|

Boundary Scan

Boundary scan is a method for testing interconnects (wire lines) on printed circuit boards or sub-blocks inside an integrated circuit. Boundary scan is also widely used as a debugging method to watch integrated circuit pin states, measure voltage, or analyze sub-blocks inside an integrated circuit. The Joint Test Action Group (JTAG) developed a specification for boundary scan testing that was standardized in 1990 as the IEEE Std. 1149.1-1990. In 1994, a supplement that contains a description of the Boundary Scan Description Language (BSDL) was added which describes the boundary-scan logic content of IEEE Std 1149.1 compliant devices. Since then, this standard has been adopted by electronic device companies all over the world. Boundary scan is now mostly synonymous with JTAG.IEEE Std 1149.1 (JTAG) Testability Primer< ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

JTAG Register

JTAG (named after the Joint Test Action Group which codified it) is an industry standard for verifying designs and testing printed circuit boards after manufacture. JTAG implements standards for on-chip instrumentation in electronic design automation (EDA) as a complementary tool to digital simulation. It specifies the use of a dedicated debug port implementing a serial communications interface for low-overhead access without requiring direct external access to the system address and data buses. The interface connects to an on-chip Test Access Port (TAP) that implements a stateful protocol to access a set of test registers that present chip logic levels and device capabilities of various parts. The Joint Test Action Group formed in 1985 to develop a method of verifying designs and testing printed circuit boards after manufacture. In 1990 the Institute of Electrical and Electronics Engineers codified the results of the effort in IEEE Standard 1149.1-1990, entitled ''Standa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Design For Test

Design for testing or design for testability (DFT) consists of IC design techniques that add testability features to a hardware product design. The added features make it easier to develop and apply manufacturing tests to the designed hardware. The purpose of manufacturing tests is to validate that the product hardware contains no manufacturing defects that could adversely affect the product's correct functioning. Tests are applied at several steps in the hardware manufacturing flow and, for certain products, may also be used for hardware maintenance in the customer's environment. The tests are generally driven by test programs that execute using automatic test equipment (ATE) or, in the case of system maintenance, inside the assembled system itself. In addition to finding and indicating the presence of defects (i.e., the test fails), tests may be able to log diagnostic information about the nature of the encountered test fails. The diagnostic information can be used to locate th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electronics Manufacturing

Electronics Manufacturing Services (EMS) is a term used for companies that design, manufacture, test, distribute, and provide return/repair services for electronic components and assemblies for original equipment manufacturers (OEMs). The concept is also referred to as Electronics Contract Manufacturing (ECM). Many consumer electronics are built in China, due to maintenance cost, availability of materials, and speed as opposed to other countries such as the United States. Cities such as Shenzhen and Penang have become important production centres for the industry, attracting many consumer electronics companies such as Apple Inc. Some companies such as Flex and Wistron are Original design manufacturers and providers of Electronics manufacturing services. History The EMS industry was initially established in 1961 by SCI Systems of Huntsville Alabama. The industry realized its most significant growth in the 1980s; at the time, most electronics manufacturing for large-scale product r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Acceptance Testing

In engineering and its various subdisciplines, acceptance testing is a test conducted to determine if the requirements of a specification or contract are met. It may involve chemical tests, physical tests, or performance tests. In systems engineering, it may involve black-box testing performed on a system (for example: a piece of software, lots of manufactured mechanical parts, or batches of chemical products) prior to its delivery. In software testing, the ISTQB defines ''acceptance testing'' as: Acceptance testing is also known as user acceptance testing (UAT), end-user testing, operational acceptance testing (OAT), acceptance test-driven development (ATDD) or field (acceptance) testing. Acceptance criteria are the criteria that a system or component must satisfy in order to be accepted by a user, customer, or other authorized entity. Overview Testing is a set of activities conducted to facilitate discovery and/or evaluation of properties of one or more items unde ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

In-circuit Test

In-circuit testing (ICT) is an example of white box testing where an electrical probe tests a populated printed circuit board (PCB), checking for shorts, opens, resistance, capacitance, and other basic quantities which will show whether the assembly was correctly fabricated. It may be performed with a "bed of nails" test fixture and specialist test equipment, or with a fixtureless in-circuit test setup. Fixtures for in-circuit testing A common form of in-circuit testing uses a bed-of-nails tester. This is a fixture that uses an array of spring-loaded pins known as "pogo pins". When a printed circuit board is aligned with and pressed down onto the bed-of-nails tester, the pins make electrical contact with locations on the circuit board, allowing them to be used as test points for in-circuit testing. Bed-of-nails testers have the advantage that many tests may be performed at a time, but have the disadvantage of placing substantial strain on the PCB. An alternative is the use o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automated X-ray Inspection

