|

Abrasive Flow Machining

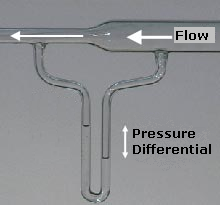

Abrasive flow machining (AFM), also known as abrasive flow deburring or extrude honing, is an interior surface finishing process characterized by flowing an abrasive-laden fluid through a workpiece. This fluid is typically very viscous, having the consistency of putty, or dough. AFM smooths and finishes rough surfaces, and is specifically used to remove burrs, polish surfaces, form radii, and even remove material. The nature of AFM makes it ideal for interior surfaces, slots, holes, cavities, and other areas that may be difficult to reach with other polishing or grinding processes. Due to its low material removal rate, AFM is not typically used for large stock-removal operations, although it can be. Abrasive flow machining was first patented by the Extrude Hone Corporation in 1970. Process In abrasive flow machining, the abrasive fluid flows through the workpiece, effectively performing erosion. Abrasive particles in the fluid contact raised features on the surface of the workp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes machine tools, in contrast to '' additive manufacturing'' (3D printing), which uses controlled addition of material. Machining is a part of the manufacture of many metal products, but it can also be used on other materials such as wood, plastic, ceramic, and composite material. A person who specializes in machining is called a machinist. A room, building, or company where machining is done is called a machine shop. Much of modern-day machining is carried out by computer numerical control (CNC), in which computers are used to control the movement and operation of the mills, lathes, and other cutting machines. This increases efficiency, as the CNC machine runs unmanned therefore reducing labour costs for machine shops. History and ter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extrude Hone Corporation

Kennametal is an American supplier of tooling and industrial materials founded in 1938 by Philip M. McKenna in the Latrobe, Pennsylvania area. Production Kennametal products: *Blades, disks, skins, fuel control systems, and landing gear for the aerospace industry *Synthetic fertilizers for agriculture *Camshafts, crankshafts, cylinder heads, rotors, calipers and differentials for automobiles *Roofing and abrasives for home construction *Asphalt, stabilization tools, and tunneling equipment for road construction *Woodworking tools * Machining industries: ** Machine tools: Machining centers, turning centers (CNC lathes), automatic lathes (screw machines) ** Tooling for machine tools: *** Indexable toolholders, collets *** fixtures *** cutting tools (via Products Group, a consolidation of various brands in this industry): inserts, tool bits, milling cutters, taps and dies, metal sawing cutters and tooling *Mining equipment *Abrasives and flow control for the oil industr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydro-erosive Grinding

Hydro-erosive grinding (HEG) is a process for radiusing orifice edges and hole intersections by flowing an abrasive fluid through. This process can calibrate the holes to flow a certain static flow rate. See also * Abrasive flow machining Abrasive flow machining (AFM), also known as abrasive flow deburring or extrude honing, is an interior surface finishing process characterized by flowing an abrasive-laden fluid through a workpiece. This fluid is typically very viscous, having th ... External links * Grinding and lapping {{metalworking-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer Numerical Control

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following coded programmed instructions and without a manual operator directly controlling the machining operation. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be printed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fixture (tool)

A fixture is a work-holding or support device used in the manufacturing industry. Fixtures are used to securely locate (position in a specific location or orientation) and support the work, ensuring that all parts produced using the fixture will maintain conformity and interchangeability. Using a fixture improves the economy of production by allowing smooth operation and quick transition from part to part, reducing the requirement for skilled labor by simplifying how workpieces are mounted, and increasing conformity across a production run. A fixture differs from a jig in that when a fixture is used, the tool must move relative to the workpiece; a jig moves the piece while the tool remains stationary. Purpose A fixture's primary purpose is to create a secure mounting point for a workpiece, allowing for support during operation and increased accuracy, precision, reliability, and interchangeability in the finished parts. It also serves to reduce working time by allowing quick set-u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bernoulli's Principle

In fluid dynamics, Bernoulli's principle states that an increase in the speed of a fluid occurs simultaneously with a decrease in static pressure or a decrease in the fluid's potential energy. The principle is named after the Swiss mathematician and physicist Daniel Bernoulli, who published it in his book ''Hydrodynamica'' in 1738. Although Bernoulli deduced that pressure decreases when the flow speed increases, it was Leonhard Euler in 1752 who derived Bernoulli's equation in its usual form. The principle is only applicable for isentropic flows: when the effects of irreversible processes (like turbulence) and non-adiabatic processes (e.g. thermal radiation) are small and can be neglected. Bernoulli's principle can be applied to various types of fluid flow, resulting in various forms of Bernoulli's equation. The simple form of Bernoulli's equation is valid for incompressible flows (e.g. most liquid flows and gases moving at low Mach number). More advanced forms may be applied ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Ram

A hydraulic ram, or hydram, is a cyclic water pump powered by hydropower. It takes in water at one "hydraulic head" (pressure) and flow rate, and outputs water at a higher hydraulic head and lower flow rate. The device uses the water hammer effect to develop pressure that allows a portion of the input water that powers the pump to be lifted to a point higher than where the water originally started. The hydraulic ram is sometimes used in remote areas, where there is both a source of low-head hydropower and a need for pumping water to a destination higher in elevation than the source. In this situation, the ram is often useful, since it requires no outside source of power other than the kinetic energy of flowing water. History The Alhambra, built by Nasrid Sultan Ibn al-Ahmar of Granada beginning AD1238, used a hydram to raise water. Through a first reservoir, filled by a channel from the Darro River, water emptied via a large vertical channel into a second reservoir be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Erosion

Erosion is the action of surface processes (such as water flow or wind) that removes soil, rock, or dissolved material from one location on the Earth's crust, and then transports it to another location where it is deposited. Erosion is distinct from weathering which involves no movement. Removal of rock or soil as clastic sediment is referred to as ''physical'' or ''mechanical'' erosion; this contrasts with ''chemical'' erosion, where soil or rock material is removed from an area by dissolution. Eroded sediment or solutes may be transported just a few millimetres, or for thousands of kilometres. Agents of erosion include rainfall; bedrock wear in rivers; coastal erosion by the sea and waves; glacial plucking, abrasion, and scour; areal flooding; wind abrasion; groundwater processes; and mass movement processes in steep landscapes like landslides and debris flows. The rates at which such processes act control how fast a surface is eroded. Typically, physical ero ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Material Removal Rate

Material removal rate (MRR) is the amount of material removed per time unit (usually per minute) when performing machining operations such as using a lathe or milling machine. The more material removed per minute, the higher the material removal rate. The MRR is a single number that enables you to do this. It is a direct indicator of how efficiently you are cutting, and how profitable you are. MRR is the volume of material removed per minute. The higher your cutting parameters, the higher the MRR. Phrased in another way, the MRR is equal to the volume of residue formed as a direct result of the removal from the workpiece per unit of time during a cutting operation. The material removal rate in a work process can be calculated as the depth of the cut, times the width of the cut, times the feed rate. The material removal rate is typically measured in cubic centimeters A cubic centimetre (or cubic centimeter in US English) (SI unit symbol: cm3; non-SI abbreviations: cc and cc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Deburring

A burr is a raised edge or small piece of material that remains attached to a workpiece after a modification process. It is usually an unwanted piece of material and is removed with a deburring tool in a process called 'deburring'. Burrs are most commonly created by machining operations, such as Grinding (abrasive cutting), grinding, drilling, Milling machine, milling, engraving or turning. It may be present in the form of a fine wire on the edge of a freshly sharpened tool or as a raised portion of a surface; this type of burr is commonly formed when a hammer strikes a surface. Deburring accounts for a significant portion of manufacturing costs. In the printmaking technique of drypoint, burr, which gives a rich fuzzy quality to the engraved line, is highly desirable—the great problem with the drypoint medium is that the burr rapidly diminishes after as few as ten impressions are printed. Types There are three types of burrs that can be formed from machining operations: ''Poi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grinding (abrasive Cutting)

Grinding is a type of abrasive machining process which uses a grinding wheel as cutting tool. A wide variety of machines are used for grinding, best classified as portable or stationary: * Portable power tools such as angle grinders, die grinders and cut-off saws * Stationary power tools such as bench grinders and cut-off saws * Stationary hydro- or hand-powered sharpening stones Milling practice is a large and diverse area of manufacturing and toolmaking. It can produce very fine finishes and very accurate dimensions; yet in mass production contexts, it can also rough out large volumes of metal quite rapidly. It is usually better suited to the machining of very hard materials than is "regular" machining (that is, cutting larger chips with cutting tools such as tool bits or milling cutters), and until recent decades it was the only practical way to machine such materials as hardened steels. Compared to "regular" machining, it is usually better suited to taking very ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polishing (metalworking)

Polishing and buffing are finishing processes for smoothing a workpiece's surface using an abrasive and a work wheel or a leather strop. Technically, ''polishing'' refers to processes that uses an abrasive that is glued to the work wheel, while ''buffing'' uses a loose abrasive applied to the work wheel. Polishing is a more aggressive process, while buffing is less harsh, which leads to a smoother, brighter finish.Oberg, p. 1439. A common misconception is that a polished surface has a mirror-bright finish, however, most mirror-bright finishes are actually buffed. Polishing is often used to enhance the appearance of an item, prevent contamination of instruments, remove oxidation, create a reflective surface, or prevent corrosion in pipes. In metallography and metallurgy, polishing is used to create a flat, defect-free surface for examination of a metal's microstructure under a microscope. Silicon-based polishing pads or a diamond solution can be used in the polishing process. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |