|

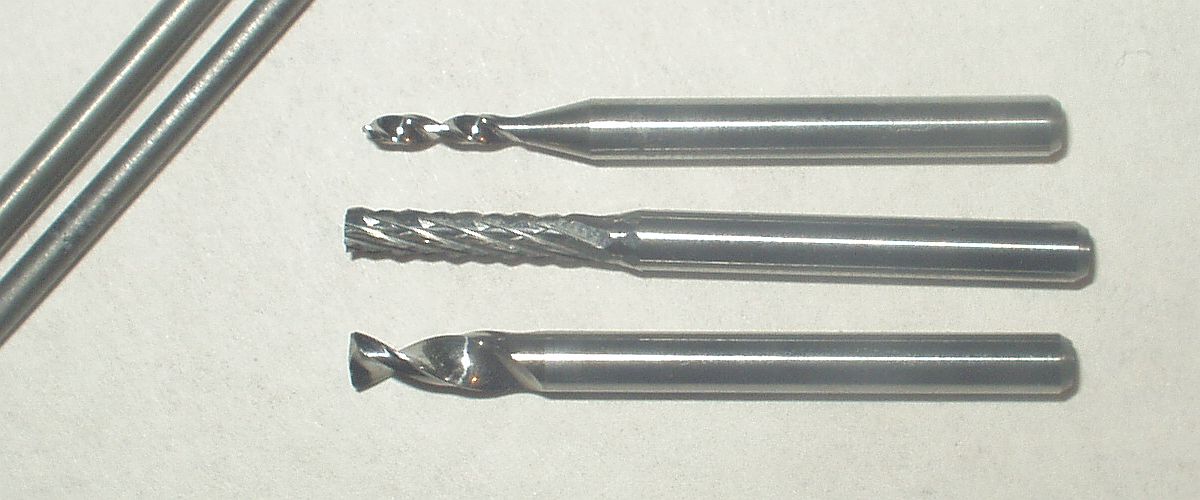

Endmill

An end mill is a type of milling cutter, a cutting tool used in industrial milling applications. They can have several end configurations: round (ball), tapered, or straight are a few popular types. They are most commonly used in "milling machines" that move a piece of material against the end mill to remove chips of the material to create a desired size or shape. It is distinguished from the drill bit in its application, geometry, and manufacture. While a drill bit can only cut in the axial direction, most milling bits can cut in the radial direction. Not all mills can cut tangentially: those designed to do so are known as end mills. End mills are used in milling applications such as profile milling, tracer milling, face milling, and plunging. Types Several broad categories of end- and face-milling tools exist, such as center-cutting versus non-center-cutting (whether the mill can take plunging cuts); and categorization by number of flutes; by helix angle; by material; and b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill Bit

A drill bit is a cutting tool used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the ''shank'' in the chuck. Drills come in standardized drill bit sizes. A comprehensive drill bit and tap size chart lists metric and imperial sized drills alongside the required screw tap sizes. There are also certain specialized drill bits that can create holes with a non-circular cross-section. Characteristics Drill geometry has several characteristics: * The spiral (or rate of twist) in the drill bit controls the rate of chip removal. A fast spiral (high twist rate or "compact flute") drill bit is used in high feed rate applications under low ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Titanium Aluminium Nitride

Titanium aluminium nitride (TiAlN) or aluminium titanium nitride (AlTiN; for aluminium contents higher than 50%) is a group of metastable hard coatings consisting of nitrogen and the metallic elements aluminium and titanium. This compound as well as similar compounds(such as TiN and TiCN) are most notably used for coating machine tools such and endmills and drills to change their properties, such as increased thermal stability and/or wear resistance. Four important compositions (metal content 100 wt.%) are deposited in industrial scale by physical vapor deposition methods: * Ti50Al50N (industrially introduced by the company CemeCoat (now CemeCon) Aachen, BRD, group T. Leydecker ca. 1989) * Al55Ti45N (industrially introduced by the company Metaplas Ionon (now Oerlikon), Bergisch Gladbach, BRD, group J. Vetter ca. 1999) * Al60Ti40N (industrially introduced by the company Kobe Steel, Kobe, Japan, ca. 1992) * Al66Ti34N (industrially introduced by the company Metaplas (now Oerlikon) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stainless Steel

Stainless steel, also known as inox, corrosion-resistant steel (CRES), or rustless steel, is an iron-based alloy that contains chromium, making it resistant to rust and corrosion. Stainless steel's resistance to corrosion comes from its chromium content of 11% or more, which forms a Passivation (chemistry), passive film that protects the material and can self-healing material, self-heal when exposed to oxygen. It can be further alloyed with elements like molybdenum, carbon, nickel and nitrogen to enhance specific properties for various applications. The alloy's properties, such as luster and resistance to corrosion, are useful in many applications. Stainless steel can be rolled into Sheet metal, sheets, plates, bars, wire, and tubing. These can be used in cookware, cutlery, surgical instruments, major appliances, vehicles, construction material in large buildings, industrial equipment (e.g., in paper mills, chemical plants, water treatment), and storage tanks and tankers for ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Burr (cutter)

Burrs or burs (sometimes called rotary files) are small cutting tools; not to be confused with small pieces of metal formed from cutting metal, used in die grinders, rotary tools, or dental drills. The name may be considered appropriate when their small-sized head (3 mm diameter shaft) is compared to a bur (fruit seed with hooks) or their teeth are compared to a metal burr. Description Burrs are a rotary analog to files that cut linearly (hence their alternate name, rotary files). They share many similarities with endmills and router bits, with the notable distinction that the latter typically have their toolpaths dictated by the machine, while burrs are frequently operated in a freehand manner. However, there is substantial overlap in the use and toolpath control of these various classes of cutters, and the outcomes accomplished with them. For example, endmills can be used in routers, and burrs can be used like endmills in milling by CNC or manual machine tools. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tungsten Carbide

Tungsten carbide (chemical formula: ) is a carbide containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes through sintering for use in industrial machinery, engineering facilities, molding blocks, cutting tools, chisels, abrasives, armor-piercing bullets and jewelry. Tungsten carbide is approximately three times as stiff as steel, with a Young's modulus of approximately 530–700 GPa, and is twice as dense as steel. It is comparable with corundum (α- ) in hardness, approaching that of a diamond, and can be polished and finished only with abrasives of superior hardness such as cubic boron nitride and diamond. Tungsten carbide tools can be operated at cutting speeds much higher than high-speed steel (a special steel blend for cutting tools). Tungsten carbide powder was first synthesized by H. Moissan in 1893, and the industrial production of the cemented form starte ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grinding Wheel

Grinding wheels are wheels that contain abrasive compounds for grinding and abrasive machining operations. Such wheels are also used in grinding machines. The wheels are generally made with composite material. This consists of coarse-particle aggregate pressed and bonded together by a cementing matrix (called the ''bond'' in grinding wheel terminology) to form a solid, circular shape. Various profiles and cross sections are available depending on the intended usage for the wheel. They may also be made from a solid steel or aluminium disc with particles bonded to the surface. Today most grinding wheels are artificial composites made with artificial aggregates, but the history of grinding wheels began with natural composite stones, such as those used for millstones. The manufacture of these wheels is a precise and tightly controlled process, due not only to the inherent safety risks of a spinning disc, but also the composition and uniformity required to prevent that disc fro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cutting Fluid

Cutting fluid is a type of coolant and lubricant designed specifically for metalworking processes, such as machining and stamping. There are various kinds of cutting fluids, which include oils, oil-water emulsions, pastes, gels, aerosols (mists), and air or other gases. Cutting fluids are made from petroleum distillates, animal fats, plant oils, water and air, or other raw ingredients. Depending on context and on which type of cutting fluid is being considered, it may be referred to as cutting fluid, cutting oil, cutting compound, coolant, or lubricant. Most metalworking and machining processes can benefit from the use of cutting fluid, depending on workpiece material. Common exceptions to this are cast iron and brass, which may be machined dry (though this is not true of all brasses, and any machining of brass will likely benefit from the presence of a cutting fluid). The properties that are sought after in a good cutting fluid are the ability to: * Keep the workpiece at a s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tool And Cutter Grinder

A Tool and Cutter Grinder is used to sharpen milling cutters and tool bits along with a host of other cutting tools. It is an extremely versatile machine used to perform a variety of grinding operations: surface, cylindrical, or complex shapes. The image shows a manually operated setup, however highly automated Computer Numerical Control ( CNC) machines are becoming increasingly common due to the complexities involved in the process. The operation of this machine (in particular, the manually operated variety) requires a high level of skill. The two main skills needed are understanding of the relationship between the grinding wheel and the metal being cut and knowledge of tool geometry. The illustrated set-up is only one of many combinations available. The huge variety in shapes and types of machining cutters requires flexibility in usage. A variety of dedicated fixtures are included that allow cylindrical grinding operations or complex angles to be ground. The vise shown can sw ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Physical Vapour Deposition

Physical vapor deposition (PVD), sometimes called physical vapor transport (PVT), describes a variety of vacuum deposition methods which can be used to produce thin films and coatings on substrates including metals, ceramics, glass, and polymers. PVD is characterized by a process in which the material transitions from a condensed phase to a vapor phase and then back to a thin film condensed phase. The most common PVD processes are sputtering and evaporation. PVD is used in the manufacturing of items which require thin films for optical, mechanical, electrical, acoustic or chemical functions. Examples include semiconductor devices such as thin-film solar cells, microelectromechanical devices such as thin film bulk acoustic resonator, aluminized PET film for food packaging and balloons, and titanium nitride coated cutting tools for metalworking. Besides PVD tools for fabrication, special smaller tools used mainly for scientific purposes have been developed. The source material ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Titanium Nitride

Titanium nitride (TiN; sometimes known as tinite) is an extremely hard ceramic material, often used as a physical vapor deposition (PVD) coating on titanium alloys, steel, carbide, and aluminium components to improve the substrate's surface properties. Applied as a thin coating, TiN is used to harden and protect cutting and sliding surfaces, for decorative purposes (for its golden appearance), and as a non-toxic exterior for medical implants. In most applications a coating of less than is applied. Characteristics TiN has a Vickers hardness of 1800–2100, hardness of , a modulus of elasticity of , a thermal expansion coefficient of 9.35 K−1, and a superconducting transition temperature of 5.6 K. TiN oxidizes at 800 °C in a normal atmosphere. It is chemically stable at 20 °C, according to laboratory tests, but can be slowly attacked by concentrated acid solutions with rising temperatures. TiN has a brown color and appears gold when applied as a coati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |