Sucrerie Centrale De Cambrai on:

[Wikipedia]

[Google]

[Amazon]

The Sucrerie centrale de Cambrai was a company which had a central

The idea to establish the Sucrerie Centrale de Cambrai came up at the time that the

The idea to establish the Sucrerie Centrale de Cambrai came up at the time that the

beet sugar factory

A beet sugar factory, or sugar factory, is a type of production facility that produces sugar from Sugar beet, sugar beets or alternative plants to sugarcane in making refined sugar. These factories process the beets to produce White sugar, refined ...

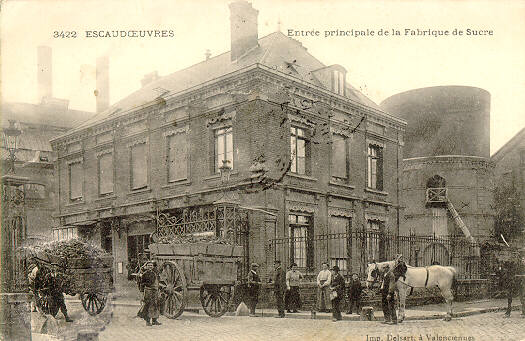

in Escaudœuvres, Nord department, France. This Sucrerie centrale d'Escaudœuvres was fed by about a dozen râperie

A râperie is a small factory depending on a central sugar factory. In a râperie sugar beet are grated and the juice is extracted before it is transported to a central sugar factory. By 2023 the Râperie de Longchamps, Éghezée, Longchamps connec ...

s. In 2003 the company was merged into its owner Tereos. The central factory then continued to operate as Sucrerie Tereos d'Escaudœuvres until 2023. The facilities are now only used for storage and logistics.

Characteristics

The official name of the company that founded the factory was 'Sucrerie centrale de Cambrai'. It was located in Escaudœuvres. The name reflected that for some time, the facility was a central factory which finished the work of satellite factories, so calledrâperie

A râperie is a small factory depending on a central sugar factory. In a râperie sugar beet are grated and the juice is extracted before it is transported to a central sugar factory. By 2023 the Râperie de Longchamps, Éghezée, Longchamps connec ...

s. These closed down in the 1960s, but the company and factory did not change their names.

The factory's location in Escaudœuvres, just north of Cambrai

Cambrai (, ; ; ), formerly Cambray and historically in English Camerick or Camericke, is a city in the Nord department and in the Hauts-de-France region of France on the Scheldt river, which is known locally as the Escaut river.

A sub-pref ...

is due to geography. The surrounding area is farm land with much clay

Clay is a type of fine-grained natural soil material containing clay minerals (hydrous aluminium phyllosilicates, e.g. kaolinite, ). Most pure clay minerals are white or light-coloured, but natural clays show a variety of colours from impuriti ...

and lime, ideal for growing sugar beet

A sugar beet is a plant whose root contains a high concentration of sucrose and that is grown commercially for sugar production. In plant breeding, it is known as the Altissima cultivar group of the common beet (''Beta vulgaris''). Together with ...

. Also, the Nord-Pas de Calais Mining Basin

The Nord-Pas-de-Calais Mining Basin is a mining basin in Northern France that stretches across the Nord (French department), Nord and Pas-de-Calais departments. The region is famous for its long history of coal extraction and its testimony to a s ...

is close by, which was important to get cheap coal

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other Chemical element, elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal i ...

. There was also a good rail and canal network in the area. The latter consisted of its location on the river Scheldt

The Scheldt ( ; ; ) is a river that flows through northern France, western Belgium, and the southwestern part of Netherlands, the Netherlands, with its mouth at the North Sea. Its name is derived from an adjective corresponding to Old Englis ...

with its many side canals.

The factory is now part of the cooperative

A cooperative (also known as co-operative, coöperative, co-op, or coop) is "an autonomy, autonomous association of persons united voluntarily to meet their common economic, social and cultural needs and aspirations through a jointly owned a ...

industrial group Tereos, which bought its owner in 2002 and then liquidated the Sucrerie centrale de Cambrai company by merging it into Béghin-Say

Tereos is a cooperative conglomerate, primarily active in the processed agricultural raw materials, in particular sugar, alcohol and starch markets. It has 44 factories in 9 countries, including Brazil, India, Indonesia, Kenia, Tanzania, Belgiu ...

.

History

Foundation and early years

The idea to establish the Sucrerie Centrale de Cambrai came up at the time that the

The idea to establish the Sucrerie Centrale de Cambrai came up at the time that the râperie

A râperie is a small factory depending on a central sugar factory. In a râperie sugar beet are grated and the juice is extracted before it is transported to a central sugar factory. By 2023 the Râperie de Longchamps, Éghezée, Longchamps connec ...

- central factory concept was popular. A râperie is a small sugar factory that extracts the raw juice from sugar beet. The juice is then transported to a central factory by means of a cast iron pipeline. At the time, this greatly reduced road transport cost, which were very high for heavy cargo.

The engineer Jules Linard invented the transport of raw juice by pipeline. He applied it for the first time in 1867. Encouraged by international free trade politics and a growing demand for sugar, he got the idea to found his own sugar factory. With the advice of the lawyer Léon Estivan, Linard opted to establish a public company

A public company is a company whose ownership is organized via shares of share capital, stock which are intended to be freely traded on a stock exchange or in over-the-counter (finance), over-the-counter markets. A public (publicly traded) co ...

so he could raise enough money to implement the concept on a very large scale.

The factory was built by Société J. F. Cail & Cie in 1872.

Initial Set up

At the end of 1873, there were 17 râperies with 87.5 miles of tubing. In order to increase production of the central factory to the designed capacity of 250,000 t of beet, there were plans for 8 more râperies. A boiler-iron reservoir for raw juice of 5,000 hectoliters stood 400 m from the factory. The lime quarry was next to the reservoir and was connected to the factory by a horse railroad. The main hall of the central factory was of brick, with an iron roof. It measured 100 by 18 m and was 30 m high. On one of its sides, four small buildings extended. The first had the repair shop and milk of lime vats below, and the filter presses above. The second building had the steam boilers. The third building held the bone black revivifying furnaces. The fourth building had below: 45 tanks of 1,000 hectoliters each for the second and third products, and above: the packing and storage room for sugar of 1,800 m2. The factory's nearby gas works furnished 500 m3 per day. Also nearby was the furnace forcarbon dioxide

Carbon dioxide is a chemical compound with the chemical formula . It is made up of molecules that each have one carbon atom covalent bond, covalently double bonded to two oxygen atoms. It is found in a gas state at room temperature and at norma ...

gas. This held 500 m3 of gas and was fed by an elevator.

The steam boilers were 16, each having a heated surface of 200 m2, giving a total of 2,400 hp. The revivifying furnaces were two from Schreiber, each supplying 150 hectoliters per day.

The main hall had the engines and turbines on the ground floor. Running along one side, on platforms, were: the tanks for the first and second carbonatation; the multiple effect evaporators; and the vacuum pans.

For 1873 or 1874 it was reported that the second and third product (sugar of lower quality) had not been made. The report said that 60 t of sugar had been manufactured daily. The central factory employed about 400 people, the râperies another 1,100.

In 1877 the râperies were in:

* Rieux-en-Cambrésis

Rieux-en-Cambrésis is a commune in the Nord department in northern France.

Heraldry

See also

*Communes of the Nord department

The following is a list of the 647 communes of the Nord department of the French Republic.

The communes c ...

* Avesnes-les-Aubert

Avesnes-les-Aubert () is a commune in the Nord department in northern France.

Population

Heraldry

See also

*Communes of the Nord department

The following is a list of the 647 communes of the Nord department of the French Republic.

...

* Carnières

Carnières () is a commune in the Nord department in northern France.

It is about east of Cambrai.

Heraldry

See also

*Communes of the Nord department

The following is a list of the 647 communes of the Nord department of the French Re ...

* Crèvecœur-sur-l'Escaut

Crèvecœur-sur-l'Escaut (, literally ''Crèvecœur on the Scheldt'') is a commune in the Nord department in northern France.

Heraldry

See also

*Communes of the Nord department

The following is a list of the 647 communes of the Nord d ...

* Honnecourt-sur-Escaut

Honnecourt-sur-Escaut (, literally '' Honnecourt on Escaut'') is a commune in the Nord department in northern France.

Heraldry

See also

*Communes of the Nord department

The following is a list of the 647 communes of the Nord departmen ...

* Villers-Guislain

Villers-Guislain () is a commune in the Nord department in northern France. The graveyard a Gauche Woodcontains the casualties who died during the Battle of Épehy when British troops were deployed between Gouzeaucourt and Villers-Guislain.

He ...

* Villers-Plouich

Villers-Plouich () is a commune in the Nord department in northern France, situated 14 km south-west of the town of Cambrai

Cambrai (, ; ; ), formerly Cambray and historically in English Camerick or Camericke, is a city in the Nord ...

* Bertincourt

Bertincourt () is a commune in the Pas-de-Calais department in the Hauts-de-France region in northern France.

Geography

Bertincourt is a farming village located 22 miles (36 km) southeast of Arras at the junction of the D7, D18 and D19 ro ...

* Flesquières

Flesquières () is a commune in the Nord department in northern France.

Heraldry

See also

*Communes of the Nord department

*Marcel Gaumont

Marcel Gaumont was a French sculptor born on 27 January 1880 in Tours. He died in Paris on ...

* Mœuvres

Mœuvres () is a commune in the Nord department in northern France.

Heraldry

See also

*Communes of the Nord department

The following is a list of the 647 communes of the Nord department of the French Republic.

The communes cooperate ...

* Fontaine-Notre-Dame, Nord

Fontaine-Notre-Dame is a commune in the Nord department in northern France.

Heraldry

Fontaine-Notre-Dame in World War I

Fontaine-Notre-Dame was the scene of intense fighting during the Battle of Cambrai in World War I.

The battle started o ...

* Bourlon

Bourlon () is a commune in the Pas-de-Calais department in the Hauts-de-France region in northern France.

Geography

A farming village located 22 miles (35 km) southeast of Arras on the D16 road, just yards from the A26 autoroute.

Populat ...

* Bantigny

* Épinoy

Épinoy (; ) is a commune in the Pas-de-Calais department in the Hauts-de-France region of France southeast of Arras. Population

See also

*Communes of the Pas-de-Calais department

The following is a list of the 887 communes of the Pas ...

* Bullecourt

Bullecourt () is a commune in the Pas-de-Calais department department in the Hauts-de-France region region of northern France.

Geography

Bullecourt is situated on the Upper Cretaceous plain of Artois between Arras and Bapaume, east of the A1 ...

* Beugnies

Beugnies () is a commune in the Nord department in northern France

France, officially the French Republic, is a country located primarily in Western Europe. Overseas France, Its overseas regions and territories include French Guiana in S ...

* Demicourt

* Lagnicourt-Marcel

Lagnicourt-Marcel () is a commune in the Pas-de-Calais department in the Hauts-de-France region of France

southeast of Arras.

Population

See also

*Communes of the Pas-de-Calais department

The following is a list of the 887 communes of ...

Situation in 1896

In 1896 the Sucrerie centrale de Cambrai was the biggest sugar factory in France, and one of the biggest in the world. It could process 3,000 t of beet per day. For this, the raw juice of the sugar beet was extracted in 16 râperies, one of which was located at the factory itself. These râperies spread out up to 15 km from the factory and were connected by 130 km of pipeline of different diameters. The scale of the factory was easily 10 times that of regular sugar factories. In 1896 the location of the facilities was very favorable. The facilities were in an area which was very well suited to grow sugar beet. This allowed the creation of the network of râperies and guaranteed the steady supply of beet at a competing price. The factory was close to the northern coal mines. Its huge demand for limestone was supplied by a nearby quarry. For transport it had a canal with quays and its own railway connection toCambrai station

Cambrai is a railway station serving the town of Cambrai, Nord department, in northern France.

Services

The station is served by regional trains to Douai, Valenciennes, Saint-Quentin and Lille

Lille (, ; ; ; ; ) is a city in the northern p ...

. Water for the machinery and central râperie was provided by the canal and several pits.

The central factory communicated to the râperies by telegraph and telephone. This was crucial, because the râperies had to stop their supply if the central factory could not process it. Otherwise, the pumpedup juice would be lost or even inundate the central factory. At the central factory there was a tank of 6,000 hectoliter to temporarily store the juice.

The râperie at the central factory also served for beet delivered by boat or rail. The beet that were delivered by boat were unloaded by steam crane

A steam crane is a crane (machine), crane powered by a steam engine. It may be fixed or mobile and, if mobile, it may run on rail tracks, caterpillar tracks, road wheels, or be mounted on a barge. It usually has a vertical boiler placed at the ...

s on rails. These beet could either be unloaded to the reception area, or to rail carriages which brought them to storage. The râperie at the central factory could process 300 t per day. The reception area with its long gutters assured a good cleaning. After cleaning, the beet were transported to the top of the building by means of a screw.

The central factory itself consisted of a great machinery hall of 100 by 18 m. It was surrounded by smaller buildings like the scum works, the generators, repair shops etc. In the great (machinery) hall the ground floor held: the vacuum pumps for the evaporators and vacuum pans, those for the ventilation system, the scum pumps and other pumps. One floor up were the boilers for the first and second carbonatation. Below these were the clearing tanks and filters. The triple effect evaporators and multiple vacuum pans were also at this level. The scum works were in a separate building. This also applied to the steam engines, which were in two parallel buildings separated by two railway tracks used to supply coal.

In 1896, the factory at Escaudœuvres was remarkable for its huge production and its perfectionism. Together with its râperies, it employed 2,000 workers, and could process 3,000 t of beet per day, which could lead to producing 3,000 bags of sugar per day. For this it used 30 wagons of coal, 15 of lime, and 3 of cokes. In 1894-1895 241,665 t of beet had been processed, and 246,822 bags of sugar of 100 kg each had been produced. This had required 31,000 t of coal.

Gruesome accident (1897)

On 14 October 1897 a gruesome accident happened in the central hall. The lower tank of one of the quintuple effect evaporators was not functioning well. The director of the factory, the chief engineer, two sous-chefs and 11 laborers were investigating and working on the malfunction in a place below the evaporator when the boiler exploded. The evaporator normally contained 30,000 liters of juice. This boiling juice now spread over the people below it. The lid of the boiler which had blown up meanwhile ripped open some steam pipes, the steam knocking out some people which were still standing after the initial shock. Chief engineer Cottereau had been burned so badly that he was unrecognizable and died soon after. Sous-chef Croisier was found dead below a broken pipe. Sous-chef Dizy was severely burned and died of his wounds. 5 laborers were expected to die of their wounds, while 7 more were seriously wounded. In the end four laborers would die. Director Camuset had been working below the boiler with the others, but had been called to his office just before the explosion.Twentieth century

During World War I, the area saw a lot of fighting. E.g. in theBattle of Cambrai (1917)

The Battle of Cambrai (Battle of Cambrai, 1917, First Battle of Cambrai and ''Schlacht von Cambrai'') was a British attack in the First World War, followed by the biggest German counter-attack against the British Expeditionary Force (BEF) sinc ...

. Some of the râperies of the company were destroyed. The factory itself was heavily damaged. The war also led to a strong modernization and concentration of the sugar industry in northern France, with many small factories not reopening.

In 1923 the factory made its first post war campaign after a rebuilt and modernization. In about 1930 the factory in Escaudœuvres had a capacity of 3,000 t of beet per day. It used 9 râperies at a maximum distance of 24 km. The juice travelled at a speed of 1 km/h. In 1939 the capacity was also 3,000 t of beet per day.

In 1960 Sucrerie centrale de Cambrai merged with Les Sucreries Millet. In 1965 it acquired the Sucrerie de Bohain. The râperies were closed, and capacity at Escaudœuvres was increased to 5,000 t per day.

In 1971 a sugar silo of 35,000 t was taken into use.

Controlled by Béghin-Say (1972)

In April 1972Béghin-Say

Tereos is a cooperative conglomerate, primarily active in the processed agricultural raw materials, in particular sugar, alcohol and starch markets. It has 44 factories in 9 countries, including Brazil, India, Indonesia, Kenia, Tanzania, Belgiu ...

made a tender offer

In corporate finance, a tender offer is a type of public takeover bid. The tender offer is a public, open offer or invitation (usually announced in a newspaper advertisement) by a prospective acquirer to all stockholders of a publicly traded corp ...

to the shareholders of Sucrerie centrale de Cambrai. In 1990 Béghin-Say

Tereos is a cooperative conglomerate, primarily active in the processed agricultural raw materials, in particular sugar, alcohol and starch markets. It has 44 factories in 9 countries, including Brazil, India, Indonesia, Kenia, Tanzania, Belgiu ...

owned 68.12% of Sucrerie centrale de Cambrai.

In 1974 capacity was increased to 8,000 t of beet per day. In 1987, a sugar silo of 80,000 t was taken into use.

Controlled by Tereos (2002-2023)

In 2002 thecooperative

A cooperative (also known as co-operative, coöperative, co-op, or coop) is "an autonomy, autonomous association of persons united voluntarily to meet their common economic, social and cultural needs and aspirations through a jointly owned a ...

industrial group Tereos bought Béghin-Say. In 2003 a Squeeze-out

A squeeze-out or squeezeout, sometimes synonymous with '' freeze-out'', is the compulsory sale of the shares of minority shareholders of a joint-stock company for which they receive a fair cash compensation.

This technique allows one or more share ...

of the minority shareholders in the Sucrerie centrale de Cambrai via an offre publique de retrait for EUR 215 per share by Béghin Say was approved.

In March 2023 Tereos announced that it would close down sugar production at Escaudœuvres. In June 2023 the reorganization plan was agreed with the labor unions. By the plan 40 of the 123 employees would continue to work at Escaudoeuvres, which would continue in use as a logistics hub.

References

Sources

* * * * * * * * * * * * * * * {{citation , last=Shapleigh , first=Waldron , year=1874 , journal=The American Chemist , title=The Cambrai Cetnral Beet-Sugar Wors, (Nord) France , publisher=Henry C. Lea, Philadelphia , pages=281–282 Sugar companies Food manufacturers of France Food manufacturing plants in France French companies established in 1872 Sugar industry of France