steam turbines on:

[Wikipedia]

[Google]

[Amazon]

A steam turbine or steam turbine engine is a

The first device that may be classified as a reaction steam turbine was little more than a toy, the classic Aeolipile, described in the 1st century by Hero of Alexandria in

The first device that may be classified as a reaction steam turbine was little more than a toy, the classic Aeolipile, described in the 1st century by Hero of Alexandria in  The modern steam turbine was invented in 1884 by Charles Parsons, whose first model was connected to a dynamo that generated of electricity. The invention of Parsons' steam turbine made cheap and plentiful electricity possible and revolutionized marine transport and naval warfare. Parsons' design was a reaction type. His patent was licensed and the turbine scaled up shortly after by an American, George Westinghouse. The Parsons turbine also turned out to be easy to scale up. Parsons had the satisfaction of seeing his invention adopted for all major world power stations, and the size of generators had increased from his first set up to units of capacity. Within Parsons' lifetime, the generating capacity of a unit was scaled up by about 10,000 times, and the total output from turbo-generators constructed by his firm C. A. Parsons and Company and by their licensees, for land purposes alone, had exceeded thirty million horse-power.

Other variations of turbines have been developed that work effectively with steam. The ''de Laval turbine'' (invented by Gustaf de Laval) accelerated the steam to full speed before running it against a turbine blade. De Laval's impulse turbine is simpler and less expensive and does not need to be pressure-proof. It can operate with any pressure of steam, but is considerably less efficient. Auguste Rateau developed a pressure compounded impulse turbine using the de Laval principle as early as 1896, obtained a US patent in 1903, and applied the turbine to a French torpedo boat in 1904. He taught at the for a decade until 1897, and later founded a successful company that was incorporated into the Alstom firm after his death. One of the founders of the modern theory of steam and gas turbines was Aurel Stodola, a Slovak physicist and engineer and professor at the Swiss Polytechnical Institute (now ETH) in Zurich. His work (English: The Steam Turbine and its prospective use as a Heat Engine) was published in Berlin in 1903. A further book (English: Steam and Gas Turbines) was published in 1922.

The ''Brown-Curtis turbine'', an impulse type, which had been originally developed and patented by the U.S. company International Curtis Marine Turbine Company, was developed in the 1900s in conjunction with

The modern steam turbine was invented in 1884 by Charles Parsons, whose first model was connected to a dynamo that generated of electricity. The invention of Parsons' steam turbine made cheap and plentiful electricity possible and revolutionized marine transport and naval warfare. Parsons' design was a reaction type. His patent was licensed and the turbine scaled up shortly after by an American, George Westinghouse. The Parsons turbine also turned out to be easy to scale up. Parsons had the satisfaction of seeing his invention adopted for all major world power stations, and the size of generators had increased from his first set up to units of capacity. Within Parsons' lifetime, the generating capacity of a unit was scaled up by about 10,000 times, and the total output from turbo-generators constructed by his firm C. A. Parsons and Company and by their licensees, for land purposes alone, had exceeded thirty million horse-power.

Other variations of turbines have been developed that work effectively with steam. The ''de Laval turbine'' (invented by Gustaf de Laval) accelerated the steam to full speed before running it against a turbine blade. De Laval's impulse turbine is simpler and less expensive and does not need to be pressure-proof. It can operate with any pressure of steam, but is considerably less efficient. Auguste Rateau developed a pressure compounded impulse turbine using the de Laval principle as early as 1896, obtained a US patent in 1903, and applied the turbine to a French torpedo boat in 1904. He taught at the for a decade until 1897, and later founded a successful company that was incorporated into the Alstom firm after his death. One of the founders of the modern theory of steam and gas turbines was Aurel Stodola, a Slovak physicist and engineer and professor at the Swiss Polytechnical Institute (now ETH) in Zurich. His work (English: The Steam Turbine and its prospective use as a Heat Engine) was published in Berlin in 1903. A further book (English: Steam and Gas Turbines) was published in 1922.

The ''Brown-Curtis turbine'', an impulse type, which had been originally developed and patented by the U.S. company International Curtis Marine Turbine Company, was developed in the 1900s in conjunction with

The present-day manufacturing industry for steam turbines consists of the following companies:

* Ansaldo

* Arabelle Solutions

*

The present-day manufacturing industry for steam turbines consists of the following companies:

* Ansaldo

* Arabelle Solutions

*

Turbine blades are of two basic types, blades and nozzles. Blades move entirely due to the impact of steam on them and their profiles do not converge. This results in a steam velocity drop and essentially no pressure drop as steam moves through the blades. A turbine composed of blades alternating with fixed nozzles is called an impulse turbine, , Rateau turbine, or Brown-Curtis turbine. Nozzles appear similar to blades, but their profiles converge near the exit. This results in a steam pressure drop and velocity increase as steam moves through the nozzles. Nozzles move due to both the impact of steam on them and the reaction due to the high-velocity steam at the exit. A turbine composed of moving nozzles alternating with fixed nozzles is called a reaction turbine or Parsons turbine.

Except for low-power applications, turbine blades are arranged in multiple stages in series, called compounding, which greatly improves

Turbine blades are of two basic types, blades and nozzles. Blades move entirely due to the impact of steam on them and their profiles do not converge. This results in a steam velocity drop and essentially no pressure drop as steam moves through the blades. A turbine composed of blades alternating with fixed nozzles is called an impulse turbine, , Rateau turbine, or Brown-Curtis turbine. Nozzles appear similar to blades, but their profiles converge near the exit. This results in a steam pressure drop and velocity increase as steam moves through the nozzles. Nozzles move due to both the impact of steam on them and the reaction due to the high-velocity steam at the exit. A turbine composed of moving nozzles alternating with fixed nozzles is called a reaction turbine or Parsons turbine.

Except for low-power applications, turbine blades are arranged in multiple stages in series, called compounding, which greatly improves

Turbine types include condensing, non-condensing, reheat, extracting and induction.

Turbine types include condensing, non-condensing, reheat, extracting and induction.

The moving steam imparts both a tangential and axial thrust on the turbine shaft, but the axial thrust in a simple turbine is unopposed. To maintain the correct rotor position and balancing, this force must be counteracted by an opposing force. Thrust bearings can be used for the shaft bearings, the rotor can use dummy pistons, it can be double flow- the steam enters in the middle of the shaft and exits at both ends, or a combination of any of these. In a double flow rotor, the blades in each half face opposite ways, so that the axial forces negate each other but the tangential forces act together. This design of rotor is also called two-flow, double-axial-flow, or double-exhaust. This arrangement is common in low-pressure casings of a compound turbine.

The moving steam imparts both a tangential and axial thrust on the turbine shaft, but the axial thrust in a simple turbine is unopposed. To maintain the correct rotor position and balancing, this force must be counteracted by an opposing force. Thrust bearings can be used for the shaft bearings, the rotor can use dummy pistons, it can be double flow- the steam enters in the middle of the shaft and exits at both ends, or a combination of any of these. In a double flow rotor, the blades in each half face opposite ways, so that the axial forces negate each other but the tangential forces act together. This design of rotor is also called two-flow, double-axial-flow, or double-exhaust. This arrangement is common in low-pressure casings of a compound turbine.

An impulse turbine has fixed nozzles that orient the steam flow into high speed jets. These jets contain significant kinetic energy, which is converted into shaft rotation by the bucket-like shaped rotor blades, as the steam jet changes direction. A pressure drop occurs across only the stationary blades, with a net increase in steam velocity across the stage.

As the steam flows through the nozzle its pressure falls from inlet pressure to the exit pressure (atmospheric pressure or, more usually, the condenser vacuum). Due to this high ratio of expansion of steam, the steam leaves the nozzle with a very high velocity. The steam leaving the moving blades has a large portion of the maximum velocity of the steam when leaving the nozzle. The loss of energy due to this higher exit velocity is commonly called the carry over velocity or leaving loss.

The law of moment of momentum states that the sum of the moments of external forces acting on a fluid which is temporarily occupying the control volume is equal to the net time change of angular momentum flux through the control volume.

The swirling fluid enters the control volume at radius with tangential velocity and leaves at radius with tangential velocity .

An impulse turbine has fixed nozzles that orient the steam flow into high speed jets. These jets contain significant kinetic energy, which is converted into shaft rotation by the bucket-like shaped rotor blades, as the steam jet changes direction. A pressure drop occurs across only the stationary blades, with a net increase in steam velocity across the stage.

As the steam flows through the nozzle its pressure falls from inlet pressure to the exit pressure (atmospheric pressure or, more usually, the condenser vacuum). Due to this high ratio of expansion of steam, the steam leaves the nozzle with a very high velocity. The steam leaving the moving blades has a large portion of the maximum velocity of the steam when leaving the nozzle. The loss of energy due to this higher exit velocity is commonly called the carry over velocity or leaving loss.

The law of moment of momentum states that the sum of the moments of external forces acting on a fluid which is temporarily occupying the control volume is equal to the net time change of angular momentum flux through the control volume.

The swirling fluid enters the control volume at radius with tangential velocity and leaves at radius with tangential velocity .

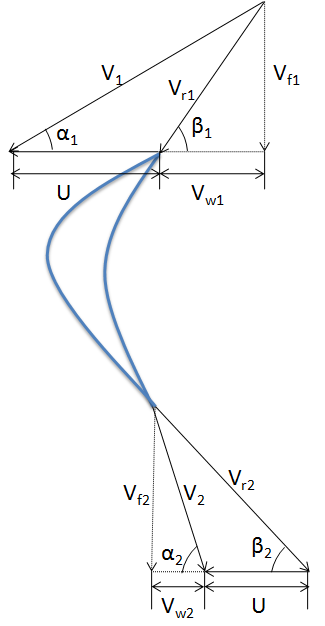

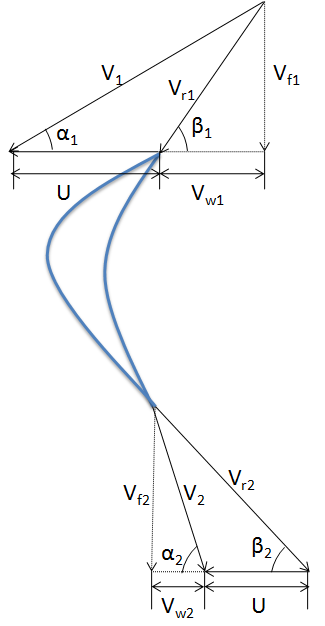

A velocity triangle paves the way for a better understanding of the relationship between the various velocities. In the adjacent figure we have:

: and are the absolute velocities at the inlet and outlet respectively.

: and are the flow velocities at the inlet and outlet respectively.

: and are the swirl velocities at the inlet and outlet respectively, in the moving reference.

: and are the relative velocities at the inlet and outlet respectively.

: is the velocity of the blade.

: is the guide vane angle and is the blade angle.

Then by the law of moment of momentum, the torque on the fluid is given by:

:

For an impulse steam turbine: . Therefore, the tangential force on the blades is . The work done per unit time or power developed: .

When ω is the angular velocity of the turbine, then the blade speed is . The power developed is then .

A velocity triangle paves the way for a better understanding of the relationship between the various velocities. In the adjacent figure we have:

: and are the absolute velocities at the inlet and outlet respectively.

: and are the flow velocities at the inlet and outlet respectively.

: and are the swirl velocities at the inlet and outlet respectively, in the moving reference.

: and are the relative velocities at the inlet and outlet respectively.

: is the velocity of the blade.

: is the guide vane angle and is the blade angle.

Then by the law of moment of momentum, the torque on the fluid is given by:

:

For an impulse steam turbine: . Therefore, the tangential force on the blades is . The work done per unit time or power developed: .

When ω is the angular velocity of the turbine, then the blade speed is . The power developed is then .

A stage of an impulse turbine consists of a nozzle set and a moving wheel. The stage efficiency defines a relationship between enthalpy drop in the nozzle and work done in the stage.

Where is the specific enthalpy drop of steam in the nozzle.

By the

A stage of an impulse turbine consists of a nozzle set and a moving wheel. The stage efficiency defines a relationship between enthalpy drop in the nozzle and work done in the stage.

Where is the specific enthalpy drop of steam in the nozzle.

By the

The enthalpy drop in the fixed blades, with the assumption that the velocity of steam entering the fixed blades is equal to the velocity of steam leaving the previously moving blades is given by:

where V0 is the inlet velocity of steam in the nozzle

is very small and hence can be neglected. Therefore,

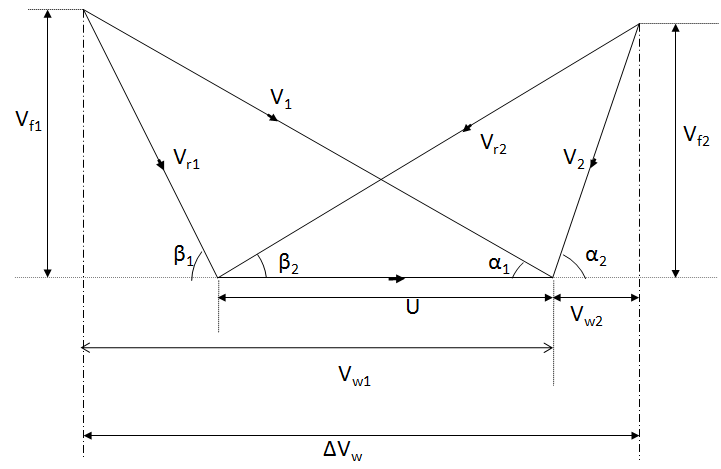

A very widely used design has half degree of reaction or 50% reaction and this is known as Parson's turbine. This consists of symmetrical rotor and stator blades. For this turbine the velocity triangle is similar and we have:

,

,

Assuming ''Parson's turbine'' and obtaining all the expressions we get

From the inlet velocity triangle we have

Work done (for unit mass flow per second):

Therefore, the blade efficiency is given by

The enthalpy drop in the fixed blades, with the assumption that the velocity of steam entering the fixed blades is equal to the velocity of steam leaving the previously moving blades is given by:

where V0 is the inlet velocity of steam in the nozzle

is very small and hence can be neglected. Therefore,

A very widely used design has half degree of reaction or 50% reaction and this is known as Parson's turbine. This consists of symmetrical rotor and stator blades. For this turbine the velocity triangle is similar and we have:

,

,

Assuming ''Parson's turbine'' and obtaining all the expressions we get

From the inlet velocity triangle we have

Work done (for unit mass flow per second):

Therefore, the blade efficiency is given by

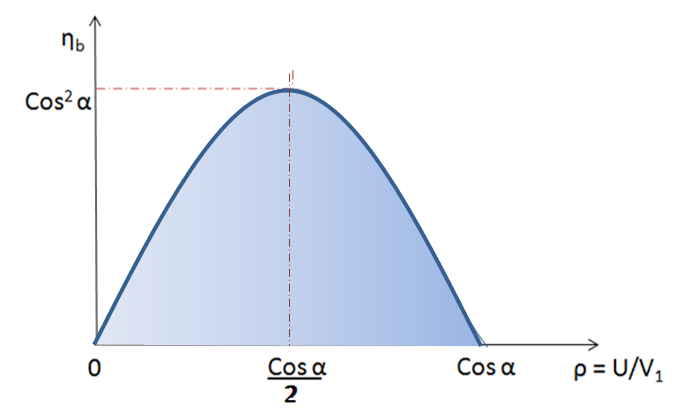

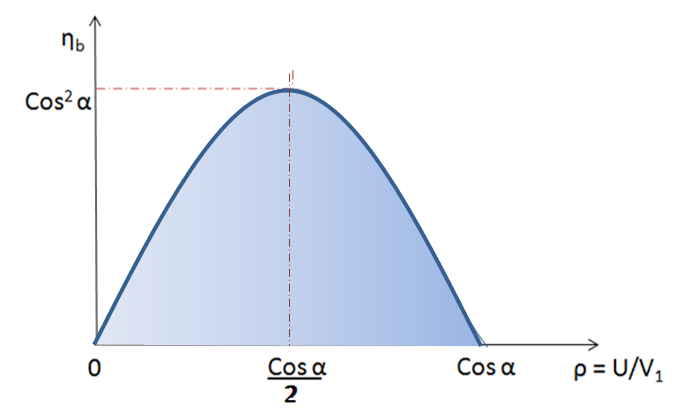

If , then

:

For maximum efficiency , we get

:

and this finally gives

Therefore, is found by putting the value of in the expression of blade efficiency

:

If , then

:

For maximum efficiency , we get

:

and this finally gives

Therefore, is found by putting the value of in the expression of blade efficiency

:

Steam turbines and their casings have a high thermal inertia due to the high pressures used in steam circuits and the materials used. When warming up a set for use, the main steam stop valves (after the boiler) have a bypass line to allow superheated steam to slowly bypass the valve and proceed to heat up the lines in the system along with the steam turbine. In addition, when there is no steam, a turning gear is engaged to slowly rotate the turbine to ensure even heating and prevent uneven expansion. After first rotating the turbine by the turning gear, allowing time for the rotor to assume a straight plane (no bowing), then the turning gear is disengaged and steam is admitted to the turbine, first to the astern blades then to the ahead blades slowly rotating the turbine at 10–15 RPM (0.17–0.25 Hz) to slowly warm the turbine. The warm-up procedure for large steam turbines may exceed ten hours.

During normal operation, rotor imbalance can lead to vibration, which, because of the high rotation velocities, could lead to a blade breaking away from the rotor and through the casing. To mitigate this risk, significant efforts are made to balance the turbine. Also, turbines are run with high-quality steam: either superheated (dry) steam, or saturated steam with a high dryness fraction. This prevents the rapid impingement and erosion of the blades which occurs when condensed water is blasted onto the blades (moisture carry over). Also, liquid water entering the blades may damage the thrust bearings for the turbine shaft. To prevent this, along with controls and baffles in the boilers to ensure high-quality steam, condensate drains are installed in the steam piping leading to the turbine.

Maintenance requirements of modern steam turbines are simple and incur low costs (typically around $0.005 per kWh); their operational life often exceeds 50 years.

Steam turbines and their casings have a high thermal inertia due to the high pressures used in steam circuits and the materials used. When warming up a set for use, the main steam stop valves (after the boiler) have a bypass line to allow superheated steam to slowly bypass the valve and proceed to heat up the lines in the system along with the steam turbine. In addition, when there is no steam, a turning gear is engaged to slowly rotate the turbine to ensure even heating and prevent uneven expansion. After first rotating the turbine by the turning gear, allowing time for the rotor to assume a straight plane (no bowing), then the turning gear is disengaged and steam is admitted to the turbine, first to the astern blades then to the ahead blades slowly rotating the turbine at 10–15 RPM (0.17–0.25 Hz) to slowly warm the turbine. The warm-up procedure for large steam turbines may exceed ten hours.

During normal operation, rotor imbalance can lead to vibration, which, because of the high rotation velocities, could lead to a blade breaking away from the rotor and through the casing. To mitigate this risk, significant efforts are made to balance the turbine. Also, turbines are run with high-quality steam: either superheated (dry) steam, or saturated steam with a high dryness fraction. This prevents the rapid impingement and erosion of the blades which occurs when condensed water is blasted onto the blades (moisture carry over). Also, liquid water entering the blades may damage the thrust bearings for the turbine shaft. To prevent this, along with controls and baffles in the boilers to ensure high-quality steam, condensate drains are installed in the steam piping leading to the turbine.

Maintenance requirements of modern steam turbines are simple and incur low costs (typically around $0.005 per kWh); their operational life often exceeds 50 years.

The control of a turbine with a

The control of a turbine with a

The steam turbine operates on basic principles of

The steam turbine operates on basic principles of

Electrical power stations use large steam turbines driving electric generators to produce most (about 80%) of the world's electricity. The advent of large steam turbines made central-station electricity generation practical, since reciprocating steam engines of large rating became very bulky, and operated at slow speeds. Most central stations are fossil fuel power plants and

Electrical power stations use large steam turbines driving electric generators to produce most (about 80%) of the world's electricity. The advent of large steam turbines made central-station electricity generation practical, since reciprocating steam engines of large rating became very bulky, and operated at slow speeds. Most central stations are fossil fuel power plants and

In steamships, advantages of steam turbines over reciprocating engines are smaller size, lower maintenance, lighter weight, and lower vibration. A steam turbine is efficient only when operating in the thousands of RPM, while the most effective propeller designs are for speeds less than 300 RPM; consequently, precise (thus expensive) reduction gears are usually required, although numerous early ships through

In steamships, advantages of steam turbines over reciprocating engines are smaller size, lower maintenance, lighter weight, and lower vibration. A steam turbine is efficient only when operating in the thousands of RPM, while the most effective propeller designs are for speeds less than 300 RPM; consequently, precise (thus expensive) reduction gears are usually required, although numerous early ships through

Turbo-electric drive was introduced on the battleship , launched in 1917. Over the next eight years the US Navy launched five additional turbo-electric-powered battleships and two aircraft carriers (initially ordered as s). Ten more turbo-electric capital ships were planned, but cancelled due to the limits imposed by the Washington Naval Treaty.

Although ''New Mexico'' was refitted with geared turbines in a 1931–1933 refit, the remaining turbo-electric ships retained the system throughout their careers. This system used two large steam turbine generators to drive an electric motor on each of four shafts. The system was less costly initially than reduction gears and made the ships more maneuverable in port, with the shafts able to reverse rapidly and deliver more reverse power than with most geared systems.

Some ocean liners were also built with turbo-electric drive, as were some troop transports and mass-production destroyer escorts in

Turbo-electric drive was introduced on the battleship , launched in 1917. Over the next eight years the US Navy launched five additional turbo-electric-powered battleships and two aircraft carriers (initially ordered as s). Ten more turbo-electric capital ships were planned, but cancelled due to the limits imposed by the Washington Naval Treaty.

Although ''New Mexico'' was refitted with geared turbines in a 1931–1933 refit, the remaining turbo-electric ships retained the system throughout their careers. This system used two large steam turbine generators to drive an electric motor on each of four shafts. The system was less costly initially than reduction gears and made the ships more maneuverable in port, with the shafts able to reverse rapidly and deliver more reverse power than with most geared systems.

Some ocean liners were also built with turbo-electric drive, as were some troop transports and mass-production destroyer escorts in

* '' gutenberg:27687, Steam Turbines: A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime Movers'' by Hubert E Collins

Steam Turbine Construction at Mike's Engineering Wonders

Tutorial: "Superheated Steam"

Flow Phenomenon in Steam Turbine Disk-Stator Cavities Channeled by Balance Holes

Guide to the Test of a 100 K.W. De Laval Steam Turbine with an Introduction on the Principles of Design circa 1920

Interactive Simulation

of 350MW Steam Turbine with Boiler developed by The University of Queensland, in Brisbane Australia

"Super-Steam...An Amazing Story of Achievement"

''Popular Mechanics'', August 1937 {{DEFAULTSORT:Steam Turbine 1884 introductions Arab inventions Egyptian inventions English inventions

machine

A machine is a physical system that uses power to apply forces and control movement to perform an action. The term is commonly applied to artificial devices, such as those employing engines or motors, but also to natural biological macromol ...

or heat engine

A heat engine is a system that transfers thermal energy to do mechanical or electrical work. While originally conceived in the context of mechanical energy, the concept of the heat engine has been applied to various other kinds of energy, pa ...

that extracts thermal energy

The term "thermal energy" is often used ambiguously in physics and engineering. It can denote several different physical concepts, including:

* Internal energy: The energy contained within a body of matter or radiation, excluding the potential en ...

from pressurized steam

Steam is water vapor, often mixed with air or an aerosol of liquid water droplets. This may occur due to evaporation or due to boiling, where heat is applied until water reaches the enthalpy of vaporization. Saturated or superheated steam is inv ...

and uses it to do mechanical work utilising a rotating output shaft. Its modern manifestation was invented by Sir Charles Parsons in 1884. It revolutionized marine propulsion

Marine propulsion is the mechanism or system used to generate thrust to move a watercraft through water. While paddles and sails are still used on some smaller boats, most modern ships are propelled by mechanical systems consisting of an electri ...

and navigation to a significant extent. Fabrication of a modern steam turbine involves advanced metalwork to form high-grade steel alloys into precision parts using technologies that first became available in the 20th century; continued advances in durability and efficiency of steam turbines remains central to the energy economics of the 21st century. The largest steam turbine ever built is the 1,770 MW Arabelle steam turbine built by Arabelle Solutions (previously GE Steam Power), two units of which will be installed at Hinkley Point C Nuclear Power Station, England.

The steam turbine is a form of heat engine

A heat engine is a system that transfers thermal energy to do mechanical or electrical work. While originally conceived in the context of mechanical energy, the concept of the heat engine has been applied to various other kinds of energy, pa ...

that derives much of its improvement in thermodynamic efficiency from the use of multiple stages in the expansion of the steam, which results in a closer approach to the ideal reversible expansion process. Because the turbine

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced can be used for generating electrical ...

generates rotary motion, it can be coupled to a generator to harness its motion into electricity. Such turbogenerators are the core of thermal power stations which can be fueled by fossil fuels

A fossil fuel is a flammable carbon compound- or hydrocarbon-containing material formed naturally in the Earth's crust from the buried remains of prehistoric organisms (animals, plants or microplanktons), a process that occurs within geologica ...

, nuclear fuels, geothermal, or solar energy

Solar energy is the radiant energy from the Sun's sunlight, light and heat, which can be harnessed using a range of technologies such as solar electricity, solar thermal energy (including solar water heating) and solar architecture. It is a ...

. About 42% of all electricity generation in the United States in 2022 was by the use of steam turbines. Technical challenges include rotor imbalance, vibration

Vibration () is a mechanical phenomenon whereby oscillations occur about an equilibrium point. Vibration may be deterministic if the oscillations can be characterised precisely (e.g. the periodic motion of a pendulum), or random if the os ...

, bearing wear, and uneven expansion (various forms of thermal shock

Thermal shock is a phenomenon characterized by a rapid change in temperature that results in a transient mechanical load on an object. The load is caused by the differential expansion of different parts of the object due to the temperature chang ...

).

History

The first device that may be classified as a reaction steam turbine was little more than a toy, the classic Aeolipile, described in the 1st century by Hero of Alexandria in

The first device that may be classified as a reaction steam turbine was little more than a toy, the classic Aeolipile, described in the 1st century by Hero of Alexandria in Roman Egypt

Roman Egypt was an imperial province of the Roman Empire from 30 BC to AD 642. The province encompassed most of modern-day Egypt except for the Sinai. It was bordered by the provinces of Crete and Cyrenaica to the west and Judaea, ...

. In 1551, Taqi al-Din in Ottoman Egypt described a steam turbine with the practical application of rotating a spit. Steam turbines were also described by the Italian Giovanni Branca (1629) and John Wilkins in England (1648). The devices described by Taqi al-Din and Wilkins are today known as steam jacks. In 1672, an impulse turbine-driven small toy car was designed by Ferdinand Verbiest. A more modern version of this car was produced some time in the late 18th century by an unknown German mechanic. In 1775, at Soho James Watt

James Watt (; 30 January 1736 (19 January 1736 OS) – 25 August 1819) was a Scottish inventor, mechanical engineer, and chemist who improved on Thomas Newcomen's 1712 Newcomen steam engine with his Watt steam engine in 1776, which was f ...

designed a reaction turbine that was put to work there. In 1807, Polikarp Zalesov designed and constructed an impulse turbine, using it for the fire pump operation. In 1827, the Frenchmen Real and Pichon patented and constructed a compound impulse turbine.

The modern steam turbine was invented in 1884 by Charles Parsons, whose first model was connected to a dynamo that generated of electricity. The invention of Parsons' steam turbine made cheap and plentiful electricity possible and revolutionized marine transport and naval warfare. Parsons' design was a reaction type. His patent was licensed and the turbine scaled up shortly after by an American, George Westinghouse. The Parsons turbine also turned out to be easy to scale up. Parsons had the satisfaction of seeing his invention adopted for all major world power stations, and the size of generators had increased from his first set up to units of capacity. Within Parsons' lifetime, the generating capacity of a unit was scaled up by about 10,000 times, and the total output from turbo-generators constructed by his firm C. A. Parsons and Company and by their licensees, for land purposes alone, had exceeded thirty million horse-power.

Other variations of turbines have been developed that work effectively with steam. The ''de Laval turbine'' (invented by Gustaf de Laval) accelerated the steam to full speed before running it against a turbine blade. De Laval's impulse turbine is simpler and less expensive and does not need to be pressure-proof. It can operate with any pressure of steam, but is considerably less efficient. Auguste Rateau developed a pressure compounded impulse turbine using the de Laval principle as early as 1896, obtained a US patent in 1903, and applied the turbine to a French torpedo boat in 1904. He taught at the for a decade until 1897, and later founded a successful company that was incorporated into the Alstom firm after his death. One of the founders of the modern theory of steam and gas turbines was Aurel Stodola, a Slovak physicist and engineer and professor at the Swiss Polytechnical Institute (now ETH) in Zurich. His work (English: The Steam Turbine and its prospective use as a Heat Engine) was published in Berlin in 1903. A further book (English: Steam and Gas Turbines) was published in 1922.

The ''Brown-Curtis turbine'', an impulse type, which had been originally developed and patented by the U.S. company International Curtis Marine Turbine Company, was developed in the 1900s in conjunction with

The modern steam turbine was invented in 1884 by Charles Parsons, whose first model was connected to a dynamo that generated of electricity. The invention of Parsons' steam turbine made cheap and plentiful electricity possible and revolutionized marine transport and naval warfare. Parsons' design was a reaction type. His patent was licensed and the turbine scaled up shortly after by an American, George Westinghouse. The Parsons turbine also turned out to be easy to scale up. Parsons had the satisfaction of seeing his invention adopted for all major world power stations, and the size of generators had increased from his first set up to units of capacity. Within Parsons' lifetime, the generating capacity of a unit was scaled up by about 10,000 times, and the total output from turbo-generators constructed by his firm C. A. Parsons and Company and by their licensees, for land purposes alone, had exceeded thirty million horse-power.

Other variations of turbines have been developed that work effectively with steam. The ''de Laval turbine'' (invented by Gustaf de Laval) accelerated the steam to full speed before running it against a turbine blade. De Laval's impulse turbine is simpler and less expensive and does not need to be pressure-proof. It can operate with any pressure of steam, but is considerably less efficient. Auguste Rateau developed a pressure compounded impulse turbine using the de Laval principle as early as 1896, obtained a US patent in 1903, and applied the turbine to a French torpedo boat in 1904. He taught at the for a decade until 1897, and later founded a successful company that was incorporated into the Alstom firm after his death. One of the founders of the modern theory of steam and gas turbines was Aurel Stodola, a Slovak physicist and engineer and professor at the Swiss Polytechnical Institute (now ETH) in Zurich. His work (English: The Steam Turbine and its prospective use as a Heat Engine) was published in Berlin in 1903. A further book (English: Steam and Gas Turbines) was published in 1922.

The ''Brown-Curtis turbine'', an impulse type, which had been originally developed and patented by the U.S. company International Curtis Marine Turbine Company, was developed in the 1900s in conjunction with John Brown & Company

John Brown and Company of Clydebank was a Scottish Naval architecture, marine engineering and shipbuilding firm. It built many notable and world-famous ships including , , , , , and ''Queen Elizabeth 2 (ship), Queen Elizabeth 2''.

At its heig ...

. It was used in John Brown-engined merchant ships and warships, including liners and Royal Navy warships.

Manufacturing

The present-day manufacturing industry for steam turbines consists of the following companies:

* Ansaldo

* Arabelle Solutions

*

The present-day manufacturing industry for steam turbines consists of the following companies:

* Ansaldo

* Arabelle Solutions

* Baker Hughes

Baker Hughes Company is an American global energy technology company co-headquartered in Houston, Texas and London, UK. As one of the world's largest oil field services, industrial and energy technology companies, it provides products and serv ...

* Doosan Škoda Power

* Dongfang Electric

* EBARA-Elliot Energy

* GE Vernova

* Harbin Electric

* Larsen & Toubro

* Leningradsky Metallichesky Zavod

* MAN Energy Solutions

* MAPNA

* Mitsubishi Heavy Industries

is a Japanese Multinational corporation, multinational engineering, electrical equipment and electronics corporation headquartered in Tokyo, Japan. MHI is one of the core companies of the Mitsubishi Group and its automobile division is the prede ...

* Shanghai Electric

* Siemens Energy

* Triveni Engineering & Industries

* Ural TW

Types

Steam turbines are made in a variety of sizes ranging from small <0.75 kW (<1 hp) units (rare) used as mechanical drives for pumps, compressors and other shaft driven equipment, to turbines used to generate electricity. There are several classifications for modern steam turbines.Blade and stage design

efficiency

Efficiency is the often measurable ability to avoid making mistakes or wasting materials, energy, efforts, money, and time while performing a task. In a more general sense, it is the ability to do things well, successfully, and without waste.

...

at low speeds. A reaction stage is a row of fixed nozzles followed by a row of moving nozzles. Multiple reaction stages divide the pressure drop between the steam inlet and exhaust into numerous small drops, resulting in a pressure-compounded turbine. Impulse stages may be either pressure-compounded, velocity-compounded, or pressure-velocity compounded. A pressure-compounded impulse stage is a row of fixed nozzles followed by a row of moving blades, with multiple stages for compounding. This is also known as a Rateau turbine, after its inventor. A velocity-compounded impulse stage (invented by Curtis and also called a "Curtis wheel") is a row of fixed nozzles followed by two or more rows of moving blades alternating with rows of fixed blades. This divides the velocity drop across the stage into several smaller drops. A series of velocity-compounded impulse stages is called a pressure-velocity compounded turbine.

By 1905, when steam turbines were coming into use on fast ships (such as ) and in land-based power applications, it had been determined that it was desirable to use one or more Curtis wheels at the beginning of a multi-stage turbine (where the steam pressure is highest), followed by reaction stages. This was more efficient with high-pressure steam due to reduced leakage between the turbine rotor and the casing. This is illustrated in the drawing of the German 1905 AEG marine steam turbine. The steam from the boiler

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, centra ...

s enters from the right at high pressure through a throttle, controlled manually by an operator (in this case a sailor known as the throttleman). It passes through five Curtis wheels and numerous reaction stages (the small blades at the edges of the two large rotors in the middle) before exiting at low pressure, almost certainly to a condenser. The condenser provides a vacuum that maximizes the energy extracted from the steam, and condenses the steam into feedwater to be returned to the boilers. On the left are several additional reaction stages (on two large rotors) that rotate the turbine in reverse for astern operation, with steam admitted by a separate throttle. Since ships are rarely operated in reverse, efficiency is not a priority in astern turbines, so only a few stages are used to save cost.

Blade design challenges

A major challenge facing turbine design was reducing the creep experienced by the blades. Because of the high temperatures and high stresses of operation, steam turbine materials become damaged through these mechanisms. As temperatures are increased in an effort to improve turbine efficiency, creep becomes significant. To limit creep, thermal coatings and superalloys with solid-solution strengthening and grain boundary strengthening are used in blade designs. Protective coatings are used to reduce the thermal damage and to limitoxidation

Redox ( , , reduction–oxidation or oxidation–reduction) is a type of chemical reaction in which the oxidation states of the reactants change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is ...

. These coatings are often stabilized zirconium dioxide-based ceramics. Using a thermal protective coating limits the temperature exposure of the nickel superalloy. This reduces the creep mechanisms experienced in the blade. Oxidation coatings limit efficiency losses caused by a buildup on the outside of the blades, which is especially important in the high-temperature environment.

The nickel-based blades are alloyed with aluminum and titanium to improve strength and creep resistance. The microstructure of these alloys is composed of different regions of composition. A uniform dispersion of the gamma-prime phase – a combination of nickel, aluminum, and titanium – promotes the strength and creep resistance of the blade due to the microstructure.

Refractory

In materials science, a refractory (or refractory material) is a material that is resistant to decomposition by heat or chemical attack and that retains its strength and rigidity at high temperatures. They are inorganic, non-metallic compound ...

elements such as rhenium and ruthenium can be added to the alloy to improve creep strength. The addition of these elements reduces the diffusion of the gamma prime phase, thus preserving the fatigue

Fatigue is a state of tiredness (which is not sleepiness), exhaustion or loss of energy. It is a signs and symptoms, symptom of any of various diseases; it is not a disease in itself.

Fatigue (in the medical sense) is sometimes associated wit ...

resistance, strength, and creep resistance.

Steam supply and exhaust conditions

Turbine types include condensing, non-condensing, reheat, extracting and induction.

Turbine types include condensing, non-condensing, reheat, extracting and induction.

Condensing turbines

Condensing turbines are most commonly found in electrical power plants. These turbines receive steam from aboiler

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, centra ...

and exhaust it to a condenser. The exhausted steam is at a pressure well below atmospheric, and is in a partially condensed state, typically of a quality

Quality may refer to:

Concepts

*Quality (business), the ''non-inferiority'' or ''superiority'' of something

*Quality (philosophy), an attribute or a property

*Quality (physics), in response theory

*Energy quality, used in various science discipli ...

near 90%.

Non-condensing turbines

Non-condensing turbines are most widely used for process steam applications, in which the steam will be used for additional purposes after being exhausted from the turbine. The exhaust pressure is controlled by a regulating valve to suit the needs of the process steam pressure. These are commonly found at refineries, district heating units, pulp and paper plants, anddesalination

Desalination is a process that removes mineral components from saline water. More generally, desalination is the removal of salts and minerals from a substance. One example is Soil salinity control, soil desalination. This is important for agric ...

facilities where large amounts of low pressure process steam are needed.

Reheat turbines

Reheat turbines are also used almost exclusively in electrical power plants. In a reheat turbine, steam flow exits from a high-pressure section of the turbine and is returned to the boiler where additional superheat is added. The steam then goes back into an intermediate pressure section of the turbine and continues its expansion. Using reheat in a cycle increases the work output from the turbine and also the expansion reaches conclusion before the steam condenses, thereby minimizing the erosion of the blades in last rows. In most of the cases, maximum number of reheats employed in a cycle is 2 as the cost of super-heating the steam negates the increase in the work output from turbine.Extracting turbines

Extracting type turbines are common in all applications. In an extracting type turbine, steam is released from various stages of the turbine, and used for industrial process needs or sent to boiler feedwater heaters to improve overall cycle efficiency. Extraction flows may be controlled with a valve, or left uncontrolled. Extracted steam results in a loss of power in the downstream stages of the turbine. Induction turbines introduce low pressure steam at an intermediate stage to produce additional power.Casing or shaft arrangements

These arrangements include single casing, tandem compound and cross compound turbines. Single casing units are the most basic style where a single casing and shaft are coupled to a generator. Tandem compound are used where two or more casings are directly coupled together to drive a single generator. A cross compound turbine arrangement features two or more shafts not in line driving two or more generators that often operate at different speeds. A cross compound turbine is typically used for many large applications. A typical 1930s-1960s naval installation is illustrated below; this shows high- and low-pressure turbines driving a common reduction gear, with a geared cruising turbine on one high-pressure turbine.Two-flow rotors

The moving steam imparts both a tangential and axial thrust on the turbine shaft, but the axial thrust in a simple turbine is unopposed. To maintain the correct rotor position and balancing, this force must be counteracted by an opposing force. Thrust bearings can be used for the shaft bearings, the rotor can use dummy pistons, it can be double flow- the steam enters in the middle of the shaft and exits at both ends, or a combination of any of these. In a double flow rotor, the blades in each half face opposite ways, so that the axial forces negate each other but the tangential forces act together. This design of rotor is also called two-flow, double-axial-flow, or double-exhaust. This arrangement is common in low-pressure casings of a compound turbine.

The moving steam imparts both a tangential and axial thrust on the turbine shaft, but the axial thrust in a simple turbine is unopposed. To maintain the correct rotor position and balancing, this force must be counteracted by an opposing force. Thrust bearings can be used for the shaft bearings, the rotor can use dummy pistons, it can be double flow- the steam enters in the middle of the shaft and exits at both ends, or a combination of any of these. In a double flow rotor, the blades in each half face opposite ways, so that the axial forces negate each other but the tangential forces act together. This design of rotor is also called two-flow, double-axial-flow, or double-exhaust. This arrangement is common in low-pressure casings of a compound turbine.

Principle of operation and design

An ideal steam turbine is considered to be an isentropic process, or constant entropy process, in which the entropy of the steam entering the turbine is equal to the entropy of the steam leaving the turbine. No steam turbine is truly isentropic, however, with typical isentropic efficiencies ranging from 20 to 90% based on the application of the turbine. The interior of a turbine comprises several sets of blades or ''buckets''. One set of stationary blades is connected to the casing and one set of rotating blades is connected to the shaft. The sets intermesh with certain minimum clearances, with the size and configuration of sets varying to efficiently exploit the expansion of steam at each stage.Impulse turbines

An impulse turbine has fixed nozzles that orient the steam flow into high speed jets. These jets contain significant kinetic energy, which is converted into shaft rotation by the bucket-like shaped rotor blades, as the steam jet changes direction. A pressure drop occurs across only the stationary blades, with a net increase in steam velocity across the stage.

As the steam flows through the nozzle its pressure falls from inlet pressure to the exit pressure (atmospheric pressure or, more usually, the condenser vacuum). Due to this high ratio of expansion of steam, the steam leaves the nozzle with a very high velocity. The steam leaving the moving blades has a large portion of the maximum velocity of the steam when leaving the nozzle. The loss of energy due to this higher exit velocity is commonly called the carry over velocity or leaving loss.

The law of moment of momentum states that the sum of the moments of external forces acting on a fluid which is temporarily occupying the control volume is equal to the net time change of angular momentum flux through the control volume.

The swirling fluid enters the control volume at radius with tangential velocity and leaves at radius with tangential velocity .

An impulse turbine has fixed nozzles that orient the steam flow into high speed jets. These jets contain significant kinetic energy, which is converted into shaft rotation by the bucket-like shaped rotor blades, as the steam jet changes direction. A pressure drop occurs across only the stationary blades, with a net increase in steam velocity across the stage.

As the steam flows through the nozzle its pressure falls from inlet pressure to the exit pressure (atmospheric pressure or, more usually, the condenser vacuum). Due to this high ratio of expansion of steam, the steam leaves the nozzle with a very high velocity. The steam leaving the moving blades has a large portion of the maximum velocity of the steam when leaving the nozzle. The loss of energy due to this higher exit velocity is commonly called the carry over velocity or leaving loss.

The law of moment of momentum states that the sum of the moments of external forces acting on a fluid which is temporarily occupying the control volume is equal to the net time change of angular momentum flux through the control volume.

The swirling fluid enters the control volume at radius with tangential velocity and leaves at radius with tangential velocity .

A velocity triangle paves the way for a better understanding of the relationship between the various velocities. In the adjacent figure we have:

: and are the absolute velocities at the inlet and outlet respectively.

: and are the flow velocities at the inlet and outlet respectively.

: and are the swirl velocities at the inlet and outlet respectively, in the moving reference.

: and are the relative velocities at the inlet and outlet respectively.

: is the velocity of the blade.

: is the guide vane angle and is the blade angle.

Then by the law of moment of momentum, the torque on the fluid is given by:

:

For an impulse steam turbine: . Therefore, the tangential force on the blades is . The work done per unit time or power developed: .

When ω is the angular velocity of the turbine, then the blade speed is . The power developed is then .

A velocity triangle paves the way for a better understanding of the relationship between the various velocities. In the adjacent figure we have:

: and are the absolute velocities at the inlet and outlet respectively.

: and are the flow velocities at the inlet and outlet respectively.

: and are the swirl velocities at the inlet and outlet respectively, in the moving reference.

: and are the relative velocities at the inlet and outlet respectively.

: is the velocity of the blade.

: is the guide vane angle and is the blade angle.

Then by the law of moment of momentum, the torque on the fluid is given by:

:

For an impulse steam turbine: . Therefore, the tangential force on the blades is . The work done per unit time or power developed: .

When ω is the angular velocity of the turbine, then the blade speed is . The power developed is then .

Blade efficiency

Blade efficiency () can be defined as the ratio of the work done on the blades to kinetic energy supplied to the fluid, and is given by :Stage efficiency

A stage of an impulse turbine consists of a nozzle set and a moving wheel. The stage efficiency defines a relationship between enthalpy drop in the nozzle and work done in the stage.

Where is the specific enthalpy drop of steam in the nozzle.

By the

A stage of an impulse turbine consists of a nozzle set and a moving wheel. The stage efficiency defines a relationship between enthalpy drop in the nozzle and work done in the stage.

Where is the specific enthalpy drop of steam in the nozzle.

By the first law of thermodynamics

The first law of thermodynamics is a formulation of the law of conservation of energy in the context of thermodynamic processes. For a thermodynamic process affecting a thermodynamic system without transfer of matter, the law distinguishes two ...

:

Assuming that is appreciably less than , we get . Furthermore, stage efficiency is the product of blade efficiency and nozzle efficiency, or .

Nozzle efficiency is given by , where the enthalpy (in J/Kg) of steam at the entrance of the nozzle is and the enthalpy of steam at the exit of the nozzle is .

The ratio of the cosines of the blade angles at the outlet and inlet can be taken and denoted . The ratio of steam velocities relative to the rotor speed at the outlet to the inlet of the blade is defined by the friction coefficient .

and depicts the loss in the relative velocity due to friction as the steam flows around the blades ( for smooth blades).

The ratio of the blade speed to the absolute steam velocity at the inlet is termed the blade speed ratio .

is maximum when or, . That implies and therefore . Now (for a single stage impulse turbine).

Therefore, the maximum value of stage efficiency is obtained by putting the value of in the expression of .

We get: .

For equiangular blades, , therefore , and we get . If the friction due to the blade surface is neglected then .

Conclusions on maximum efficiency

: # For a given steam velocity work done per kg of steam would be maximum when or . # As increases, the work done on the blades reduces, but at the same time surface area of the blade reduces, therefore there are less frictional losses.Reaction turbines

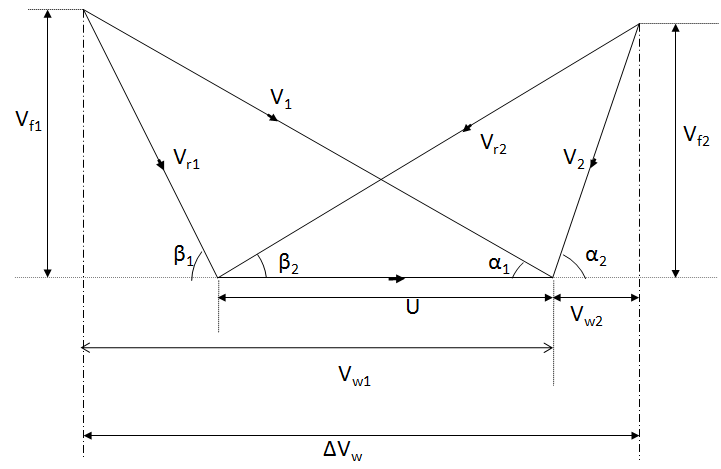

In the ''reaction turbine'', the rotor blades themselves are arranged to form convergent nozzles. This type of turbine makes use of the reaction force produced as the steam accelerates through the nozzles formed by the stator. Steam is directed onto the rotor by the fixed vanes of the stator. It leaves the stator as a jet that fills the entire circumference of the rotor. The steam then changes direction and increases its speed relative to the speed of the blades. A pressure drop occurs across both the stator and the rotor, with steam accelerating through the stator and decelerating through the rotor, with no net change in steam velocity across the stage but with a decrease in both pressure and temperature, reflecting the work performed in the driving of the rotor.Blade efficiency

Energy input to the blades in a stage: is equal to the kinetic energy supplied to the fixed blades (f) + the kinetic energy supplied to the moving blades (m). Or, = enthalpy drop over the fixed blades, + enthalpy drop over the moving blades, . The effect of expansion of steam over the moving blades is to increase the relative velocity at the exit. Therefore, the relative velocity at the exit is always greater than the relative velocity at the inlet . In terms of velocities, the enthalpy drop over the moving blades is given by: (it contributes to a change in static pressure) The enthalpy drop in the fixed blades, with the assumption that the velocity of steam entering the fixed blades is equal to the velocity of steam leaving the previously moving blades is given by:

where V0 is the inlet velocity of steam in the nozzle

is very small and hence can be neglected. Therefore,

A very widely used design has half degree of reaction or 50% reaction and this is known as Parson's turbine. This consists of symmetrical rotor and stator blades. For this turbine the velocity triangle is similar and we have:

,

,

Assuming ''Parson's turbine'' and obtaining all the expressions we get

From the inlet velocity triangle we have

Work done (for unit mass flow per second):

Therefore, the blade efficiency is given by

The enthalpy drop in the fixed blades, with the assumption that the velocity of steam entering the fixed blades is equal to the velocity of steam leaving the previously moving blades is given by:

where V0 is the inlet velocity of steam in the nozzle

is very small and hence can be neglected. Therefore,

A very widely used design has half degree of reaction or 50% reaction and this is known as Parson's turbine. This consists of symmetrical rotor and stator blades. For this turbine the velocity triangle is similar and we have:

,

,

Assuming ''Parson's turbine'' and obtaining all the expressions we get

From the inlet velocity triangle we have

Work done (for unit mass flow per second):

Therefore, the blade efficiency is given by

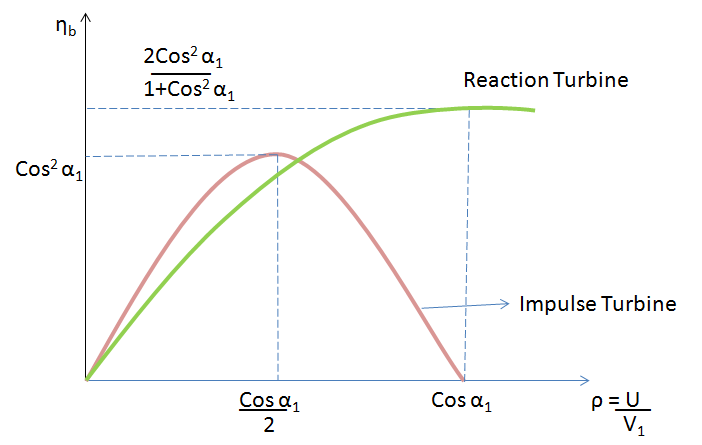

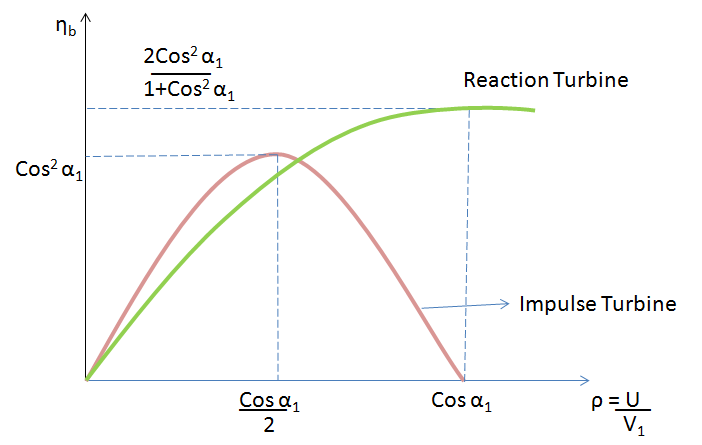

Condition of maximum blade efficiency

If , then

:

For maximum efficiency , we get

:

and this finally gives

Therefore, is found by putting the value of in the expression of blade efficiency

:

If , then

:

For maximum efficiency , we get

:

and this finally gives

Therefore, is found by putting the value of in the expression of blade efficiency

:

Operation and maintenance

Steam turbines and their casings have a high thermal inertia due to the high pressures used in steam circuits and the materials used. When warming up a set for use, the main steam stop valves (after the boiler) have a bypass line to allow superheated steam to slowly bypass the valve and proceed to heat up the lines in the system along with the steam turbine. In addition, when there is no steam, a turning gear is engaged to slowly rotate the turbine to ensure even heating and prevent uneven expansion. After first rotating the turbine by the turning gear, allowing time for the rotor to assume a straight plane (no bowing), then the turning gear is disengaged and steam is admitted to the turbine, first to the astern blades then to the ahead blades slowly rotating the turbine at 10–15 RPM (0.17–0.25 Hz) to slowly warm the turbine. The warm-up procedure for large steam turbines may exceed ten hours.

During normal operation, rotor imbalance can lead to vibration, which, because of the high rotation velocities, could lead to a blade breaking away from the rotor and through the casing. To mitigate this risk, significant efforts are made to balance the turbine. Also, turbines are run with high-quality steam: either superheated (dry) steam, or saturated steam with a high dryness fraction. This prevents the rapid impingement and erosion of the blades which occurs when condensed water is blasted onto the blades (moisture carry over). Also, liquid water entering the blades may damage the thrust bearings for the turbine shaft. To prevent this, along with controls and baffles in the boilers to ensure high-quality steam, condensate drains are installed in the steam piping leading to the turbine.

Maintenance requirements of modern steam turbines are simple and incur low costs (typically around $0.005 per kWh); their operational life often exceeds 50 years.

Steam turbines and their casings have a high thermal inertia due to the high pressures used in steam circuits and the materials used. When warming up a set for use, the main steam stop valves (after the boiler) have a bypass line to allow superheated steam to slowly bypass the valve and proceed to heat up the lines in the system along with the steam turbine. In addition, when there is no steam, a turning gear is engaged to slowly rotate the turbine to ensure even heating and prevent uneven expansion. After first rotating the turbine by the turning gear, allowing time for the rotor to assume a straight plane (no bowing), then the turning gear is disengaged and steam is admitted to the turbine, first to the astern blades then to the ahead blades slowly rotating the turbine at 10–15 RPM (0.17–0.25 Hz) to slowly warm the turbine. The warm-up procedure for large steam turbines may exceed ten hours.

During normal operation, rotor imbalance can lead to vibration, which, because of the high rotation velocities, could lead to a blade breaking away from the rotor and through the casing. To mitigate this risk, significant efforts are made to balance the turbine. Also, turbines are run with high-quality steam: either superheated (dry) steam, or saturated steam with a high dryness fraction. This prevents the rapid impingement and erosion of the blades which occurs when condensed water is blasted onto the blades (moisture carry over). Also, liquid water entering the blades may damage the thrust bearings for the turbine shaft. To prevent this, along with controls and baffles in the boilers to ensure high-quality steam, condensate drains are installed in the steam piping leading to the turbine.

Maintenance requirements of modern steam turbines are simple and incur low costs (typically around $0.005 per kWh); their operational life often exceeds 50 years.

Speed regulation

The control of a turbine with a

The control of a turbine with a governor

A governor is an politician, administrative leader and head of a polity or Region#Political regions, political region, in some cases, such as governor-general, governors-general, as the head of a state's official representative. Depending on the ...

is essential, as turbines need to be run up slowly to prevent damage and some applications (such as the generation of alternating current electricity) require precise speed control. Uncontrolled acceleration of the turbine rotor can lead to an overspeed trip, which causes the governor and throttle valves that control the flow of steam to the turbine to close. If these valves fail then the turbine may continue accelerating until it breaks apart, often catastrophically. Turbines are expensive to make, requiring precision manufacture and special quality materials.

During normal operation in synchronization with the electricity network, power plants are governed with a five percent droop speed control. This means the full load speed is 100% and the no-load speed is 105%. This is required for the stable operation of the network without hunting and drop-outs of power plants. Normally the changes in speed are minor. Adjustments in power output are made by slowly raising the droop curve by increasing the spring pressure on a centrifugal governor. Generally this is a basic system requirement for all power plants because the older and newer plants have to be compatible in response to the instantaneous changes in frequency without depending on outside communication.

Thermodynamics of steam turbines

The steam turbine operates on basic principles of

The steam turbine operates on basic principles of thermodynamics

Thermodynamics is a branch of physics that deals with heat, Work (thermodynamics), work, and temperature, and their relation to energy, entropy, and the physical properties of matter and radiation. The behavior of these quantities is governed b ...

using the part 3-4 of the Rankine cycle shown in the adjoining diagram. Superheated steam (or dry saturated steam, depending on application) leaves the boiler at high temperature and high pressure. At entry to the turbine, the steam gains kinetic energy by passing through a nozzle (a fixed nozzle in an impulse type turbine or the fixed blades in a reaction type turbine). When the steam leaves the nozzle it is moving at high velocity towards the blades of the turbine rotor. A force is created on the blades due to the pressure of the vapor on the blades causing them to move. A generator or other such device can be placed on the shaft, and the energy that was in the steam can now be stored and used. The steam leaves the turbine as a saturated vapor (or liquid-vapor mix depending on application) at a lower temperature and pressure than it entered with and is sent to the condenser to be cooled. The first law enables us to find a formula for the rate at which work is developed per unit mass. Assuming there is no heat transfer to the surrounding environment and that the changes in kinetic and potential energy are negligible compared to the change in specific enthalpy we arrive at the following equation:

:

where

: is the rate at which work is developed per unit time

: is the rate of mass flow through the turbine

Isentropic efficiency

To measure how well a turbine is performing we can look at its isentropic efficiency. This compares the actual performance of the turbine with the performance that would be achieved by an ideal, isentropic, turbine. When calculating this efficiency, heat lost to the surroundings is assumed to be zero. Steam's starting pressure and temperature is the same for both the actual and the ideal turbines, but at turbine exit, steam's energy content ('specific enthalpy') for the actual turbine is greater than that for the ideal turbine because of irreversibility in the actual turbine. The specific enthalpy is evaluated at the same steam pressure for the actual and ideal turbines in order to give a good comparison between the two. The isentropic efficiency is found by dividing the actual work by the ideal work. where * is the specific enthalpy at state three * is the specific enthalpy at state 4 for the actual turbine * is the specific enthalpy at state 4s for the isentropic turbine (but note that the adjacent diagram does not show state 4s: it is vertically below state 3)Direct drive

Electrical power stations use large steam turbines driving electric generators to produce most (about 80%) of the world's electricity. The advent of large steam turbines made central-station electricity generation practical, since reciprocating steam engines of large rating became very bulky, and operated at slow speeds. Most central stations are fossil fuel power plants and

Electrical power stations use large steam turbines driving electric generators to produce most (about 80%) of the world's electricity. The advent of large steam turbines made central-station electricity generation practical, since reciprocating steam engines of large rating became very bulky, and operated at slow speeds. Most central stations are fossil fuel power plants and nuclear power plant

A nuclear power plant (NPP), also known as a nuclear power station (NPS), nuclear generating station (NGS) or atomic power station (APS) is a thermal power station in which the heat source is a nuclear reactor. As is typical of thermal power st ...

s; some installations use geothermal steam, or use concentrated solar power (CSP) to create the steam. Steam turbines can also be used directly to drive large centrifugal pumps, such as feedwater pumps at a thermal power plant.

The turbines used for electric power generation are most often directly coupled to their generators. As the generators must rotate at constant synchronous speeds according to the frequency of the electric power system, the most common speeds are 3,000 RPM for 50 Hz systems, and 3,600 RPM for 60 Hz systems. Since nuclear reactors have lower temperature limits than fossil-fired plants, with lower steam quality

Quality may refer to:

Concepts

*Quality (business), the ''non-inferiority'' or ''superiority'' of something

*Quality (philosophy), an attribute or a property

*Quality (physics), in response theory

*Energy quality, used in various science discipli ...

, the turbine generator sets may be arranged to operate at half these speeds, but with four-pole generators, to reduce erosion of turbine blades.

Marine propulsion

In steamships, advantages of steam turbines over reciprocating engines are smaller size, lower maintenance, lighter weight, and lower vibration. A steam turbine is efficient only when operating in the thousands of RPM, while the most effective propeller designs are for speeds less than 300 RPM; consequently, precise (thus expensive) reduction gears are usually required, although numerous early ships through

In steamships, advantages of steam turbines over reciprocating engines are smaller size, lower maintenance, lighter weight, and lower vibration. A steam turbine is efficient only when operating in the thousands of RPM, while the most effective propeller designs are for speeds less than 300 RPM; consequently, precise (thus expensive) reduction gears are usually required, although numerous early ships through World War I

World War I or the First World War (28 July 1914 – 11 November 1918), also known as the Great War, was a World war, global conflict between two coalitions: the Allies of World War I, Allies (or Entente) and the Central Powers. Fighting to ...

, such as '' Turbinia'', had direct drive from the steam turbines to the propeller shafts. Another alternative is turbo-electric transmission, in which an electrical generator run by the high-speed turbine is used to run one or more slow-speed electric motors connected to the propeller shafts; precision gear cutting may be a production bottleneck during wartime. Turbo-electric drive was most used in large US warships designed during World War I and in some fast liners, and was used in some troop transports and mass-production destroyer escorts in World War II

World War II or the Second World War (1 September 1939 – 2 September 1945) was a World war, global conflict between two coalitions: the Allies of World War II, Allies and the Axis powers. World War II by country, Nearly all of the wo ...

.

The higher cost of turbines and the associated gears or generator/motor sets is offset by lower maintenance requirements and the smaller size of a turbine in comparison with a reciprocating engine of equal power, although the fuel costs are higher than those of a diesel engine because steam turbines have lower thermal efficiency

In thermodynamics, the thermal efficiency (\eta_) is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, steam turbine, steam engine, boiler, furnace, refrigerator, ACs etc.

For ...

. To reduce fuel costs the thermal efficiency of both types of engine have been improved over the years.

Early development

The development of steam turbine marine propulsion from 1894 to 1935 was dominated by the need to reconcile the high efficient speed of the turbine with the low efficient speed (less than 300 rpm) of the ship's propeller at an overall cost competitive with reciprocating engines. In 1894, efficient reduction gears were not available for the high powers required by ships, so direct drive was necessary. In ''Turbinia'', which has direct drive to each propeller shaft, the efficient speed of the turbine was reduced after initial trials by directing the steam flow through all three direct drive turbines (one on each shaft) in series, probably totaling around 200 turbine stages operating in series. Also, there were three propellers on each shaft for operation at high speeds. The high shaft speeds of the era are represented by one of the first US turbine-powered destroyers, , launched in 1909, which had direct drive turbines and whose three shafts turned at 724 rpm at . The use of turbines in several casings exhausting steam to each other in series became standard in most subsequent marine propulsion applications, and is a form of cross-compounding. The first turbine was called the high pressure (HP) turbine, the last turbine was the low pressure (LP) turbine, and any turbine in between was an intermediate pressure (IP) turbine. A much later arrangement than ''Turbinia'' can be seen on inLong Beach, California

Long Beach is a coastal city in southeastern Los Angeles County, California, United States. It is the list of United States cities by population, 44th-most populous city in the United States, with a population of 451,307 as of 2022. A charter ci ...

, launched in 1934, in which each shaft is powered by four turbines in series connected to the ends of the two input shafts of a single-reduction gearbox. They are the HP, 1st IP, 2nd IP, and LP turbines.

Cruising machinery and gearing

The quest for economy was even more important when cruising speeds were considered. Cruising speed is roughly 50% of a warship's maximum speed and 20-25% of its maximum power level. This would be a speed used on long voyages when fuel economy is desired. Although this brought the propeller speeds down to an efficient range, turbine efficiency was greatly reduced, and early turbine ships had poor cruising ranges. A solution that proved useful through most of the steam turbine propulsion era was the cruising turbine. This was an extra turbine to add even more stages, at first attached directly to one or more shafts, exhausting to a stage partway along the HP turbine, and not used at high speeds. As reduction gears became available around 1911, some ships, notably thebattleship

A battleship is a large, heavily naval armour, armored warship with a main battery consisting of large naval gun, guns, designed to serve as a capital ship. From their advent in the late 1880s, battleships were among the largest and most form ...

, had them on cruising turbines while retaining direct drive main turbines. Reduction gears allowed turbines to operate in their efficient range at a much higher speed than the shaft, but were expensive to manufacture.

Cruising turbines competed at first with reciprocating engines for fuel economy. An example of the retention of reciprocating engines on fast ships was the famous of 1911, which along with her sisters and had triple-expansion engines on the two outboard shafts, both exhausting to an LP turbine on the center shaft. After adopting turbines with the s launched in 1909, the United States Navy

The United States Navy (USN) is the naval warfare, maritime military branch, service branch of the United States Department of Defense. It is the world's most powerful navy with the largest Displacement (ship), displacement, at 4.5 millio ...

reverted to reciprocating machinery on the s of 1912, then went back to turbines on ''Nevada'' in 1914. The lingering fondness for reciprocating machinery was because the US Navy had no plans for capital ships exceeding until after World War I, so top speed was less important than economical cruising. The United States had acquired the Philippines

The Philippines, officially the Republic of the Philippines, is an Archipelagic state, archipelagic country in Southeast Asia. Located in the western Pacific Ocean, it consists of List of islands of the Philippines, 7,641 islands, with a tot ...

and Hawaii

Hawaii ( ; ) is an island U.S. state, state of the United States, in the Pacific Ocean about southwest of the U.S. mainland. One of the two Non-contiguous United States, non-contiguous U.S. states (along with Alaska), it is the only sta ...

as territories in 1898, and lacked the British Royal Navy

The Royal Navy (RN) is the naval warfare force of the United Kingdom. It is a component of His Majesty's Naval Service, and its officers hold their commissions from the King of the United Kingdom, King. Although warships were used by Kingdom ...

's worldwide network of coaling stations. Thus, the US Navy in 1900–1940 had the greatest need of any nation for fuel economy, especially as the prospect of war with Japan

Japan is an island country in East Asia. Located in the Pacific Ocean off the northeast coast of the Asia, Asian mainland, it is bordered on the west by the Sea of Japan and extends from the Sea of Okhotsk in the north to the East China Sea ...

arose following World War I. This need was compounded by the US not launching any cruisers 1908–1920, so destroyers were required to perform long-range missions usually assigned to cruisers. So, various cruising solutions were fitted on US destroyers launched 1908–1916. These included small reciprocating engines and geared or ungeared cruising turbines on one or two shafts. However, once fully geared turbines proved economical in initial cost and fuel they were rapidly adopted, with cruising turbines also included on most ships. Beginning in 1915 all new Royal Navy destroyers had fully geared turbines, and the United States followed in 1917.

In the Royal Navy

The Royal Navy (RN) is the naval warfare force of the United Kingdom. It is a component of His Majesty's Naval Service, and its officers hold their commissions from the King of the United Kingdom, King. Although warships were used by Kingdom ...

, speed was a priority until the Battle of Jutland in mid-1916 showed that in the battlecruisers too much armour had been sacrificed in its pursuit. The British used exclusively turbine-powered warships from 1906. Because they recognized that a long cruising range would be desirable given their worldwide empire, some warships, notably the s, were fitted with cruising turbines from 1912 onwards following earlier experimental installations.

In the US Navy, the s, launched 1935–36, introduced double-reduction gearing. This further increased the turbine speed above the shaft speed, allowing smaller turbines than single-reduction gearing. Steam pressures and temperatures were also increasing progressively, from / aturated steamon the World War I-era to / uperheated steamon some World War II s and later ships. A standard configuration emerged of an axial-flow high-pressure turbine (sometimes with a cruising turbine attached) and a double-axial-flow low-pressure turbine connected to a double-reduction gearbox. This arrangement continued throughout the steam era in the US Navy and was also used in some Royal Navy designs. Machinery of this configuration can be seen on many preserved World War II-era warships in several countries.

When US Navy warship construction resumed in the early 1950s, most surface combatants and aircraft carriers used / steam. This continued until the end of the US Navy steam-powered warship era with the s of the early 1970s. Amphibious and auxiliary ships continued to use steam post-World War II, with , launched in 2001, possibly the last non-nuclear steam-powered ship built for the US Navy.

Turbo-electric drive

World War II

World War II or the Second World War (1 September 1939 – 2 September 1945) was a World war, global conflict between two coalitions: the Allies of World War II, Allies and the Axis powers. World War II by country, Nearly all of the wo ...

. However, when the US designed the "treaty cruisers", beginning with launched in 1927, geared turbines were used to conserve weight, and remained in use for all fast steam-powered ships thereafter.

Current usage

Since the 1980s, steam turbines have been replaced bygas turbine