Wright Etch on:

[Wikipedia]

[Google]

[Amazon]

The Wright etch (also Wright-Jenkins etch) is a preferential etch for revealing defects in <100>- and <111>-oriented, p- and n-type

The Wright etch (also Wright-Jenkins etch) is a preferential etch for revealing defects in <100>- and <111>-oriented, p- and n-type

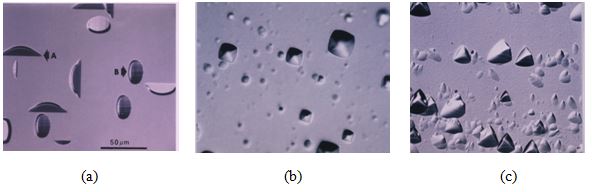

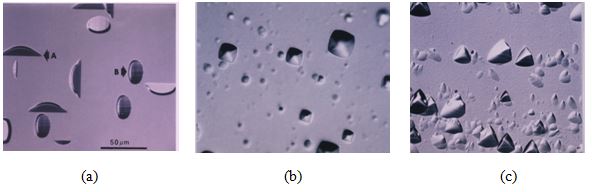

Figure 1 (a) shows oxidation-induced stacking faults on a <100>-oriented, 7-10 Ω-cm, boron-doped wafer after 30 minutes Wright etch (the A arrow in this figure points to the shape of faults that intersect the surface, while B points to bulk faults). Figure 1 (b) and (c) show dislocation pits on <100>- and <111>-oriented wafers respectively after 20 minutes Wright etch.

Figure 1 (a) shows oxidation-induced stacking faults on a <100>-oriented, 7-10 Ω-cm, boron-doped wafer after 30 minutes Wright etch (the A arrow in this figure points to the shape of faults that intersect the surface, while B points to bulk faults). Figure 1 (b) and (c) show dislocation pits on <100>- and <111>-oriented wafers respectively after 20 minutes Wright etch.

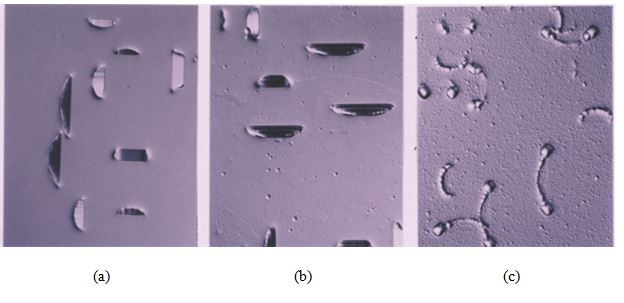

Figure 2 shows a comparison of oxidation-induced stacking fault delineation on <100>-oriented wafers after Wright etch, Secco and Sirtl etch respectively.

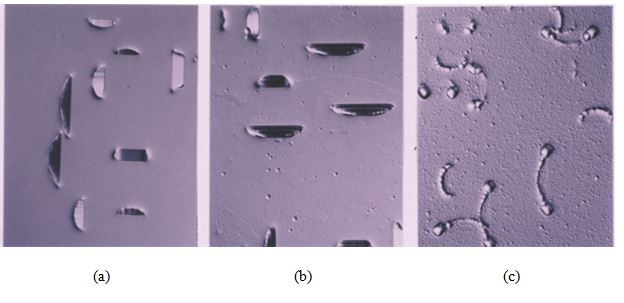

Figure 3 shows a comparison of dislocation pits delineation on <100>-oriented wafers after Wright etch, Secco and Sirtl etch. The final figure 4 shows a comparison of dislocation pits revealed on a <111>-oriented wafer after etching with Wright etch, Secco and Sirtl etch respectively.

Figure 2 shows a comparison of oxidation-induced stacking fault delineation on <100>-oriented wafers after Wright etch, Secco and Sirtl etch respectively.

Figure 3 shows a comparison of dislocation pits delineation on <100>-oriented wafers after Wright etch, Secco and Sirtl etch. The final figure 4 shows a comparison of dislocation pits revealed on a <111>-oriented wafer after etching with Wright etch, Secco and Sirtl etch respectively.

Figure 3 shows a comparison of dislocation delineation on a <100>-oriented, 10-20 Ω-cm, boron doped wafer after oxidation and preferential etching. (a) After 20 minutes Wright etch, (b) 10 minutes Secco etch and (c) 6 minutes Sirtl etch.

Figure 3 shows a comparison of dislocation delineation on a <100>-oriented, 10-20 Ω-cm, boron doped wafer after oxidation and preferential etching. (a) After 20 minutes Wright etch, (b) 10 minutes Secco etch and (c) 6 minutes Sirtl etch.

Figure 4 shows a comparison of dislocation delineation on a <111>-oriented, 10-20 Ω-cm, boron-doped wafer after oxidation and preferential etching. (a) After 10 minutes Wright etch, (b) 10 minutes Secco etch and (c) 3 minutes Sirtl etch. The arrows indicate slip direction.

Figure 4 shows a comparison of dislocation delineation on a <111>-oriented, 10-20 Ω-cm, boron-doped wafer after oxidation and preferential etching. (a) After 10 minutes Wright etch, (b) 10 minutes Secco etch and (c) 3 minutes Sirtl etch. The arrows indicate slip direction.

The Wright etch (also Wright-Jenkins etch) is a preferential etch for revealing defects in <100>- and <111>-oriented, p- and n-type

The Wright etch (also Wright-Jenkins etch) is a preferential etch for revealing defects in <100>- and <111>-oriented, p- and n-type silicon

Silicon is a chemical element; it has symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic lustre, and is a tetravalent metalloid (sometimes considered a non-metal) and semiconductor. It is a membe ...

wafers used for making transistors

A transistor is a semiconductor device used to Electronic amplifier, amplify or electronic switch, switch electrical signals and electric power, power. It is one of the basic building blocks of modern electronics. It is composed of semicondu ...

, microprocessors

A microprocessor is a computer processor for which the data processing logic and control is included on a single integrated circuit (IC), or a small number of ICs. The microprocessor contains the arithmetic, logic, and control circuitry r ...

, memories, and other components. Revealing, identifying, and remedying such defects is essential for progress along the path predicted by Moore's law

Moore's law is the observation that the Transistor count, number of transistors in an integrated circuit (IC) doubles about every two years. Moore's law is an observation and Forecasting, projection of a historical trend. Rather than a law of ...

. It was developed by Margaret Wright Jenkins (1936-2018) in 1976 while working in research and development

Research and development (R&D or R+D), known in some countries as OKB, experiment and design, is the set of innovative activities undertaken by corporations or governments in developing new services or products. R&D constitutes the first stage ...

at Motorola Inc. in Phoenix, AZ. It was published in 1977. This etchant reveals clearly defined oxidation

Redox ( , , reduction–oxidation or oxidation–reduction) is a type of chemical reaction in which the oxidation states of the reactants change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is ...

-induced stacking faults, dislocations, swirls and striations with minimum surface roughness or extraneous pitting. These defects are known causes of shorts and current leakage in finished semiconductor

A semiconductor is a material with electrical conductivity between that of a conductor and an insulator. Its conductivity can be modified by adding impurities (" doping") to its crystal structure. When two regions with different doping level ...

devices (such as transistors) should they fall across isolated junctions. A relatively low etch rate (~1 micrometre per minute) at room temperature provides etch control. The long shelf life of this etchant allows the solution to be stored in large quantities.

Etch formula

The composition of the Wright etch is as follows: * 60 ml concentrated HF (hydrofluoric acid

Hydrofluoric acid is a solution of hydrogen fluoride (HF) in water. Solutions of HF are colorless, acidic and highly corrosive. A common concentration is 49% (48–52%) but there are also stronger solutions (e.g. 70%) and pure HF has a boiling p ...

)

* 30 ml concentrated HNO3 (nitric acid

Nitric acid is an inorganic compound with the formula . It is a highly corrosive mineral acid. The compound is colorless, but samples tend to acquire a yellow cast over time due to decomposition into nitrogen oxide, oxides of nitrogen. Most com ...

)

* 30 ml of 5 mole CrO3 (mix 1 gram of chromium trioxide

Chromium trioxide (also known as chromium(VI) oxide or chromic anhydride) is an inorganic compound with the formula . It is the acidic anhydride of chromic acid, and is sometimes marketed under the same name.

This compound is a dark-purple solid ...

per 2 ml of water; the numbers are suspiciously round because the molecular weight of chromium trioxide

Chromium trioxide (also known as chromium(VI) oxide or chromic anhydride) is an inorganic compound with the formula . It is the acidic anhydride of chromic acid, and is sometimes marketed under the same name.

This compound is a dark-purple solid ...

is almost exactly 100).

* 2 grams Cu(NO3)2 . 3H2O ( Copper II Nitrate Trihydrate)

* 60 ml concentrated CH3COOH (acetic acid

Acetic acid , systematically named ethanoic acid , is an acidic, colourless liquid and organic compound with the chemical formula (also written as , , or ). Vinegar is at least 4% acetic acid by volume, making acetic acid the main compone ...

)

* 60 ml H2O (deionized water

Purified water is water that has been mechanically filtered or processed to remove impurities and make it suitable for use. Distilled water was, formerly, the most common form of purified water, but, in recent years, water is more frequently pu ...

)

In mixing the solution, the best results are obtained by first dissolving the copper nitrate in the given amount of water; otherwise the order of mixing is not critical.

Etch mechanism

The Wright etch consistently produces well-defined etch figures of common defects on silicon surfaces. This effect is attributed to the interactions of the selectedchemical

A chemical substance is a unique form of matter with constant chemical composition and characteristic properties. Chemical substances may take the form of a single element or chemical compounds. If two or more chemical substances can be combin ...

s in the formula. Robbins and Schwartz described chemical etching of silicon in detail using an HF, HNO3 and H2O system; and an HF, HNO3, H2O and CH3COOH (acetic acid) system. Briefly, the etching of silicon is a two-step process. First, the top surface of the silicon is converted into a soluble oxide

An oxide () is a chemical compound containing at least one oxygen atom and one other element in its chemical formula. "Oxide" itself is the dianion (anion bearing a net charge of −2) of oxygen, an O2− ion with oxygen in the oxidation st ...

by a suitable oxidizing agent(s). Then the resulting oxide layer is removed from the surface by dissolution in a suitable solvent

A solvent (from the Latin language, Latin ''wikt:solvo#Latin, solvō'', "loosen, untie, solve") is a substance that dissolves a solute, resulting in a Solution (chemistry), solution. A solvent is usually a liquid but can also be a solid, a gas ...

, usually HF. This is a continuous process during the etch cycle. In order to delineate a crystal defect, the defect area must be oxidized at a slower or faster rate than the surrounding area thereby forming a mound or pit during the preferential etch process.

In the present system, the silicon is oxidized with HNO3, CrO3 solution (which in this case contains the Cr2O72− dichromate ion, since the pH is low - see the phase diagram in chromic acid

Chromic acid is a chemical compound with the chemical formula . It is also a jargon for a solution formed by the addition of sulfuric acid to aqueous solutions of dichromate. It consists at least in part of chromium trioxide.

The term "chromic ...

) and Cu (NO3)2. The dichromate ion, a strong oxidizing agent, is considered to be the principal oxidizing agent

An oxidizing agent (also known as an oxidant, oxidizer, electron recipient, or electron acceptor) is a substance in a redox chemical reaction that gains or " accepts"/"receives" an electron from a (called the , , or ''electron donor''). In ot ...

. The ratio of HNO3 to CrO3 solution stated in the formula produces a superior etched surface. Other ratios produce less desirable finishes. With the addition of a small amount of Cu (NO3)2, the definition of the defect was enhanced. Therefore, it is believed that the Cu (NO3)2 affects the localized differential oxidation rate at the defect site. The addition of the acetic acid gave the background surface of the etched silicon a smooth finish. It is theorized that this effect is attributed to the wetting action of the acetic acid which prevents the formation of bubbles during etching.

All experimental preferential etching to show defects was done on cleaned and oxidized wafers. All oxidations were performed at 1200 °C in steam for 75 minutes. Figure 1 (a) shows oxidation-induced stacking faults in <100>-oriented wafers after 30 minutes Wright etch, (b) and (c) show dislocation pits on <100>- and <111>-oriented wafers respectively after 20 minutes Wright etch.

Figure 1 (a) shows oxidation-induced stacking faults on a <100>-oriented, 7-10 Ω-cm, boron-doped wafer after 30 minutes Wright etch (the A arrow in this figure points to the shape of faults that intersect the surface, while B points to bulk faults). Figure 1 (b) and (c) show dislocation pits on <100>- and <111>-oriented wafers respectively after 20 minutes Wright etch.

Figure 1 (a) shows oxidation-induced stacking faults on a <100>-oriented, 7-10 Ω-cm, boron-doped wafer after 30 minutes Wright etch (the A arrow in this figure points to the shape of faults that intersect the surface, while B points to bulk faults). Figure 1 (b) and (c) show dislocation pits on <100>- and <111>-oriented wafers respectively after 20 minutes Wright etch.

Summary

This etch process is a quick and reliable method of determining the integrity of pre-processed polishedsilicon wafer

In electronics, a wafer (also called a slice or substrate) is a thin slice of semiconductor, such as a crystalline silicon (c-Si, silicium), used for the fabrication of integrated circuits and, in photovoltaics, to manufacture solar cells.

The ...

s or to reveal defects that may be induced at any point during wafer processing. It has been demonstrated that Wright etch is superior in revealing stacking faults and dislocation etch figures when compared with those revealed by Sirtl and Secco etchings.

This etch is widely used in failure analysis of electrical devices at various wafer processing stages. In comparison, the Wright etch was often the preferred etchant to reveal defects in silicon crystals.

Figure 2 shows a comparison of oxidation-induced stacking fault delineation on <100>-oriented wafers after Wright etch, Secco and Sirtl etch respectively.

Figure 3 shows a comparison of dislocation pits delineation on <100>-oriented wafers after Wright etch, Secco and Sirtl etch. The final figure 4 shows a comparison of dislocation pits revealed on a <111>-oriented wafer after etching with Wright etch, Secco and Sirtl etch respectively.

Figure 2 shows a comparison of oxidation-induced stacking fault delineation on <100>-oriented wafers after Wright etch, Secco and Sirtl etch respectively.

Figure 3 shows a comparison of dislocation pits delineation on <100>-oriented wafers after Wright etch, Secco and Sirtl etch. The final figure 4 shows a comparison of dislocation pits revealed on a <111>-oriented wafer after etching with Wright etch, Secco and Sirtl etch respectively.

Figure 3 shows a comparison of dislocation delineation on a <100>-oriented, 10-20 Ω-cm, boron doped wafer after oxidation and preferential etching. (a) After 20 minutes Wright etch, (b) 10 minutes Secco etch and (c) 6 minutes Sirtl etch.

Figure 3 shows a comparison of dislocation delineation on a <100>-oriented, 10-20 Ω-cm, boron doped wafer after oxidation and preferential etching. (a) After 20 minutes Wright etch, (b) 10 minutes Secco etch and (c) 6 minutes Sirtl etch.

Figure 4 shows a comparison of dislocation delineation on a <111>-oriented, 10-20 Ω-cm, boron-doped wafer after oxidation and preferential etching. (a) After 10 minutes Wright etch, (b) 10 minutes Secco etch and (c) 3 minutes Sirtl etch. The arrows indicate slip direction.

Figure 4 shows a comparison of dislocation delineation on a <111>-oriented, 10-20 Ω-cm, boron-doped wafer after oxidation and preferential etching. (a) After 10 minutes Wright etch, (b) 10 minutes Secco etch and (c) 3 minutes Sirtl etch. The arrows indicate slip direction.

References

{{DEFAULTSORT:Wright etch Etching (microfabrication)