|

Contact Patch

Contact patch is the portion of a vehicle's tire that is in actual contact with the road surface. It is commonly used in the discussion of pneumatic (i.e. pressurized) tires, where the term is used strictly to describe the portion of the tire’s tread that touches the road surface. The term “footprint” is used almost synonymously. Solid wheels also exhibit a contact patch which is generally smaller than the pneumatic “footprint”. Contact patch size The contact patch is the only connection between the road and the vehicle. Pneumatic rubber tires The size and shape of the contact patch, as well as the pressure distribution within the contact patch, are important to the ride qualities and handling characteristics of a vehicle. Since the wear characteristics of tires is a highly competitive area between tire manufacturers, a lot of the research done concerning the contact patch is considered highly proprietary and, therefore, very little is published on the subject. Beca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Contact Mechanics

Contact mechanics is the study of the deformation of solids that touch each other at one or more points.Johnson, K. L, 1985, Contact mechanics, Cambridge University Press.Popov, Valentin L., 2010, ''Contact Mechanics and Friction. Physical Principles and Applications'', Springer-Verlag, 362 p., . A central distinction in contact mechanics is between stresses acting perpendicular to the contacting bodies' surfaces (known as normal stress) and frictional stresses acting tangentially between the surfaces (shear stress). Normal contact mechanics or frictionless contact mechanics focuses on normal stresses caused by applied normal forces and by the adhesion present on surfaces in close contact, even if they are clean and dry. '' Frictional contact mechanics'' emphasizes the effect of friction forces. Contact mechanics is part of mechanical engineering. The physical and mathematical formulation of the subject is built upon the mechanics of materials and continuum mechanics and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slip (vehicle Dynamics)

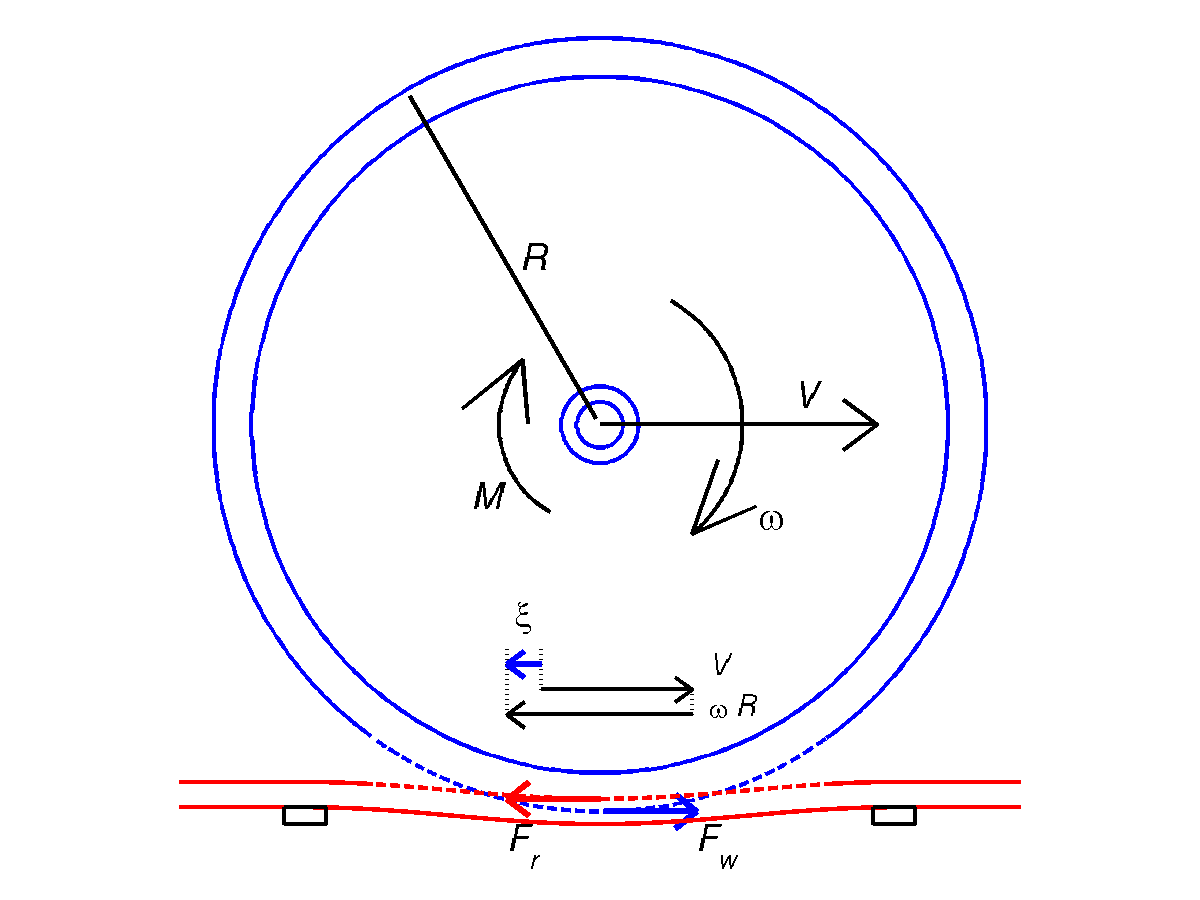

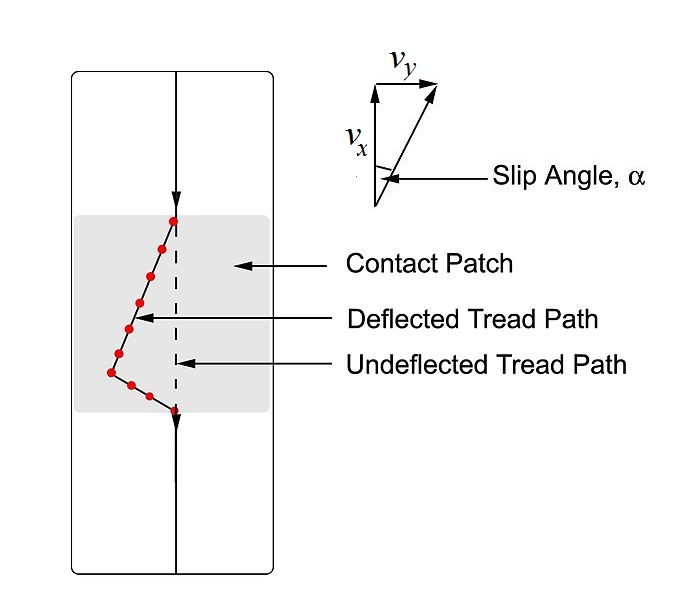

In (automotive) vehicle dynamics, slip is the relative motion between a tire and the road surface it is moving on. This slip can be generated either by the tire's rotational speed being greater or less than the free-rolling speed (usually described as ''percent'' slip), or by the tire's plane of rotation being at an angle to its direction of motion (referred to as slip angle). In rail vehicle dynamics, this overall slip of the wheel relative to the rail is called ''creepage''. It is distinguished from the local sliding velocity of surface particles of wheel and rail, which is called ''micro-slip''. Longitudinal slip The longitudinal slip is generally given as a percentage of the difference between the surface speed of the wheel compared to the speed between axle and road surface, as: : \text=-\frac where \Omega is the longitudinal component of the rotational speed of the wheel, r is wheel radius at the point of contact and v_x is vehicle speed in the plane of the tire. A posi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pneumatic Trail

Pneumatic trail or trail of the tire is a trail-like effect generated by compliant tires rolling on a hard surface and subject to side loads, as in a turn. More technically, it is the distance that the resultant force of side-slip occurs behind the geometric center of the contact patch. Causes Pneumatic trail is caused by the progressive build-up of lateral force along the length of the contact patch, such that lateral forces are greater towards the rear of the contact patch (though less so when the rear of the contact patch begins sliding) and this creates a torque on the tire called the self aligning torque. Because the direction of the side-slip is towards the outside of a turn, the force on the tire is towards the center of the turn. Therefore, this torque tends to turn the front wheel in the direction of the side-slip, away from the direction of the turn. Variation Pneumatic trail is at its maximum when the slip angle is zero and decreases as slip angle increases. Pneumatic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ground Pressure

Ground pressure is the pressure exerted on the ground by the tires or tracks of a motorized vehicle, and is one measure of its potential mobility, especially over soft ground. It also applies to the feet of a walking person or machine. Ground pressure is measured in pascals (Pa) which corresponds to the United States customary units unit of pounds per square inch (psi). Average ground pressure can be calculated using the standard formula for average pressure: ''P'' = ''F''/''A''. In an idealized case, i.e. a static, uniform net force normal to level ground, this is simply the object's weight divided by contact area. The ground pressure of motorized vehicles is often compared to the ground pressure of a human foot, which can be 60 – 80 kPa while walking or as much as 13 MPa for a person in spike heels. Increasing the size of the contact area on the ground (the ''footprint'') in relation to the weight decreases the ground pressure. Ground pressure of 14 kPa (2 psi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Frictional Contact Mechanics

Contact mechanics is the study of the deformation of solids that touch each other at one or more points. This can be divided into compressive and adhesive forces in the direction perpendicular to the interface, and frictional forces in the tangential direction. Frictional contact mechanics is the study of the deformation of bodies in the presence of frictional effects, whereas '' frictionless contact mechanics'' assumes the absence of such effects. Frictional contact mechanics is concerned with a large range of different scales. * At the macroscopic scale, it is applied for the investigation of the motion of contacting bodies (see Contact dynamics). For instance the bouncing of a rubber ball on a surface depends on the frictional interaction at the contact interface. Here the total force versus indentation and lateral displacement are of main concern. * At the intermediate scale, one is interested in the local stresses, strains and deformations of the contacting bodies in and n ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cornering Force

