|

Control Loop

A control loop is the fundamental building block of control systems in general and industrial control systems in particular. It consists of the process sensor, the controller function, and the final control element (FCE) which controls the process necessary to automatically adjust the value of a measured process variable (PV) to equal the value of a desired set-point (SP). There are two common classes of control loop: open loop and closed loop. * In an open-loop control system, the control action from the controller is independent of the process variable. An example of this is a central heating boiler controlled only by a timer. The control action is the switching on or off of the boiler. The process variable is the building temperature. This controller operates the heating system for a constant time regardless of the temperature of the building. * In a closed-loop control system, the control action from the controller is dependent on the desired and actual process variable. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Control System

A control system manages, commands, directs, or regulates the behavior of other devices or systems using control loops. It can range from a single home heating controller using a thermostat controlling a domestic boiler to large industrial control systems which are used for controlling processes or machines. The control systems are designed via control engineering process. For continuously modulated control, a feedback controller is used to automatically control a process or operation. The control system compares the value or status of the process variable (PV) being controlled with the desired value or setpoint (SP), and applies the difference as a control signal to bring the process variable output of the plant to the same value as the setpoint. For sequential and combinational logic, software logic, such as in a programmable logic controller, is used. Open-loop and closed-loop control Feedback control systems Logic control Logic control systems for indus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Closed-loop Controller

A closed-loop controller or feedback controller is a control loop which incorporates feedback, in contrast to an '' open-loop controller'' or ''non-feedback controller''. A closed-loop controller uses feedback to control states or outputs of a dynamical system. Its name comes from the information path in the system: process inputs (e.g., voltage applied to an electric motor) have an effect on the process outputs (e.g., speed or torque of the motor), which is measured with sensors and processed by the controller; the result (the control signal) is "fed back" as input to the process, closing the loop. In the case of linear feedback systems, a control loop including sensors, control algorithms, and actuators is arranged in an attempt to regulate a variable at a setpoint (SP). An everyday example is the cruise control on a road vehicle; where external influences such as hills would cause speed changes, and the driver has the ability to alter the desired set speed. The PID algorit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

IEC 61346

International Standard IEC/ISO 81346 series "Industrial systems, installations and equipment and industrial products – structuring principles and reference designations" defines the rules for reference designation systems (RDS). It is published as a double logo standard prepared by IEC technical committee 3: Information structures and elements, identification and marking principles, documentation and graphical symbols, in cooperation with ISO technical committee 10: Technical product documentation. The 81346 series replaces the deprecated IEC 61346:1996. Contents * Part 1: Basic rules (IEC 81346-1:2022) * Part 2: Classification of objects and codes for classes (IEC 81346-2:2019) * Part 10: Power supply systems (ISO/IEC 81346-10:2022) * Part 12: Construction works (ISO/IEC 81346-12:2018) Double Logo Standards Future developments of the standards on reference designations will be made in cooperation between the IEC and the ISO and published as IEC 81346. (Standards develo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ISO 14617

ISO 14617 ''Graphical symbols for diagrams'' is a library of graphical symbols for diagrams used in technical applications. ISO 14617 consists of the following parts: * Part 1: General information and indexes * Part 2: Symbols having general application * Part 3: Connections and related devices * Part 4: Actuators and related devices * Part 5: Measurement and control devices * Part 6: Measurement and control functions * Part 7: Basic mechanical components * Part 8: Valves and dampers * Part 9: Pumps, compressors and fans * Part 10: Fluid power converters * Part 11: Devices for heat transfer and heat engines * Part 12: Devices for separating, purification and mixing * Part 13: Devices for material processing * Part 14: Devices for transport and handling of material * Part 15: Installation diagrams and network maps The standard is developed in cooperation with the International Electrotechnical Commission and has some common elements with IEC 60617 ''Graphical symbols for diagrams''. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Instrument Society Of America

The International Society of Automation (ISA) Is a non-profit technical society for engineers, technicians, businesspeople, educators and students, who work, study or are interested in automation and pursuits related to it, such as instrumentation. Originally known as the Instrumentation Society of America, the society is more commonly known by its acronym, ISA. The society's scope now includes many technical and engineering disciplines. ISA is one of the foremost professional organizations in the world for setting standards and educating industry professionals in automation. Instrumentation and automation are some of the key technologies involved in nearly all industrialized manufacturing. Modern industrial manufacturing is a complex interaction of numerous systems. Instrumentation provides regulation for these complex systems using many different measurement and control devices. Automation provides the programmable devices that permit greater flexibility in the operation of thes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ANSI

The American National Standards Institute (ANSI ) is a private nonprofit organization that oversees the development of voluntary consensus standards for products, services, processes, systems, and personnel in the United States. The organization also coordinates U.S. standards with international standards so that American products can be used worldwide. ANSI accredits standards that are developed by representatives of other standards organizations, government agencies, consumer groups, companies, and others. These standards ensure that the characteristics and performance of products are consistent, that people use the same definitions and terms, and that products are tested the same way. ANSI also accredits organizations that carry out product or personnel certification in accordance with requirements defined in international standards. The organization's headquarters are in Washington, D.C. ANSI's operations office is located in New York City. The ANSI annual operating ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Process Flow Diagram

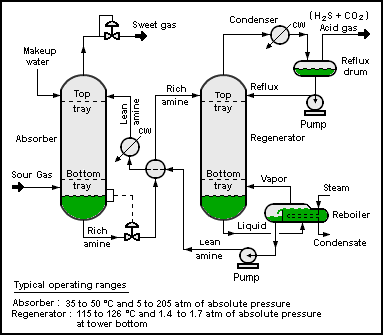

A process flow diagram (PFD) is a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment. The PFD displays the relationship between ''major'' equipment of a plant facility and does not show minor details such as piping details and designations. Another commonly used term for a PFD is ''process'' ''flowsheet''. It is the key document in process design. Typical content of a process flow diagram Typically, process flow diagrams of a single unit process include the following: * Process piping * Major equipment items *Connections with other systems * Major bypass and recirculation (recycle) streams * Operational data (temperature, pressure, mass flow rate, density, etc.), often by stream references to a mass balance * Process stream names Process flow diagrams generally do not include: * Pipe classes or piping line numbers * Instrumentation details * Minor bypass lines * Instrumentation * Controllers like Level Con ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piping And Instrumentation Diagram

A Piping and Instrumentation Diagram (P&ID) is a detailed diagram in the process industry which shows process equipment together with the instrumentation and control devices. It is also called as mechanical flow diagram (MFD). Superordinate to the P&ID is the process flow diagram (PFD) which indicates the more general flow of plant processes and the relationship between major equipment of a plant facility. Contents and function A piping and instrumentation diagram (P&ID) is defined as follows: # A diagram which shows the interconnection of process equipment and the instrumentation used to control the process. In the process industry, a Symbolic language (engineering), standard set of symbols is used to prepare drawings of processes. The instrument symbols used in these drawings are generally based on International Society of Automation (ISA) Standard S5.1 # The primary schematic drawing used for laying out a process control installation. They usually contain the following inf ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Programmable Logic Controller

A programmable logic controller (PLC) or programmable controller is an industrial computer that has been ruggedized and adapted for the control of manufacturing processes, such as assembly lines, machines, robotic devices, or any activity that requires high reliability, ease of programming, and process fault diagnosis. PLCs can range from small modular devices with tens of Input/output, inputs and outputs (I/O), in a housing integral with the processor, to large rack-mounted modular devices with thousands of I/O, and which are often networked to other PLC and SCADA systems. They can be designed for many arrangements of digital and analog I/O, extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact. PLCs were first developed in the automobile manufacturing industry to provide flexible, rugged and easily programmable controllers to replace hard-wired relay logic systems. Dick Morley, who invented the first PLC, the Modicon 084, for Gene ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

PID Controller

PID or Pid may refer to: Medicine * Pelvic inflammatory disease or pelvic inflammatory disorder, an infection of the upper part of the female reproductive system * Primary immune deficiency, disorders in which part of the body's immune system is missing or does not function properly * Prolapsed intervertebral disc, commonly called a herniated disc Science, technology and engineering * BBC Programme Identifier, a unique identifier for a BBC television or radio programme brand, a season or series, or an individual episode * OBD-II PIDs (on-board diagnostics parameter IDs), requests for data through an OBD connector in automotive repair * Packet Identifier, a field in a MPEG transport stream#Packet Identifier (PID), MPEG transport stream packet * Partial information decomposition, an extension of information theory * Passive infrared detector, a passive infrared sensor * Payload Interface Document (used on space engineering program for example) * Persistent identifier, a long-lastin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Control Loop

Industrial may refer to: Industry * Industrial archaeology, the study of the history of the industry * Industrial engineering, engineering dealing with the optimization of complex industrial processes or systems * Industrial city, a city dominated by one or more industries * Industrial loan company, a financial institution in the United States that lends money, and may be owned by non-financial institutions * Industrial organization, a field that builds on the theory of the firm by examining the structure and boundaries between firms and markets * Industrial Revolution, the development of industry in the 18th and 19th centuries **Second Industrial Revolution * Industrial society, a society that has undergone industrialization * Industrial technology, a broad field that includes designing, building, optimizing, managing and operating industrial equipment, and predesignated as acceptable for industrial uses, like factories * Industrial video, a video that targets “industry” as it ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Feedback

Feedback occurs when outputs of a system are routed back as inputs as part of a chain of cause and effect that forms a circuit or loop. The system can then be said to ''feed back'' into itself. The notion of cause-and-effect has to be handled carefully when applied to feedback systems: History Self-regulating mechanisms have existed since antiquity, and the idea of feedback started to enter economic theory in Britain by the 18th century, but it was not at that time recognized as a universal abstraction and so did not have a name. The first ever known artificial feedback device was a float valve, for maintaining water at a constant level, invented in 270 BC in Alexandria, Egypt. This device illustrated the principle of feedback: a low water level opens the valve, the rising water then provides feedback into the system, closing the valve when the required level is reached. This then reoccurs in a circular fashion as the water level fluctuates. Centrifugal governors were ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |