|

Air Compressor

An air compressor is a machine that takes ambient air from the surroundings and discharges it at a higher pressure. It is an application of a gas compressor and a Pneumatics, pneumatic device that energy conversion, converts mechanical power (from an electric motor, Diesel engine, diesel or gasoline engine, etc.) into potential energy stored in compressed air, which has many uses. A common application is to compress air into a storage tank, for immediate or later use. When the delivery pressure reaches its set upper limit, the compressor is shut off, or the excess air is released through an overpressure valve. The compressed air is stored in the tank until it is needed. The pressure energy provided by the compressed air can be used for a variety of applications such as pneumatic tools as it is released. When tank pressure reaches its lower limit, the air compressor turns on again and re-pressurizes the tank. A compressor is different from a pump because it works on a gas, while pum ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

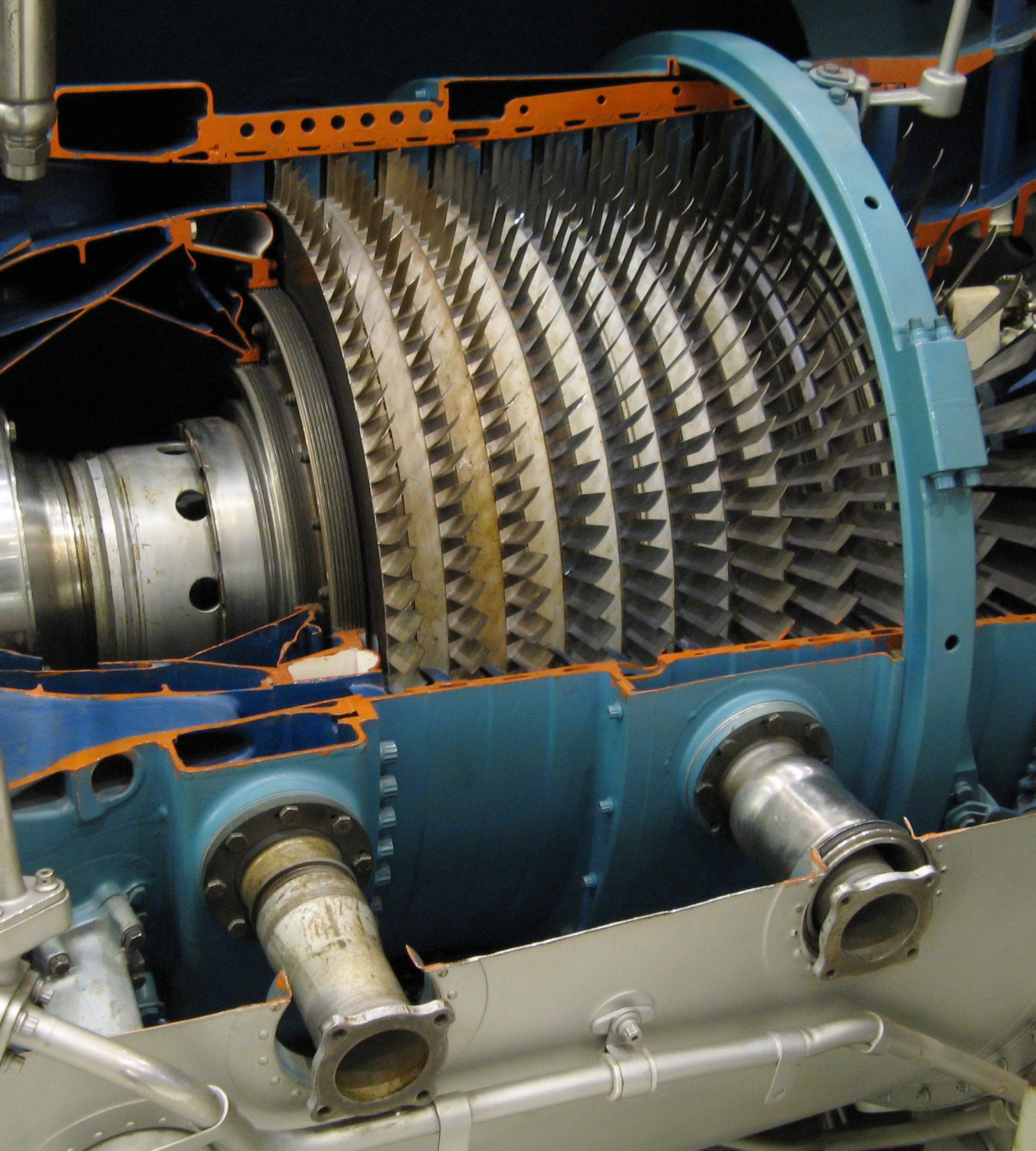

Axial Compressor

An axial compressor is a gas compressor that can continuously pressurize gases. It is a rotating, airfoil-based compressor in which the gas or working fluid principally flows parallel to the axis of rotation, or axially. This differs from other rotating compressors such as centrifugal compressor, axi-centrifugal compressors and mixed-flow compressors where the fluid flow will include a "radial component" through the compressor. The energy level of the fluid increases as it flows through the compressor due to the action of the rotor blades which exert a torque on the fluid. The stationary blades slow the fluid, converting the circumferential component of flow into pressure. Compressors are typically driven by an electric motor or a steam or a gas turbine. Axial flow compressors produce a continuous flow of compressed gas, and have the benefits of high efficiency and large mass flow rate, particularly in relation to their size and cross-section. They do, however, require several ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Air Cooling

Air cooling is a method of dissipating heat. It works by expanding the surface area or increasing the flow of air over the object to be cooled, or both. An example of the former is to add cooling fins to the surface of the object, either by making them integral or by attaching them tightly to the object's surface (to ensure efficient heat transfer). In the case of the latter, it is done by using a fan blowing air into or onto the object one wants to cool. The addition of fins to a heat sink increases its total surface area, resulting in greater cooling effectiveness. There are two types of cooling pads that can be used for air cooling: one is the honeycomb design and another one is excelsior. In all cases, the air has to be cooler than the object or surface from which it is expected to remove heat. This is due to the second law of thermodynamics, which states that heat will only move spontaneously from a hot reservoir (the heat sink) to a cold reservoir (the air). Derating at ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Waste Heat

Waste heat is heat that is produced by a machine, or other process that uses energy, as a byproduct of doing work. All such processes give off some waste heat as a fundamental result of the laws of thermodynamics. Waste heat has lower utility (or in thermodynamics lexicon a lower exergy or higher entropy) than the original energy source. Sources of waste heat include all manner of human activities, natural systems, and all organisms, for example, incandescent light bulbs get hot, a refrigerator warms the room air, a building gets hot during peak hours, an internal combustion engine generates high-temperature exhaust gases, and electronic components get warm when in operation. Instead of being "wasted" by release into the ambient environment, sometimes waste heat (or cold) can be used by another process (such as using hot engine coolant to heat a vehicle), or a portion of heat that would otherwise be wasted can be reused in the same process if make-up heat is added to the sys ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Adiabatic Heating

An adiabatic process (''adiabatic'' ) is a type of thermodynamic process that occurs without transferring heat between the thermodynamic system and its environment. Unlike an isothermal process, an adiabatic process transfers energy to the surroundings only as work and/or mass flow.. A translation may be founhere. Also a mostly reliabltranslation is to be foundin As a key concept in thermodynamics, the adiabatic process supports the theory that explains the first law of thermodynamics. The opposite term to "adiabatic" is ''diabatic''. Some chemical and physical processes occur too rapidly for energy to enter or leave the system as heat, allowing a convenient "adiabatic approximation".Bailyn, M. (1994), pp. 52–53. For example, the adiabatic flame temperature uses this approximation to calculate the upper limit of flame temperature by assuming combustion loses no heat to its surroundings. In meteorology, adiabatic expansion and cooling of moist air, which can be triggered by w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Axial Compressor

An axial compressor is a gas compressor that can continuously pressurize gases. It is a rotating, airfoil-based compressor in which the gas or working fluid principally flows parallel to the axis of rotation, or axially. This differs from other rotating compressors such as centrifugal compressor, axi-centrifugal compressors and mixed-flow compressors where the fluid flow will include a "radial component" through the compressor. The energy level of the fluid increases as it flows through the compressor due to the action of the rotor blades which exert a torque on the fluid. The stationary blades slow the fluid, converting the circumferential component of flow into pressure. Compressors are typically driven by an electric motor or a steam or a gas turbine. Axial flow compressors produce a continuous flow of compressed gas, and have the benefits of high efficiency and large mass flow rate, particularly in relation to their size and cross-section. They do, however, require several ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Centrifugal Compressor

Centrifugal compressors, sometimes called impeller compressors or radial compressors, are a sub-class of dynamic axisymmetric work-absorbing turbomachinery. They achieve pressure rise by adding energy to the continuous flow of fluid through the rotor/impeller. The equation in the next section shows this specific energy input. A substantial portion of this energy is kinetic which is converted to increased potential energy/static pressure by slowing the flow through a diffuser. The static pressure rise in the impeller may roughly equal the rise in the diffuser. Components of a simple centrifugal compressor A simple centrifugal compressor stage has four components (listed in order of throughflow): inlet, impeller/rotor, diffuser, and collector. Figure 1.1 shows each of the components of the flow path, with the flow (working gas) entering the centrifugal impeller axially from left to right. This turboshaft (or turboprop) impeller is rotating counter-clockwise when looking downs ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Horsepower

Horsepower (hp) is a unit of measurement of power, or the rate at which work is done, usually in reference to the output of engines or motors. There are many different standards and types of horsepower. Two common definitions used today are the imperial horsepower as in "hp" or "bhp" which is about , and the metric horsepower as in "cv" or "PS" which is approximately . The electric horsepower "hpE" is exactly , while the boiler horsepower is 9809.5 or 9811 watts, depending on the exact year. The term was adopted in the late 18th century by Scottish engineer James Watt to compare the output of steam engines with the power of draft horses. It was later expanded to include the output power of other power-generating machinery such as piston engines, turbines, and electric motors. The definition of the unit varied among geographical regions. Most countries now use the SI unit watt for measurement of power. With the implementation of the EU Directive 80/181/EEC on 1 January 201 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cubic Feet Per Minute

The cubic foot (symbol ft3 or cu ft) , . is an Imperial unit, imperial and (non-metric) unit of volume, used in the United States and the United Kingdom. It is defined as the volume of a with sides of one () in |

Actual Cubic Feet Per Minute

Actual cubic feet per minute (ACFM) is a unit of volumetric flow. It is commonly used by manufacturers of blowers and compressors.CAGI Performance Verification Data Sheets . This is the actual gas delivery with reference to inlet conditions, whereas cubic foot per minute (CFM) is an unqualified term and should only be used in general and never accepted as a specific definition without explanation. Since the volumetric capacity refers to the volume of or other |

Pounds Per Square Inch

The pound per square inch (abbreviation: psi) or, more accurately, pound-force per square inch (symbol: lbf/in2), is a unit of measurement of pressure or of stress based on avoirdupois units and used primarily in the United States. It is the pressure resulting from a force with magnitude of one pound-force applied to an area of one square inch. In SI units, 1 psi is approximately . The pound per square inch absolute (psia) is used to make it clear that the pressure is relative to a vacuum rather than the ambient atmospheric pressure. Since atmospheric pressure at sea level is around , this will be added to any pressure reading made in air at sea level. The converse is pound per square inch gauge (psig), indicating that the pressure is relative to atmospheric pressure. For example, a bicycle tire pumped up to 65 psig in a local atmospheric pressure at sea level (14.7 psi) will have a pressure of 79.7 psia (14.7 psi + 65 psi). When gauge pressure is referenced to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Standard Cubic Feet Per Minute

Standard cubic feet per minute (SCFM) is the molar flow rate of a gas expressed as a volumetric flow at a "standardized" temperature and pressure thus representing a fixed number of moles of gas regardless of composition and actual flow conditions. It is related to the mass flow rate of the gas by a multiplicative constant which depends only on the molecular weight of the gas. There are different standard conditions for temperature and pressure, so care is taken when choosing a particular standard value. Worldwide, the "standard" condition for pressure is variously defined as an absolute pressure of 101,325 pascals (Atmospheric pressure), 1.0 bar (i.e., 100,000 pascals), 14.73 psia, or 14.696 psia and the "standard" temperature is variously defined as 68 °F, 60 °F, 0 °C, 15 °C, 20 °C, or 25 °C. The relative humidity (e.g., 36% or 0%) is also included in some definitions of standard conditions. In Europe, the standard temperature ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |