth hardness measurement was conceived in 1908 by Viennese professor Paul Ludwik in his book ''Die Kegelprobe'' (crudely, "the cone test"). The differential-depth method subtracted out the errors associated with the mechanical imperfections of the system, such as backlash and surface imperfections. The Brinell scale, Brinell hardness test, invented in Sweden, wa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shear Stress

Shear stress (often denoted by , Greek alphabet, Greek: tau) is the component of stress (physics), stress coplanar with a material cross section. It arises from the shear force, the component of force vector parallel to the material cross section. ''Normal stress'', on the other hand, arises from the force vector component perpendicular to the material cross section on which it acts. General shear stress The formula to calculate average shear stress or force per unit area is: \tau = ,where is the force applied and is the cross-sectional area. The area involved corresponds to the material face (geometry), face parallel to the applied force vector, i.e., with surface normal vector perpendicular to the force. Other forms Wall shear stress Wall shear stress expresses the retarding force (per unit area) from a wall in the layers of a fluid flowing next to the wall. It is defined as:\tau_w := \mu\left.\frac\_,where is the dynamic viscosity, is the flow velocity, and is the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compressive Strength

In mechanics, compressive strength (or compression strength) is the capacity of a material or Structural system, structure to withstand Structural load, loads tending to reduce size (Compression (physics), compression). It is opposed to ''tensile strength'' which withstands loads tending to elongate, resisting Tension (physics), tension (being pulled apart). In the study of strength of materials, compressive strength, tensile strength, and shear strength can be analyzed independently. Some materials fracture at their compressive strength limit; others Plasticity (physics), deform irreversibly, so a given amount of Deformation (engineering), deformation may be considered as the limit for compressive load. Compressive strength is a key value for Structural engineering, design of structures. Compressive strength is often measured on a universal testing machine. Measurements of compressive strength are affected by the specific test method and conditions of measurement. Compressive s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strain Hardening

Work hardening, also known as strain hardening, is the process by which a material's load-bearing capacity (strength) increases during plastic (permanent) deformation. This characteristic is what sets ductile materials apart from brittle materials. Work hardening may be desirable, undesirable, or inconsequential, depending on the application. This strengthening occurs because of dislocation movements and dislocation generation within the crystal structure of the material. Many non-brittle metals with a reasonably high melting point as well as several polymers can be strengthened in this fashion. Alloys not amenable to heat treatment, including low-carbon steel, are often work-hardened. Some materials cannot be work-hardened at low temperatures, such as indium, however others can be strengthened only via work hardening, such as pure copper and aluminum. Undesirable work hardening An example of undesirable work hardening is during machining when early passes of a cutting tool (ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

National Physical Laboratory, UK

The National Physical Laboratory (NPL) is the national measurement standards laboratory of the United Kingdom. It sets and maintains physical standards for British industry. Founded in 1900, the NPL is one of the oldest metrology institutes in the world. Research and development work at the laboratory has contributed to the advancement of many disciplines of science, including the development of early computers in the late 1940s and 1950s, construction of the first accurate atomic clock in 1955, and the invention and first implementation of packet switching in the 1960s, which is today one of the fundamental technologies of the Internet. The former heads of NPL include many individuals who were pillars of the British scientific establishment. NPL is based at Bushy Park in Teddington, southwest London. It is operated by NPL Management Ltd, a company owned by the Department for Science, Innovation and Technology, and is one of the most extensive government laboratories in the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bierbaum Test

Bierbaum is a German surname. Notable people with the surname include: *Otto Julius Bierbaum (1865–1910), German writer *Rosina Bierbaum (born 1952), dean of the University of Michigan School of Natural Resources and Environment *Tom and Mary Bierbaum Tom and Mary Bierbaum are an American husband-and-wife writing team, known for their work on the DC comic book ''Legion of Super-Heroes''. Biography The Bierbaums entered the world of professional comic book writing through Legion fandom. Tom B ... (born 1956, 1955, respectively), married couple known for their work in ''Legion of Super-Heroes'' * Veronica M. Bierbaum, American chemist See also * Bierbaum am Auersbach, municipal district in Austria {{surname, Bierbaum German-language surnames ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

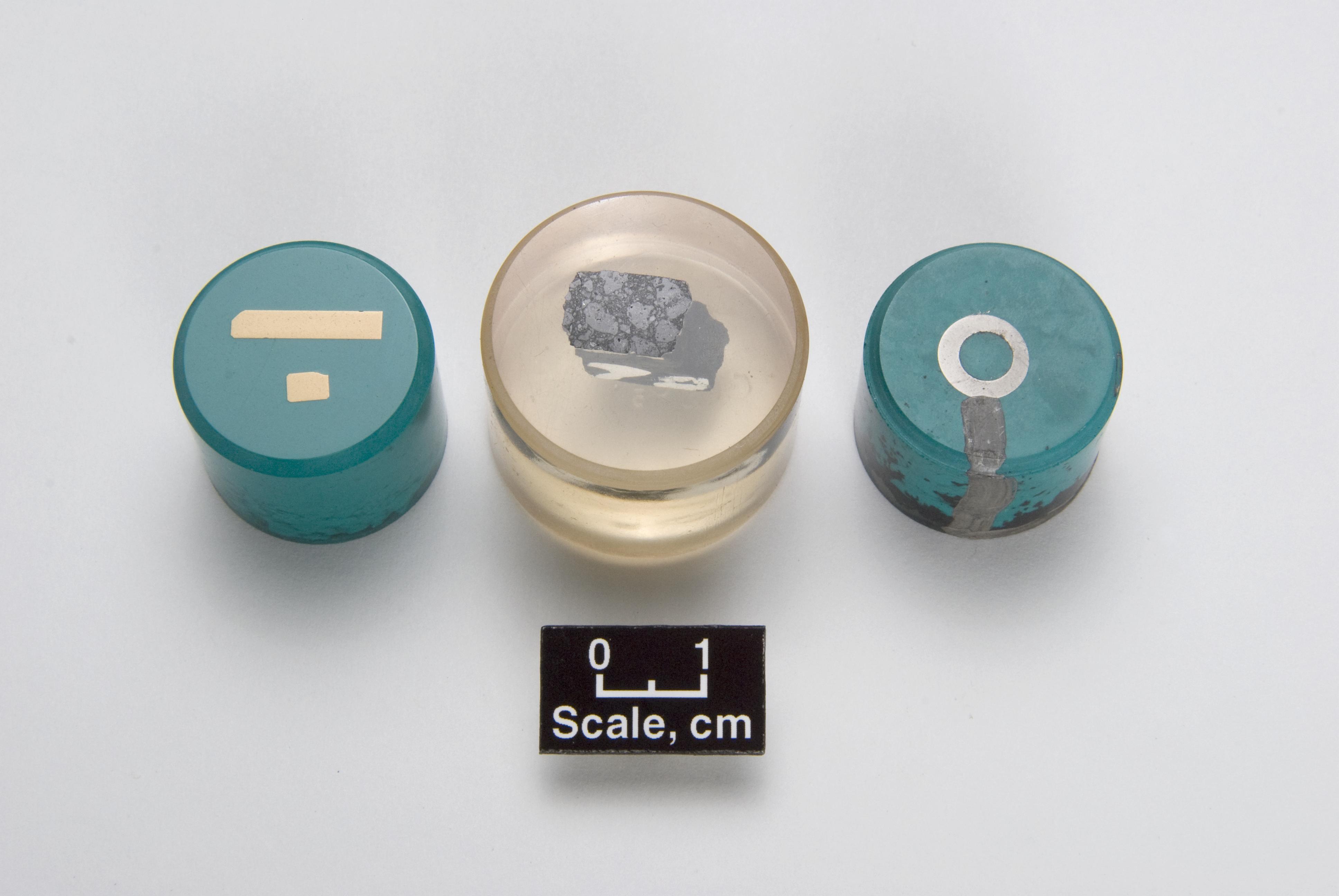

Ceramography

Ceramography is the art and science of preparation, examination and evaluation of ceramic microstructures. Ceramography can be thought of as the metallography of ceramics. The microstructure is the structure level of approximately 0.1 to 100 Micrometre, μm, between the minimum wavelength of Visible spectrum, visible light and the resolution limit of the naked eye. The microstructure includes most grains, secondary phases, Grain boundary, grain boundaries, pores, micro-cracks and hardness microindentations. Most bulk mechanical, optical, thermal, Electroceramics, electrical and magnetic properties are significantly affected by the microstructure. The fabrication method and process conditions are generally indicated by the microstructure. The root cause of many ceramic failures is evident in the microstructure. Ceramography is part of the broader field of materialography, which includes all the microscopic techniques of material analysis, such as metallography, petrography and plastog ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Micrometres

The micrometre (English in the Commonwealth of Nations, Commonwealth English as used by the International Bureau of Weights and Measures; SI symbol: μm) or micrometer (American English), also commonly known by the non-SI term micron, is a unit of length in the International System of Units (SI) equalling (SI standard prefix "micro-" = ); that is, one millionth of a metre (or one thousandth of a millimetre, , or about ). The nearest smaller common SI Unit, SI unit is the nanometre, equivalent to one thousandth of a micrometre, one millionth of a millimetre or one billionth of a metre (). The micrometre is a common unit of measurement for wavelengths of infrared radiation as well as sizes of biological cell (biology), cells and bacteria, and for grading wool by the diameter of the fibres. The width of a single human hair ranges from approximately 20 to . Examples Between 1 μm and 10 μm: * 1–10 μm – length of a typical bacterium * 3–8 μm – width of str ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Newton (unit)

The newton (symbol: N) is the unit of force in the International System of Units (SI). Expressed in terms of SI base units, it is 1 kg⋅m/s2, the force that accelerates a mass of one kilogram at one metre per second squared. The unit is named after Isaac Newton in recognition of his work on classical mechanics, specifically his second law of motion. Definition A newton is defined as 1 kg⋅m/s2 (it is a named derived unit defined in terms of the SI base units). One newton is, therefore, the force needed to accelerate one kilogram of mass at the rate of one metre per second squared in the direction of the applied force. The units "metre per second squared" can be understood as measuring a rate of change in velocity per unit of time, i.e. an increase in velocity by one metre per second every second. In 1946, the General Conference on Weights and Measures (CGPM) Resolution 2 standardized the unit of force in the MKS system of units to be the amount need ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gram Force

The kilogram-force (kgf or kgF), or kilopond (kp, from ), is a non-standard gravitational metric unit of force. It is not accepted for use with the International System of Units (SI) and is deprecated for most uses. The kilogram-force is equal to the magnitude of the force exerted on one kilogram of mass in a gravitational field (standard gravity, a conventional value approximating the average magnitude of gravity on Earth). That is, it is the weight of a kilogram under standard gravity. One kilogram-force is defined as .NISTbr>''Guide for the Use of the International System of Units (SI)''Special Publication 811, (1995) page 51 Similarly, a gram-force is , and a milligram-force is . History The gram-force and kilogram-force were never well-defined units until the CGPM adopted a ''standard acceleration of gravity'' of 9.80665 m/s2 for this purpose in 1901, though they had been used in low-precision measurements of force before that time. Even then, the proposal to define ki ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |