Sulfur Vulcanization on:

[Wikipedia]

[Google]

[Amazon]

Sulfur vulcanization is a

Sulfur vulcanization is a

The details of vulcanization remain murky because the process converts mixtures of polymers to mixtures of insoluble derivatives. By design the reaction does not proceed to completion because fully crosslinked polymer would be too rigid for applications. There has long been uncertainly as to whether vulcanization proceeds in a radical or ionic manner.

It is agreed that the reactive sites, often referred to as 'cure sites', are the

The details of vulcanization remain murky because the process converts mixtures of polymers to mixtures of insoluble derivatives. By design the reaction does not proceed to completion because fully crosslinked polymer would be too rigid for applications. There has long been uncertainly as to whether vulcanization proceeds in a radical or ionic manner.

It is agreed that the reactive sites, often referred to as 'cure sites', are the

Benzo(d)thiazole-2-thiol_200.svg , Mercaptobenzothiazole (MBT)

Di(benzothiazool-2-yl)disulfide.svg , Mercaptobenzothiazole disulfide (MBTS)

N-Cyclohexylbenzothiazol-2-sulfenamide.svg, N-Cyclohexylbenzothiazol-2-sulfenamide (CBS)

N,N-dicyclohexyl-2-benzothiazolesulfenamide.svg , Dicyclohexyl-2-benzothiazolesulfenamide (DCBS)

Oxidative dimerization of MBT gives mercaptobenzothiazole

Thiuram.svg , Thiuram

Zn(Me2dtc)2Improved.png , Zinc bis(dimethyldithiocarbamate) (

Secondary accelerants have very fast vulcanization speeds with minimal induction time, making them unsuitable as primary accelerants in highly unsaturated rubbers such as NR or SBR. However, they can be used as primary accelerants in compounds with fewer curing site such as

Sulfur vulcanization is a

Sulfur vulcanization is a chemical process

In a scientific sense, a chemical process is a method or means of somehow changing one or more chemicals or chemical compounds. Such a chemical process can occur by itself or be caused by an outside force, and involves a chemical reaction of som ...

for converting natural rubber

Rubber, also called India rubber, latex, Amazonian rubber, ''caucho'', or ''caoutchouc'', as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds.

Types of polyisoprene ...

or related polymer

A polymer () is a chemical substance, substance or material that consists of very large molecules, or macromolecules, that are constituted by many repeat unit, repeating subunits derived from one or more species of monomers. Due to their br ...

s into materials of varying hardness, elasticity, and mechanical durability by heating them with sulfur

Sulfur ( American spelling and the preferred IUPAC name) or sulphur ( Commonwealth spelling) is a chemical element; it has symbol S and atomic number 16. It is abundant, multivalent and nonmetallic. Under normal conditions, sulfur atoms ...

or sulfur-containing compounds. Sulfur forms cross-link

In chemistry and biology, a cross-link is a bond or a short sequence of bonds that links one polymer chain to another. These links may take the form of covalent bonds or ionic bonds and the polymers can be either synthetic polymers or natural ...

ing bridges between sections of polymer chain

A polymer () is a chemical substance, substance or material that consists of very large molecules, or macromolecules, that are constituted by many repeat unit, repeating subunits derived from one or more species of monomers. Due to their br ...

s which affects the mechanical properties. Many products are made with vulcanized rubber, including tire

A tire (North American English) or tyre (Commonwealth English) is a ring-shaped component that surrounds a Rim (wheel), wheel's rim to transfer a vehicle's load from the axle through the wheel to the ground and to provide Traction (engineeri ...

s, shoe soles, hoses, and conveyor belts. The term is derived from Vulcan, the Roman god

Roman mythology is the body of myths of ancient Rome as represented in the Latin literature, literature and Roman art, visual arts of the Romans, and is a form of Roman folklore. "Roman mythology" may also refer to the modern study of these ...

of fire.

The main polymers subjected to sulfur vulcanization are polyisoprene

Polyisoprene is, strictly speaking, a collective name for polymers that are produced by polymerization of isoprene. In practice polyisoprene is commonly used to refer to synthetic ''cis''-1,4-polyisoprene, made by the industrial polymerisation of ...

(natural rubber, NR), polybutadiene rubber (BR) and styrene-butadiene

Styrene-butadiene or styrene-butadiene rubber (SBR) describe families of synthetic rubbers derived from styrene and butadiene (the version developed by Goodyear is called Neolite). These materials have good abrasion resistance and good aging ...

rubber (SBR), and ethylene propylene diene monomer rubber (EPDM rubber

EPDM rubber (ethylene propylene diene monomer rubber) is a type of synthetic rubber that is used in many applications.

EPDM is an M-Class rubber under ASTM standard D-1418; the ''M'' class comprises elastomers with a saturated polyethylene chai ...

). All of these materials contain alkene groups adjacent to methylene groups. Other specialty rubbers may also be vulcanized, such as nitrile rubber

Nitrile rubber, also known as nitrile butadiene rubber, NBR, Buna-N, and acrylonitrile butadiene rubber, is a synthetic rubber derived from acrylonitrile (ACN) and butadiene. Trade names include Perbunan, Nipol, Krynac and Europrene. This rubber is ...

(NBR) and butyl rubber

Butyl rubber, sometimes just called butyl, is a synthetic rubber, a copolymer of isobutylene with isoprene. The abbreviation IIR stands for isobutylene isoprene rubber. Polyisobutylene, also known as "PIB" or polyisobutene, (C4H8)n, is the homop ...

(IIR). Vulcanization, in common with the curing of other thermosetting polymer

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening (" curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and ...

s, is generally irreversible. Efforts have focused on developing de-vulcanization (see tire recycling

Tire recycling, or rubber recycling, is the process of recycling waste tires that are no longer suitable for use on vehicles due to wear or irreparable damage. These tires are a challenging source of waste, due to the large volume produced, th ...

) processes for recycling of rubber waste but with little success.

Structural and mechanistic details

The details of vulcanization remain murky because the process converts mixtures of polymers to mixtures of insoluble derivatives. By design the reaction does not proceed to completion because fully crosslinked polymer would be too rigid for applications. There has long been uncertainly as to whether vulcanization proceeds in a radical or ionic manner.

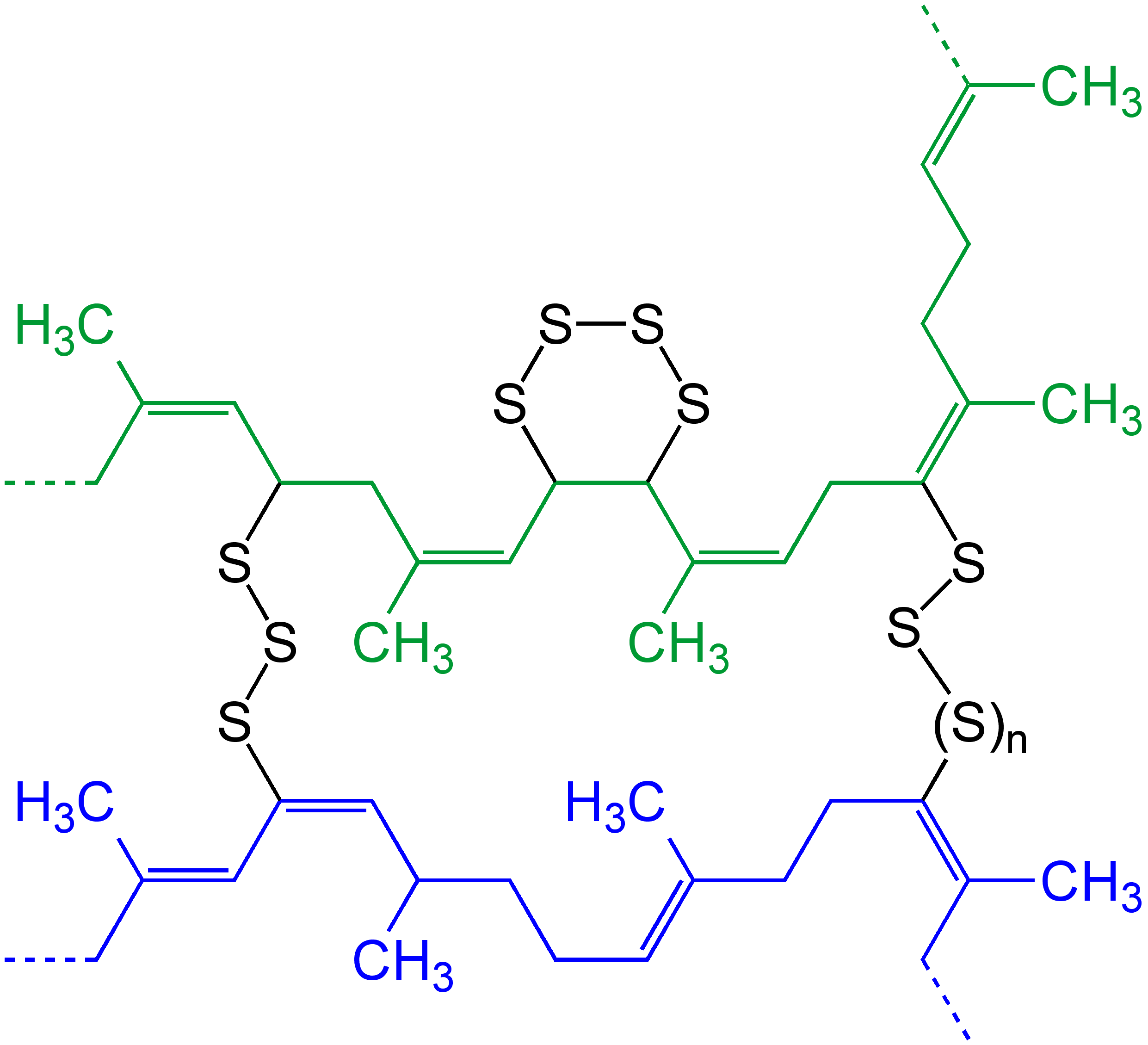

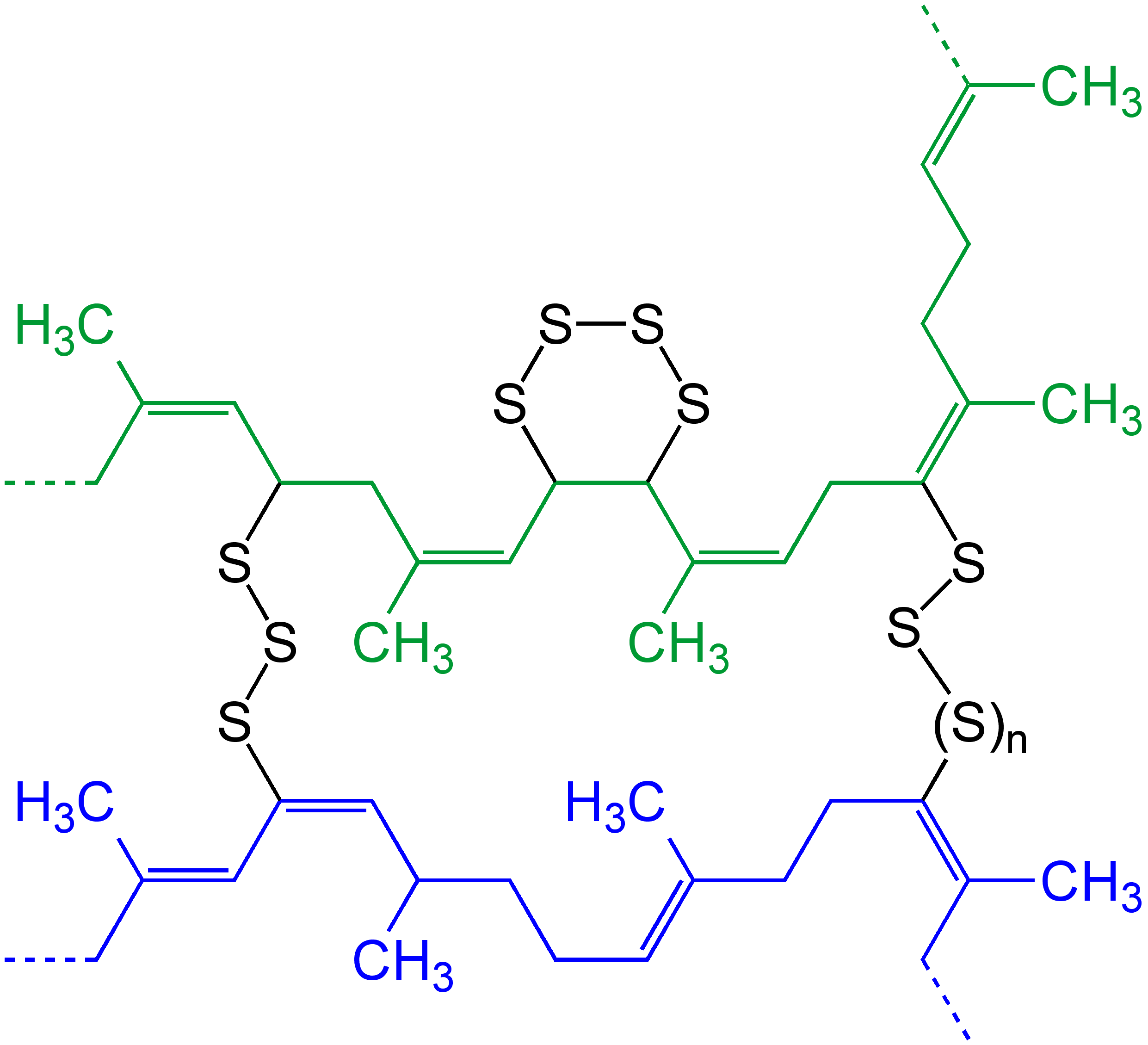

It is agreed that the reactive sites, often referred to as 'cure sites', are the

The details of vulcanization remain murky because the process converts mixtures of polymers to mixtures of insoluble derivatives. By design the reaction does not proceed to completion because fully crosslinked polymer would be too rigid for applications. There has long been uncertainly as to whether vulcanization proceeds in a radical or ionic manner.

It is agreed that the reactive sites, often referred to as 'cure sites', are the allyl

In organic chemistry, an allyl group is a substituent with the structural formula . It consists of a methylene bridge () attached to a vinyl group (). The name is derived from the scientific name for garlic, . In 1844, Theodor Wertheim isolated a ...

groups (-CH=CH-CH2-). Sulfur forms bridge between these sites, crosslinking the polymer chains. These bridges may consist of one or several sulfur atoms and are separated by hundreds or thousands of carbons in the polymer chain.

Both the extent of crosslinking and the number of sulfur atoms in the crosslinks strongly influences the physical properties of the rubber produced:

* Excessive crosslinking can convert the rubber into a hard and brittle substance (i.e. ebonite).

* Short crosslinks, possessing lower numbers of sulfur atoms, give the rubber better resistance to heat and weathering.

* Longer crosslinks, with higher numbers of sulfur atoms, give the rubber improved physical durability and tensile strength

Ultimate tensile strength (also called UTS, tensile strength, TS, ultimate strength or F_\text in notation) is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials, the ultimate ...

.

Sulfur, by itself, is a slow vulcanizing agent and does not vulcanize synthetic polyolefins. Even with natural rubber, large amounts of sulfur as well as high temperatures and prolonged heating periods are necessary, with the end products often being of an unsatisfactory quality.

Since the early 1900s, various chemical additives have been developed to improve the speed and efficiency of vulcanization, as well as to control the nature of the cross-linking. When used together, this collection – the "cure package" – gives a rubber with particular properties.

Cure package

The cure package consists of various reagents that modify the kinetics and chemistry of crosslinking. These include accelerants, activators, retarders and inhibitors. Note that these are merely the additives used for vulcanization and that other compounds may also be added to the rubber, such asfillers

In animal feed, a filler is an ingredient added to provide dietary fiber, bulk or some other non-nutritive purpose. Products like corn fiber (corncobs), fruit fibers (pulp), rice bran, and whole grains are possible fillers.

Purpose

As source ...

, tackifiers, polymer stabilizers and antiozonants.

Sulfur source

Ordinary sulfur (octasulfur, or S8) is rarely used, despite its low cost, because it is soluble in the polymer. High-temperature vulcanisation with ordinary sulfur leads to rubbersupersaturated

In physical chemistry, supersaturation occurs with a solution when the concentration of a solute exceeds the concentration specified by the value of solubility at equilibrium. Most commonly the term is applied to a solution of a solid in a ...

with S8, upon cooling this migrates to the surface and crystallises as sulfur bloom. This can cause problems if multiple layers of rubber are being added to form a composite item, such as a tire. Instead, various forms of polymeric sulfur are used, which are insoluble in the uncured rubber. It is also possible to replace sulfur with other sulfur-donating compounds, for example accelerants bearing disulfide

In chemistry, a disulfide (or disulphide in British English) is a compound containing a functional group or the anion. The linkage is also called an SS-bond or sometimes a disulfide bridge and usually derived from two thiol groups.

In inorg ...

groups, in what is often termed "efficient vulcanization" (EV). Disulfur dichloride

Disulfur dichloride (or disulphur dichloride by the British English spelling) is the inorganic compound of sulfur and chlorine with the Chemical formula, formula . It is an amber oily liquid.

Sometimes, this compound is incorrectly named ''sulfur ...

may also be used for "cold vulcanization".

Accelerants

Accelerants (accelerators) act much likecatalysts

Catalysis () is the increase in reaction rate, rate of a chemical reaction due to an added substance known as a catalyst (). Catalysts are not consumed by the reaction and remain unchanged after it. If the reaction is rapid and the catalyst ...

allowing vulcanization to be performed cooler yet faster and with a more efficient use of sulfur. They achieve this by reacting with the sulfur to form a reactive intermediate, referred to as a sulfurating agent. This, in turn, reacts with cure sites in the rubber to bring about vulcanization.

There are two major classes of vulcanization accelerants: primary accelerants and secondary accelerants (also known as ultra accelerants). Primary activators date from the use of ammonia in 1881, while secondary accelerants have been developed since around 1920.

;Primary (fast-accelerants)

Primary accelerants perform the bulk of the accelerating and mostly consist of thiazoles, often derivatised with sulfenamide groups. The principal compound is 2- mercaptobenzothiazole (MBT), which has been in use since the 1920s. It remains a moderately fast curing agent giving sulfur chains of a medium length, but its relatively short induction period can be a disadvantage. Other primary accelerants are essentially "masked" forms of MBT, which take time to decompose into MBT during vulcanization and thus have longer inductions periods.

disulfide

In chemistry, a disulfide (or disulphide in British English) is a compound containing a functional group or the anion. The linkage is also called an SS-bond or sometimes a disulfide bridge and usually derived from two thiol groups.

In inorg ...

(MBTS), and sulfenamide derivatives are produced by reacting this with primary amine

In chemistry, amines (, ) are organic compounds that contain carbon-nitrogen bonds. Amines are formed when one or more hydrogen atoms in ammonia are replaced by alkyl or aryl groups. The nitrogen atom in an amine possesses a lone pair of elec ...

s like cyclohexylamine or tert-butylamine

''tert''-Butylamine (also erbumine and other names) is an organic chemical compound with the formula (CH3)3CNH2. It is a colorless liquid with a typical amine-like odor. ''tert''-Butylamine is one of the four isomeric amines of butane, the othe ...

. Secondary amines like dicyclohexylamine can be used and result in even slower accelerants. Such a slow accelerant is required in applications in which the rubber is being cured onto a metal component to which it is required to adhere, such as the steel cords in vehicle tires.

;Secondary (ultra-accelerants)

Secondary or ultra-accelerants are used in small amounts to augment the behaviour of primary accelerants. They act to boost the cure speed and increase cross-link density, but also shorten the induction time, which can lead to premature vulcanization. Chemically, they consist mainly of thio-carbonyl species such as thiurams, dithiocarbamate

In organic chemistry, a dithiocarbamate is a chemical compound with the general formula . It contains the functional group with the Chemical structure, structure . It is the analog of a carbamate in which both oxygen atoms are replaced by sulfur ...

s, xanthate

A xanthate is a Salt (chemistry), salt or ester of a xanthic acid. The formula of the salt of xanthic acid is (where R is organyl group and M is usually Sodium, Na or Potassium, K). Xanthate also refers to the anion . The formula of a xanthic a ...

s and organic thiourea

Thiourea () is an organosulfur compound with the formula and the structure . It is structurally similar to urea (), with the oxygen atom replaced by sulfur atom (as implied by the '' thio-'' prefix). The properties of urea and thiourea differ s ...

s; aromatic guanidine

Guanidine is the compound with the formula HNC(NH2)2. It is a colourless solid that dissolves in polar solvents. It is a strong base that is used in the production of plastics and explosives. It is found in urine predominantly in patients experi ...

s are also used. These compounds need to be combined with activators, typically zinc ions, in order to be fully active.

Ziram

Zinc dimethyldithiocarbamate is a coordination complex of zinc with dimethyldithiocarbamate. It is a pale yellow solid that is used as a fungicide, the sulfur vulcanization of rubber, and other industrial applications.

Applications

Known as ziram ...

)

1,3-difenylguanidine t.png , diphenylguanidine (DPG)

EPDM

EPDM rubber (ethylene propylene diene monomer rubber) is a type of synthetic rubber that is used in many applications.

EPDM is an M-Class rubber under ASTM standard D-1418; the ''M'' class comprises elastomers with a saturated and unsaturated co ...

. Xanthates (principally, zinc isopropyl xanthate) are important in the vulcanization of latex, which is cured at relatively low temperatures (100-120 °C), and therefore needs an inherently rapid accelerant. The major thiurams used are TMTD ( tetramethylthiuram disulfide) and TETD ( tetraethylthiuram disulfide). The major dithiocarbamates are the zinc salts ZDMC ( zinc dimethyldithiocarbamate), ZDEC (zinc diethyldithiocarbamate) and ZDBC (zinc dibutyldithiocarbamate).

Activators

Activators consist of various metal salts, fatty acids, as well as nitrogen-containing bases, the most important these beingzinc oxide

Zinc oxide is an inorganic compound with the Chemical formula, formula . It is a white powder which is insoluble in water. ZnO is used as an additive in numerous materials and products including cosmetics, Zinc metabolism, food supplements, rubbe ...

. Zinc actives many accelerants by coordination, for example causing thiuram to convert into ziram

Zinc dimethyldithiocarbamate is a coordination complex of zinc with dimethyldithiocarbamate. It is a pale yellow solid that is used as a fungicide, the sulfur vulcanization of rubber, and other industrial applications.

Applications

Known as ziram ...

. Zinc also coordinates to the sulfur-chains of sulfurating agents, changing the most likely bond to break during cross-link formation. Ultimately, activators promote the efficient use of sulfur to give a high density of cross-links. Due to the low solubility of ZnO it is often combined with fatty acids such as stearic acid

Stearic acid ( , ) is a saturated fatty acid with an 18-carbon chain. The IUPAC name is octadecanoic acid. It is a soft waxy solid with the formula . The triglyceride derived from three molecules of stearic acid is called stearin. Stearic acid ...

to form more soluble metallic soap, ''i.e.'', zinc stearate.

Retarders and inhibitors

To ensure high-quality vulcanization, the rubber, sulfur, accelerants, activators and other compounds are blended to give a homogeneous mixture. In practice, mixing can result in melting the sulfur (melting point 115 °C for S8). At these temperatures vulcanization can begin prematurely, which is often undesirable, as the mixture may still need to be pumped and moulded into its final form before it sets solid. Premature vulcanization is often called "scorch". Scorch can be prevented by the use of retarders or inhibitors, which increase the induction period before vulcanization commences and thus provide scorch resistance. A retarder slows both the onset and rate of vulcanization, whereas inhibitors only delay the start of vulcanization and do not affect the rate to any great extent. In general inhibitors are preferred, with cyclohexylthiophthalimide (often termed PVI — pre-vulcanization inhibitor) being the most common example.Devulcanization

The market for new raw rubber or equivalent is large. The auto industry consumes a substantial fraction of natural and synthetic rubber. Reclaimed rubber has altered properties and is unsuitable for use in many products, including tires. Tires and other vulcanized products are potentially amenable to devulcanization, but this technology has not produced material that can supplant unvulcanized materials. The main problem is that the carbon-sulfur linkages are not readily broken, without the input of costly reagents and heat. Thus, more than half of scrap rubber is simply burned for fuel.Inverse vulcanization

Although polymeric sulfur reverts to its monomer at room temperature, polymers consisting mostly of sulfur can be stabilized with organic linkers such as 1,3‐diisopropenylbenzene. This process is called inverse vulcanization and produces polymers where sulfur is the main component.History

The curing of rubber has been carried out since prehistoric times. The name of the first major civilization in Guatemala and Mexico, theOlmec

The Olmecs () or Olmec were an early known major Mesoamerican civilization, flourishing in the modern-day Mexican states of Veracruz and Tabasco from roughly 1200 to 400 Before the Common Era, BCE during Mesoamerica's Mesoamerican chronolog ...

, means 'rubber people' in the Aztec

The Aztecs ( ) were a Mesoamerican civilization that flourished in central Mexico in the Post-Classic stage, post-classic period from 1300 to 1521. The Aztec people included different Indigenous peoples of Mexico, ethnic groups of central ...

language. Ancient Mesoamerica

Mesoamerica is a historical region and cultural area that begins in the southern part of North America and extends to the Pacific coast of Central America, thus comprising the lands of central and southern Mexico, all of Belize, Guatemala, El S ...

ns, spanning from ancient Olmecs to Aztecs, extracted latex

Latex is an emulsion (stable dispersion) of polymer microparticles in water. Latices are found in nature, but synthetic latices are common as well.

In nature, latex is found as a wikt:milky, milky fluid, which is present in 10% of all floweri ...

from '' Castilla elastica'', a type of rubber tree in the area. The juice of a local vine, '' Ipomoea alba'', was then mixed with this latex to create processed rubber as early as 1600 BCE. In the Western world, rubber remained a curiosity, although it was eventually used to produce waterproofed products, such as Mackintosh

The Mackintosh raincoat (abbreviated as mac) is a form of waterproof raincoat, first sold in 1824, made of rubberised textile, fabric.

The Mackintosh is named after its Scotland, Scottish inventor Charles Macintosh, although many writers adde ...

rainwear, beginning in the early 1800s.

Modern developments

In 1832–1834 Nathaniel Hayward and Friedrich Ludersdorf discovered that rubber treated with sulfur lost its stickiness. It is likely Hayward shared his discovery withCharles Goodyear

Charles Goodyear (December 29, 1800 – July 1, 1860) was an American self-taught chemist and manufacturing engineer who developed vulcanized rubber, for which he received patent number 3633 from the United States Patent Office on June 15, 1844 ...

, possibly inspiring him to make the discovery of vulcanization.

Charles Goodyear

Charles Goodyear (December 29, 1800 – July 1, 1860) was an American self-taught chemist and manufacturing engineer who developed vulcanized rubber, for which he received patent number 3633 from the United States Patent Office on June 15, 1844 ...

(1800–1860), a scientist and engineer, was the first to patent vulcanization of rubber. He was awarded a patent on June 15, 1844. A year later, after viewing Goodyear's work, Thomas Hancock was awarded the British Patent for the process. This was court granted after British scientist claimed that examining Goodyear's rubber could not produce the formula for vulcanizing rubber. It was Hancock's friend William Brockedon

William Brockedon (13 October 1787 – 29 August 1854) was a 19th-century English painter, writer and inventor.

Early life

Brockedon was born at Totnes on 13 October 1787, son of a watchmaker. He was educated at a private school in Totnes, bu ...

who coined term 'vulcanization'.

Goodyear claimed that he had discovered vulcanization earlier, in 1839. He wrote the story of the discovery in 1853 in his autobiographical book ''Gum-Elastica''. Here is Goodyear's account of the invention

An invention is a unique or novelty (patent), novel machine, device, Method_(patent), method, composition, idea, or process. An invention may be an improvement upon a machine, product, or process for increasing efficiency or lowering cost. It m ...

, taken from ''Gum-Elastica''. Although the book is an autobiography

An autobiography, sometimes informally called an autobio, is a self-written account of one's own life, providing a personal narrative that reflects on the author's experiences, memories, and insights. This genre allows individuals to share thei ...

, Goodyear chose to write it in the third person so that and referred to in the text are the author. He describes the scene in a rubber factory

A factory, manufacturing plant or production plant is an industrial facility, often a complex consisting of several buildings filled with machinery, where workers manufacture items or operate machines which process each item into another. Th ...

where his brother worked:

The inventor made experiments to ascertain the effect of heat on the same compound that had decomposed in the mail-bags and other articles. He was surprised to find that the specimen, being carelessly brought into contact with a hot stove, charred like leather.Goodyear goes on to describe how his discovery was not readily accepted.

He directly inferred that if the process of charring could be stopped at the right point, it might divest the gum of its native adhesiveness throughout, which would make it better than the native gum. Upon further trial with heat, he was further convinced of the correctness of this inference, by finding that the India rubber could not be melted in boiling sulfur at any heat, but always charred. He made another trial of heating a similar fabric before an open fire. The same effect, that of charring the gum, followed. There were further indications of success in producing the desired result, as upon the edge of the charred portion appeared a line or border, that was not charred, but perfectly cured.Goodyear then goes on to describe how he moved to

Woburn, Massachusetts

Woburn ( ) is a city in Middlesex County, Massachusetts, Middlesex County, Massachusetts, United States. The population was 40,876 at the 2020 United States census, 2020 census. Woburn is located north of Boston. Woburn uses Massachusetts' ...

and carried out a series of systematic experiments to optimize the curing of rubber, collaborating with Nathaniel Hayward.

On ascertaining to a certainty that he had found the object of his search and much more, and that the new substance was proof against cold and the solvent of the native gum, he felt himself amply repaid for the past, and quite indifferent to the trials of the future.

Later developments

The discovery of the rubber-sulfur reaction revolutionized the use and applications of rubber, changing the face of the industrial world. Formerly, the only way to seal a small gap between moving machine parts was to useleather

Leather is a strong, flexible and durable material obtained from the tanning (leather), tanning, or chemical treatment, of animal skins and hides to prevent decay. The most common leathers come from cattle, sheep, goats, equine animals, buffal ...

soaked in oil. This practice was acceptable only at moderate pressures, but above a certain point, machine designers were forced to compromise between the extra friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. Types of friction include dry, fluid, lubricated, skin, and internal -- an incomplete list. The study of t ...

generated by tighter packing and greater leakage of steam. Vulcanized rubber solved this problem. It could be formed to precise shapes and dimensions, it accepted moderate to large deformations under load and recovered quickly to its original dimensions once the load is removed. These exceptional qualities, combined with good durability and lack of stickiness, were critical for an effective sealing material. Further experiments in the processing and compounding of rubber by Hancock and his colleagues led to a more reliable process.

Around 1900, disulfiram

Disulfiram is a medication used to support the treatment of chronic alcoholism by producing an acute sensitivity to ethanol (drinking alcohol). Disulfiram works by Enzyme inhibition, inhibiting the enzyme aldehyde dehydrogenase (specifically ALD ...

was introduced as a vulcanizing agent, and became widely used.

In 1905 George Oenslager discovered that a derivative of aniline

Aniline (From , meaning ' indigo shrub', and ''-ine'' indicating a derived substance) is an organic compound with the formula . Consisting of a phenyl group () attached to an amino group (), aniline is the simplest aromatic amine. It is an in ...

called thiocarbanilide accelerated the reaction of sulfur with rubber, leading to shorter cure times and reducing energy consumption. This breakthrough was almost as fundamental to the rubber industry as Goodyear's sulfur cure. Accelerators made the cure process faster, improved the reliability of the process and enabled vulcanization to be applied to synthetic polymers. One year after his discovery, Oenslager had found hundreds of applications for his additive. Thus, the science of accelerators and retarders was born. An accelerator speeds up the cure reaction, while a retarder delays it. A typical retarder is cyclohexylthiophthalimide. In the subsequent century chemists developed other accelerators and ultra-accelerators, which are used in the manufacture of most modern rubber goods.

See also

* Sulfur concreteReferences

{{Authority control Chemical processes Rubber 1837 introductions