|

Converting (metallurgy)

Converting is a type of metallurgical smelting that includes several processes; the most commercially important form is the treatment of molten metal sulfides to produce crude metal and slag, as in the case of copper and nickel converting. A now-uncommon form is batch treatment of pig iron to produce steel by the Bessemer process. The vessel used was called the ''Bessemer converter''. Modern steel mills use basic oxygen process converters. Equipment The converting process occurs in a ''converter''. Two kinds of converters are widely used: horizontal and vertical. Horizontal (which are an improvement of the ) prevail in the metallurgy of non ferrous metals. Such a converter is a horizontal barrel lined with refractory material inside. A hood for the purpose of the loading/unloading operations is located on the upper side of the converter. Two belts of tuyeres come along the axis on either sides of the converter. Molten sulfide material, referred to as matte, is poured thro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Smelting

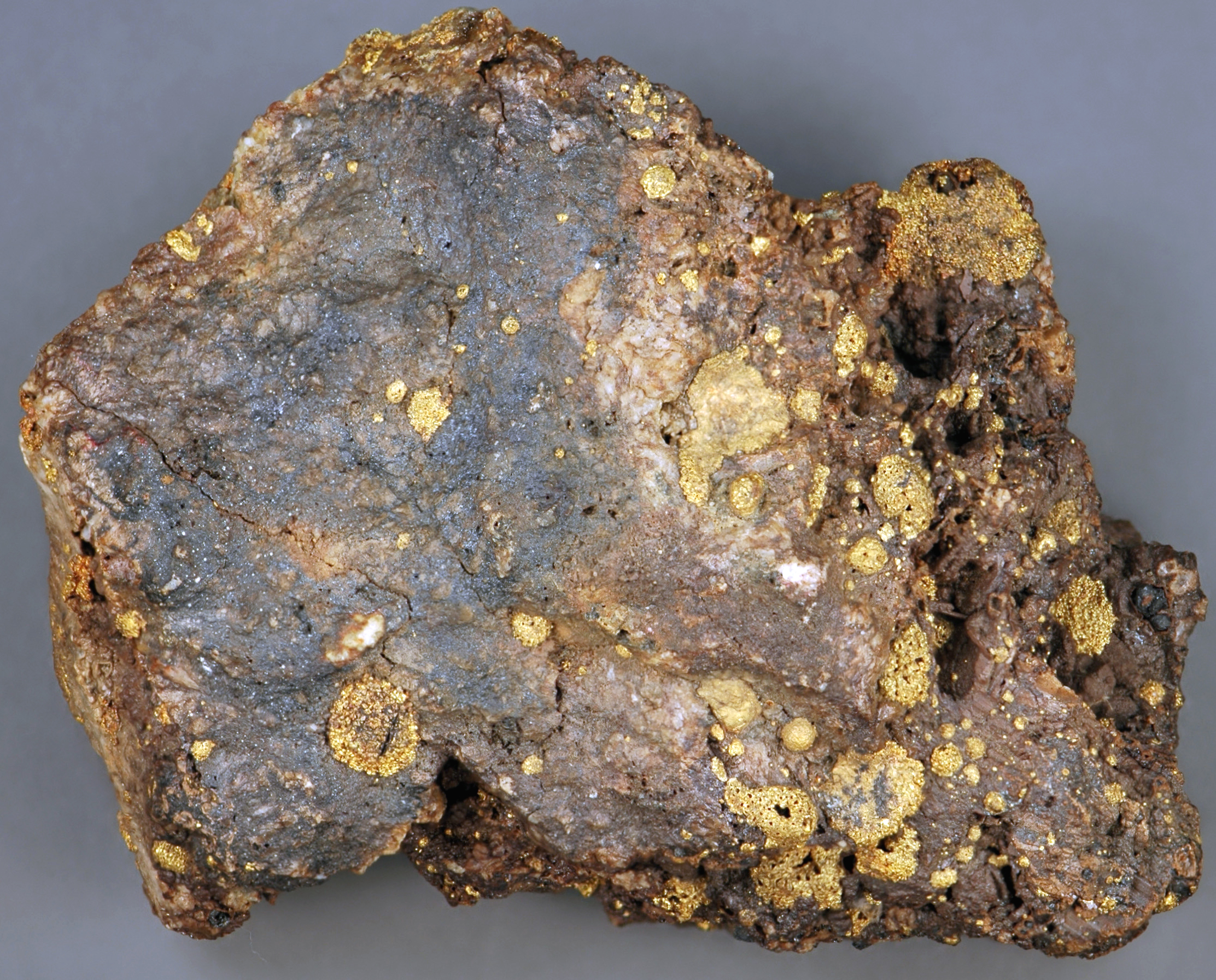

Smelting is a process of applying heat to ore, to extract a base metal. It is a form of extractive metallurgy. It is used to extract many metals from their ores, including silver, iron, copper, and other base metals. Smelting uses heat and a chemical reducing agent to decompose the ore, driving off other elements as gases or slag and leaving the metal base behind. The reducing agent is commonly a fossil fuel source of carbon, such as coke—or, in earlier times, charcoal. The oxygen in the ore binds to carbon at high temperatures due to the lower potential energy of the bonds in carbon dioxide (). Smelting most prominently takes place in a blast furnace to produce pig iron, which is converted into steel. The carbon source acts as a chemical reactant to remove oxygen from the ore, yielding the purified metal element as a product. The carbon source is oxidized in two stages. First, the carbon (C) combusts with oxygen (O2) in the air to produce carbon monoxide (CO). Sec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Basic Oxygen Process

Basic oxygen steelmaking (BOS, BOP, BOF, or OSM), also known as Linz-Donawitz steelmaking or the oxygen converter processBrock and Elzinga, p. 50. is a method of primary steelmaking in which carbon-rich molten pig iron is made into steel. Blowing oxygen through molten pig iron lowers the carbon content of the alloy and changes it into low-carbon steel. The process is known as ''basic'' because fluxes of burnt lime or dolomite, which are chemical '' bases'', are added to promote the removal of impurities and protect the lining of the converter. The process was invented in 1948 by Swiss engineer Robert Durrer and commercialized in 1952–1953 by the Austrian steelmaking company VOEST and ÖAMG. The LD converter, named after the Austrian towns Linz and Donawitz (a district of Leoben) is a refined version of the Bessemer converter where blowing of air is replaced with blowing oxygen. It reduced capital cost of the plants and smelting time, and increased labor productivity. Between ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metallurgy

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are known as alloys. Metallurgy encompasses both the science and the technology of metals; that is, the way in which science is applied to the production of metals, and the engineering of metal components used in products for both consumers and manufacturers. Metallurgy is distinct from the craft of metalworking. Metalworking relies on metallurgy in a similar manner to how medicine relies on medical science for technical advancement. A specialist practitioner of metallurgy is known as a metallurgist. The science of metallurgy is further subdivided into two broad categories: chemical metallurgy and physical metallurgy. Chemical metallurgy is chiefly concerned with the reduction and oxidation of metals, and the chemical performance of metals. Subjects of study in chemical metallurgy include m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Non Ferrous Metals

In metallurgy, non-ferrous metals are metals or alloys that do not contain iron (allotropes of iron, ferrite, and so on) in appreciable amounts. Generally more costly than ferrous metals, non-ferrous metals are used because of desirable properties such as low weight (e.g. aluminium), higher conductivity (e.g. copper), non-magnetic properties or resistance to corrosion (e.g. zinc). Some non-ferrous materials are also used in the iron and steel industries. For example, bauxite is used as flux for blast furnaces, while others such as wolframite, pyrolusite, and chromite are used in making ferrous alloys. Important non-ferrous metals include aluminium, copper, lead, tin, titanium, and zinc, and alloys such as brass. Precious metals such as gold, silver, and platinum and exotic or rare metals such as mercury, tungsten, beryllium, bismuth, cerium, cadmium, niobium, indium, gallium, germanium, lithium, selenium, tantalum, tellurium, vanadium, and zirconium are also non-ferrous. T ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tuyeres

A tuyere or tuyère (; ) is a tube, nozzle or pipe through which air is blown into a furnace or hearth.W. K. V. Gale, The iron and Steel industry: a dictionary of terms (David and Charles, Newton Abbot 1972), 216–217. Air or oxygen is injected into a hearth under pressure from bellows or a blowing engine or other devices. This causes the fire to be hotter in front of the blast than it would otherwise have been, enabling metals to be smelted or melted or made hot enough to be worked in a forge, though these are blown only with air. This applies to any process where a blast is delivered under pressure to make a fire hotter. The term (like many technical terms relating to ironmaking) was introduced to England from French with the new technology of the blast furnace and finery forge in around 1500, and was sometimes anglicised as tue-iron or tue iron. Following the introduction of hot blast, tuyeres are often water-cooled. Examples * A bloomery normally had one tuye ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Matte (metallurgy)

Matte is a term used in the field of pyrometallurgy given to the molten metal sulfide phases typically formed during smelting of copper, nickel, and other base metals. Typically, a matte is the phase in which the principal metal being extracted is recovered prior to a final reduction process (usually converting) to produce blister copper. The matte may also collect some valuable minor constituents such as noble metals, minor base metals, selenium or tellurium. Mattes may also be used to collect impurities from a metal phase, such as in the case of antimony smelting. Molten mattes are insoluble in both slag Slag is a by-product of smelting ( pyrometallurgical) ores and used metals. Broadly, it can be classified as ferrous (by-products of processing iron and steel), ferroalloy (by-product of ferroalloy production) or non-ferrous/base metals (by-p ... and metal phases. This insolubility, combined with differences in specific gravities between mattes, slags, and metals, allows ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roasting (metallurgy)

Roasting is a process of heating a sulfide ore to a high temperature in the presence of air. It is a step in the processing of certain ores. More specifically, roasting is often a metallurgical process involving gas–solid reactions at elevated temperatures with the goal of purifying the metal component(s). Often before roasting, the ore has already been partially purified, e.g. by froth flotation. The concentrate is mixed with other materials to facilitate the process. The technology is useful in making certain ores usable but it can also be a serious source of air pollution. Roasting consists of thermal gas–solid reactions, which can include oxidation, reduction, chlorination, sulfation, and pyrohydrolysis. In roasting, the ore or ore concentrate is treated with very hot air. This process is generally applied to sulfide minerals. During roasting, the sulfide is converted to an oxide, and sulfur is released as sulfur dioxide, a gas. For the ores Cu2S (chalcocite) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sulfur Trioxide

Sulfur trioxide (alternative spelling sulphur trioxide, also known as ''nisso sulfan'') is the chemical compound with the formula SO3. It has been described as "unquestionably the most important economically" sulfur oxide. It is prepared on an industrial scale as a precursor to sulfuric acid. Sulfur trioxide exists in several forms - gaseous monomer, crystalline trimer, and solid polymer. Sulfur trioxide is a solid at just below room temperature with a relatively narrow liquid range. Gaseous SO3 is the primary precursor to acid rain. Molecular structure and bonding Monomer The molecule SO3 is trigonal planar. As predicted by VSEPR theory, its structure belongs to the D3h point group. The sulfur atom has an oxidation state of +6 and may be assigned a formal charge value as low as 0 (if all three sulfur-oxygen bonds are assumed to be double bonds) or as high as +2 (if the Octet Rule is assumed). When the formal charge is non-zero, the S-O bonding is assumed to be delocalized. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Arsenic Trioxide

Arsenic trioxide, sold under the brand name Trisenox among others, is an inorganic compound and medication. As an industrial chemical, whose major uses include in the manufacture of wood preservatives, pesticides, and glass. As a medication, it is used to treat a type of cancer known as acute promyelocytic leukemia. For this use it is given by injection into a vein. Common side effects include vomiting, diarrhea, swelling, shortness of breath, and headaches. Severe side effects may include APL differentiation syndrome and heart problems. Use during pregnancy or breastfeeding may harm the baby. Arsenic trioxide has the formula . Its mechanism in treating cancer is not entirely clear. Arsenic trioxide was approved for medical use in the United States in 2000. It is on the World Health Organization's List of Essential Medicines. Approximately 50,000 tonnes are produced a year. Due to its toxicity, a number of countries have regulations around its manufacture and sale. Uses Med ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Smelting

Smelting is a process of applying heat to ore, to extract a base metal. It is a form of extractive metallurgy. It is used to extract many metals from their ores, including silver, iron, copper, and other base metals. Smelting uses heat and a chemical reducing agent to decompose the ore, driving off other elements as gases or slag and leaving the metal base behind. The reducing agent is commonly a fossil fuel source of carbon, such as coke—or, in earlier times, charcoal. The oxygen in the ore binds to carbon at high temperatures due to the lower potential energy of the bonds in carbon dioxide (). Smelting most prominently takes place in a blast furnace to produce pig iron, which is converted into steel. The carbon source acts as a chemical reactant to remove oxygen from the ore, yielding the purified metal element as a product. The carbon source is oxidized in two stages. First, the carbon (C) combusts with oxygen (O2) in the air to produce carbon monoxide (CO). Sec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |