Turning (other) on:

[Wikipedia]

[Google]

[Amazon]

Turning is a

Turning is a

: Facing removes material from the end of a workpiece by moving the cutting tool perpendicular to the workpiece's axis of rotation.

; Grooving

: Facing removes material from the end of a workpiece by moving the cutting tool perpendicular to the workpiece's axis of rotation.

; Grooving

: Grooving is the cutting of grooves to a specific depth in the workpiece. It can be performed on either internal or external surfaces, as well as on the face of the part. This is called "face grooving" or "trepanning."

; Parting

: "Parting off" or "cutoff" is performed by creating a deep groove, all the way through the workpiece, until the end falls off.

;

: Grooving is the cutting of grooves to a specific depth in the workpiece. It can be performed on either internal or external surfaces, as well as on the face of the part. This is called "face grooving" or "trepanning."

; Parting

: "Parting off" or "cutoff" is performed by creating a deep groove, all the way through the workpiece, until the end falls off.

;

;

;

Turning is a

Turning is a machining

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which util ...

process in which a cutting tool

Cutting is the separation or opening of a physical object, into two or more portions, through the application of an acutely directed force.

Implements commonly used for cutting are the knife and saw, or in medicine and science the scalpel an ...

is held nearly stationary to cut a rotating workpiece. The cutting tool can be slowly moved back-and-forth, and in-and-out to cut cylindrical shapes, and flat surfaces on the workpiece. Turning is usually done with a lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the w ...

.

Usually the term "turning" is used for cutting ''external'' surfaces, and " boring" for internal surfaces, or holes. Thus the phrase "turning and boring" categorizes the larger family of processes known as lathing. Additionally, "facing" is cutting the ends of the workpiece, to create flat faces.

Turning is typically done with either a manual lathe, or a computer numerical control

Computer numerical control (CNC) or CNC machining is the Automation, automated control of machine tools by a computer. It is an evolution of numerical control (NC), where machine tools are directly managed by data storage media such as punched ...

(CNC) lathe. With a manual lathe, an operator turns cranks to move the cutting tool. On a CNC lathe, the cutting tool is moved by a computer, controlling electric motors to follow a pre-programmed path. Early manual lathes could be used to produce complex geometric figures, even the platonic solids

In geometry, a Platonic solid is a convex, regular polyhedron in three-dimensional Euclidean space. Being a regular polyhedron means that the faces are congruent (identical in shape and size) regular polygons (all angles congruent and all edge ...

; though this is now usually done with CNC machines.

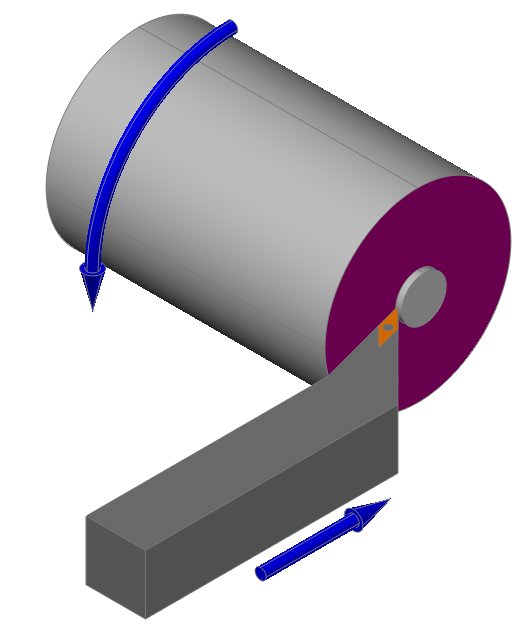

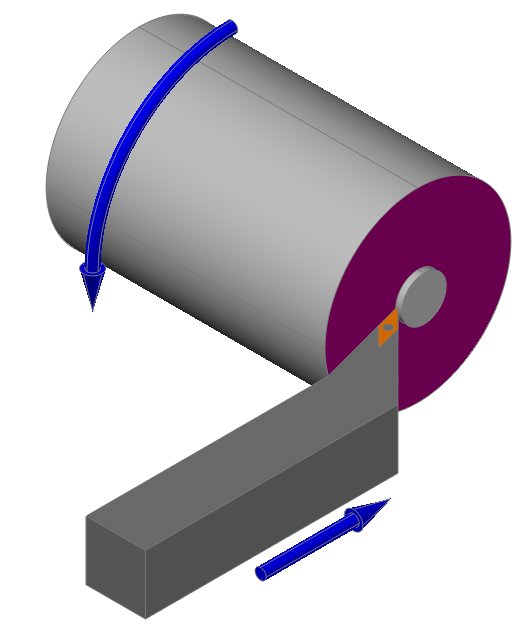

Different turning processes are typically carried out on a lathe, such as ''straight turning'', ''taper turning'', ''profiling'' or ''external grooving''. Those types of turning processes can produce various shapes of materials such as ''straight'', ''conical'', ''curved'', or ''grooved'' workpieces.

In general, turning uses simple ''single-point cutting'' tools.

The waste metal cut off of the workpiece from turning operations is known as chips in North America, or swarf

Swarf, also known as chips or by other process-specific names (such as turnings, filings, or shavings), are pieces of metal, wood, or plastic that are the debris or waste resulting from machining, woodworking, or similar subtractive (material-r ...

in Britain. In some areas they may be known as ''turnings''.

A component that is made by turning is often called a ''turned part''.

Turning operations

; Turning : The general process of turning involves rotating a workpiece while a single-point cutting tool is moved parallel to the axis of rotation. Turning can be done on the external surface of the part as well as the internal surface (the process known as boring). The starting material is generally a workpiece generated by other processes such ascasting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or ...

, forging

Forging is a manufacturing process involving the shaping of metal using localized compression (physics), compressive forces. The blows are delivered with a hammer (often a power hammer) or a die (manufacturing), die. Forging is often classif ...

, extrusion

Extrusion is a process used to create objects of a fixed cross section (geometry), cross-sectional profile by pushing material through a Die (manufacturing), die of the desired cross-section. Its two main advantages over other manufacturing pro ...

, or drawing

Drawing is a Visual arts, visual art that uses an instrument to mark paper or another two-dimensional surface, or a digital representation of such. Traditionally, the instruments used to make a drawing include pencils, crayons, and ink pens, some ...

.

:; Tapered turning : Tapered turning produces a cylindrical shape that gradually decreases in diameter from one end to the other.Workshop Technology by W.A.J. Chapman Ph.D. M.Sc.(Eng.), M.I.Mech.E., M.I.Prod.E. Principal Hatfield College of Technology, Hertfordshire first published 1951 part one, two and three published by Edward Arnold (publishers Limited

:; Spherical generation : Spherical generation produces a spherical finished surface by turning a form around a fixed axis of revolution.

:; : Hard turning is performed on workpieces with a hardness greater than 45 Rockwell C. It is typically performed after the workpiece is heat treated. It is generally better than grinding for rough stock removal. However, grinding generally produces a better surface finish and can produce parts with greater dimensional accuracy.

; Boring

: Cutting the inside surface of a hole or tube. A hole is usually first created by drilling, and then it is bored to enlarge it to its final diameter.

;Drilling

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross section (geometry), cross-section in solid materials. The drill bit is usually a rotary Cutting tool (machining), cutting tool, often multi-point. The bit i ...

: Removes material from the inside of a workpiece with a drill bit

A drill bit is a cutting tool used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In orde ...

. This process is the reverse of normal drilling operations in that the drill bit is held stationary and the workpiece is rotated. Reamers can also be used to enlarge a hole after it has been drilled.

;

: Facing removes material from the end of a workpiece by moving the cutting tool perpendicular to the workpiece's axis of rotation.

; Grooving

: Facing removes material from the end of a workpiece by moving the cutting tool perpendicular to the workpiece's axis of rotation.

; Grooving

: Grooving is the cutting of grooves to a specific depth in the workpiece. It can be performed on either internal or external surfaces, as well as on the face of the part. This is called "face grooving" or "trepanning."

; Parting

: "Parting off" or "cutoff" is performed by creating a deep groove, all the way through the workpiece, until the end falls off.

;

: Grooving is the cutting of grooves to a specific depth in the workpiece. It can be performed on either internal or external surfaces, as well as on the face of the part. This is called "face grooving" or "trepanning."

; Parting

: "Parting off" or "cutoff" is performed by creating a deep groove, all the way through the workpiece, until the end falls off.

; Knurling

Knurling is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is rolled into the material. Knurling can also refer to material that has a knurled pattern.

Etymology

The terms ''knur ...

: Pressing a serrated pattern onto the surface of a part to use as a hand grip or as a visual enhancement using a special purpose knurling tool.

; Threading

: Screw threads can be turned on a lathe using a cutting tool with the shape of the thread. The axial movement of the cutting tool is linked to the rotation of the workpiece to create the thread's pitch. When this is performed on an outer surface, similar to turning, external threads are created. When performed on an internal surface, similar to boring, internal threads are created. This is referred to as "single point threading."

: Alternately, taps and dies can be used to cut internal and external threads, respectively.

; Polygonal turning

: Non-circular forms are machined.

Lathes

Turning is usually performed on alathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the w ...

, which range in size from tabletop machines suitable for jewelry, to building-sized machines for manufacturing ship propeller shafts.

Workholding methods

;

;Chuck

Chuck () is a masculine given name or a nickname for Charles or Charlie. It may refer to:

People

Arts and entertainment

* Chuck Alaimo, American saxophonist, leader of the Chuck Alaimo Quartet

* Chuck Barris (1929–2017), American TV produce ...

: Chucks grip a workpiece with movable jaws. They are less accurate than collets, but can hold a wider range of workpiece sizes.

;Collet

A collet is a segmented sleeve, band or ''collar''. One of the two radial surfaces of a collet is usually tapered (i.e a truncated cone) and the other is cylindrical. The term ''collet'' commonly refers to a type of chuck that uses collets ...

: Collets grip a workpiece by deforming around it. They grip over a larger surface than chucks, which puts less pressure on the workpiece, and center the workpiece better. Each collet has only a narrow range of workpiece diameters that it can deform enough to hold, so large sets of different collets are needed.

; Faceplate: A faceplate is a plate that a workpiece is attached to, often with clamps or t-slot nuts. It is often used with a drive dog and mandrel. It can hold even more irregularly shaped workpieces than a chuck.

; Centers: Centers are pointed cones, which support either a hollow tube workpiece, or a workpiece with holes drilled in its ends. Workpieces are ofter driven by a "dog".

; Drive center: A drive center is a center which grips the workpiece strongly enough to drive it without the use of a dog. They often use hydraulic or spring-loaded teeth that bite into the end of workpieces. When supporting a workpiece only with centers, the entire outside of the workpiece may be machined in one setup.

Tooling

Turning tooling usually cuts with a single point, as opposed to adrill bit

A drill bit is a cutting tool used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In orde ...

or end mill

An end mill is a type of milling cutter, a cutting tool used in industrial milling applications. They can have several end configurations: round (ball), tapered, or straight are a few popular types. They are most commonly used in "milling machi ...

which cut with several sharp edges. The angles around the sharp point are important, such as ''rake angle

In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. There are three types of rake angles: ''positive'', ''zero'' or ''neutral'', and ''negative''.

...

'', ''side rake angle'', ''cutting-edge angle'', and ''relief angle''. Additionally, the cutting point may have a ''nose radius'' which creates radii when cutting corners in the workpiece and extends the life of the tool tip, but increases machining forces.

The tool bit is held with a rigid tool holder during operation. CNC machines are typically able to switch tools automatically.

Dynamics of turning

Forces

Significant forces are required for turning operation, and must be accounted for in the design and selection of the machine tools, the workpiece holding, and any additional supports. A setup that is not strong enough may allow the workpiece to break free during operation, ruining the part being made, and endangering the operator. A setup that is not rigid enough will deform during operation, and create chatter when cutting, creating an undesirable surface finish, and inaccurate dimensions. There are three principal forces in turning: *The cutting or tangential force acts downward on the tool tip and upwards on the workpiece upward. This is the force required to cut chips off of the workpiece. The force required to cut the material is called the specific cutting force, and depends on the material, cut depth, cut speed, and lubrication. *The axial or feed force acts in the longitudinal, or feed direction. This is the force necessary to feed the tool along the rotational axis of the workpiece. *The radial or thrust force acts in the radial direction and tends to push the tool out of the workpiece.Speeds and feeds

Speeds and feeds

The phrase speeds and feeds or feeds and speeds refers to two separate parameters in machine tool practice, cutting speed and feed rate. They are often considered as a pair because of their combined effect on the cutting process. Each, however, ...

refer to the rotational speed that the workpiece is rotated at, and the feed speed that the tool is moved at. They are chosen based on the workpiece material, cutter material, setup rigidity, machine tool rigidity, spindle power, and whether coolant is used.

The rotational speed is measured in revolutions per minute (rpm).

The feed rate is the distance that the tool is fed into the workpiece per workpiece revolution. It is measured either as millimeters per revolution (mm/rev), or as inches per revolution (in/rev).

See also

*Diamond turning

Diamond turning is turning using a cutting tool with a diamond tip. It is a process of mechanical machining of precision elements using lathes or derivative machine tools (e.g., turn-mills, rotary transfers) equipped with natural or synthetic diam ...

*Engine turning

Engine turning is a form of ornamental turning. The finishing technique may use lathes or engines to produce a pattern. Aluminium is often the metal chosen to decorate. The technique has been used in various industries, including aircraft and doc ...

*Surface feet per minute

Surface feet per minute (SFPM or SFM) is the combination of a physical quantity (''surface speed'') and an imperial and American customary unit (''feet per minute'' or ''FPM''). It is defined as the number of linear feet that a location on a ro ...

*Woodturning

Woodturning is the craft of using a wood lathe with hand-held tools to cut a shape that is symmetrical around the axis of rotation. Like the potter's wheel, the wood lathe is a mechanism that can generate a variety of forms. The operator is kno ...

References

External links

* {{Authority control Lathes