Automated inspection (AXI) is a technology based on the same principles as automated optical inspection (AOI). It uses as its source, instead of visible light, to automatically inspect features, which are typically hidden from view. Automated X-ray inspection is used in a wide range of industries and applications, predominantly with two major goals: # Process optimization, i.e. the results of the inspection are used to optimize following processing steps, # Anomaly detection, i.e. the result of the inspection serve as a criterion to reject a part (for scrap or re-work). Whilst AOI is mainly associated with electronics manufacturing (due to widespread use in PCB manufacturing), AXI has a much wider range of applications. It ranges from the quality check of alloy wheels to the detection of bone fragments in processed meat. Wherever large numbers of very similar items are produced according to a defined standard, automatic inspection using advanced image processing and pattern reco ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automated Optical Inspection

Automated optical inspection (AOI) is an automated visual inspection of printed circuit board (PCB) (or LCD, transistor) manufacture where a camera autonomously scans the device under test for both catastrophic failure (e.g. missing component) and quality defects (e.g. fillet size or shape or component skew). It is commonly used in the manufacturing process because it is a non-contact test method. It is implemented at many stages through the manufacturing process including bare board inspection, solder paste inspection (SPI), pre-reflow and post-reflow as well as other stages. Historically, the primary place for AOI systems has been after solder reflow or "post-production." Mainly because, post-reflow AOI systems can inspect for most types of defects (component placement, solder shorts, missing solder, etc.) at one place in the line with one single system. In this way the faulty boards are reworked and the other boards are sent to the next process stage. SMT inspection AOIs fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Level-sensitive Scan Design

Within the field of electronics Level-sensitive scan design (LSSD) is part of an integrated circuit manufacturing test process. It is a DFT scan design method which uses separate system and scan clocks to distinguish between normal and test mode. Latches are used in pairs, each has a normal data input, data output and clock for system operation. For test operation, the two latches form a master/slave pair with one scan input, one scan output and non-overlapping scan clocks A and B which are held low during system operation but cause the scan data to be latched when pulsed high during scan. ____ , , Sin ----, S , A ------, > , , Q, ---+--------------- Q1 D1 -----, D , , CLK1 ---, > , , , ____, , ____ , , , +---, S , B -------------------, > , , Q, ------ Q2 / SOut D2 ------------------, D , CLK2 ----------------, > , , ____, In a single latch LSSD configuration, the second latch is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

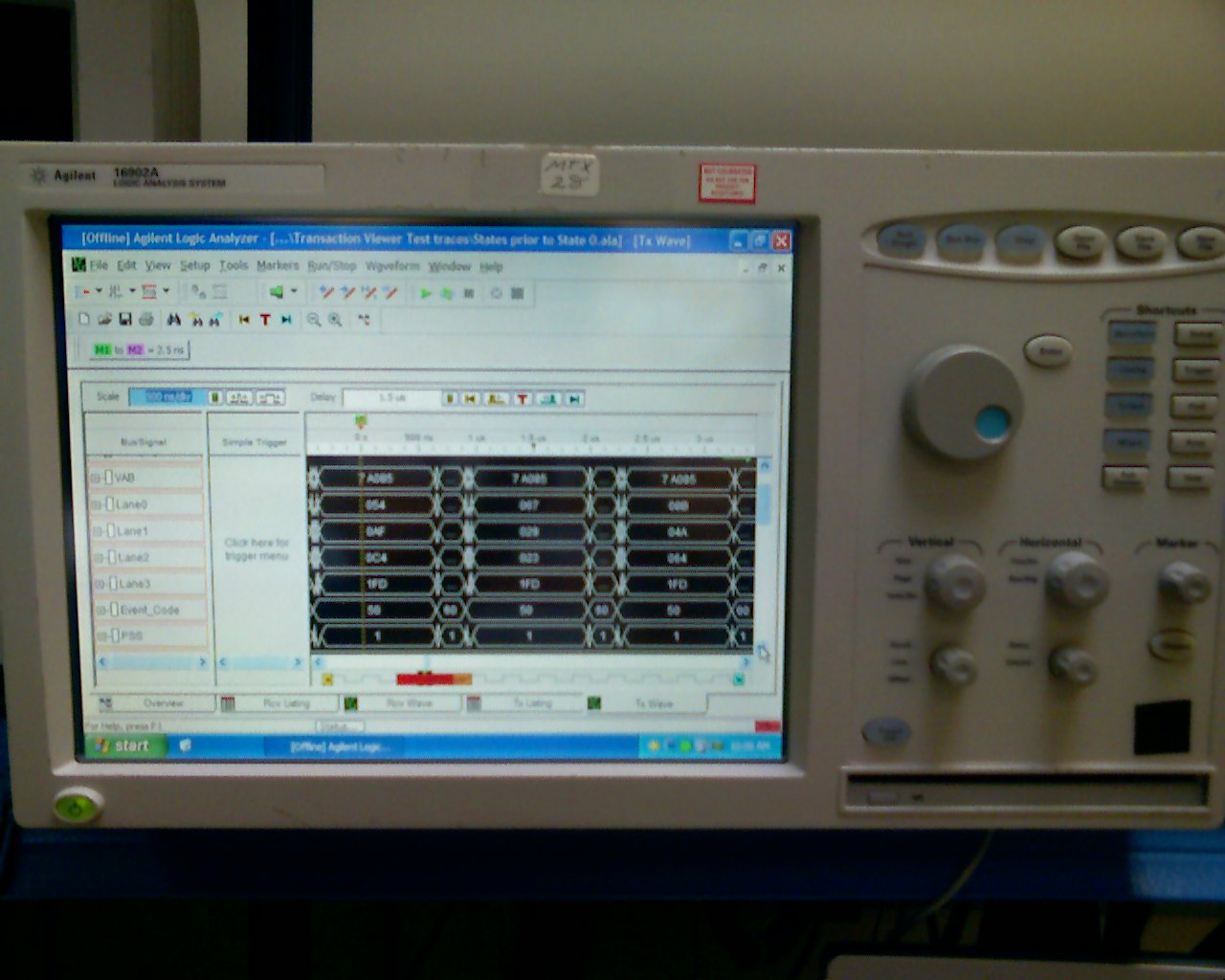

Logic Analyzer

A logic analyzer is an electronic instrument that captures and displays multiple signals from a digital system or digital circuit. A logic analyzer may convert the captured data into timing diagrams, protocol decodes, state machine traces, assembly language, or may correlate assembly with source-level software. Logic analyzers have advanced triggering capabilities, and are useful when a user needs to see the timing relationships between many signals in a digital system. Overview Presently, there are three distinct categories of logic analyzers available on the market: * Modular LAs, which consist of both a chassis or mainframe and logic analyzer modules. The mainframe/chassis contains the display, controls, control computer, and multiple slots into which the actual data-capturing hardware is installed. The modules each have a specific number of channels, and multiple modules may be combined to obtain a very high channel count. While modular logic analyzers are typically mor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrical Engineer

Electrical engineering is an engineering discipline concerned with the study, design, and application of equipment, devices, and systems which use electricity, electronics, and electromagnetism. It emerged as an identifiable occupation in the latter half of the 19th century after commercialization of the electric telegraph, the telephone, and electrical power generation, distribution, and use. Electrical engineering is now divided into a wide range of different fields, including computer engineering, systems engineering, power engineering, telecommunications, radio-frequency engineering, signal processing, instrumentation, photovoltaic cells, electronics, and optics and photonics. Many of these disciplines overlap with other engineering branches, spanning a huge number of specializations including hardware engineering, power electronics, electromagnetics and waves, microwave engineering, nanotechnology, electrochemistry, renewable energies, mechatronics/control, and elec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Software Developer

Software development is the process of conceiving, specifying, designing, programming, documenting, testing, and bug fixing involved in creating and maintaining applications, frameworks, or other software components. Software development involves writing and maintaining the source code, but in a broader sense, it includes all processes from the conception of the desired software through to the final manifestation of the software, typically in a planned and structured process. Software development also includes research, new development, prototyping, modification, reuse, re-engineering, maintenance, or any other activities that result in software products. Methodologies One system development methodology is not necessarily suitable for use by all projects. Each of the available methodologies are best suited to specific kinds of projects, based on various technical, organizational, project, and team considerations. Software development activities Identification of need The s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |