Total metal jacket on:

[Wikipedia]

[Google]

[Amazon]

Total metal jacket (TMJ or full metal case) bullets are made by

Total metal jacket (TMJ or full metal case) bullets are made by

Total metal jacket (TMJ or full metal case) bullets are made by

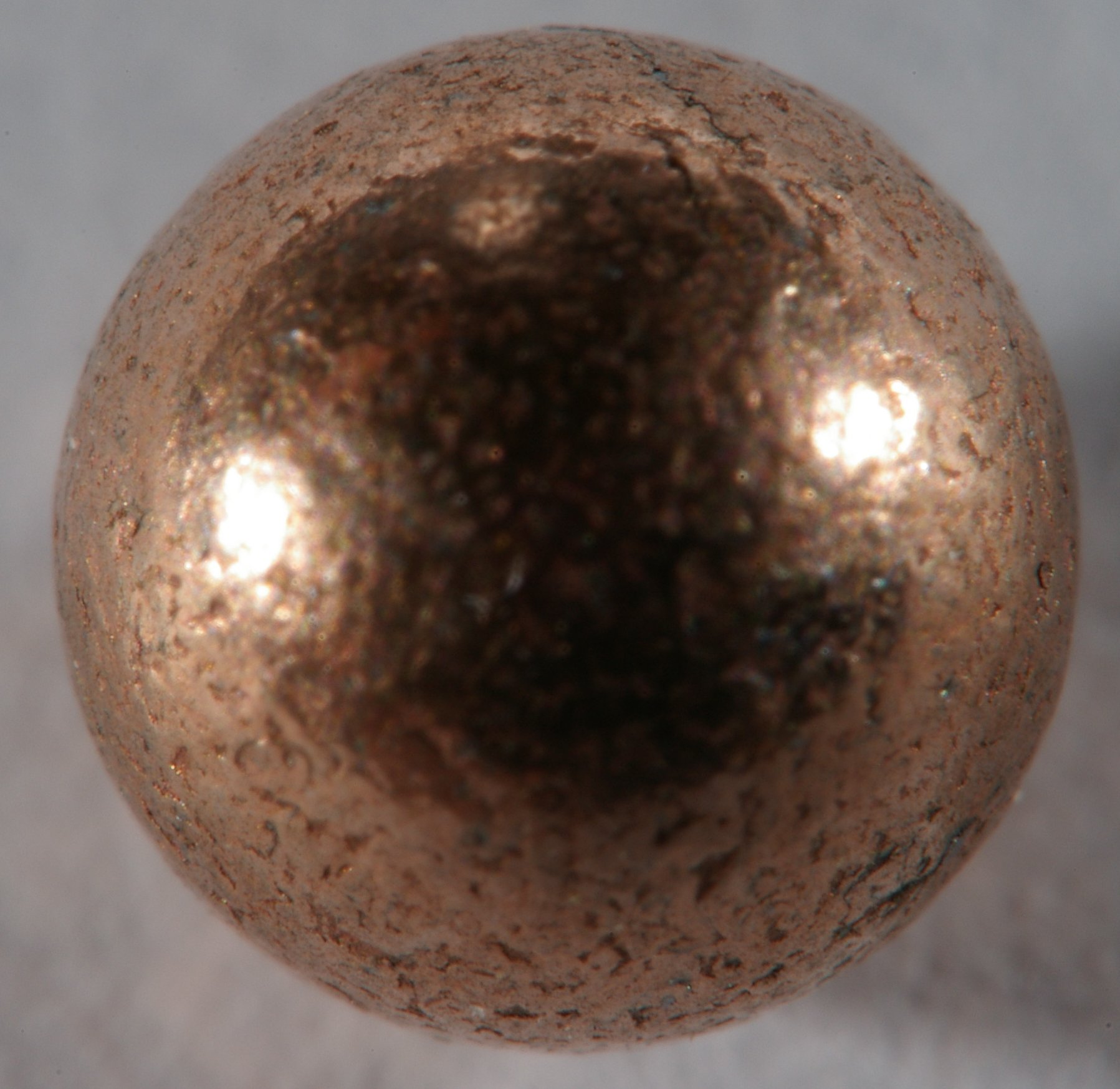

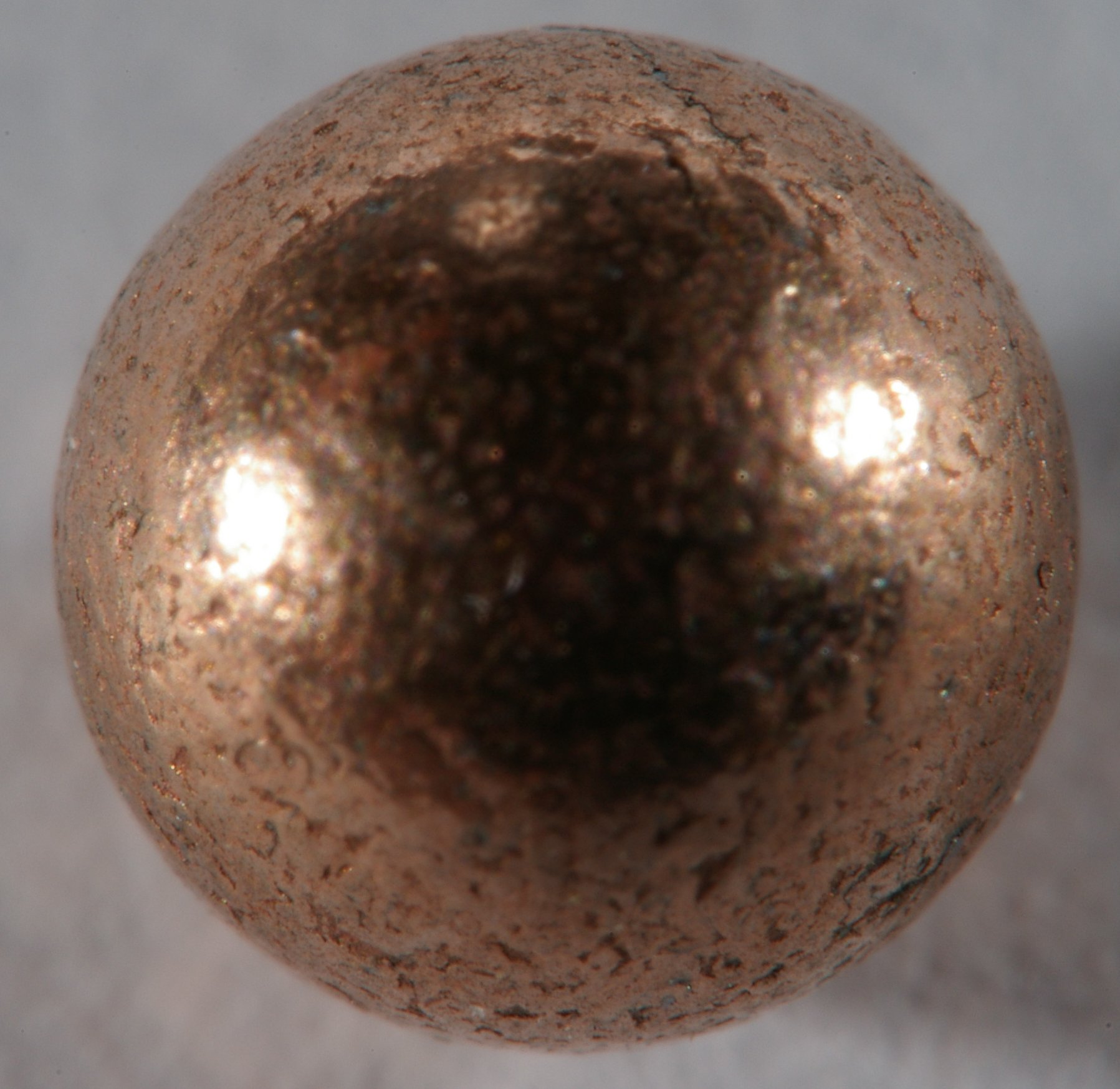

Total metal jacket (TMJ or full metal case) bullets are made by electroplating

Electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the redox, reduction of cations of that metal by means of a direct current, direct electric cur ...

a thin jacket of ductile

Ductility refers to the ability of a material to sustain significant plastic deformation before fracture. Plastic deformation is the permanent distortion of a material under applied stress, as opposed to elastic deformation, which is reversi ...

metal (usually copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

) over a core of different metal requiring protection from abrasion or corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engine ...

. Similar full metal jacket bullets mechanically swage

Swaging () is a forging process in which the dimensions of an item are altered using dies into which the item is forced. Swaging is usually a cold working process, but also may be hot worked.

The term swage may apply to the process (verb) o ...

a thin sheet of metal over the core. The swaging process leaves an opening exposing the core on the base or nose of the bullet, while electroplating deposits a jacket over the entire bullet surface. Protecting the base of a lead

Lead () is a chemical element; it has Chemical symbol, symbol Pb (from Latin ) and atomic number 82. It is a Heavy metal (elements), heavy metal that is density, denser than most common materials. Lead is Mohs scale, soft and Ductility, malleabl ...

-core bullet from burning powder gas may prevent molten lead from being released as a fine spray in turbulent gas leaving the muzzle of a firearm. Electrolytic deposition can create very thin jackets, while jackets applied by swaging must be thick enough to avoid being torn during the swaging process. Uniformly electroplated jackets may produce more accurate bullets than jacket and core materials deformed during swaging. Thinner electroplated jackets may not be as strong as conventional swaged jackets of similar metal, and may not prevent leading at higher bullet velocities. Thinner jackets may be damaged by and foul barrel ports for gas-operated reloading

Gas-operation is a system of operation used to provide energy to operate locked breech, autoloading firearms. In gas-operation, a portion of high-pressure gas from the cartridge being fired is used to power a mechanism to dispose of the spent ...

or recoil compensation.

Sources

Handloading Bullets {{Ammo-stub