|

Fiber-reinforced Composite

__NOTOC__ A fiber-reinforced composite (FRC) is a composite building material that consists of three components:Serope Kalpakjian, Steven R Schmid. "Manufacturing Engineering and Technology". International edition. 4th Ed. Prentice Hall, Inc. 2001. . #the fibers as the discontinuous or dispersed phase, #the matrix as the continuous phase, and #the fine interphase region, also known as the interface. This is a type of advanced composite group, which makes use of rice husk, rice hull, rice shell, and plastic as ingredients. This technology involves a method of refining, blending, and compounding natural fibers from cellulosic waste streams to form a high-strength fiber composite material in a polymer matrix. The designated waste or base raw materials used in this instance are those of waste thermoplastics and various categories of cellulosic waste including rice husk and saw dust. Introduction FRC is high-performance fiber composite achieved and made possible by cross-linking ce ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Material

A composite or composite material (also composition material) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions. Composite materials with more than one distinct layer are called ''composite laminates''. Typical engineered composite materials are made up of a binding agent forming the ''matrix'' and a Filler (materials), filler material (particulates or fibres) giving ''substance'', e.g.: * Concrete, reinforced concrete and masonry with cement, lime or Mortar (masonry), mortar (which is itself a composite material) as a binder * Composite wood such as glulam and plywood with wood glue as a binder * Reinforced plastics, such as fiberglass and fibre-rein ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

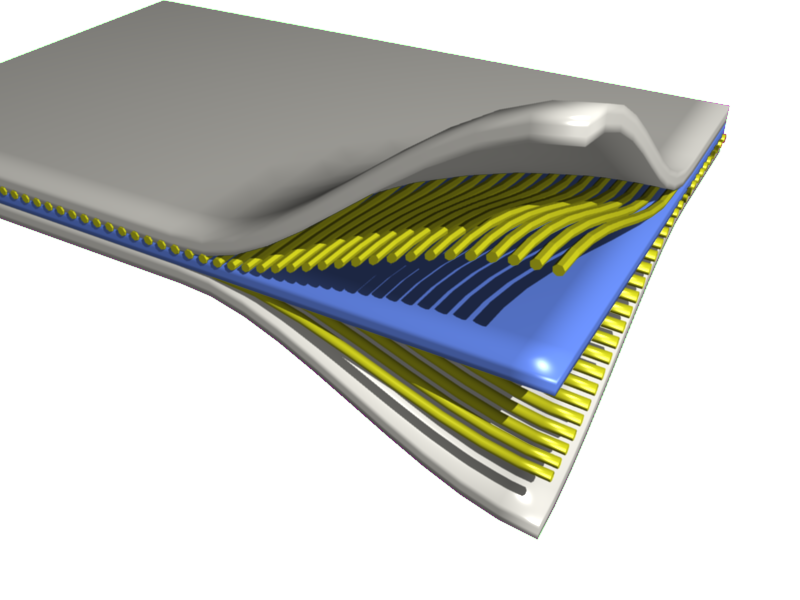

Delamination

Delamination is a mode of failure where a material fractures into layers. A variety of materials, including Lamination, laminate Composite material, composites and concrete, can fail by delamination. Processing can create layers in materials, such as steel formed by Rolling (metalworking), rolling and plastics and metals from 3D printing which can fail from layer separation. Also, surface coatings, such as paints and films, can delaminate from the coated substrate. In Lamination, laminated composites, the adhesion between layers often fails first, causing the layers to separate. For example, in Fibre-reinforced plastic, fiber-reinforced plastics, sheets of high strength reinforcement (e.g., Carbon fibers, carbon fiber, fiberglass) are bound together by a much weaker polymer matrix (e.g., epoxy). In particular, loads applied perpendicular to the high strength layers, and shear loads can cause the polymer matrix to fracture or the fiber reinforcement to debond from the polymer. Del ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Lumber

Plastic lumber is a plastic form of lumber made of virgin or recycling, recycled plastic. It is mostly made of plastic and binders such as fiberglass or rebar; not to be confused with Wood-plastic composite, wood-plastic composite lumber. Widely employed in outdoor Deck (building), decking, it is also used for molding (decorative), molding and trim and garden furniture such as park benches. Resistant to cracking and splitting when appropriately installed, plastic lumber can be molded with or without simulated wood grain details. Even with a wood grain design, plastic lumber is still easy to distinguish visually from natural timber: the grains are the same uniform color as the rest of the material. Manufacturers claim plastic lumber is more environmentally-friendly and requires less maintenance than wood/plastic composites or rot-resistant wood. Commercially available polyvinyl chloride fiberglass composite lumber sold for decking meets stringent fire code standards. Plastic lumbe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wood Plastic Composite

Wood is a structural tissue/material found as xylem in the stems and roots of trees and other woody plants. It is an organic materiala natural composite of cellulosic fibers that are strong in tension and embedded in a matrix of lignin that resists compression. Wood is sometimes defined as only the secondary xylem in the stems of trees, or more broadly to include the same type of tissue elsewhere, such as in the roots of trees or shrubs. In a living tree, it performs a mechanical-support function, enabling woody plants to grow large or to stand up by themselves. It also conveys water and nutrients among the leaves, other growing tissues, and the roots. Wood may also refer to other plant materials with comparable properties, and to material engineered from wood, woodchips, or fibers. Wood has been used for thousands of years for fuel, as a construction material, for making tools and weapons, furniture and paper. More recently it emerged as a feedstock for the production of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rule Of Mixtures

In materials science, a general rule of mixtures is a weighted mean used to predict various properties of a composite material . It provides a theoretical upper- and lower-bound on properties such as the elastic modulus, ultimate tensile strength, thermal conductivity, and electrical conductivity. In general there are two models, the ''rule of mixtures'' for axial loading (Voigt model), and the ''inverse rule of mixtures'' for transverse loading (Reuss model). For some material property E, the rule of mixtures states that the overall property in the direction parallel to the fibers could be as high as : E_\parallel = fE_f + \left(1-f\right)E_m The inverse rule of mixtures states that in the direction perpendicular to the fibers, the elastic modulus of a composite could be as low as :E_\perp = \left(\frac + \frac\right)^. where * f = \frac is the volume fraction of the fibers * E_\parallel is the material property of the composite parallel to the fibers * E_\perp is the materi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fiber Volume Ratio

Fiber volume ratio is an important mathematical element in composite engineering. Fiber volume ratio, or fiber volume fraction, is the percentage of fiber volume in the entire volume of a fiber-reinforced composite material.Derek Hull. (1981).''An Introduction to Composite Materials''. Cambridge University Press. When manufacturing polymer composites, fibers are impregnated with resin. The amount of resin to fiber ratio is calculated by the geometric organization of the fibers, which affects the amount of resin that can enter the composite. The impregnation around the fibers is highly dependent on the orientation of the fibers and the architecture of the fibers. The geometric analysis of the composite can be seen in the cross-section of the composite. Voids are often formed in a composite structure throughout the manufacturing process and must be calculated into the total fiber volume fraction of the composite. The fraction of fiber reinforcement is very important in determining t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fracture Mechanics

Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics to characterize the material's resistance to fracture. Theoretically, the stress ahead of a sharp crack tip becomes infinite and cannot be used to describe the state around a crack. Fracture mechanics is used to characterise the loads on a crack, typically using a single parameter to describe the complete loading state at the crack tip. A number of different parameters have been developed. When the plastic zone at the tip of the crack is small relative to the crack length the stress state at the crack tip is the result of elastic forces within the material and is termed linear elastic fracture mechanics (LEFM) and can be characterised using the stress intensity factor K. Although the load on a crack can be arbitrary, in 1957 G. Irwin foun ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Composite (other)

Plastic composite may refer to: * Wood-plastic composite * Composite lumber See also * Composite armour * Composite material * Fiber-reinforced composite * Plastic recycling Plastic recycling is the processing of plastic waste into other products. Recycling can reduce dependence on landfills, conserve resources and protect the environment from plastic pollution and greenhouse gas emissions. Recycling rates lag beh ... {{Disamb ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

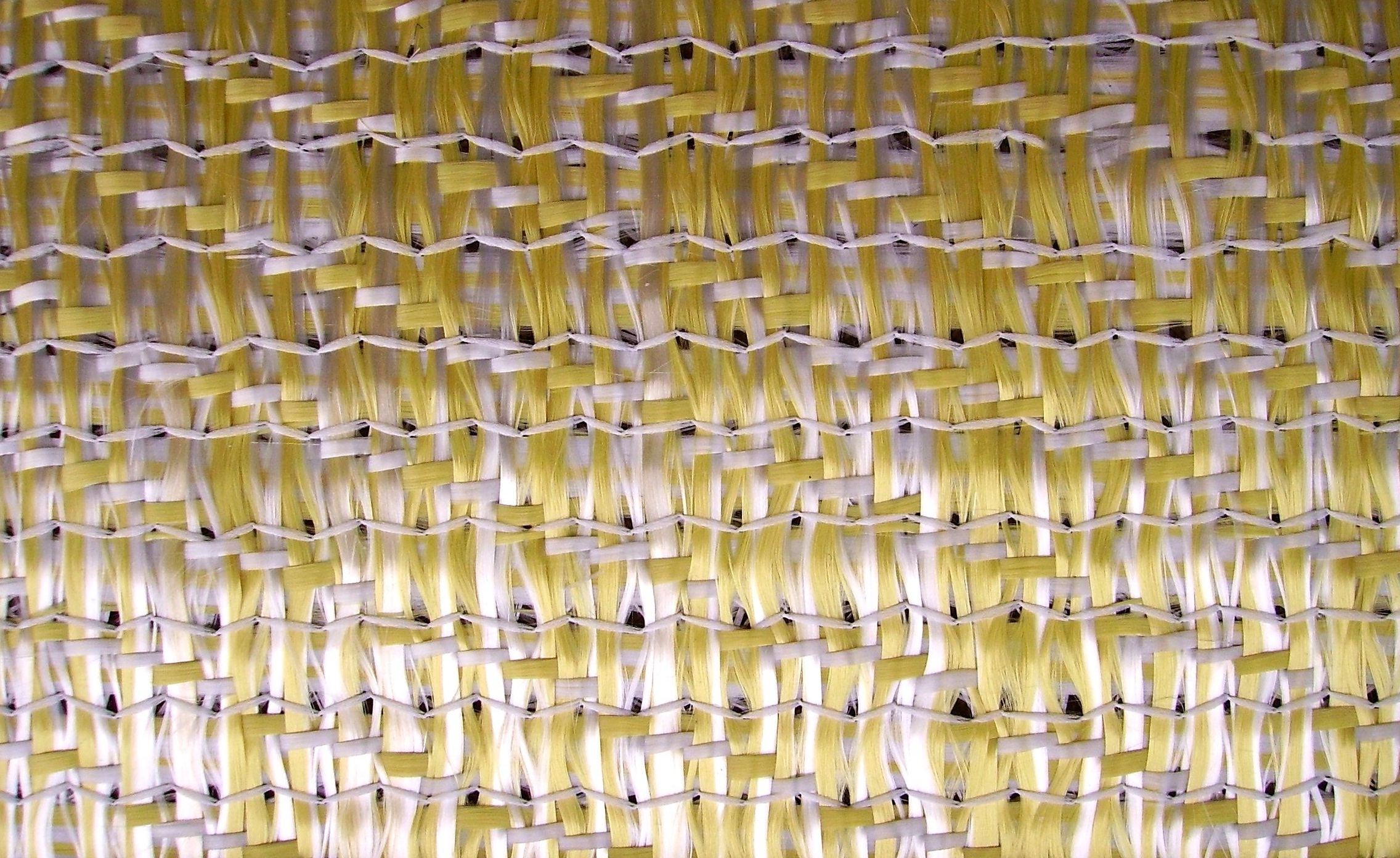

Fibre-reinforced Plastic

Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English ''fiber'') is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon-fibre-reinforced polymer), aramid, or basalt. Rarely, other fibres such as paper, wood, boron, or asbestos have been used. The polymer is usually an epoxy, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use. FRPs are commonly used in the aerospace, automotive, marine, and construction industries. They are commonly found in ballistic armour and cylinders for self-contained breathing apparatuses. History Bakelite was the first fibre-reinforced plastic. Leo Baekeland had originally set out to find a replacement for shellac (made from the excretion of lac bugs). Chemists had begun to recognize that many natural resins and fibres were polymers, and Baekeland investigated the reactions of phenol an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodworking Materials

Woodworking is the skill of making items from wood, and includes cabinetry, furniture making, wood carving, joinery, carpentry, and woodturning. History Along with stone, clay and animal parts, wood was one of the first materials worked by early humans. Microwear analysis of the Mousterian stone tools used by the Neanderthals show that many were used to work wood. The development of civilization was closely tied to the development of increasingly greater degrees of skill in working these materials. Among the earlliest finds of woodworking are shaped sticks displaying notches from Kalambo Falls in southen Africa, dating to around 476,000 years ago. The Clacton spearhead from Clacton-on-Sea, England, dating to around 400,000 years ago,Allington-Jones, L., (2015) ''Archaeological Journal'', 172 (2) 273–296 The Clacton Spear – The Last One Hundred Years the Schöningen spears, from Schöningen (Germany) dating around 300,000 years ago and the Lehringen spear from northern G ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |