|

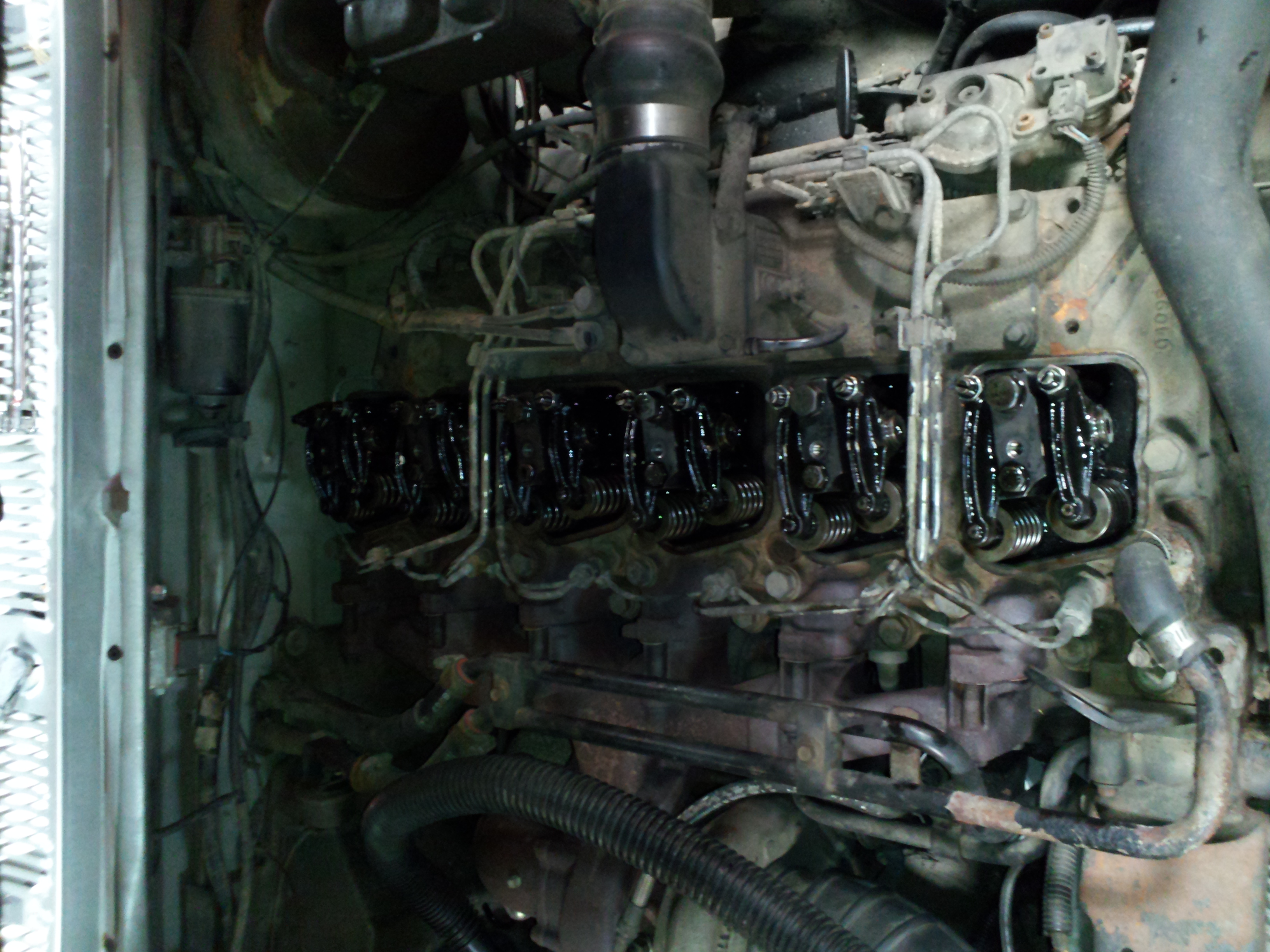

6.7L ISB Cummins

The Cummins B Series is a family of diesel engines produced by American manufacturer Cummins. In production since 1984, the B series engine family is intended for multiple applications on and off-highway, light-duty, and medium-duty. In the automotive industry, it is best known for its use in school buses, public service buses (most commonly the Dennis Dart and the Alexander Dennis Enviro400) in the United Kingdom, and Dodge/ Ram pickup trucks. Since its introduction, three generations of the B series engine have been produced, offered in both inline-four and inline-six configurations in multiple displacements. General engine features The B-series features engine bores machined directly into the block (rather than the wet liners used on earlier Cummins engines). It is also set apart by the use of a shallow one-piece head, requiring closer tolerances than in other Cummins products. Unlike earlier diesel engines the B-series Cummins used direct injection and did not need glow p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cummins

Cummins Inc. is an American multinational corporation, multinational corporation that designs, manufactures, and distributes engines, electric vehicle components, and power generation products. Cummins also services engines and related equipment, including Fuel injection, fuel systems, air handling systems Control system, controls, filtration, Emission control system, emission control, Electricity generation, electrical power generation systems, and Engine control unit, engine control units. Headquartered in Columbus, Indiana, Cummins sells in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributors and approximately 7,200 dealers. History The Cummins Engine Company was founded in Columbus, Indiana on February 3, 1919, by mechanic Clessie Cummins and banker William Glanton Irwin. The company focused on developing the diesel engine, which was invented 20 years earlier. Despite several well-publicized endu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dennis Dart

The Dennis Dart is a Rear-engine design, rear-engined single-decker bus, single-decker midibus chassis that was introduced by Dennis Specialist Vehicles, Dennis of Guildford, England, in 1989, replacing the Dennis Domino. Initially built as a high-floor design, in 1996 the Low-floor bus, low-floor second generation Dennis Dart SLF was launched. In 2001, production of the Dart SLF passed to TransBus International, during which time it was sold as the TransBus Dart SLF; Alexander Dennis took over production in 2004, renaming the product as the Alexander Dennis Dart SLF. More than 12,600Darts were produced in total during a 19-year production run. Most were purchased by United Kingdom operators, although examples were sold in Europe, North America, Australia and Hong Kong. In the United States, the Dart SLF, with Alexander ALX200 bodywork, was built and sold by Thomas Built Buses as the Thomas SLF 200. The first generation Dart ceased production in 1998. Production of the Dart SL ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbodiesel

The term turbo-diesel, also written as turbodiesel and turbo diesel, refers to any diesel engine equipped with a turbocharger. As with other engine types, turbocharging a diesel engine can significantly increase its efficiency and power output, especially when used in combination with an intercooler. Turbocharging of diesel engines began in the 1920s with large marine and stationary engines. Trucks became available with turbo-diesel engines in the mid-1950s, followed by passenger cars in the late 1970s. Since the 1990s, the compression ratio of turbo-diesel engines has been dropping. Principle Diesel engines are typically well suited to turbocharging due to two factors: * A "lean" air–fuel ratio, caused when the turbocharger supplies excess air into the engine, is not a problem for diesel engines, because the torque control is dependent on the mass of fuel that is injected into the combustion chamber (i.e. air-fuel ratio), rather than the quantity of the air-fuel mixture. * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Multi-valve

A multi-valve or multivalve Four-stroke engine, four-stroke internal combustion engine is one where each Cylinder (engine), cylinder has ''more than two'' poppet valve, valves – more than the minimum required of one of each, for the purposes of air and fuel intake, and Exhaust system, venting exhaust gases. Multi-valve engines were conceived to improve one or both of these, often called "better breathing", and with the added benefit of more valves that are smaller, thus having less mass in motion (per individual valve and spring), may also be able to operate at higher revolutions per minute (RPM) than a two-valve engine, delivering even more intake an/or exhaust per unit of time, thus potentially more power (physics), power. Multi-valve rationale Multi-valve engine design A multi-valve engine design has three, four, or five poppet valves per cylinder, to achieve greater performance. In automotive engineering, any four-stroke internal combustion engine needs at least two v ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbocharger

In an internal combustion engine, a turbocharger (also known as a turbo or a turbosupercharger) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake air, forcing more air into the engine in order to produce more power for a given displacement. Turbochargers are distinguished from superchargers in that a turbocharger is powered by the kinetic energy of the exhaust gases, whereas a is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the inv ...[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Camshaft

A camshaft is a shaft that contains a row of pointed cams in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition systems and early electric motor speed controllers. Camshafts in piston engines are usually made from steel or cast iron, and the shape of the cams greatly affects the engine's characteristics. History Trip hammers are one of the early uses of a form of cam to convert rotating motion, e.g. from a waterwheel, into the reciprocating motion of a hammer used in forging or to pound grain. Evidence for these exists back to the Han dynasty in China, and they were widespread by the medieval period. Camshafts were first described by Ismail al-Jazari in 1206. Once the rotative version of the steam engine was developed in the late 18th century, the operation of the valve gear was usually by an eccentric, which turned the rotation of the crankshaft i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glow Plug (diesel Engine)

In a diesel engine, a glow plug (also spelled glowplug) is a heating device used to aid starting of the engine in cold weather. This device is a pencil-shaped piece of metal with an electric heating element at the tip. A glowplug system consists of either a single glowplug in the inlet manifold, or one glowplug per cylinder. In older systems, the driver is required to manually activate the glowplug system and wait approximately 20 seconds before starting the engine. Newer systems automatically activate the glowplug(s) before the engine is started and have a quicker warm-up time. Design Glowplugs are typically used as starting-aid devices, when the engine is being cranked by a starter motor, and in most cases switched off when the engine has reached a defined minimum operating temperature. Diesel engines, unlike common spark-ignition engines, do not use spark plugs to ignite the air-fuel mixture. Instead, they rely solely on compression to raise the temperature of the air to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Direct Injection Diesel

The diesel engine, named after the German engineer Rudolf Diesel, is an internal combustion engine in which ignition of diesel fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is called a compression-ignition engine (CI engine). This contrasts with engines using spark plug-ignition of the air-fuel mixture, such as a petrol engine (gasoline engine) or a gas engine (using a gaseous fuel like natural gas or liquefied petroleum gas). Introduction Diesel engines work by compressing only air, or air combined with residual combustion gases from the exhaust (known as exhaust gas recirculation, "EGR"). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases air temperature inside the cylinder so that atomised diesel fuel injected into the combustion chamber ignites. The torque a diesel engine produces is controlled by manipulating the air-fuel ra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |