Visco-elastic Jets on:

[Wikipedia]

[Google]

[Amazon]

Visco-elastic jets are the jets of viscoelastic fluids, i.e. fluids that disobey Newton's law of

Visco-elastic jets are the jets of viscoelastic fluids, i.e. fluids that disobey Newton's law of

Visco-elastic jets are the jets of viscoelastic fluids, i.e. fluids that disobey Newton's law of

Visco-elastic jets are the jets of viscoelastic fluids, i.e. fluids that disobey Newton's law of Viscocity

The viscosity of a fluid is a measure of its resistance to deformation at a given rate. For liquids, it corresponds to the informal concept of "thickness": for example, syrup has a higher viscosity than water.

Viscosity quantifies the inter ...

. A Viscoelastic fluid that returns to its original shape after the applied stress is released.

Everybody has witnessed a situation where a liquid is poured out of an orifice at a given height and speed, and it hits a solid surface. For example, – dropping of honey onto a bread slice, or pouring shower gel onto one's hand. Honey is a purely viscous, Newtonian fluid: the jet thins continuously and coils regularly.

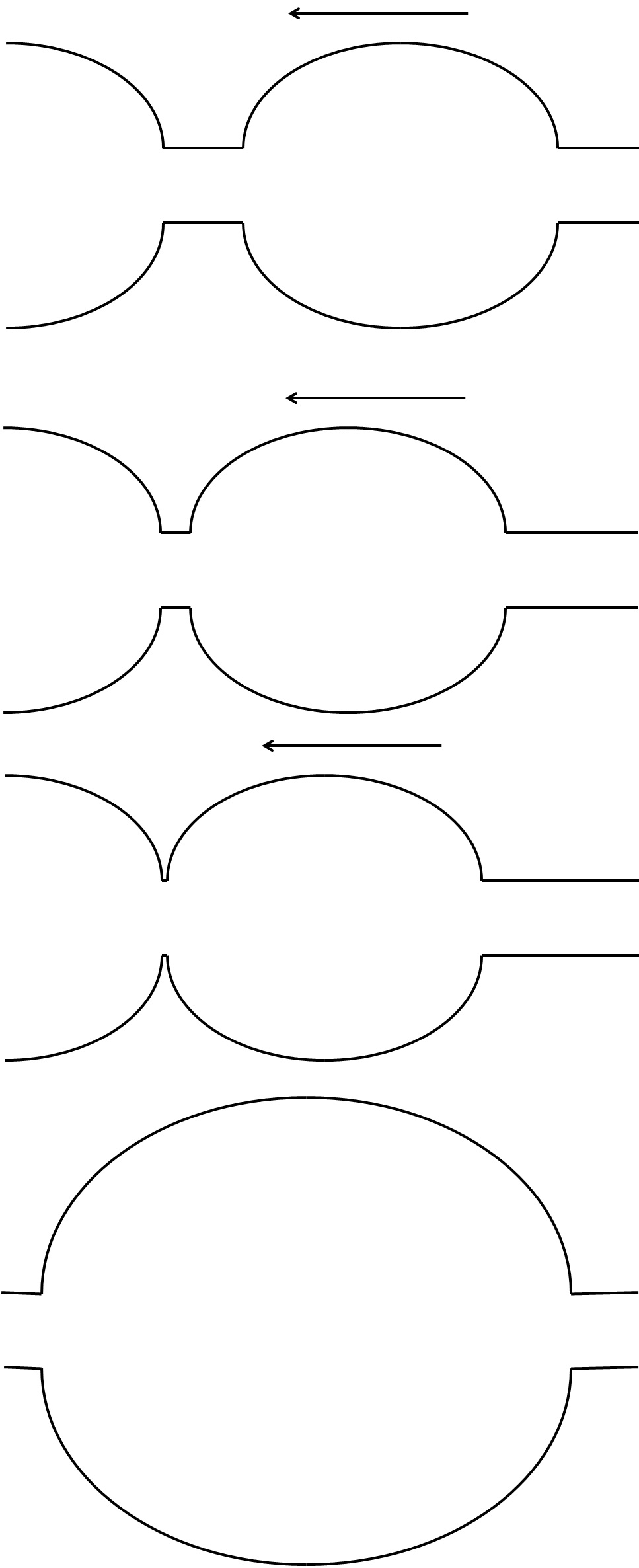

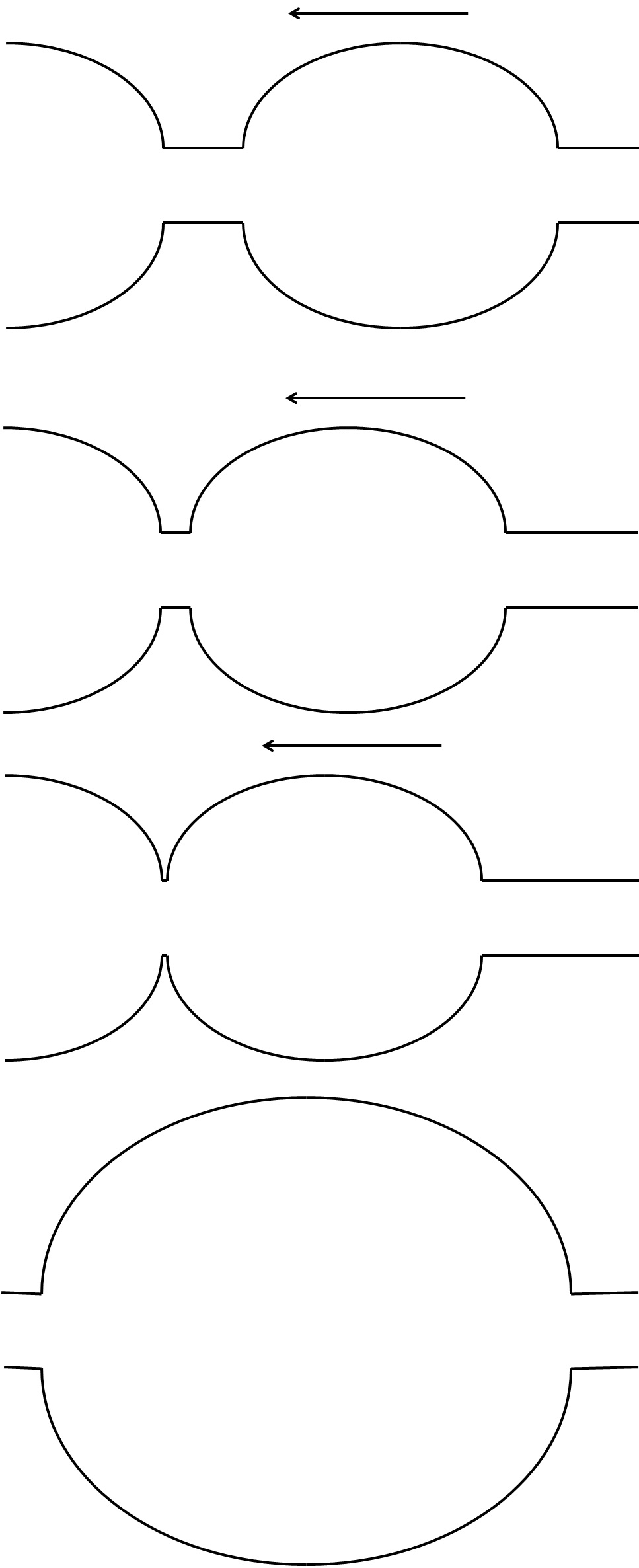

Jets of non-Newtonian Viscoelastic fluids show a novel behaviour. A viscoelastic jet breaks up much more slowly than a Newtonian jet. Typically, it evolves into the so-called beads-on-string structure, where large drops are connected by thin threads. The jet widens at its base (reverse swell phenomenon) and folds back and forth on itself. The slow breakup process provides the viscoelastic jet sufficient time to exhibit some new phenomena, including drop migration, drop oscillation, drop merging and drop draining.

These properties are a result of the interplay of non-Newtonian properties (viscoelasticity, shear-thinning) with gravitational, viscous, and inertial effects in the jets.

Free surface continuous jets of viscoelastic fluids are relevant in many engineering applications involving blood, paints, adhesives or foodstuff and industrial processes like fiber spinning, bottle-filling, oil drilling etc. In many of these processes, an understanding of the instabilities a jet undergoes due to changes in fluid parameters like Reynolds number

In fluid mechanics, the Reynolds number () is a dimensionless quantity that helps predict fluid flow patterns in different situations by measuring the ratio between inertial and viscous forces. At low Reynolds numbers, flows tend to be domi ...

or Deborah number The Deborah number (De) is a dimensionless number, often used in rheology to characterize the fluidity of materials under specific flow conditions. It quantifies the observation that given enough time even a solid-like material might flow, or a flui ...

is essential from process engineering point of view. With the advent of microfluidics, an understanding of the jetting properties of non-Newtonian fluids becomes essential from micro- to macro length scales, and from low to high Reynolds numbers7–9. Like other fluids, When considering viscoelastic flows, the velocity, pressure and stress must satisfy the mass and momentum equation, supplemented with a constitutive equation involving the velocity and stress.

The temporal evolution of a viscoelastic fluid thread depends on the relative magnitude of the viscous, inertial, and elastic stresses and the capillary pressure. To study the inertio-elasto-capillary balance for a jet, two dimensionless parameters are defined: the Ohnesorge number (Oℎ)

:

, which is the inverse of the Reynolds number based on a characteristic capillary velocity and, secondly, the intrinsic Deborah number De,

:

, defined as the ratio of the time scale for elastic stress relaxation, λ, to the “Rayleigh time scale” for inertio-capillary breakup of an inviscid jet, . In these expressions, is the fluid density, is the fluid zero shear viscosity, is the surface tension, is the initial radius of the jet, and is the relaxation time associated with the polymer solution.

Mathematical Equations governing bead formation, filament thinning & breakup in weakly viscoelastic jets

, where (z, t) is the axial velocity; and are the solvent and polymer contribution to the total viscosity, respectively (total viscosity ); indicates the partial derivative ; and are the diagonal terms of the extra-stress tensor. Equation (1) represents mass conservation, Equation (2) represents momentum equation in one dimension. Extra stress tensors and can be calculated as follows: , where is the relaxation time of the liquid; is a positive dimensionless parameter corresponding to the anisotropy of the hydrodynamic drag on the polymer molecules and is called the mobility factor {{-Beads on string structure

Drop Draining

In drop draining a small bead between two beads gets smaller in size and the fluid particle moves towards the adjacent beads. The smaller bead drains out as shown in the figure.Drop Merging

In drop merging, a smaller bead and a larger bead move close to each other and merge to form a single bead.Drop Collision

In drop collision, two adjacent beads collide to form a single bead.Drop Oscillation

In drop oscillation, two adjacent beads start oscillating and eventually the distance between them decreases. After sometime they merge to form a single bead.References

# http://www2.eng.cam.ac.uk/~jl305/VisJet/recoil_mv.gif # http://www2.eng.cam.ac.uk/~jl305/VisJet/merging.gif # http://www2.eng.cam.ac.uk/~jl305/VisJet/collison.gif # http://www2.eng.cam.ac.uk/~jl305/VisJet/oscil.gif # http://www2.eng.cam.ac.uk/~jl305/VisJet/draining.gif # http://www2.eng.cam.ac.uk/~jl305/VisJet/dropdyn.html # http://web.mit.edu/nnf/research/phenomena/viscoelastic_jet.html Elasticity (physics) Non-Newtonian fluids