|

Abrasive Machining

Abrasive machining is a machining process where material is removed from a workpiece using a multitude of small abrasive particles. Common examples include grinding, honing, and polishing. Abrasive processes are usually expensive, but capable of tighter tolerances and better surface finish than other machining processes Mechanics of abrasive machining Abrasive machining works by forcing the abrasive particles, or grains, into the surface of the workpiece so that each particle cuts away a small bit of material. Abrasive machining is similar to conventional machining, such as milling or turning, because each of the abrasive particles acts like a miniature cutting tool. However, unlike conventional machining the grains are much smaller than a cutting tool, and the geometry and orientation of individual grains are not well defined. As a result, abrasive machining is less power efficient and generates more heat. The grain size may be different based on the machining. For rough grinding, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machining

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which utilizes machine tools, in contrast to ''additive manufacturing'' (e.g. 3D printing processes, 3D printing), which uses controlled addition of material. Machining is a major process of the manufacture of many metal products, but it can also be used on other materials such as wood, plastic, ceramic, and composite material, composites. A person who specializes in machining is called a machinist. As a commercial venture, machining is generally performed in a machine shop, which consists of one or more workrooms containing primary machine tools. Although a machine shop can be a standalone operation, many businesses maintain internal machine shops or tool rooms that support their specialized needs. Much modern-day machining uses Numerical control, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mass Finishing

Mass finishing is a group of manufacturing processes that allow large quantities of parts to be simultaneously finished. The goal of this type of finishing is to burnish, deburr, clean, radius, de-flash, descale, remove rust, polish, brighten, surface harden, prepare parts for further finishing, or break off die cast runners. The two main types of mass finishing are tumble finishing, also known as barrel finishing, and vibratory finishing.Degarmo, pp. 781–784. Both involve the use of a cyclical action to create grinding contact between surfaces. Sometimes the workpieces are finished against each other; however, usually a finishing medium is used. Mass finishing can be performed dry or wet; wet processes have liquid lubricants, cleaners, or abrasives, while dry processes do not. Cycle times can be as short as 10 minutes for nonferrous workpieces or as long as 2 hours for hardened steel. Mass finishing processes can be configured as either batch systems, in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Borazon

Borazon is a brand name of a cubic form of boron nitride (cBN). Its color ranges from black to brown and gold. It is one of the hardest known materials, along with various forms of diamond and other kinds of boron nitride. Borazon is a crystal created by heating equal quantities of boron and nitrogen at temperatures greater than 1800 °C (3300 °F) at 7 GPa (1 million lbf/in2). Borazon was first produced in 1957 by Robert H. Wentorf, Jr., a physical chemist working for the General Electric. In 1969, General Electric adopted the name Borazon as its trademark for the material. The trademark is now owned by Diamond Innovations, doing business aHyperion Materials & Technologies, Inc. and Borazon is manufactured only by Hyperion Materials & Technologies. Uses and production Borazon has a number of uses , such as: cutting tools, dies, punches, shears, knives, saw blades, bearing rings, needles, rollers, spacers, balls, pump and compressor parts, engine and drive ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

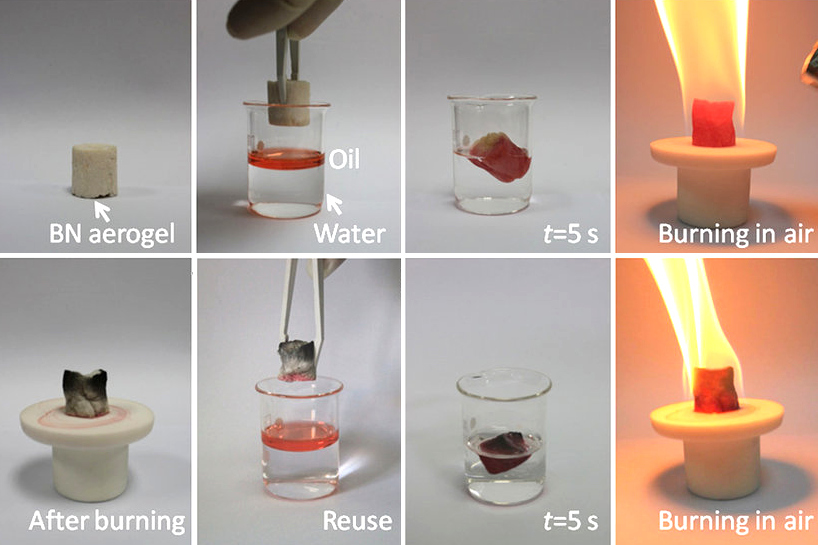

Cubic Boron Nitride

Boron nitride is a thermally and chemically resistant refractory compound of boron and nitrogen with the chemical formula B N. It exists in various crystalline forms that are isoelectronic to a similarly structured carbon lattice. The hexagonal form corresponding to graphite is the most stable and soft among BN polymorphs, and is therefore used as a lubricant and an additive to cosmetic products. The cubic ( zincblende aka sphalerite structure) variety analogous to diamond is called c-BN; it is softer than diamond, but its thermal and chemical stability is superior. The rare wurtzite BN modification is similar to lonsdaleite but slightly softer than the cubic form. Because of excellent thermal and chemical stability, boron nitride ceramics are used in high-temperature equipment and metal casting. Boron nitride has potential use in nanotechnology. History Boron nitride was discovered by chemistry teacher of the Liverpool Institute in 1842 via reduction of boric acid with ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

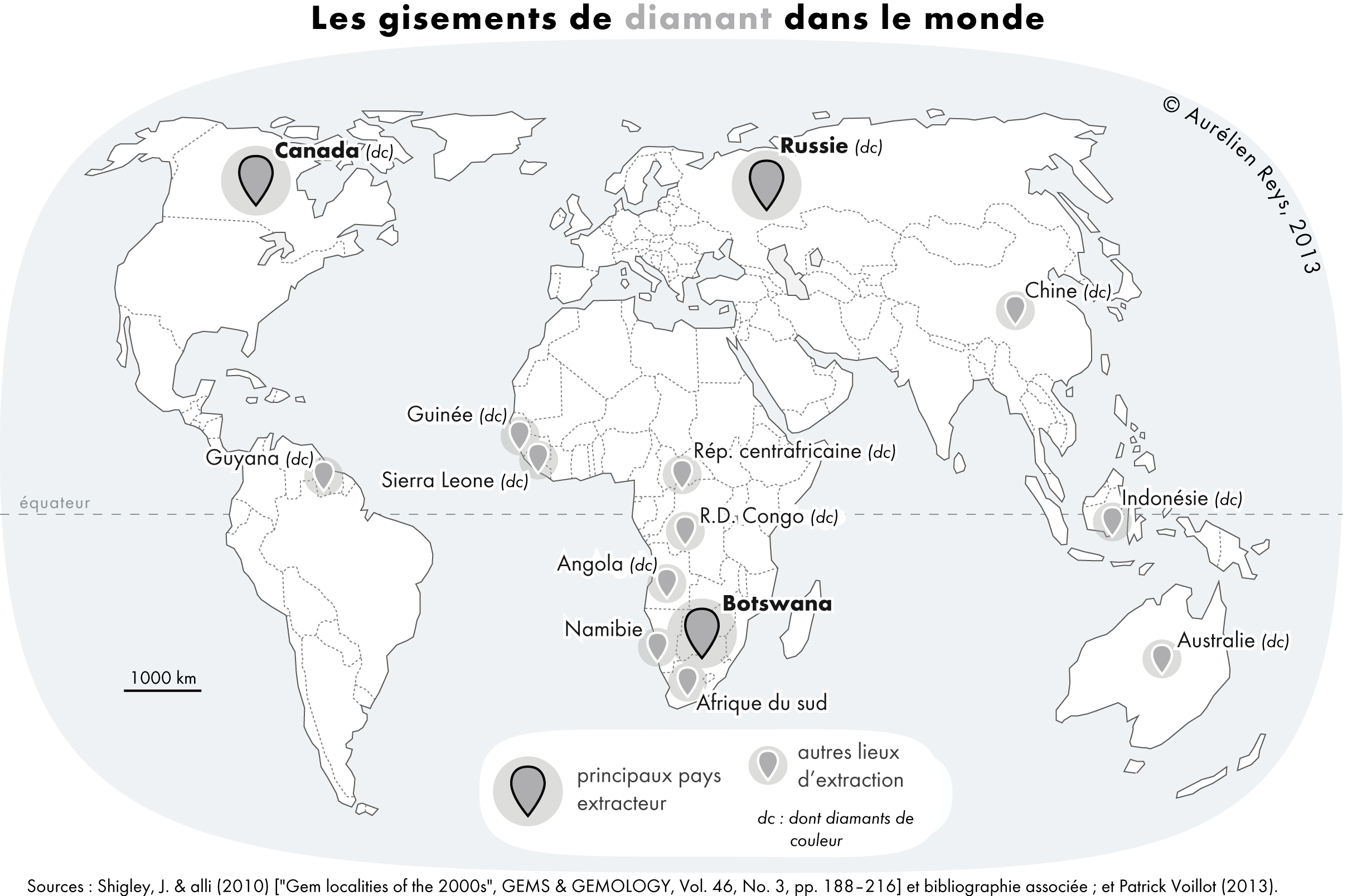

Diamond

Diamond is a Allotropes of carbon, solid form of the element carbon with its atoms arranged in a crystal structure called diamond cubic. Diamond is tasteless, odourless, strong, brittle solid, colourless in pure form, a poor conductor of electricity, and insoluble in water. Another solid form of carbon known as graphite is the Chemical stability, chemically stable form of carbon at Standard temperature and pressure, room temperature and pressure, but diamond is metastable and converts to it at a negligible rate under those conditions. Diamond has the highest Scratch hardness, hardness and thermal conductivity of any natural material, properties that are used in major industrial applications such as cutting and polishing tools. Because the arrangement of atoms in diamond is extremely rigid, few types of impurity can contaminate it (two exceptions are boron and nitrogen). Small numbers of lattice defect, defects or impurities (about one per million of lattice atoms) can color ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel Abrasive

Steel abrasives are steel particles that are used as abrasive or peening media. They are usually available in two different shapes (shot and grit) that address different industrial applications. Steel shot refers to spherical grains made of molten steel through an atomization (" granulation") process, available in different sizes and hardnesses. Steel grit characterizes grains with a predominantly angular shape. These grains are obtained by crushing steel shot, therefore they exhibit sharp edges and broken sections. Harder than steel shot, it is also available in different sizes and hardnesses. Properties Most steel abrasives are made of a high-carbon steel composition, the best compromise between mechanical properties, efficiency and durability. The most important properties for steel abrasives are hardness, grain size and shape, toughness and cleanliness (lack of oxides, contaminants, etc.). Recyclability and environmental impact The recyclability of steel shot and grit ra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sand

Sand is a granular material composed of finely divided mineral particles. Sand has various compositions but is usually defined by its grain size. Sand grains are smaller than gravel and coarser than silt. Sand can also refer to a textural class of soil or soil type; i.e., a soil containing more than 85 percent sand-sized particles by mass. The composition of sand varies, depending on the local rock sources and conditions, but the most common constituent of sand in inland continental settings and non-tropical coastal settings is silica (silicon dioxide, or SiO2), usually in the form of quartz. Calcium carbonate is the second most common type of sand. One such example of this is aragonite, which has been created over the past 500million years by various forms of life, such as coral and shellfish. It is the primary form of sand apparent in areas where reefs have dominated the ecosystem for millions of years, as in the Caribbean. Somewhat more rarely, sand may be composed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pumice

Pumice (), called pumicite in its powdered or dust form, is a volcanic rock that consists of extremely vesicular rough-textured volcanic glass, which may or may not contain crystals. It is typically light-colored. Scoria is another vesicular volcanic rock that differs from pumice in having larger vesicles, thicker vesicle walls, and being dark colored and denser.Jackson, J.A., J. Mehl, and K. Neuendorf (2005) ''Glossary of Geology'' American Geological Institute, Alexandria, Virginia. 800 pp. McPhie, J., M. Doyle, and R. Allen (1993) ''Volcanic Textures A guide to the interpretation of textures in volcanic rocks'' Centre for Ore Deposit and Exploration Studies, University of Tasmania, Hobart, Tasmania..198 pp. Pumice is created when super-heated, highly pressurized rock is rapidly ejected from a volcano. The unusual foamy configuration of pumice happens because of simultaneous rapid cooling and rapid depressurization. The depressurization creates bubbles by lowering the sol ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Emery (mineral)

Emery, or corundite, is a dark granular rock used to make an abrasive powder. The rock largely consists of corundum (aluminium oxide), mixed with other minerals. Industrial emery may contain a variety of other minerals and synthetic compounds. Crushed or naturally eroded emery (known as ''black sand'') is used as an abrasive. Turkey and Greece are the main suppliers of the world's emery. Description Emery is a granular rock used to make an abrasive powder. It largely consists of corundum (aluminium oxide), mixed with other minerals such as the iron-bearing spinels, hercynite, and magnetite, and also rutile ( titania). Industrial emery may contain a variety of other minerals and synthetic compounds such as magnesia, mullite, and silica. Emery is black or dark grey in colour, less dense than translucent-brown corundum with a specific gravity of between 3.5 and 3.8. Because it can be a mixture of minerals, no definite Mohs hardness can be assigned: the hardness of corundum i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicon Carbide

Silicon carbide (SiC), also known as carborundum (), is a hard chemical compound containing silicon and carbon. A wide bandgap semiconductor, it occurs in nature as the extremely rare mineral moissanite, but has been mass-produced as a powder and crystal since 1893 for use as an abrasive. Grains of silicon carbide can be bonded together by sintering to form very hard ceramics that are widely used in applications requiring high endurance, such as car brakes, car clutches and ceramic plates in bulletproof vests. Large single crystals of silicon carbide can be grown by the Lely method and they can be cut into gems known as synthetic moissanite. Electronic applications of silicon carbide such as light-emitting diodes (LEDs) and Cat's whisker detector, detectors in early radios were first demonstrated around 1907. SiC is used in semiconductor electronics devices that operate at high temperatures or high voltages, or both. Natural occurrence Naturally occurring moissanite is found ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corundum

Corundum is a crystalline form of aluminium oxide () typically containing traces of iron, titanium, vanadium, and chromium. It is a rock (geology), rock-forming mineral. It is a naturally transparency and translucency, transparent material, but can have different colors depending on the presence of transition metal impurities in its crystalline structure. Corundum has two primary gemstone, gem varieties: ruby and sapphire. Rubies are red due to the presence of chromium, and sapphires exhibit a range of colors depending on what transition metal is present. A rare type of sapphire, Sapphire#Padparadscha, padparadscha sapphire, is pink-orange. The name "corundum" is derived from the Tamil language, Tamil-Dravidian languages, Dravidian word ''kurundam'' (ruby-sapphire) (appearing in Sanskrit as ''kuruvinda''). Because of corundum's hardness (pure corundum is defined to have 9.0 on the Mohs scale), it can scratch almost all other minerals. Emery (rock), Emery, a variety of corundum w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminium Oxide

Aluminium oxide (or aluminium(III) oxide) is a chemical compound of aluminium and oxygen with the chemical formula . It is the most commonly occurring of several Aluminium oxide (compounds), aluminium oxides, and specifically identified as aluminium oxide. It is commonly called alumina and may also be called aloxide, aloxite, ALOX or alundum in various forms and applications and alumina is refined from bauxite. It occurs naturally in its crystalline Polymorphism (materials science), polymorphic phase (matter), phase α-Al2O3 as the mineral corundum, varieties of which form the precious gemstones ruby and sapphire,which have an alumina content approaching 100%. Al2O3 is used as feedstock to produce aluminium metal, as an abrasive owing to its hardness, and as a refractory material owing to its high melting point. Natural occurrence Corundum is the most common naturally occurring crystallinity, crystalline form of aluminium oxide. ruby, Rubies and sapphires are gem-quality forms o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |