Ultrasonic Inspection on:

[Wikipedia]

[Google]

[Amazon]

Ultrasonic testing (UT) is a family of

Ultrasonic testing (UT) is a family of

In ultrasonic testing, an ultrasound

In ultrasonic testing, an ultrasound

One of the examples that utilize ultrasound for proving material property is the measurement of grain size of specific material. Unlike destructive measurement, ultrasound offers methods to measure grain size in non-destructive way with even higher detection efficiency. Measurement of grain size using ultrasound can be accomplished through evaluating ultrasonic velocities, attenunations, and backscatter feature. Theoretical foundation for scattering attenunation model was developed by Stanke, Kino, and Weaver.

With constant frequency, the scattering attenuation coefficient depends mainly on the grain size; Zeng et al, figured out that in pure Niobium, attenuation is linearly correlated with grain size through grain boundary scattering. This concepts of ultrasonic proving can be used to inversely resolve the grain size in the time domain when the scattering attenuation coefficient is measured from testing data, providing the non-destructive way to predict material's property with rather simple instruments.

Chapter 1

online (PDF, 61 kB)). * Nondestructive Testing Handbook, Third ed.: Volume 7, Ultrasonic Testing. Columbus, OH: American Society for Nondestructive Testing. * Detection and location of defects in electronic devices by means of scanning ultrasonic microscopy and the wavelet transform measurement, Volume 31, Issue 2, March 2002, Pages 77–91, L. Angrisani, L. Bechou, D. Dallet, P. Daponte, Y. Ousten * {{Authority control Nondestructive testing Ultrasound Welding

Ultrasonic testing (UT) is a family of

Ultrasonic testing (UT) is a family of non-destructive testing

Nondestructive testing (NDT) is any of a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage.

The terms nondestructive examination (NDE), n ...

techniques based on the propagation of ultrasonic

Ultrasound is sound with frequencies greater than 20 kilohertz. This frequency is the approximate upper audible limit of human hearing in healthy young adults. The physical principles of acoustic waves apply to any frequency range, includi ...

waves in the object or material tested. In most common UT applications, very short ultrasonic pulse waves with centre frequencies ranging from 0.1-15MHz and occasionally up to 50MHz, are transmitted into materials to detect internal flaws or to characterize materials. A common example is ultrasonic thickness measurement

In the field of industrial ultrasonic testing, ultrasonic thickness measurement (UTM) is a method of performing non-destructive measurement (gauging) of the local thickness of a solid element (typically made of metal, if using ultrasound testing ...

, which tests the thickness of the test object, for example, to monitor pipework corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engine ...

and erosion. Ultrasonic testing is extensively used to detect flaws in welds.

Ultrasonic testing is often performed on steel and other metals

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. These properties are all associated with having electrons available at the Fermi level, as against no ...

and alloys, though it can also be used on concrete

Concrete is a composite material composed of aggregate bound together with a fluid cement that cures to a solid over time. It is the second-most-used substance (after water), the most–widely used building material, and the most-manufactur ...

, wood and composites, albeit with less resolution. It is used in many industries including steel and aluminum construction, metallurgy, manufacturing, aerospace

Aerospace is a term used to collectively refer to the atmosphere and outer space. Aerospace activity is very diverse, with a multitude of commercial, industrial, and military applications. Aerospace engineering consists of aeronautics and astron ...

, automotive and other transportation

Transport (in British English) or transportation (in American English) is the intentional Motion, movement of humans, animals, and cargo, goods from one location to another. Mode of transport, Modes of transport include aviation, air, land tr ...

sectors.

History

The first efforts to use ultrasonic testing to detect flaws in solid material occurred in the 1930s.''Nondestructive Flaw Detection in Metallic Components'' Quality magazine August 2015 issue Pages 31-32 by Dan DeVries On May 27, 1940, U.S. researcher Dr. Floyd Firestone of theUniversity of Michigan

The University of Michigan (U-M, U of M, or Michigan) is a public university, public research university in Ann Arbor, Michigan, United States. Founded in 1817, it is the oldest institution of higher education in the state. The University of Mi ...

applies for a U.S. invention patent for the first practical ultrasonic testing method. The patent is granted on April 21, 1942, as U.S. Patent No. 2,280,226, titled "Flaw Detecting Device and Measuring Instrument". Extracts from the first two paragraphs of the patent for this entirely new nondestructive testing method succinctly describe the basics of such ultrasonic testing. "My invention pertains to a device for detecting the presence of inhomogeneities of density or elasticity in materials. For instance, if a casting has a hole or a crack within it, my device allows the presence of the flaw to be detected and its position located, even though the flaw lies entirely within the casting and no portion of it extends out to the surface. ... The general principle of my device consists of sending high frequency vibrations into the part to be inspected and the determination of the time intervals of the arrival of the direct and reflected vibrations at one or more stations on the surface of the part."

James F. McNulty (U.S. radio engineer)

Fluoroscopy (), informally referred to as "fluoro", is an imaging technique that uses X-rays to obtain real-time moving images of the interior of an object. In its primary application of medical imaging, a fluoroscope () allows a surgeon to see t ...

of Automation Industries, Inc., then, in El Segundo, California, an early improver of the many foibles and limits of this and other nondestructive testing methods, teaches in further detail on ultrasonic testing in his U.S. Patent 3,260,105 (application filed December 21, 1962, granted July 12, 1966, titled “Ultrasonic Testing Apparatus and Method”) that “Basically ultrasonic testing is performed by applying to a piezoelectric crystal transducer

A transducer is a device that Energy transformation, converts energy from one form to another. Usually a transducer converts a signal in one form of energy to a signal in another.

Transducers are often employed at the boundaries of automation, M ...

periodic electrical pulses of ultrasonic frequency. The crystal vibrates at the ultrasonic frequency and is mechanically coupled to the surface of the specimen to be tested. This coupling may be affected by immersion of both the transducer and the specimen in a body of liquid or by actual contact through a thin film of liquid such as oil. The ultrasonic vibrations pass through the specimen and are reflected by any discontinuities which may be encountered. The echo pulses that are reflected are received by the same or by a different transducer and are converted into electrical signals which indicate the presence of the defect.” To characterize microstructural features in the early stages of fatigue or creep damage, more advanced nonlinear ultrasonic tests should be employed. These nonlinear methods are based on the fact that an intensive ultrasonic wave is getting distorted as it faces micro damages in the material. The intensity of distortion is correlated with the level of damage. This intensity can be quantified by the acoustic nonlinearity parameter (β). β is related to first and second harmonic amplitudes. These amplitudes can be measured by harmonic decomposition of the ultrasonic signal through fast Fourier transformation or wavelet transformation.

How it works

In ultrasonic testing, an ultrasound

In ultrasonic testing, an ultrasound transducer

A transducer is a device that Energy transformation, converts energy from one form to another. Usually a transducer converts a signal in one form of energy to a signal in another.

Transducers are often employed at the boundaries of automation, M ...

connected to a diagnostic machine is passed over the object being inspected. The transducer is typically separated from the test object by a couplanthttps://www.nde-ed.org/EducationResources/CommunityCollege/Ultrasonics/EquipmentTrans/Couplant.htm ''Couplant'' Iowa State University - Center for Non-Destructive Evaluation retrieved 8//1/2021 such as a gel, oil or water, as in immersion testing. However, when ultrasonic testing is conducted with an Electromagnetic Acoustic Transducer (EMAT) the use of couplant is not required.

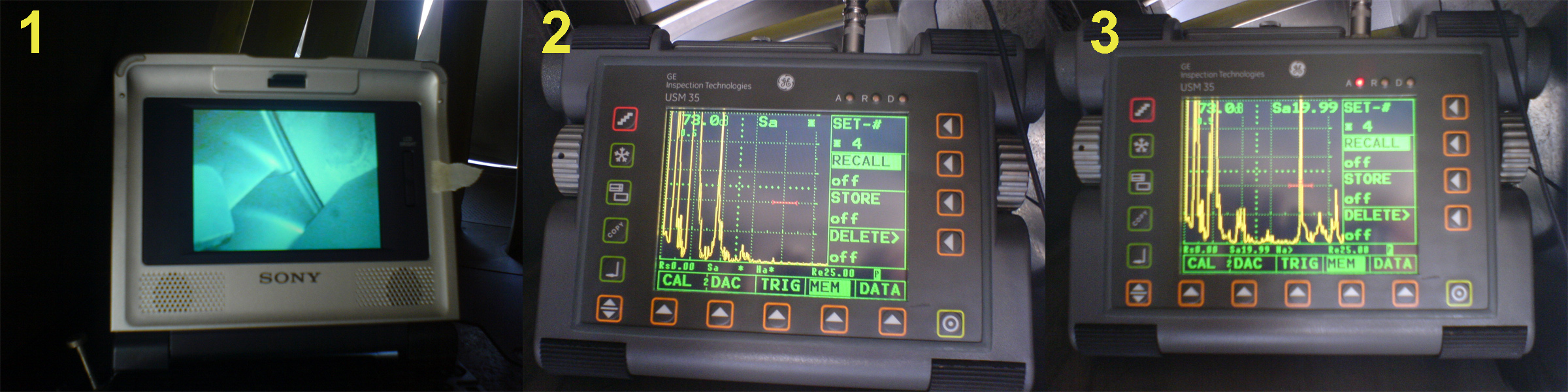

There are two methods of receiving the ultrasound waveform: reflection and attenuation

In physics, attenuation (in some contexts, extinction) is the gradual loss of flux intensity through a Transmission medium, medium. For instance, dark glasses attenuate sunlight, lead attenuates X-rays, and water and air attenuate both light and ...

. In reflection (or pulse-echo) mode, the transducer performs both the sending and the receiving of the pulsed waves as the "sound" is reflected back to the device. Reflected ultrasound comes from an interface, such as the back wall of the object or from an imperfection within the object. The diagnostic machine displays these results in the form of a signal with an amplitude

The amplitude of a periodic variable is a measure of its change in a single period (such as time or spatial period). The amplitude of a non-periodic signal is its magnitude compared with a reference value. There are various definitions of am ...

representing the intensity of the reflection and the distance, representing the arrival time

Arrival(s) or The Arrival(s) may refer to:

Film

* The Arrival (1991 film), ''The Arrival'' (1991 film), an American science fiction horror film

* The Arrival (1996 film), ''The Arrival'' (1996 film), an American-Mexican science fiction horror fil ...

of the reflection. In attenuation (or through-transmission) mode, a transmitter sends ultrasound through one surface, and a separate receiver detects the amount that has reached it on another surface after travelling through the medium. Imperfections or other conditions in the space between the transmitter and receiver reduce the amount of sound transmitted, thus revealing their presence. Using the couplant increases the efficiency of the process by reducing the losses in the ultrasonic wave energy due to separation between the surfaces.

Features

Advantages

#High penetrating power allows the detection of flaws deep in the part. #High sensitivity, permitting the detection of extremely small flaws. #Greater accuracy than other non-destructive methods in determining the depth of internal flaws and the thickness of parts with parallel surfaces. #Some capability of estimating the size, orientation, shape and nature of defects. #Some capability of estimating the structure of alloys of components with different acoustic properties. # Non-hazardous to operations or to nearby personnel and has no effect on equipment and materials in the vicinity. #Capable of portable, highly automated or remote operation. #Results are immediate, allowing on-the-spot decisions to be made. #It needs to access only one surface of the product that is being inspected.Disadvantages

#Manual operation requires careful attention by experienced technicians. The transducers alert to both normal structure of some materials, tolerable anomalies of other specimens (both termed “noise”) and to faults therein severe enough to compromise specimen integrity. These signals must be distinguished by a skilled technician, possibly requiring follow up with other nondestructive testing methods.U.S. Patent 3,260,105 for Ultrasonic Testing Apparatus and Method to James F. McNulty at lines 37-48 and 60-72 of Column 1 and lines 1-4 of Column 2. #Extensive technical knowledge is required for the development of inspection procedures. #Rough surface finish, irregular geometry, small parts, thin thicknesses, or un-homogeneous material composition can make testing difficult. #Surface must be prepared by cleaning and removing loose scale, paint, etc., although paint that is properly bonded to a surface, may not need to be removed. #Couplants are needed to effectively transfer ultrasonic wave energy between transducers and parts being inspected unless a non-contact technique is used. Non-contact techniques include Laser and Electro Magnetic Acoustic Transducers (EMAT

An electromagnetic acoustic transducer (EMAT) is a transducer for non-contact acoustic wave generation and reception in conducting materials. Its effect is based on electromagnetic mechanisms, which do not need direct coupling with the surface of ...

).

#Equipment can be expensive.

#Requires reference standards and calibration.

Standards

;International Organization for Standardization

The International Organization for Standardization (ISO ; ; ) is an independent, non-governmental, international standard development organization composed of representatives from the national standards organizations of member countries.

M ...

(ISO)

* ISO 2400: ''Non-destructive testing - Ultrasonic testing - Specification for calibration block No. 1'' (2012)

* ISO 7963: ''Non-destructive testing — Ultrasonic testing — Specification for calibration block No. 2'' (2006)

* ISO 10863: ''Non-destructive testing of welds -- Ultrasonic testing -- Use of time-of-flight diffraction technique (TOFD)'' (2011)

* ISO 11666: ''Non-destructive testing of welds — Ultrasonic testing — Acceptance levels'' (2010)

* ISO 16809: ''Non-destructive testing -- Ultrasonic thickness measurement'' (2012)

* ISO 16831: ''Non-destructive testing -- Ultrasonic testing -- Characterization and verification of ultrasonic thickness measuring equipment'' (2012)

* ISO 17640: ''Non-destructive testing of welds - Ultrasonic testing - Techniques, testing levels, and assessment'' (2010)

* ISO 22825, ''Non-destructive testing of welds - Ultrasonic testing - Testing of welds in austenitic steels and nickel-based alloys'' (2012)

* ISO 5577: ''Non-destructive testing -- Ultrasonic inspection -- Vocabulary'' (2000)

;European Committee for Standardization

The European Committee for Standardization (CEN, ) is a public standards organization whose mission is to foster the economy of the European Single Market and the wider European continent in global trading, the welfare of European citizens an ...

(CEN)

*EN 583, ''Non-destructive testing - Ultrasonic examination''

*EN 1330-4, ''Non destructive testing - Terminology - Part 4: Terms used in ultrasonic testing''

*EN 12668-1, ''Non-destructive testing - Characterization and verification of ultrasonic examination equipment - Part 1: Instruments''

*EN 12668-2, ''Non-destructive testing - Characterization and verification of ultrasonic examination equipment - Part 2: Probes''

*EN 12668-3, ''Non-destructive testing - Characterization and verification of ultrasonic examination equipment - Part 3: Combined equipment''

*EN 12680, ''Founding - Ultrasonic examination''

*EN 14127, ''Non-destructive testing - Ultrasonic thickness measurement''

(Note: Part of CEN standards in Germany accepted as DIN EN, in Czech Republic as CSN EN.)

See also

* Non-Contact Ultrasound *Phased array ultrasonics

A phaser is an electronic sound processor used to filter a signal by creating a series of peaks and troughs in the frequency spectrum. The position of the peaks and troughs of the waveform being affected is typically modulated by an intern ...

*Time-of-flight diffraction ultrasonics

Time-of-flight diffraction (TOFD) method of ultrasonic testing is a sensitive and accurate method for the nondestructive testing of welds for defects. TOFD originated from tip diffraction techniques which were first published by Silk and Lidding ...

(TOFD)

*Time-of-flight ultrasonic determination of 3D elastic constants {{no footnotes, date=August 2010

The three-dimensional elastic constants of materials can be measured using the ultrasonic immersion method. This was pioneered by Zimmer and Cost from the National Physical Laboratory in the 1960s. It has mainly be ...

(TOF)

*Internal rotary inspection system

Internal rotary inspection system (IRIS) is an ultrasonic method for the nondestructive testing of pipes and tubes

Tube or tubes may refer to:

* ''Tube'' (2003 film), a 2003 Korean film

* "Tubes" (Peter Dale), performer on the Soccer AM televis ...

(IRIS) ultrasonics for tubes

* EMAT Electromagnetic Acoustic Transducer

*ART (Acoustic Resonance Technology)

Acoustic resonance technology (ART) is an acoustic inspection technology developed by Det Norske Veritas over the past 20 years. ART exploits the phenomenon of half-wave resonance, whereby a suitably excited resonant target (such as a pipeline wa ...

References

Further reading

* Albert S. Birks, Robert E. Green, Jr., technical editors; Paul McIntire, editor. ''Ultrasonic testing'', 2nd ed. Columbus, OH :American Society for Nondestructive Testing

The American Society for Nondestructive Testing, Inc. or ASNT is a technical society for nondestructive testing (NDT) professionals. ASNT evolved from ''The American Industrial Radium and X-ray Society'' which was founded in 1941. Its headquarters ...

, 1991. .

* Josef Krautkrämer, Herbert Krautkrämer. ''Ultrasonic testing of materials'', 4th fully rev. ed. Berlin; New York: Springer-Verlag, 1990. .

* J.C. Drury. ''Ultrasonic Flaw Detection for Technicians'', 3rd ed., UK: Silverwing Ltd. 2004. (SeChapter 1

online (PDF, 61 kB)). * Nondestructive Testing Handbook, Third ed.: Volume 7, Ultrasonic Testing. Columbus, OH: American Society for Nondestructive Testing. * Detection and location of defects in electronic devices by means of scanning ultrasonic microscopy and the wavelet transform measurement, Volume 31, Issue 2, March 2002, Pages 77–91, L. Angrisani, L. Bechou, D. Dallet, P. Daponte, Y. Ousten * {{Authority control Nondestructive testing Ultrasound Welding