Cornering force or side force is the lateral (i.e., parallel to wheel axis) force produced by a vehicle tire during cornering. Cornering force is generated by tire slip and is proportional to slip angle at low slip angles. The rate at which cornering force builds up is described by relaxation length. Slip angle describes the deformation of the tire contact patch, and this deflection of the contact patch deforms the tire in a fashion akin to a spring. As with deformation of a spring, deformation of the tire contact patch generates a reaction force in the tire; the cornering force. Integrating the force generated by every tread element along the contact patch length gives the total cornering force. Although the term, "tread element" is used, the compliance in the tire that leads to this effect is actually a combination of sidewall deflection and deflection of the rubber within the contact patch. The exact ratio of sidewall compliance to tread compliance is a factor in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Camber Thrust

Camber thrust and camber force are terms used to describe the force generated perpendicular to the direction of travel of a rolling tire due to its camber angle and finite contact patch. Camber thrust is generated when a point on the outer surface of a leaned and rotating tire, that would normally follow a path that is elliptical when projected onto the ground, is forced to follow a straight path while coming in contact with the ground, due to friction. This deviation towards the direction of the lean causes a deformation in the tire tread and carcass that is transmitted to the vehicle as a force in the direction of the lean. Camber thrust is approximately linearly proportional to camber angle for small angles, reaches its steady-state value nearly instantaneously after a change in camber angle, and so does not have an associated relaxation length. Bias-ply tires have been found to generate more camber thrust than radial tires. Camber stiffness is a parameter used to describe the c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dime (United States Coin)

The dime, in United States usage, is a ten-cent coin, one tenth of a United States dollar, labeled formally as "one dime". The denomination was first authorized by the Coinage Act of 1792. The dime is the smallest in diameter and is the thinnest of all U.S. coins currently minted for circulation, being in diameter and in thickness. The obverse of the current dime depicts the profile of President Franklin D. Roosevelt and the reverse boasts an olive branch, a torch, and an oak branch, from left to right respectively. The word ''dime'' comes from the Old French ''disme'' ( Modern French dîme), meaning "tithe" or "tenth part", from the Latin ''decima ars'. The dime is currently the only United States coin in general circulation that is not denominated in terms of dollars or cents. , the dime cost 5.65 cents to produce. History The Coinage Act of 1792 established the dime (spelled "disme" in the legislation), cent, and mill as subdivisions of the dollar equal to , and dol ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Young's Modulus

Young's modulus E, the Young modulus, or the modulus of elasticity in tension or compression (i.e., negative tension), is a mechanical property that measures the tensile or compressive stiffness of a solid material when the force is applied lengthwise. It quantifies the relationship between tensile/compressive stress \sigma (force per unit area) and axial strain \varepsilon (proportional deformation) in the linear elastic region of a material and is determined using the formula: E = \frac Young's moduli are typically so large that they are expressed not in pascals but in gigapascals (GPa). Example: * Silly Putty (increasing pressure: length increases quickly, meaning tiny E) * Aluminum (increasing pressure: length increases slowly, meaning high E) Higher Young's modulus corresponds to greater (lengthwise) stiffness. Although Young's modulus is named after the 19th-century British scientist Thomas Young, the concept was developed in 1727 by Leonhard Euler. The first exp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Area

Area is the quantity that expresses the extent of a region on the plane or on a curved surface. The area of a plane region or ''plane area'' refers to the area of a shape or planar lamina, while '' surface area'' refers to the area of an open surface or the boundary of a three-dimensional object. Area can be understood as the amount of material with a given thickness that would be necessary to fashion a model of the shape, or the amount of paint necessary to cover the surface with a single coat. It is the two-dimensional analogue of the length of a curve (a one-dimensional concept) or the volume of a solid (a three-dimensional concept). The area of a shape can be measured by comparing the shape to squares of a fixed size. In the International System of Units (SI), the standard unit of area is the square metre (written as m2), which is the area of a square whose sides are one metre long. A shape with an area of three square metres would have the same area as three such s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tire

A tire (American English) or tyre (British English) is a ring-shaped component that surrounds a wheel's rim to transfer a vehicle's load from the axle through the wheel to the ground and to provide traction on the surface over which the wheel travels. Most tires, such as those for automobiles and bicycles, are pneumatically inflated structures, which also provide a flexible cushion that absorbs shock as the tire rolls over rough features on the surface. Tires provide a footprint, called a contact patch, that is designed to match the weight of the vehicle with the bearing strength of the surface that it rolls over by providing a bearing pressure that will not deform the surface excessively. The materials of modern pneumatic tires are synthetic rubber, natural rubber, fabric, and wire, along with carbon black and other chemical compounds. They consist of a tread and a body. The tread provides traction while the body provides containment for a quantity of compressed a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)