Standard transmission on:

[Wikipedia]

[Google]

[Amazon]

A manual transmission (MT), also known as manual gearbox, standard transmission (in

A manual transmission (MT), also known as manual gearbox, standard transmission (in

File:Gearbox 4gears.gif, Operation of a constant-mesh 4-speed manual transmission

File:Crash gearbox 3gears and reverse.gif, Non-synchronous "crash" gearbox; with ''sliding-mesh'' design, used in older vehicles

File:Gearbox 4gears sequential.gif, Operation of a constant-mesh 4-speed sequential manual transmission, commonly used in

Image:Manual transmission clutch First gear.PNG, First gear (blue, to back)

Image:Manual transmission clutch Second gear.PNG, Second gear (blue, to front)

Image:Manual transmission clutch Third gear.PNG, Third gear (purple, to back)

Image:Manual transmission clutch Fourth gear.PNG, Fourth gear (purple, to front)

Image:Manual transmission clutch Reverse gear.PNG, Reverse (green engaged)

Image:Manual transmission clutch Neutral.PNG, Neutral (all disengaged)

In order to provide smooth gearshifts without requiring the driver to manually match the engine revs for each gearshift, most modern passenger car transmissions use 'synchromesh' (also called 'synchronizer rings') on the forward gears. These devices automatically match the speed of the input shaft with that of the gear being selected, thus removing the need for the driver to use techniques such as double-clutching. The synchromesh transmission was invented in 1919 by Earl Avery Thompson and first used on production cars by Cadillac in 1928.

The need for synchromesh in a constant-mesh transmission is that the dog clutches require the input shaft speed to match that of the gear being selected; otherwise, the dog teeth will fail to engage and a loud grinding sound will be heard as they clatter together. Therefore, to speed up or slow down the input shaft as required, cone-shaped brass synchronizer rings are attached to each gear. When the driver moves the gearshift lever towards the next gear, these synchronizer rings press on the cone-shaped sleeve on the dog collar so that the friction forces can reduce the difference in rotational speeds. Once these speeds are equalized, the dog clutch can engage, and thus the new gear is now in use. In a modern gearbox, the action of all of these components is so smooth and fast it is hardly noticed. Many transmissions do not include synchromesh on the reverse gear (see Reverse gear section below).

The synchromesh system must also prevent the collar from bridging the locking rings while the speeds are still being synchronized. This is achieved through 'blocker rings' (also called 'baulk rings'). The synchro ring rotates slightly because of the frictional torque from the cone clutch. In this position, the dog clutch is prevented from engaging. Once the speeds are synchronized, friction on the blocker ring is relieved and the blocker ring twists slightly, bringing into alignment certain grooves or notches that allow the dog clutch to fall into the engagement.

Common metals for synchronizer rings are

In order to provide smooth gearshifts without requiring the driver to manually match the engine revs for each gearshift, most modern passenger car transmissions use 'synchromesh' (also called 'synchronizer rings') on the forward gears. These devices automatically match the speed of the input shaft with that of the gear being selected, thus removing the need for the driver to use techniques such as double-clutching. The synchromesh transmission was invented in 1919 by Earl Avery Thompson and first used on production cars by Cadillac in 1928.

The need for synchromesh in a constant-mesh transmission is that the dog clutches require the input shaft speed to match that of the gear being selected; otherwise, the dog teeth will fail to engage and a loud grinding sound will be heard as they clatter together. Therefore, to speed up or slow down the input shaft as required, cone-shaped brass synchronizer rings are attached to each gear. When the driver moves the gearshift lever towards the next gear, these synchronizer rings press on the cone-shaped sleeve on the dog collar so that the friction forces can reduce the difference in rotational speeds. Once these speeds are equalized, the dog clutch can engage, and thus the new gear is now in use. In a modern gearbox, the action of all of these components is so smooth and fast it is hardly noticed. Many transmissions do not include synchromesh on the reverse gear (see Reverse gear section below).

The synchromesh system must also prevent the collar from bridging the locking rings while the speeds are still being synchronized. This is achieved through 'blocker rings' (also called 'baulk rings'). The synchro ring rotates slightly because of the frictional torque from the cone clutch. In this position, the dog clutch is prevented from engaging. Once the speeds are synchronized, friction on the blocker ring is relieved and the blocker ring twists slightly, bringing into alignment certain grooves or notches that allow the dog clutch to fall into the engagement.

Common metals for synchronizer rings are

Another design of transmission that is used in older

Another design of transmission that is used in older

Some vehicles have a gear lever mounted on the steering column. A 3-speed column shifter, which came to be popularly known as a "three on the tree", began appearing in America in the late 1930s and became common during the 1940s and 1950s. If a U.S. vehicle was equipped with overdrive, it was very likely to be a

Some vehicles have a gear lever mounted on the steering column. A 3-speed column shifter, which came to be popularly known as a "three on the tree", began appearing in America in the late 1930s and became common during the 1940s and 1950s. If a U.S. vehicle was equipped with overdrive, it was very likely to be a  Later, European and Japanese models began to have 4-speed column shifters with this shift pattern:

Later, European and Japanese models began to have 4-speed column shifters with this shift pattern:

A majority of North American-spec vehicles sold in the U.S. and Canada had a 3-speed column-mounted shifter—the first generation Chevrolet/GMC vans of 1964–70 vintage had an ultra-rare 4-speed column shifter. The column-mounted manual shifter disappeared in North America by the mid-1980s, last appearing in the 1987 Chevrolet pickup truck. Prior to 1980, the GM X platform compacts (Chevrolet Nova and its rebadged corporate clones) were the final passenger cars to have a column-mounted manual shifter. Outside North America, the column-mounted shifter remained in production. All

A majority of North American-spec vehicles sold in the U.S. and Canada had a 3-speed column-mounted shifter—the first generation Chevrolet/GMC vans of 1964–70 vintage had an ultra-rare 4-speed column shifter. The column-mounted manual shifter disappeared in North America by the mid-1980s, last appearing in the 1987 Chevrolet pickup truck. Prior to 1980, the GM X platform compacts (Chevrolet Nova and its rebadged corporate clones) were the final passenger cars to have a column-mounted manual shifter. Outside North America, the column-mounted shifter remained in production. All

As Stick Shifts Fade Into Obscurity, Collectors See Opportunity

24 June 2021 New York Times article by Rob Sass {{DEFAULTSORT:Manual Transmission Automotive transmission technologies Automobile transmissions

A manual transmission (MT), also known as manual gearbox, standard transmission (in

A manual transmission (MT), also known as manual gearbox, standard transmission (in Canada

Canada is a country in North America. Its Provinces and territories of Canada, ten provinces and three territories extend from the Atlantic Ocean to the Pacific Ocean and northward into the Arctic Ocean, making it the world's List of coun ...

, the United Kingdom

The United Kingdom of Great Britain and Northern Ireland, commonly known as the United Kingdom (UK) or Britain, is a country in Northwestern Europe, off the coast of European mainland, the continental mainland. It comprises England, Scotlan ...

and the United States

The United States of America (USA), also known as the United States (U.S.) or America, is a country primarily located in North America. It is a federal republic of 50 U.S. state, states and a federal capital district, Washington, D.C. The 48 ...

), or stick shift (in the United States), is a multi-speed motor vehicle

A motor vehicle, also known as a motorized vehicle, automotive vehicle, automobile, or road vehicle, is a self-propelled land vehicle, commonly wheeled, that does not operate on railway track, rails (such as trains or trams), does not fly (such ...

transmission system

In telecommunications, a transmission system is a communication system that transmits a signal from one place to another. The signal can be an signal (electrical engineering), electrical, fiber-optic communication, optical or radio wave, radio s ...

where gear changes require the driver to manually select the gears by operating a gear stick

A gear stick (rarely spelled ''gearstick''), gear lever (both UK English), gearshift or shifter (both U.S. English), more formally known as a transmission lever, is a metal lever attached to the transmission of an automobile. The term ''gear s ...

and clutch

A clutch is a mechanical device that allows an output shaft to be disconnected from a rotating input shaft. The clutch's input shaft is typically attached to a motor, while the clutch's output shaft is connected to the mechanism that does th ...

(which is usually a foot pedal for cars or a hand lever for motorcycles).

Early automobiles used ''sliding-mesh'' manual transmissions with up to three forward gear ratios. Since the 1950s, ''constant-mesh'' manual transmissions have become increasingly commonplace, and the number of forward ratios has increased to 5-speed and 6-speed manual transmissions for current vehicles.

The alternative to a manual transmission is an automatic transmission

An automatic transmission (AT) or automatic gearbox is a multi-speed transmission (mechanics), transmission used in motor vehicles that does not require any input from the driver to change forward gears under normal driving conditions.

The 1904 ...

. Common types of automatic transmissions are the hydraulic automatic transmission (AT) and the continuously variable transmission

A continuously variable transmission (CVT) is an automated Transmission (mechanical device), transmission that can change through a continuous range of gear ratios, typically resulting in better fuel economy in gasoline applications. This contr ...

(CVT). The automated manual transmission

The automated manual transmission (AMT) is a type of transmission (mechanics), transmission for motor vehicles. It is essentially a conventional manual transmission equipped with automatic actuation to operate the clutch and/or shift Gear train ...

(AMT) and dual-clutch transmission

A dual-clutch transmission (DCT) (sometimes referred to as a twin-clutch transmission) is a type of multi-speed motor vehicle, vehicle Transmission (mechanics), transmission system, that uses two separate clutches for odd and even gear train, ...

(DCT) are internally similar to a conventional manual transmission, but are shifted automatically.

Alternatively, there are semi-automatic transmissions. These systems are based on the design of, and are technically similar to, a conventional manual transmission. They have a gear shifter which requires the driver's input to manually change gears, but the driver is not required to engage a clutch pedal before changing gear. Instead, the mechanical linkage for the clutch pedal is replaced by an actuator

An actuator is a machine element, component of a machine that produces force, torque, or Displacement (geometry), displacement, when an electrical, Pneumatics, pneumatic or Hydraulic fluid, hydraulic input is supplied to it in a system (called an ...

, servo, or solenoid

upright=1.20, An illustration of a solenoid

upright=1.20, Magnetic field created by a seven-loop solenoid (cross-sectional view) described using field lines

A solenoid () is a type of electromagnet formed by a helix, helical coil of wire whos ...

and sensor

A sensor is often defined as a device that receives and responds to a signal or stimulus. The stimulus is the quantity, property, or condition that is sensed and converted into electrical signal.

In the broadest definition, a sensor is a devi ...

s, which operate the clutch system automatically when the driver touches or moves the gearshift. This removes the need for a physical clutch pedal.

Overview

A manual transmission requires the driver to operate thegear stick

A gear stick (rarely spelled ''gearstick''), gear lever (both UK English), gearshift or shifter (both U.S. English), more formally known as a transmission lever, is a metal lever attached to the transmission of an automobile. The term ''gear s ...

and clutch

A clutch is a mechanical device that allows an output shaft to be disconnected from a rotating input shaft. The clutch's input shaft is typically attached to a motor, while the clutch's output shaft is connected to the mechanism that does th ...

in order to change gears (unlike an automatic transmission

An automatic transmission (AT) or automatic gearbox is a multi-speed transmission (mechanics), transmission used in motor vehicles that does not require any input from the driver to change forward gears under normal driving conditions.

The 1904 ...

or semi-automatic transmission

A semi-automatic transmission is a multiple-speed Transmission (mechanics), transmission where part of its operation is Automation, automated (typically the actuation of the clutch), but the driver's input is still required to launch the vehicle f ...

, where one (typically the clutch) or both of these functions are automated

Automation describes a wide range of technologies that reduce human intervention in processes, mainly by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machine ...

). Most manual transmissions for cars allow the driver to select any gear ratio at any time, for example shifting from second to fourth gear, or fifth to third gear. However, sequential manual transmission

A sequential manual transmission, also known as a sequential gearbox or sequential transmission, is a type of Non-synchronous transmission, non-synchronous manual transmission used mostly in motorcycles and Auto racing, racing cars. It produces ...

s, which are commonly used in motorcycle

A motorcycle (motorbike, bike; uni (if one-wheeled); trike (if three-wheeled); quad (if four-wheeled)) is a lightweight private 1-to-2 passenger personal motor vehicle Steering, steered by a Motorcycle handlebar, handlebar from a saddle-style ...

s and racing car

Auto racing (also known as car racing, motor racing, or automobile racing) is a motorsport involving the racing of automobiles for competition. In North America, the term is commonly used to describe all forms of automobile sport including ...

s, only allow the driver to select the next-higher or next-lower gear.

In a vehicle with a manual transmission, the flywheel

A flywheel is a mechanical device that uses the conservation of angular momentum to store rotational energy, a form of kinetic energy proportional to the product of its moment of inertia and the square of its rotational speed. In particular, a ...

is attached to the engine's crankshaft

A crankshaft is a mechanical component used in a reciprocating engine, piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating Shaft (mechanical engineering), shaft containing one or more crankpins, ...

, therefore rotating at engine speed. A clutch disc sits between the flywheel and the transmission pressure plate which is attached to the transmission input shaft, controlling whether the transmission is connected to the engine or not. The clutch pedal controls the pressure plate (''clutch engaged'' – the clutch pedal is not being pressed) or not connected to the engine (''clutch disengaged'' – the clutch pedal is being pressed down). When the engine is running and the clutch is engaged (i.e., clutch pedal up), the flywheel spins the clutch pressure plate and hence the transmission.

The design of most manual transmissions for cars is that gear ratios are selected by locking selected gear pairs to the output shaft inside the transmission. This is a fundamental difference compared with a typical hydraulic automatic transmission, which uses an epicyclic (planetary) design, and a hydraulic torque converter. An automatic transmission that allows the driver to control the gear selection (such as shift paddles or "+/−" positions on the gear selector) is called a manumatic

The modern usage of the automotive term manumatic denotes an automatic transmission that allows the driver to select a specific gear, typically using paddle-shifters, steering wheel-mounted push-buttons, or "+" and "-" controls on the gear selec ...

transmission, and is not considered a manual transmission. Some automatic transmissions are based on the mechanical build and internal design of a manual transmission but have added components (such as computer

A computer is a machine that can be Computer programming, programmed to automatically Execution (computing), carry out sequences of arithmetic or logical operations (''computation''). Modern digital electronic computers can perform generic set ...

-controlled actuator

An actuator is a machine element, component of a machine that produces force, torque, or Displacement (geometry), displacement, when an electrical, Pneumatics, pneumatic or Hydraulic fluid, hydraulic input is supplied to it in a system (called an ...

s and sensor

A sensor is often defined as a device that receives and responds to a signal or stimulus. The stimulus is the quantity, property, or condition that is sensed and converted into electrical signal.

In the broadest definition, a sensor is a devi ...

s) which automatically control the timing and speed of the gear shifts and clutch; this design is typically called an automated manual transmission

The automated manual transmission (AMT) is a type of transmission (mechanics), transmission for motor vehicles. It is essentially a conventional manual transmission equipped with automatic actuation to operate the clutch and/or shift Gear train ...

(or sometimes a ''clutchless manual transmission'').

Contemporary manual transmissions for cars typically use five or six forward gears ratios and one reverse gear, however, transmissions with between two and seven gears have been produced at times. Transmissions for trucks and other heavy equipment often have between eight and twenty-five gears, in order to keep the engine speed within the optimal power band

The power band of an internal combustion engine or electric motor is the range of operating speeds under which the engine or motor is able to output the most power, that is, the maximum energy per unit of time. This usually means that maximum ...

for all typical road speeds. Operating such transmissions often uses the same pattern of shifter movement with a single or multiple switches to engage the next sequence of gears.

motorcycles

A motorcycle (motorbike, bike; uni (if one-wheeled); trike (if three-wheeled); quad (if four-wheeled)) is a lightweight private 1-to-2 passenger personal motor vehicle Steering, steered by a Motorcycle handlebar, handlebar from a saddle-style ...

and race car

Race, RACE or The Race may refer to:

* Race (biology), an informal taxonomic classification within a species, generally within a sub-species

* Race (human categorization), classification of humans into groups based on physical traits, and/or s ...

s

File:0762 Spinning Levers 04 45 20 00 3mb.webm, 1936 film of automobile gearbox

History

1890s to 1940s

Many of the first automobiles were rear-engined, with a simple belt-drive functioning as a single-speed transmission. The 1891 Panhard et Levassor is considered a significant advance in automotive transmissions since it used a three-speed manual transmission. This transmission, along with many similar designs that it inspired, was a non-synchronous (also called ''sliding-mesh'') design where gear changes involved sliding the gears along their shafts so that the desired cogs became meshed. The driver was therefore required to use careful timing andthrottle

A throttle is a mechanism by which fluid flow is managed by construction or obstruction.

An engine's power can be increased or decreased by the restriction of inlet gases (by the use of a throttle), but usually decreased. The term ''throttle'' ha ...

manipulation when shifting, so the gears would be spinning at roughly the same speed when engaged; otherwise, the teeth would refuse to mesh. This was difficult to achieve, so gear changes were often accompanied by grinding or crunching sounds, resulting in the gearboxes being nicknamed "crash boxes". Even after passenger cars had switched to synchronous transmissions (i.e. with synchronizers), many transmissions for heavy trucks, motorcycles and racing cars remained non-synchronous, in order to withstand the forces required or provide a faster shift time

Shift time refers to the time interval between gear changes in a transmission. This interval is the time in which power delivery is transferred to the next selected gear, and engine speed is reduced or increased to synchronize the speed of the ...

.

1950s to 1980s

The first car to use a manual transmission withsynchromesh

A manual transmission (MT), also known as manual gearbox, standard transmission (in Canada, the United Kingdom and the United States), or stick shift (in the United States), is a multi-speed motor vehicle transmission system where gear changes ...

was the 1929 Cadillac. Most North American marques had adopted synchronized manual transmissions, usually for second and high gears, by the mid-1930s. In 1947, Porsche patented the ''split ring'' synchromesh system. The 1952 Porsche 356

The Porsche 356 is a rear-engine sports car, and the first ever production Porsche model.

The 356 is a lightweight and nimble-handling, rear-engine, rear-wheel drive, two-door available both in hardtop coupé and open configurations. Engineer ...

was the first car to use a transmission with synchromesh on all forward gears. In the early 1950s, most cars only had synchromesh for the shift from third gear to second gear (drivers' manuals in vehicles suggested that if the driver needed to shift from second to first, it was best to come to a complete stop beforehand).

Up until the late 1970s, most transmissions had three or four forward gear ratios, although five-speed manual transmissions were occasionally used in sports cars such as the 1948 Ferrari 166 Inter and the 1953 Alfa Romeo 1900 Super Sprint. Five-speed transmissions became widespread during the 1980s, as did the use of synchromesh on all forward gears.

1990s to present

Six-speed manual transmissions started to emerge in high-performance vehicles in the early 1990s, such as the 1990 BMW 850i and the 1992 Ferrari 456. The first 6-speed manual transmission was introduced in the 1967Alfa Romeo 33 Stradale

The Alfa Romeo 33 Stradale is a Mid-engine design, mid-engine sports car built by Italian automobile manufacturer Alfa Romeo. It was the fastest commercially available car for the standing kilometer upon its introduction.Alfa Romeo 33 Stradale tu ...

. The first 7-speed manual transmission was introduced in the 2012 Porsche 911 (991).

In 2008, 75.2% of vehicles produced in Western Europe were equipped with manual transmission, versus 16.1% with automatic and 8.7% with other.

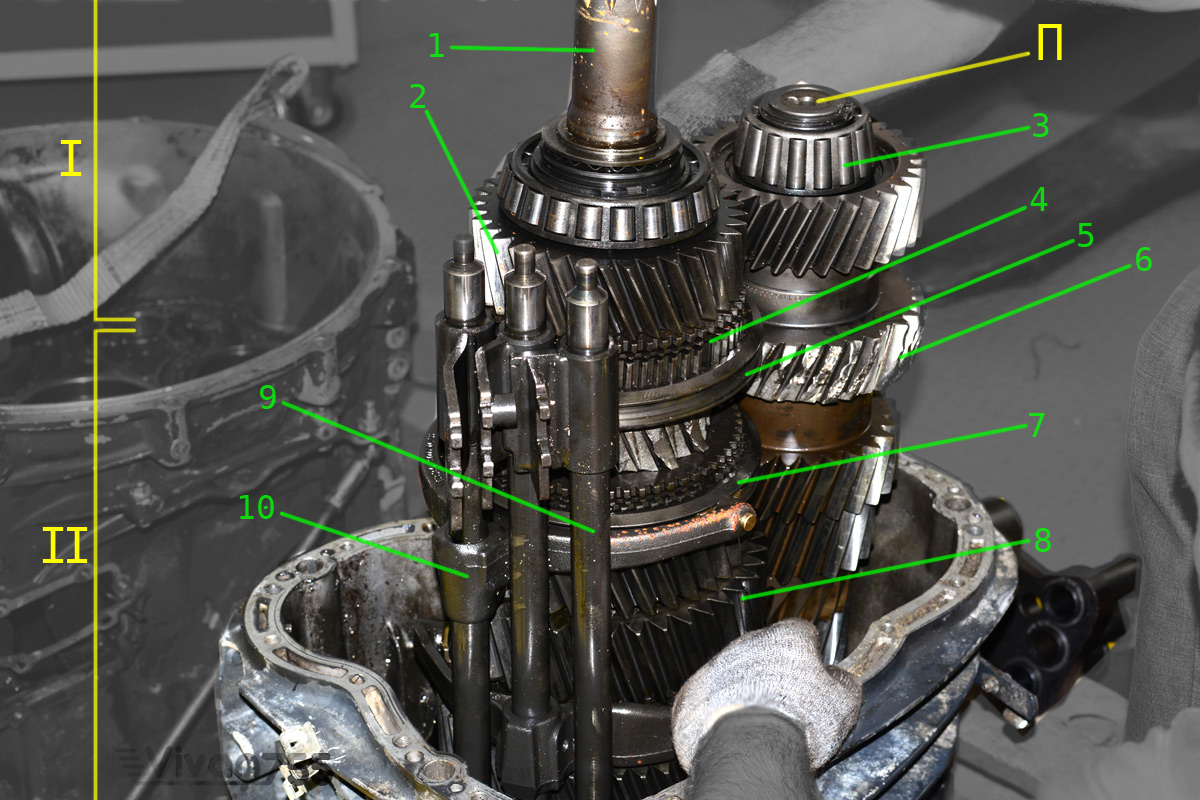

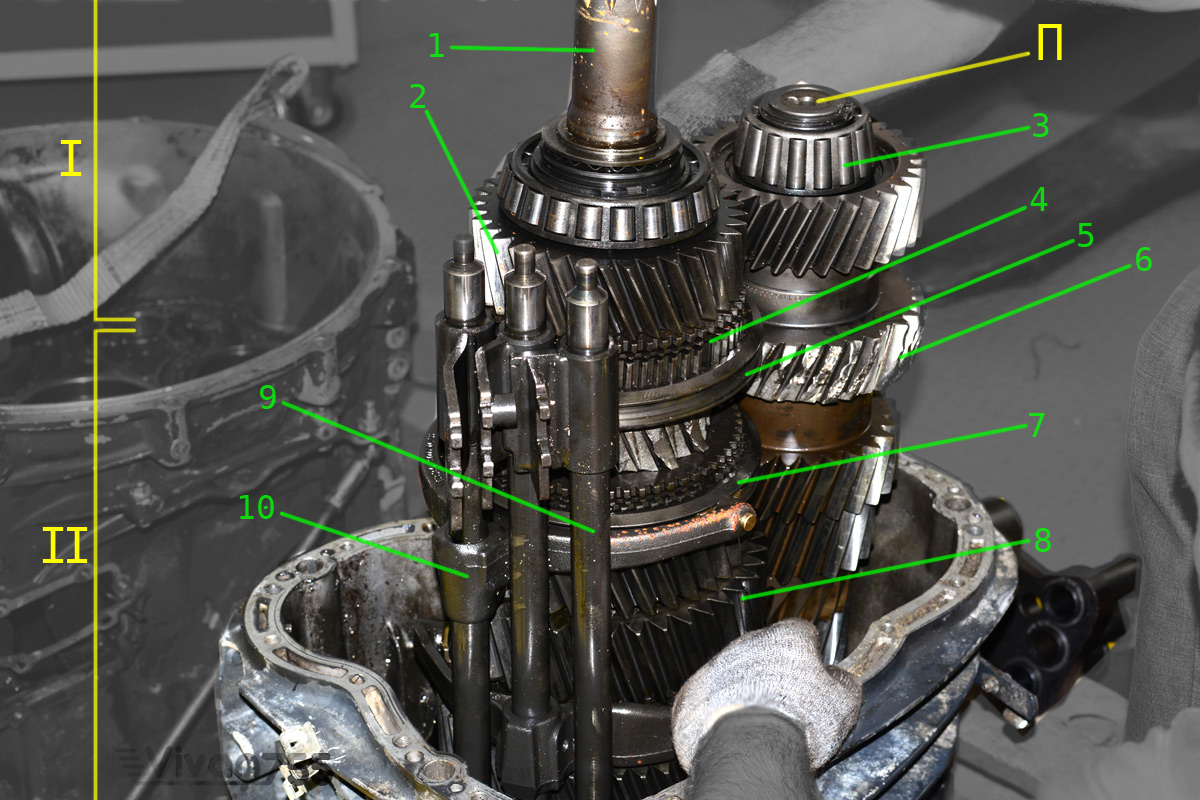

Internals

Shafts

A manual transmission has several shafts with various gears and other components attached to them. Most modern passenger cars use 'constant-mesh' transmissions consisting of three shafts: an ''input shaft'', a ''countershaft'' (also called a layshaft) and an ''output shaft''. The ''input shaft'' is connected to the engine and spins at engine speed whenever the clutch is engaged. The ''countershaft'' has gears of various sizes, which are permanently meshed with the corresponding gear on the input shaft. The gears on the ''output shaft'' are also permanently meshed with a corresponding gear on the countershaft; however, the output shaft gears are able to rotate independently of the output shaft itself (through the use of bearings located between the gears and the shaft). Through the use of collars (operated using the ''shift rods''), the speed of the output shaft becomes temporarily locked to the speed of the selected gear. Some transmission designs—such as in the Volvo 850 and S70—have two countershafts, both driving an output pinion meshing with the front-wheel-drive transaxle's ring gear. This allows for a narrower transmission since the length of each countershaft is halved compared with one that contains four gears and two shifters. The fixed and free gears can be mounted on either the input or output shaft or both. For example, a five-speed transmission might have the first-to-second selectors on the countershaft, but the third-to-fourth selector and the fifth selector on the main shaft. This means that when the vehicle is stopped and idling in neutral with the clutch engaged and the input shaft spinning, the third-, fourth-, and fifth-gear pairs do not rotate. When neutral is selected, none of the gears on the output shaft are locked to the shaft, allowing the input and output shafts to rotate independently. For reverse gear, an idler gear is used to reverse the direction in which the output shaft rotates. In many transmissions, the input and output shafts can be directly locked together (bypassing the countershaft) to create a 1:1 gear ratio which is referred to as ''direct-drive''. In a transmission for longitudinal engined vehicles (e.g. most rear-wheel-drive cars), it is common for the input shaft and output shaft to be located on the same axis, since this reduces the torsional forces to which the transmission casing must withstand. The assembly consisting of both the input and output shafts is referred to as the ''main shaft'' (although sometimes this term refers to just the input shaft or output shaft). Independent rotation of the input and output shafts is made possible by one shaft being located inside the hollow bore of the other shaft, with a bearing located between the two shafts. In a transmission fortransverse engine

A transverse engine is an engine mounted in a vehicle so that the engine's crankshaft axis is perpendicular to the direction of travel. Many modern front-wheel drive vehicles use this arrangement. Most rear-wheel drive vehicles use a longitudinal ...

d vehicles (e.g., front-wheel-drive cars), there are usually only two shafts: input and countershaft (sometimes called input and output). The input shaft runs the whole length of the gearbox, and there is no separate input pinion. These transmissions also have an integral differential unit, which is connected via a pinion gear at the end of the counter/output shaft.

Dog clutch

In a modern constant-mesh manual transmission, the gear teeth are permanently in contact with each other, and dog clutches (sometimes called ''dog teeth'') are used to select the gear ratio for the transmission. When the dog clutches for all gears are disengaged (i.e. when the transmission is in neutral), all of the gears are able to spin freely around the output shaft. When the driver selects a gear, the dog clutch for that gear is engaged (via the gear selector rods), locking the transmission's output shaft to a particular gear set. This means the output shaft rotates at the same speed as the selected gear, thus determining the gear ratio of the transmission. The dog clutch is a sliding selector mechanism that sits around the output shaft. It has teeth to fit into the splines on the shaft, forcing that shaft to rotate at the same speed as the gear hub. However, the clutch can move back and forth on the shaft, to either engage or disengage the splines. This movement is controlled by a selector fork that is linked to the gear lever. The fork does not rotate, so it is attached to a collar bearing on the selector. The selector is typically symmetric: it slides between two gears and has a synchromesh and teeth on each side in order to lock either gear to the shaft. Unlike some other types of clutches (such as the foot-operated clutch of a manual-transmission car), a dog clutch provides non-slip coupling and is not suited to intentional slipping.Synchromesh

In order to provide smooth gearshifts without requiring the driver to manually match the engine revs for each gearshift, most modern passenger car transmissions use 'synchromesh' (also called 'synchronizer rings') on the forward gears. These devices automatically match the speed of the input shaft with that of the gear being selected, thus removing the need for the driver to use techniques such as double-clutching. The synchromesh transmission was invented in 1919 by Earl Avery Thompson and first used on production cars by Cadillac in 1928.

The need for synchromesh in a constant-mesh transmission is that the dog clutches require the input shaft speed to match that of the gear being selected; otherwise, the dog teeth will fail to engage and a loud grinding sound will be heard as they clatter together. Therefore, to speed up or slow down the input shaft as required, cone-shaped brass synchronizer rings are attached to each gear. When the driver moves the gearshift lever towards the next gear, these synchronizer rings press on the cone-shaped sleeve on the dog collar so that the friction forces can reduce the difference in rotational speeds. Once these speeds are equalized, the dog clutch can engage, and thus the new gear is now in use. In a modern gearbox, the action of all of these components is so smooth and fast it is hardly noticed. Many transmissions do not include synchromesh on the reverse gear (see Reverse gear section below).

The synchromesh system must also prevent the collar from bridging the locking rings while the speeds are still being synchronized. This is achieved through 'blocker rings' (also called 'baulk rings'). The synchro ring rotates slightly because of the frictional torque from the cone clutch. In this position, the dog clutch is prevented from engaging. Once the speeds are synchronized, friction on the blocker ring is relieved and the blocker ring twists slightly, bringing into alignment certain grooves or notches that allow the dog clutch to fall into the engagement.

Common metals for synchronizer rings are

In order to provide smooth gearshifts without requiring the driver to manually match the engine revs for each gearshift, most modern passenger car transmissions use 'synchromesh' (also called 'synchronizer rings') on the forward gears. These devices automatically match the speed of the input shaft with that of the gear being selected, thus removing the need for the driver to use techniques such as double-clutching. The synchromesh transmission was invented in 1919 by Earl Avery Thompson and first used on production cars by Cadillac in 1928.

The need for synchromesh in a constant-mesh transmission is that the dog clutches require the input shaft speed to match that of the gear being selected; otherwise, the dog teeth will fail to engage and a loud grinding sound will be heard as they clatter together. Therefore, to speed up or slow down the input shaft as required, cone-shaped brass synchronizer rings are attached to each gear. When the driver moves the gearshift lever towards the next gear, these synchronizer rings press on the cone-shaped sleeve on the dog collar so that the friction forces can reduce the difference in rotational speeds. Once these speeds are equalized, the dog clutch can engage, and thus the new gear is now in use. In a modern gearbox, the action of all of these components is so smooth and fast it is hardly noticed. Many transmissions do not include synchromesh on the reverse gear (see Reverse gear section below).

The synchromesh system must also prevent the collar from bridging the locking rings while the speeds are still being synchronized. This is achieved through 'blocker rings' (also called 'baulk rings'). The synchro ring rotates slightly because of the frictional torque from the cone clutch. In this position, the dog clutch is prevented from engaging. Once the speeds are synchronized, friction on the blocker ring is relieved and the blocker ring twists slightly, bringing into alignment certain grooves or notches that allow the dog clutch to fall into the engagement.

Common metals for synchronizer rings are brass

Brass is an alloy of copper and zinc, in proportions which can be varied to achieve different colours and mechanical, electrical, acoustic and chemical properties, but copper typically has the larger proportion, generally copper and zinc. I ...

and steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength a ...

, and are produced either by forging

Forging is a manufacturing process involving the shaping of metal using localized compression (physics), compressive forces. The blows are delivered with a hammer (often a power hammer) or a die (manufacturing), die. Forging is often classif ...

or sheet metal shaping. The latter involves stamping the piece out of a sheet metal strip and then machining

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing, which util ...

to obtain the exact shape required. The rings are sometimes coated with anti-wear linings (also called 'friction linings') made from molybdenum

Molybdenum is a chemical element; it has Symbol (chemistry), symbol Mo (from Neo-Latin ''molybdaenum'') and atomic number 42. The name derived from Ancient Greek ', meaning lead, since its ores were confused with lead ores. Molybdenum minerals hav ...

, iron

Iron is a chemical element; it has symbol Fe () and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, forming much of Earth's o ...

, bronze

Bronze is an alloy consisting primarily of copper, commonly with about 12–12.5% tin and often with the addition of other metals (including aluminium, manganese, nickel, or zinc) and sometimes non-metals (such as phosphorus) or metalloid ...

or carbon

Carbon () is a chemical element; it has chemical symbol, symbol C and atomic number 6. It is nonmetallic and tetravalence, tetravalent—meaning that its atoms are able to form up to four covalent bonds due to its valence shell exhibiting 4 ...

(with the latter usually reserved for high-performance transmissions due to their high cost).

Mechanical wear of the synchronizer rings and sleeves can cause the synchromesh system to become ineffective over time. These rings and sleeves have to overcome the momentum of the entire input shaft and clutch disk during each gearshift (and also the momentum and power of the engine, if the driver attempts a gearshift without fully disengaging the clutch). Larger differences in speed between the input shaft and the gear require higher friction forces from the synchromesh components, potentially increasing their wear rate.

Reverse gear

Even in modern transmissions where all of the forward gears are in a constant-mesh configuration, often the reverse gear uses the older ''sliding-mesh'' ("crash box") configuration. This means that moving the gearshift lever into reverse results in gears moving to mesh together. Another unique aspect of the reverse gear is that it consists of two gears—an idler gear on the countershaft and another gear on the output shaft—and both of these are directly fixed to the shaft (i.e. they are always rotating at the same speed as the shaft). These gears are usuallyspur gear

Spur gears or straight-cut gears are the simplest type of gear. They consist of a cylinder or disk with teeth projecting radially. Viewing the gear at 90 degrees from the shaft length (side on) the tooth faces are straight and aligned parallel to ...

s with straight-cut teeth which—unlike the helical teeth used for forward gear—results in a whining sound as the vehicle moves in reverse.

When reverse gear is selected, the idler gear is physically moved to mesh with the corresponding gears on the input and output shafts. To avoid grinding as the gears begin to the mesh, they need to be stationary. Since the input shaft is often still spinning due to momentum (even after the car has stopped), a mechanism is needed to stop the input shaft, such as using the synchronizer rings for fifth gear. However, some vehicles do employ a synchromesh system for the reverse gear, thus preventing possible crunching if reverse gear is selected while the input shaft is still spinning.

Most transmissions include a lockout mechanism to prevent reverse gear from being accidentally selected while the car is moving forwards. This can take the form of a collar underneath the gear knob which needs to be lifted or requiring extra force to push the gearshift lever into the plane of reverse gear.

Non-synchronous transmission

Another design of transmission that is used in older

Another design of transmission that is used in older car

A car, or an automobile, is a motor vehicle with wheels. Most definitions of cars state that they run primarily on roads, seat one to eight people, have four wheels, and mainly transport people rather than cargo. There are around one billio ...

s, trucks

A truck or lorry is a motor vehicle designed to transport freight, carry specialized payloads, or perform other utilitarian work. Trucks vary greatly in size, power, and configuration, but the vast majority feature body-on-frame construction ...

, and tractor

A tractor is an engineering vehicle specifically designed to deliver a high tractive effort (or torque) at slow speeds, for the purposes of hauling a Trailer (vehicle), trailer or machinery such as that used in agriculture, mining or constructio ...

s, is a non-synchronous transmission (also known as a crash gearbox). Non-synchronous transmissions use a sliding-mesh (or constant-mesh, in later years) design and have the nickname "crash" because the difficulty in changing gears can lead to gear shifts accompanied by crashing/crunching noises.

Clutch

Vehicles with manual transmissions use a clutch to manage the linkage between the engine and the transmission, and decouple the transmission from the engine during gearshifts and when the vehicle is stationary. Without a clutch, the engine would stall any time the vehicle stopped, and changing gears would be difficult (deselecting a gear while the transmission requires the driver to adjust the throttle so that the transmission is not under load, and selecting a gear requires the engine RPM to be at the exact speed that matches the road speed for the gear being selected). Most motor vehicles use a pedal to operate the clutch; except for motorcycles, which usually have a clutch lever on the left handlebar.Gear shift types

In most vehicles with a manual transmission, the driver selects gears by manipulating a lever called a ''gear stick'' (also called a ''gearshift'', ''gear lever'' or ''shifter''). In most automobiles, the gear stick is located on the floor between the driver and front passenger, but some cars have a gear stick that is mounted to the steering column or center console. The movement of the gear stick is transferred (via solid linkages or cables) to the selector forks within the transmission. Motorcycles typically employsequential manual transmission

A sequential manual transmission, also known as a sequential gearbox or sequential transmission, is a type of Non-synchronous transmission, non-synchronous manual transmission used mostly in motorcycles and Auto racing, racing cars. It produces ...

s, although the shift pattern is modified slightly for safety reasons. Gear selection is usually via the left-foot (or, on older motorcycles; right-foot) shift lever with a layout of

"Three on the tree" vs. "four on the floor"

During the period when U.S. vehicles usually had only three forward speeds, the most common gear-shifter location was on the steering column, a layout that was sometimes called "three on the tree". By contrast, high-performance cars, and European vehicles in general, mostly used a four-speed transmission with floor-mounted shifters. That layout was referred to as "four on the floor". Most FR (front-engined, rear-wheel drive) vehicles have a transmission that sits between the driver and the front passenger seat. Floor-mounted shifters are often connected directly to the transmission. FF (front-engined, front-wheel drive) vehicles, RR (rear-engined, rear-wheel drive) vehicles and front-engined vehicles with rear-mounted gearboxes often require a mechanical linkage to connect the shifter to the transmission.Column-mounted shifter

Some vehicles have a gear lever mounted on the steering column. A 3-speed column shifter, which came to be popularly known as a "three on the tree", began appearing in America in the late 1930s and became common during the 1940s and 1950s. If a U.S. vehicle was equipped with overdrive, it was very likely to be a

Some vehicles have a gear lever mounted on the steering column. A 3-speed column shifter, which came to be popularly known as a "three on the tree", began appearing in America in the late 1930s and became common during the 1940s and 1950s. If a U.S. vehicle was equipped with overdrive, it was very likely to be a Borg-Warner

BorgWarner Inc. is an American automotive and e-mobility supplier headquartered in Auburn Hills, Michigan. As of 2023, the company maintains production facilities and sites at 92 locations in 24 countries, and generates revenues of US$14.2 bi ...

type, operated by briefly backing off the accelerator pedal when above to enable, and momentarily flooring the same pedal to return to normal gear. The control simply disables overdrive for such situations as parking on a hill or preventing unwanted shifting into overdrive.

Toyota Crown

The is an automobile which has been produced by Toyota in Japan since 1955. It is primarily a line of mid-size luxury cars that is marketed as an upmarket offering in the Toyota lineup.

In North America, the first through fourth generation ...

and Nissan Cedric

The is a large automobile produced by Nissan Motors, Nissan from 1960 to 2015. It was developed to provide upscale transportation, competing with the Prince Skyline and Prince Gloria, Gloria which were later merged into the Nissan family. In late ...

taxis in Hong Kong had the 4-speed column shift until 1999 when automatic transmissions were first offered. Since the late 1980s or early 1990s, a 5-speed column shifter has been offered in some vans sold in Asia and Europe, such as Toyota Hiace

The (pronounced "High Ace") is a light commercial vehicle produced by the Japanese automobile manufacturer Toyota. First launched in October 1967, the HiAce has since been available in a wide range of body configurations, including a minivan/M ...

, Mitsubishi L400 and the first-gen Fiat Ducato

The Fiat Ducato is a light commercial vehicle jointly developed by FCA Italy and PSA Group (currently Stellantis), and mainly manufactured by Sevel, a joint venture between the two companies since 1981. It has also been sold as the Citroën C ...

. Many European cars had manual column shifts and the Renault 16TX had a 5 speed.

Column shifters are mechanically similar to floor shifters, although shifting occurs in a vertical plane instead of a horizontal one. Because the shifter is further away from the transmission, and the movements at the shifter and at the transmission are in different planes, column shifters require more complicated linkage than floor shifters. Advantages of a column shifter are the ability to switch between the two most commonly used gears—second and third—without letting go of the steering wheel, and the lack of interference with passenger seating space in vehicles equipped with a bench seat

A bench seat is a full width continuous pad forming the front seat of automobiles. The second row of seating in most sedans is usually a bench. The third row of most SUVs and minivans, which may be forward-facing or rear-facing, is also a benc ...

.

Console-mounted shifter

Some smaller cars in the 1950s and 1960s, such asCitroën 2CV

The Citroën 2CV (, , lit. "two horses", meaning "two Tax horsepower#France, ''taxable'' horsepower") is an economy car produced by the French company Citroën from 1948 to 1990. Introduced at the 1948 Paris Paris Auto Show, Salon de l'Automobi ...

, Renault 4 and early Renault 5 feature a shifter in the dash panel. This was cheaper to manufacture than a column shifter and more practical, as the gearbox was mounted in front of the engine. The linkage for the shifter could then be positioned on top of the engine. The disadvantage is that shifting is less comfortable and usually slower to operate.

Newer small cars and MPVs, like the Suzuki MR Wagon, the Fiat Multipla, the Toyota Matrix, the Pontiac Vibe

The Pontiac Vibe is a compact car that was sold by Pontiac (automobile), Pontiac from 2002 to 2010. It was jointly developed by General Motors along with Toyota, which manufactured the mechanically similar Toyota Matrix. Manufactured by the Toyot ...

, the Chrysler RT platform cars, the Honda Element

The Honda Element is a crossover SUV, compact crossover SUV manufactured by Honda and marketed in North America over a single generation for model years 2003–2011 — and noted for its boxy exterior styling with bi-parting side doors and i ...

, the Honda Civic

The is a series of automobiles manufactured by Honda since 1972. , the Civic is positioned between the Honda Fit/Honda City, City and Honda Accord in Honda's global passenger car line-up.

The first-generation Civic was introduced in July 1972 ...

, the Daihatsu Sigra, and the Honda Avancier, may feature a manual or automatic transmission

An automatic transmission (AT) or automatic gearbox is a multi-speed transmission (mechanics), transmission used in motor vehicles that does not require any input from the driver to change forward gears under normal driving conditions.

The 1904 ...

gear shifter located on the vehicle's instrument panel, similar to the mid-1950s Chryslers and Powerglide Corvairs. Console-mounted shifters are similar to floor-mounted gear shifters in that most of the ones used in modern vehicles operate on a horizontal plane and can be mounted to the vehicle's transmission in much the same way a floor-mounted shifter can. However, because of the location of the gear shifter in comparison to the locations of the column shifter and the floor shifter, as well as the positioning of the shifter to the rest of the controls on the panel often require that the gearshift be mounted in a space that does not feature a lot of controls integral to the vehicle's operation, or frequently used controls, such as those for the stereo system

Stereophonic sound, commonly shortened to stereo, is a method of sound reproduction that recreates a multi-directional, 3-dimensional audible perspective. This is usually achieved by using two independent audio channels through a configurat ...

or HVAC system, to help prevent accidental activation or driver confusion.

More and more small cars and vans from manufacturers such as Suzuki

is a Japanese multinational mobility manufacturer headquartered in Hamamatsu, Shizuoka Prefecture, Shizuoka. It manufactures automobiles, motorcycles, all-terrain vehicles (ATVs), outboard motor, outboard marine engines, wheelchairs and a va ...

, Honda

commonly known as just Honda, is a Japanese multinational corporation, multinational Conglomerate (company), conglomerate automotive manufacturer headquartered in Minato, Tokyo, Japan.

Founded in October 1946 by Soichiro Honda, Honda has bee ...

, and Volkswagen

Volkswagen (VW; )English: , . is a German automotive industry, automobile manufacturer based in Wolfsburg, Lower Saxony, Germany. Established in 1937 by German Labour Front, The German Labour Front, it was revitalized into the global brand it ...

are featuring console shifters in that they free up space on the floor for other features such as storage compartments without requiring that the gear shift be mounted on the steering column. Also, the basic location of the gear shift in comparison to the column shifter makes console shifters easier to operate than column shifters.

External overdrive

In the 1950s, 1960s, and 1970s, fuel-efficient highway cruising with low engine speed was in some cases enabled on vehicles equipped with 3- or 4-speed transmissions by means of a separate overdrive unit in or behind the rear housing of the transmission. This was actuated either manually while in high gear by throwing a switch or pressing a button on the gearshift knob or on the steering column, or automatically by momentarily lifting the foot from the accelerator with the vehicle traveling above a certain road speed. Automatic overdrives were disengaged by flooring the accelerator, and a lockout control was provided to enable the driver to disable overdrive and operate the transmission as a normal (non-overdrive) transmission. The term 'overdrive' is also used to describe a gear with a ratio of less than one (e.g., if the top gear of the transmission has a ratio of 0.8:1).Push starting

Vehicles with a manual transmission can often bepush start

Push starting, also known as bump starting, roll starting, clutch starting, popping the clutch or crash starting, is a method of starting a motor vehicle with an internal combustion engine that has a manual transmission, a mechanical fuel pump, a ...

ed when the starter motor is not operational, such as when the car has a dead battery or when the starter motor itself has malfunctioned and is unable to deliver sufficient rotational energy to turn the engine over.

When push-starting, the energy generated by the wheels moving on the road is transferred to the driveshaft, then the transmission, and eventually the crankshaft. When the crankshaft spins as a result of the energy generated by the rolling of the vehicle, the motor is cranked over. This simulates what the starter is intended for and operates in a similar way to crank handles on very old cars from the early 20th century, with the cranking motion being replaced by the pushing of the car.

Driving techniques

Recently, many automatic transmissions have included more gear ratios than their manual counterparts. In some countries, a driving license issued for vehicles with an automatic transmission is not valid for driving vehicles with a manual transmission, but a license for manual transmissions covers both.Hill starts

Starting from a stationary position in a manual transmission vehicle requires extra torque to accelerate the vehicle up the hill, with the potential for the vehicle to roll backward in the time it takes to move the driver's foot from the brake pedal to the accelerator pedal (to increase the engine RPM before engaging the clutch). A traditional method of hill starts in a manual transmission car is to use theparking brake

In road vehicles, the parking brake, also known as a handbrake or emergency brake (e-brake), is a mechanism used to keep the vehicle securely motionless when parked. Parking brakes often consist of a pulling mechanism attached to a Wire rope, ...

(also called "handbrake", " emergency brake", or "e-brake") to hold the vehicle stationary. This means that the driver's right foot is not needed to operate the brake pedal, freeing it up to be used on the accelerator pedal instead. Once the required engine RPM is obtained, the driver can engage the clutch, also releasing the parking brake as the clutch engages.

A device called the hill-holder was introduced on the 1936 Studebaker. Many modern vehicles use an electronically actuated parking brake, which often includes a hill-holder feature whereby the parking brake is automatically released as the driven wheels start to receive power from the engine.

In many light-duty vehicles, skilled drivers can slip the clutch just barely enough to hold the vehicle from much rollback during the second while the right foot is moving from the brake pedal to the accelerator pedal; this method effectively solves the hill-holding problem without any parking brake use and with negligible clutch life reduction, although it requires some skill.

Other driving techniques

* Rev-matching is where the driver uses the throttle to match the revs to the road speed so that gear changes are not jerky. This is commonly used by drivers with non-synchromesh gearboxes, or those driving racing vehicles * Double-clutching is required on non-synchro gearboxes. To double-clutch while downshifting: depress the clutch pedal and move the gear lever to neutral, release the clutch pedal, "blip" the throttle to speed up the layshaft to increase the rotational speed of the lower gear, depress the clutch pedal again, move the gear lever to the lower gear, then release the clutch pedal. *Heel-and-toe shifting

Heel-and-toe shifting is an advanced driving technique used mostly in performance driving with a manual gearbox, although some drivers use it on the road in everyday conditions in the interest of effectiveness. It involves operating the throttle ...

is where the driver uses one foot to modulate the brake and accelerator pedal simultaneously to allow for rev matching under braking.

* Rowing, block shifting or skip shifting is the technique of downshifting more than one gear in order to reduce wear and tear on the gearbox. Rev-matching may need to be used to create a smooth shift. Combining this with Heel-and Toe downshifting provides for maximum braking when going from top gear to a much lower gear, and optimal engine RPM for exiting the corner.

Synchronized downshift rev-matching system

The synchronized down shift rev-matching system is a computer-controlled technology that mimics the manual rev-matching technique.Truck transmissions

Some trucks have transmissions that look and behave like ordinary consumer vehicle transmissions, operated by a single lever—these transmissions are used on lighter trucks, typically have up to 6 gears, and usually havesynchromesh

A manual transmission (MT), also known as manual gearbox, standard transmission (in Canada, the United Kingdom and the United States), or stick shift (in the United States), is a multi-speed motor vehicle transmission system where gear changes ...

.

For trucks needing more gears, the standard "H" pattern can be complicated for some truck drivers, so additional controls are used to select additional gears. The "H" pattern is retained, then an additional control selects among alternatives. In older trucks, the control is often a separate lever mounted on the floor or more recently a pneumatic switch mounted on the "H" lever; in newer trucks, the control is often an electrical switch mounted on the "H" lever. Multi-control transmissions are built in much higher power ratings but rarely use synchromesh.

There are several common alternatives for the shifting pattern. The standard types are:

*Range transmissions use an "H" pattern through a narrow range of gears, then a "range" control shifts the "H" pattern between high and low ranges. For example, an 8-speed range transmission has an H shift pattern with four gears. The first through fourth gears are accessed when a low range is selected. To access the fifth through eighth gears, the range selector is moved to high range, and the gear lever again shifted through the first through fourth gear positions. In high range, the first gear position becomes fifth, the second gear position becomes sixth, and so on.

*Splitter transmissions use an "H" pattern with a wide range of gears, and the other selector splits each sequential gear position in two: First gear is in the first position/low split, second gear is in the first position/high split, third gear is in second position/low split, fourth gear is in second position/high split, and so on.

*Range-splitter transmissions combine range-splitting and gear-splitting. This allows even more gear ratios. Both a range selector and a splitter selector are provided.

Although there are many gear positions, shifting through gears usually follows a regular pattern. For example, a series of up shifts might use "move to splitter direct; move to splitter overdrive; move the shift lever to No. 2 and move splitter to underdrive; move splitter to direct; move splitter to overdrive; move the shifter to No. 3 and move splitter to underdrive"; and so on. In older trucks using floor-mounted levers, a bigger problem is common gear shifts require the drivers to move their hands between shift levers in a single shift, and without synchromesh, shifts must be carefully timed or the transmission will not engage. For this reason, some splitter transmissions have an additional "under under" range, so when the splitter is already in "under" it can be quickly downshifted again, without the delay of a double shift.

Modern truck transmissions are most commonly "range-splitter". The most common 13-speed has a standard H pattern, and the pattern from the left upper corner is as follows: R, down to L, over and up to 1, down to 2, up and over to 3, down to 4. The "butterfly" range lever in the center front of the knob is flipped up to high range while in 4th, then shifted back to 1. The 1 through 4 positions of the knob is repeated. Also, each can be split using the thumb-actuated under-overdrive lever on the left side of the knob while in high range. The "thumb" lever is not available in low range, except in 18 speeds; 1 through 4 in the low range can be split using the thumb lever and L can be split with the "Butterfly" lever. L cannot be split using the thumb lever in either the 13- or 18-speed. The 9-speed transmission is like a 13-speed without the under-overdrive thumb lever.

Truck transmissions use many physical layouts. For example, the output of an N-speed transmission may drive an M-speed secondary transmission, giving a total of N*M gear combinations. Transmissions may be in separate cases with a shaft in between; in separate cases bolted together; or all in one case, using the same lubricating oil. The second transmission is often called a "Brownie" or "Brownie box" after a popular brand. With a third transmission, gears are multiplied yet again, giving greater range or closer spacing. Some trucks thus have dozens of gear positions, although most are duplicates. Sometimes a secondary transmission is integrated with the differential in the rear axle, called a "two-speed rear end". Two-speed differentials are always splitters. In newer transmissions, there may be two counter shafts, so each main shaft gear can be driven from one or the other countershaft; this allows construction with short and robust countershafts, while still allowing many gear combinations inside a single gear case.

Heavy-duty transmissions are mostly non-synchromesh. Sometimes synchromesh adds weight that could be payload, and is one more thing to fail, and drivers spend thousands of hours driving so can take the time to learn to drive efficiently with a non-synchromesh transmission. Float shifting

Float shifting or floating gears, also called "slip shifting", "dead sticking", or "bang shifting", is the process of changing gears, in typically a non-synchronous transmission, without depressing the clutch. Shifting in this manner is also used ...

(also called "floating gears") is changing gears without disengaging the clutch, usually on a non-synchronized transmission used by large trucks. Since the clutch is not used, it is easy to mismatch speeds of gears, and the driver can quickly cause major (and expensive) damage to the gears and the transmission.

Heavy trucks are usually powered with diesel engine

The diesel engine, named after the German engineer Rudolf Diesel, is an internal combustion engine in which Combustion, ignition of diesel fuel is caused by the elevated temperature of the air in the cylinder due to Mechanics, mechanical Compr ...

s. Diesel truck engines from the 1970s and earlier tend to have a narrow power band, so they need many close-spaced gears. Starting with the 1968 Maxidyne, diesel truck engines have increasingly used turbochargers and electronic controls that widen the power band, allowing fewer and fewer gear ratios. As of 2021, fleet operators often use 9, 10, 13, or 18-speed transmissions, but automated manual transmission

The automated manual transmission (AMT) is a type of transmission (mechanics), transmission for motor vehicles. It is essentially a conventional manual transmission equipped with automatic actuation to operate the clutch and/or shift Gear train ...

s are becoming more common on heavy vehicles, as they can improve efficiency and drivability, reduce the barrier to entry for new drivers, and may improve safety by allowing the driver to concentrate on road conditions.

Lubrication

Manual transmissions are lubricated withgear oil

Gear oil is a lubricant made specifically for transmissions, transfer cases, and differentials in automobiles, trucks, and other machinery. It has high viscosity and usually contains organosulfur compounds. Some modern automatic transaxles ...

(or engine oil

Motor oil, engine oil, or engine lubricant is any one of various substances used for the lubrication of internal combustion engines. They typically consist of base oils enhanced with various additives, particularly antiwear additives, deter ...

in some vehicles) which must be changed periodically in some vehicles, although not as frequently as the fluid in an automatic transmission. Gear oil has a characteristic aroma because it contains added sulfur-bearing anti-wear compounds. These compounds are used to reduce the high sliding friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. Types of friction include dry, fluid, lubricated, skin, and internal -- an incomplete list. The study of t ...

by the helical gear cut of the teeth (this cut eliminates the characteristic whine of straight-cut spur gear

Spur gears or straight-cut gears are the simplest type of gear. They consist of a cylinder or disk with teeth projecting radially. Viewing the gear at 90 degrees from the shaft length (side on) the tooth faces are straight and aligned parallel to ...

s). On motorcycles with "wet" clutches (clutch is bathed in engine oil), there is usually nothing separating the lower part of the engine from the transmission

Transmission or transmit may refer to:

Science and technology

* Power transmission

** Electric power transmission

** Transmission (mechanical device), technology that allows controlled application of power

*** Automatic transmission

*** Manual tra ...

, so the same oil lubricates both the engine

An engine or motor is a machine designed to convert one or more forms of energy into mechanical energy.

Available energy sources include potential energy (e.g. energy of the Earth's gravitational field as exploited in hydroelectric power ge ...

and transmission.

See also

*Automatic transmission

An automatic transmission (AT) or automatic gearbox is a multi-speed transmission (mechanics), transmission used in motor vehicles that does not require any input from the driver to change forward gears under normal driving conditions.

The 1904 ...

* Diesel–electric transmission

*Freewheel

image:Freewheel en.svg, Freewheel mechanism

In mechanical engineering, mechanical or automotive engineering, a freewheel or overrunning clutch is a device in a transmission (mechanics), transmission that disengages the driveshaft from the driv ...

*Gear train

A gear train or gear set is a machine element of a mechanical system formed by mounting two or more gears on a frame such that the teeth of the gears engage.

Gear teeth are designed to ensure the pitch circles of engaging gears roll on each oth ...

* Non-synchronous transmission

*Overdrive (mechanics)

Overdrive is the operation of an automobile cruising at sustained speed with reduced engine speed (rpm), leading to better fuel consumption, lower noise, and lower wear. The term is ambiguous. The most fundamental meaning is that of an over ...

*Preselector gearbox

A preselector gearbox is a type of manual transmission mostly used on passenger cars and racing cars in the 1930s, in buses from 1940–1960 and in armoured vehicles from the 1930s to the 1970s. The defining characteristic of a preselector gearb ...

*Torque converter

A torque converter is a device, usually implemented as a type of fluid coupling, that transfers rotating power from a prime mover, like an internal combustion engine, to a rotating driven load. In a vehicle with an automatic transmission, the ...

*Transmission (mechanical device)

A transmission (also called a gearbox) is a mechanical device invented by Louis Renault (who founded Renault) which uses a gear set—two or more gears working together—to change the speed, direction of rotation, or torque multiplication/r ...

References

External links

As Stick Shifts Fade Into Obscurity, Collectors See Opportunity

24 June 2021 New York Times article by Rob Sass {{DEFAULTSORT:Manual Transmission Automotive transmission technologies Automobile transmissions