|

Blowout Preventer

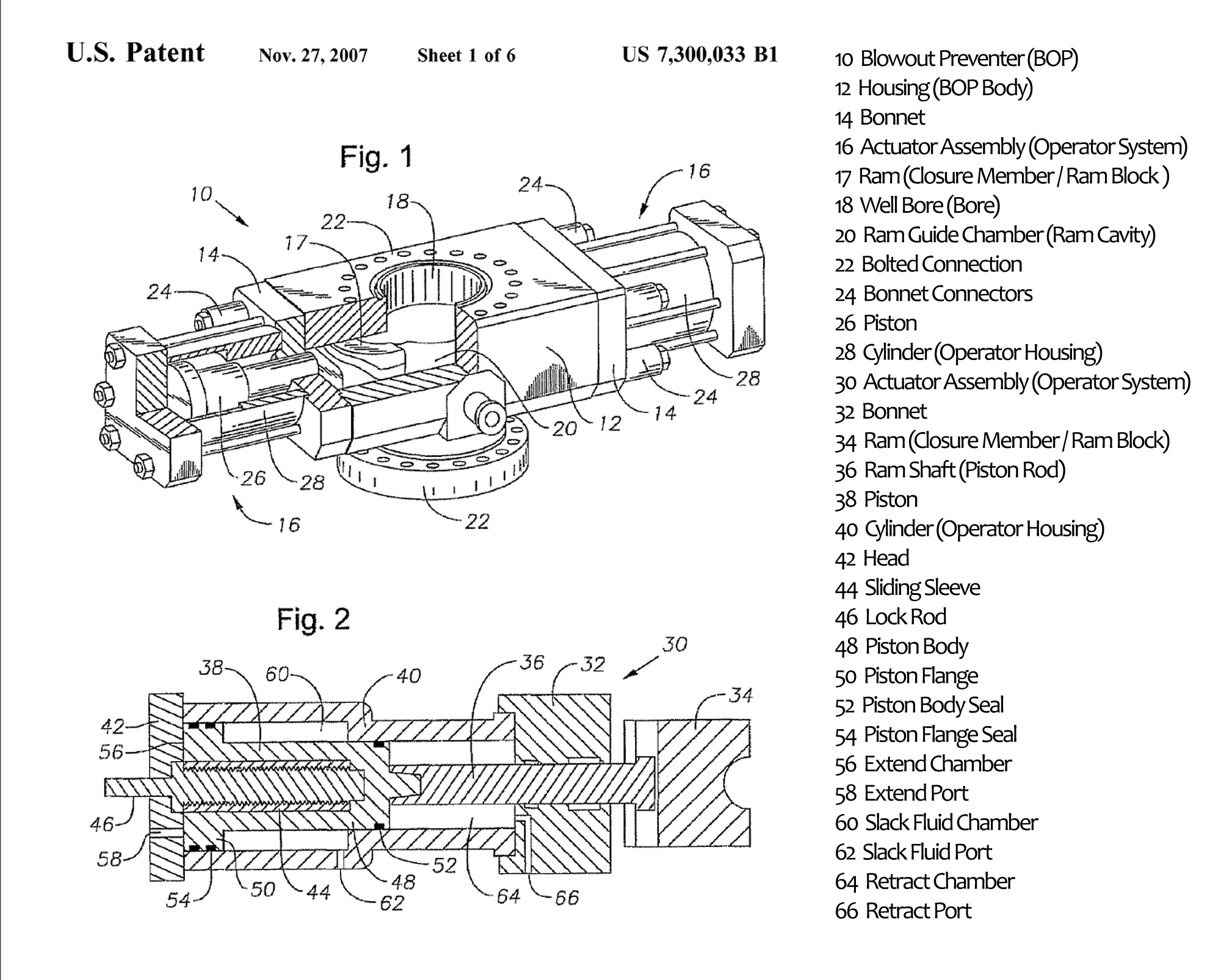

A blowout preventer (BOP) (pronounced B-O-P, not "bop") is a specialized valve or similar mechanical device, used to seal, control and monitor oil and gas wells to prevent blowouts, the uncontrolled release of crude oil or natural gas from a well. They are usually installed in stacks of other valves. Blowout preventers were developed to cope with extreme erratic pressures and uncontrolled flow ( formation kick) emanating from a well reservoir during drilling. Kicks can lead to a potentially catastrophic event known as a blowout. In addition to controlling the downhole (occurring in the drilled hole) pressure and the flow of oil and gas, blowout preventers are intended to prevent tubing (e.g. drill pipe and well casing), tools and drilling fluid from being blown out of the wellbore (also known as bore hole, the hole leading to the reservoir) when a blowout threatens. Blowout preventers are critical to the safety of crew, rig (the equipment system used to drill a wellbore) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blow Out Preventer

A blowout preventer (BOP) (pronounced B-O-P, not "bop") is a specialized valve or similar mechanical device, used to seal, control and monitor oil and gas wells to prevent blowouts, the uncontrolled release of crude oil or natural gas from a well. They are usually installed in stacks of other valves. Blowout preventers were developed to cope with extreme erratic pressures and uncontrolled flow ( formation kick) emanating from a well reservoir during drilling. Kicks can lead to a potentially catastrophic event known as a blowout. In addition to controlling the downhole (occurring in the drilled hole) pressure and the flow of oil and gas, blowout preventers are intended to prevent tubing (e.g. drill pipe and well casing), tools and drilling fluid from being blown out of the wellbore (also known as bore hole, the hole leading to the reservoir) when a blowout threatens. Blowout preventers are critical to the safety of crew, rig (the equipment system used to drill a wellbore) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Redundancy (engineering)

In engineering, redundancy is the intentional duplication of critical components or functions of a system with the goal of increasing reliability of the system, usually in the form of a backup or fail-safe, or to improve actual system performance, such as in the case of GNSS receivers, or multi-threaded computer processing. In many safety-critical systems, such as fly-by-wire and hydraulic systems in aircraft, some parts of the control system may be triplicated, which is formally termed triple modular redundancy (TMR). An error in one component may then be out-voted by the other two. In a triply redundant system, the system has three sub components, all three of which must fail before the system fails. Since each one rarely fails, and the sub components are expected to fail independently, the probability of all three failing is calculated to be extraordinarily small; it is often outweighed by other risk factors, such as human error. Redundancy may also be known by the term ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blowout Preventer

A blowout preventer (BOP) (pronounced B-O-P, not "bop") is a specialized valve or similar mechanical device, used to seal, control and monitor oil and gas wells to prevent blowouts, the uncontrolled release of crude oil or natural gas from a well. They are usually installed in stacks of other valves. Blowout preventers were developed to cope with extreme erratic pressures and uncontrolled flow ( formation kick) emanating from a well reservoir during drilling. Kicks can lead to a potentially catastrophic event known as a blowout. In addition to controlling the downhole (occurring in the drilled hole) pressure and the flow of oil and gas, blowout preventers are intended to prevent tubing (e.g. drill pipe and well casing), tools and drilling fluid from being blown out of the wellbore (also known as bore hole, the hole leading to the reservoir) when a blowout threatens. Blowout preventers are critical to the safety of crew, rig (the equipment system used to drill a wellbore) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cameron Ram-type Blowout Preventer (1922)

The Cameron ram-type blowout preventer was the first successful blowout preventer (BOP) for oil wells. It was developed by James S. Abercrombie and Harry S. Cameron in 1922. The device was issued on January 12, 1926. The blowout preventer was designated as a Mechanical Engineering Landmark in 2003. History While drilling an oil or gas well, the top of the wellbore is lined with a casing. The drill string runs through the casing. The annular (ring-shaped) region between the casing and the drill stem is filled with drilling mud which provides hydrostatic pressure to keep the formation fluid from coming up the wellbore. If the pressure of the formation fluid exceeds the hydrostatic pressure of the drilling mud, the oil or gas can blow out of the wellbore. This has caused spills of large quantities of oil and fires on drilling rigs. The blowout of the Lucas well at the Spindletop field in 1901 lasted for over nine days and spilled over of oil. James Smither Abercrombie (1891–1975 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drilling Rig (petroleum)

This article lists the main components of a petroleum onshore drilling rig. Offshore drilling rigs have similar elements, but are configured with a number of different drilling systems to suit drilling in the marine environment. The equipment associated with a rig is to some extent dependent on the type of rig but typically includes at least some of the items listed below. {{clear List of items # Mud tank # Shale shakers # Suction line (mud pump) # Mud pump # Motor or power source #hose #Drawworks # Standpipe #Kelly hose # Goose-neck #Traveling block #Drill line #Crown block #Derrick # Racking Board (Sometimes referred to as the Monkey Board) #Stand (of drill pipe) # Setback (floor) #Swivel (On newer rigs this may be replaced by a top drive) #Kelly drive #Rotary table #Drill floor #Bell nipple #Blowout preventer (BOP) Annular type #Blowout preventer (BOP) Pipe ram & blind ram #Drill string #Drill bit #Casing head or Wellhead # Flow line Explanation *Bell nipple (#22) is a sec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Well Integrity

Well integrity, in regard to oil wells, is defined bNORSOK D-010as the "“Application of technical, operational and organizational solutions to reduce risk of uncontrolled release of formation fluids throughout the life cycle of a well”. There are various facets to well integrity, including accountability/responsibility, well operating processes, well service processes, tubing/annulus integrity, tree/wellhead integrity and testing of safety systems. A similar form of words are used in ISO 16530 well integrity standard Accountability/responsibility Accountability is the position that ensures a particular task is being done. They typically control the budget and organizational chart structure. Responsibility is the position that actually does the task. There are a variety of tasks associated with well integrity and responsibility can reside with a field's well operations engineer, operators, well service technicians, etc. Well operating processes This includes processes such ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fluid Statics

Fluid statics or hydrostatics is the branch of fluid mechanics that studies the condition of the equilibrium of a floating body and submerged body " fluids at hydrostatic equilibrium and the pressure in a fluid, or exerted by a fluid, on an immersed body". It encompasses the study of the conditions under which fluids are at rest in stable equilibrium as opposed to fluid dynamics, the study of fluids in motion. Hydrostatics is a subcategory of fluid statics, which is the study of all fluids, both compressible or incompressible, at rest. Hydrostatics is fundamental to hydraulics, the engineering of equipment for storing, transporting and using fluids. It is also relevant to geophysics and astrophysics (for example, in understanding plate tectonics and the anomalies of the Earth's gravitational field), to meteorology, to medicine (in the context of blood pressure), and many other fields. Hydrostatics offers physical explanations for many phenomena of everyday life, such ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drilling Fluid

In geotechnical engineering, drilling fluid, also called drilling mud, is used to aid the drilling of boreholes into the earth. Often used while drilling oil and natural gas wells and on exploration drilling rigs, drilling fluids are also used for much simpler boreholes, such as water wells. One of the functions of drilling mud is to carry cuttings out of the hole. The three main categories of drilling fluids are: water-based muds (WBs), which can be dispersed and non-dispersed; non-aqueous muds, usually called oil-based muds (OBs); and gaseous drilling fluid, in which a wide range of gases can be used. Along with their formatives, these are used along with appropriate polymer and clay additives for drilling various oil and gas formations. The main functions of drilling fluids include providing hydrostatic pressure to prevent formation fluids from entering into the well bore, keeping the drill bit cool and clean during drilling, carrying out drill cuttings, and susp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill Pipe

Drill pipe, is hollow, thin-walled, steel or aluminium alloy piping that is used on drilling rigs. It is hollow to allow drilling fluid to be pumped down the hole through the bit and back up the annulus. It comes in a variety of sizes, strengths, and wall thicknesses, but is typically 27 to 32 feet in length (Range 2). Longer lengths, up to 45 feet, exist (Range 3). Background Drill stems must be designed to transfer drilling torque for combined lengths that often exceed several miles down into the Earth's crust, and also must be able to resist pressure differentials between inside and outside (or vice versa), and have sufficient strength to suspend the total weight of deeper components. For deep wells this requires tempered steel tubes that are expensive, and owners spend considerable efforts to reuse them after finishing a well. A used drill stem is inspected on site, or off location. Ultrasonic testing and modified instruments similar to the spherometer are used at inspecti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wellhead

A wellhead is the component at the surface of an oil or gas well that provides the structural and pressure-containing interface for the drilling and production equipment. The primary purpose of a wellhead is to provide the suspension point and pressure seals for the casing strings that run from the bottom of the hole sections to the surface pressure control equipment. While drilling the oil well, surface pressure control is provided by a blowout preventer (BOP). If the pressure is not contained during drilling operations by the column of drilling fluid, casings, wellhead, and BOP, a well blowout could occur. When the well has been drilled, it is completed to provide an interface with the reservoir rock and a tubular conduit for the well fluids. The surface pressure control is provided by a Christmas tree, which is installed on top of the wellhead, with isolation valves and choke equipment to control the flow of well fluids during production. Wellheads are typically welded ont ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Formation Fluid

Formation fluid refers to the naturally occurring liquids and gases contained in geologic formations. Fluids introduced during the drilling process are called drilling fluids. Fluids in an oil or gas reservoir are called reservoir fluids. The fluids flowing from the wellhead A wellhead is the component at the surface of an oil or gas well that provides the structural and pressure-containing interface for the drilling and production equipment. The primary purpose of a wellhead is to provide the suspension point and ... of an oil or gas well are called production fluids. References Oilfield terminology {{geology-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Well Kill

A well kill is the operation of placing a column of heavy fluid into a well bore in order to prevent the flow of reservoir fluids without the need for pressure control equipment at the surface. It works on the principle that the hydrostatic head of the "kill fluid" or "kill mud" will be enough to suppress the pressure of the formation fluids. Well kills may be planned in the case of advanced interventions such as workovers, or be contingency operations. The situation calling for a well kill will dictate the method taken. Not all well kills are deliberate. Sometimes, the unintended buildup of fluids, either from injection of chemicals like methanol from surface, or from liquids produced from the reservoir, can be enough to kill the well, particularly gas wells, which are notoriously easy to kill. Well control in general is an extremely expensive and dangerous operation. Extensive training, testing, proof of competence, and experience are prerequisites for planning and performing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)

.jpg)